SecureAire AQM-150 User manual

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Part Number D-001

Operating Guide

Thank you for purchasing the SecureAire AQM-150 Air Quality

Monitor, the most advanced handheld instrument available

today. With a large dynamic measuring range that spans from

0.3 µm to 25.0 µm, with true variable binning for channel size

adjustment settings to 0.01 µm. The Real-Time Meter function

is unique in its ability to ne-tune the instrument’s sensitivity

in order to locate particulate sources with visual and audible

indications.

This versatile Air Quality Monitor’s ability to count higher

than typical particle concentrations allows the Real-Time

Meter to nd point source contamination in cleanrooms

as well as locating higher particle concentrations being

generated in many indoor environments.

Happy Monitoring!

Air

Purication

for a Safe,

Healthy,

and Clean

Environment™

AQM-150

Air Quality Monitor

ACTIVE Particle Control Technology

for Cleaner Air™

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-0012

Preface

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 3

Safety Information

Important Safety Information

This section presents important information intended to ensure safe and eective use of this product.

Please read this section carefully and store it in an accessible location.

• Do not use near explosive, ammable, or reactive gases

• Do not attach directly to pressurized gases or liquids

• Do not improperly discard electronic instruments, only dispose of in accordance with local regulatory

requirements or contact Particles Plus for trade-in option

• Defective or non-working Lithium-Ion batteries must be recycled, do not throw in trash

• This device contains a Class I laser product that is not accessible during normal operation, do not take

this device apart, exposure to harmful laser radiation can occur

• Taking the device apart will void all warranties

• Do not use this device for any purpose other than measuring of particles in ambient environments

• Do not operate the instrument with the inlet capped or plugged, as this can cause damage to the

vacuum pump

• Do not allow water or any other liquid to enter the inlet of the particle counter; this will damage the unit

• Any changes or modications to Particles Plus equipment not expressly approved by Particles Plus could

void the user’s authorization to operate the equipment, can risk serious injury, and will void all warranties

Key to Symbols

The symbols in this manual are identied by their level of importance, as dened below. Read the

following carefully before handling the product.

WARNING: Warnings must be observed carefully to avoid serious bodily injury.

CAUTION: Cautions must be observed to avoid minor injury to yourself or damage to your

equipment.

NOTE: The laser in this product is completely enclosed within a sensor with no user serviceable parts. In

addition, the emission level does not exceed the AEL (Accessible Emission Limit) of Class 1 under all

conditions of operation, maintenance, service and failure.

Legal Notices

The information contained in this document is subject to change without notice. This document

contains proprietary information that is protected by copyright. All rights are reserved. No part of this

document may be photocopied, reproduced, or translated to another language without the prior written

consent of SecureAire Incorporated.

Technical Support: Please contact us at 813-300-6077 with any questions or problems.

Printing History

This manual was rst printed in July 2020. The edition number will change when a new edition is printed.

Minor changes may be made at reprint without changing the edition number. The part number will

change when extensive changes are made.

4www.secureaire.com | Proudly made in the U.S.A. | APS-1000X-Rev A

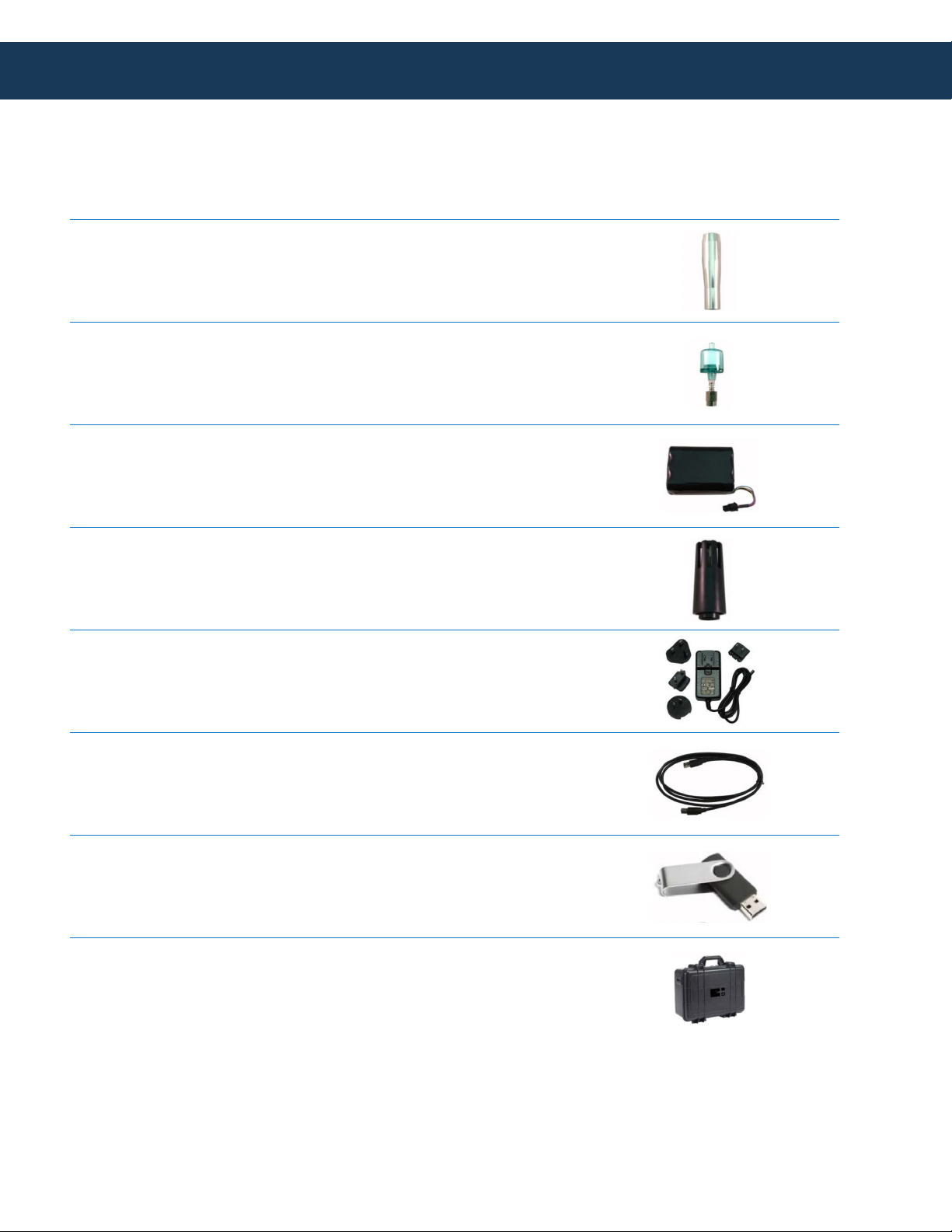

Package Contents

Included Accessories

Description Part Number

Isoprobe Threaded 0.1 CFM

Nickel Plated Aluminum PS-12041

Purge Filter Assembly 0.1 CFM (2.83 LPM) AS-99002A

Rechargeable Battery 55Wh EE-80003A

Temperature / RH Probe 32-122°F (0-60°C)

±1°F (0.5°C), 15 -90% ±2%

NOTE: This probe is optional for 8303 & 8503

EE-80014A

Power Supply 15V ~2amp 100-240VAC

(Select adapter -US, -EU, -UK or -CN) EE-80127-XX

USB Cable 6’ (1.8m) AS-99010

Handheld User Manual and Instrument

Management Software (USB Key) MN-24001

Handheld Carrying Case AS-99023

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 5

Overview and Operating Instructions

AQM-150 Product Views

Operating the AQM-150

Powering Up and Charging Status LED

(on power button)

The External one-touch power and sample button on the handle will

power the instrument on and o and will turnsampling on and o.

1. Pressing the button momentarily starts the pump and begins sampling.

2. Pressing the one-touch button again for 1 second stops sampling.

3. Holding the button for 3 seconds turns the instrument o.

Prior to starting the instrument, you must remove the sensor probe cap, failure to

do so will cause damage to the internal pump. Also, when storing the instrument,

please make sure that the sensor probe cap is replaced.

Isokinetic Probe

4.3” Touch Screen

Kickstand

Battery Compartment

Touch Screen Stylus

Power Switch & One

Touch Sample Button

¼-20 Threaded Tripod

Mounting Adapter

FRONT

Left-side View:

Input/output connections

BACK

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-0016

Power and charging status are indicated externally on the instrument

in the middle of the one-touch power and sample button. The indication

provides information on the charging rates and status.

Unit plugged into AC (instrument screen on or o)

Charging: Red LED on | Charging Complete: Green LED on

Unit not plugged into AC (instrument screen on)

Battery Charge <10%: Red LED blinks every 3 seconds

Unit not plugged into AC (instrument screen o)

All LEDs o

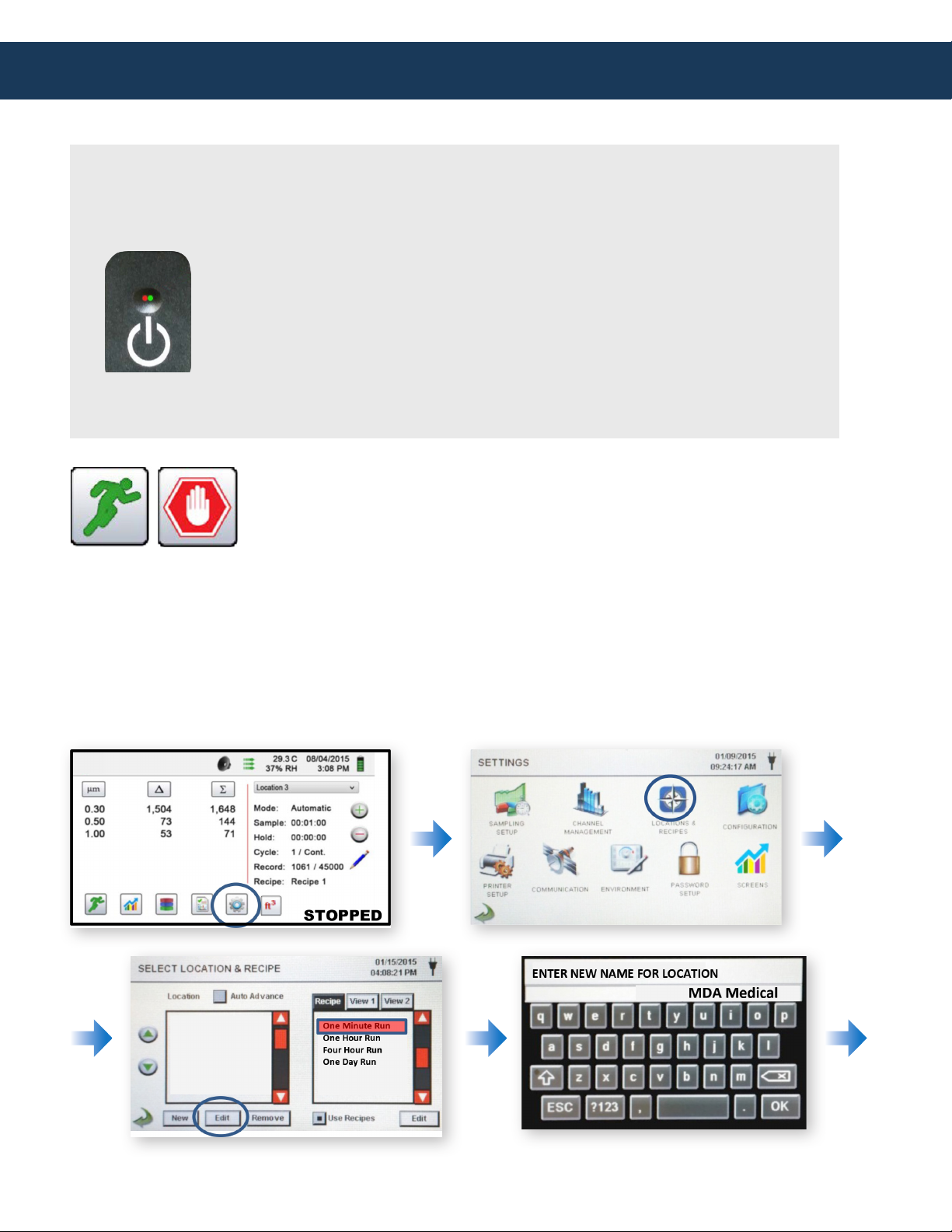

Operating Instructions

Running the AQM-150

Start and stop sampling icon buttons

Controls the instrument to begin sampling or to stop sampling.

There are three preloaded programs on the AQM-150

One Minute Run — Set for taking a count every minute.

One Hour Run — set for taking a count every hour.

Four Hour Run — set for taking a count every 4 hours

The following steps should be followed to switch between the programs.

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 7

Operating Instructions

Clearing Data in AQM-150

The following steps should be followed to clear the data from the AQM-150.

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-0018

Operating Instructions

Collecting Data on a PC

1 Insert the provided Thumb Drive into a USB port on your PC.

2 Connect the provided USB cable (6’) to AQM 150 and your PC.

3 Install setup.exe. on your PC.

4 Open setup.exe on your PC.

5 Turn AQM 150 on.

For most ecient operation, follow the following steps:

1

2

5

3

4

1

3

2

Starts the data download from the connected instrument

Select the Data Columns to be displayed and copied to clipboard

Fast Access to Real-Time Graph remote operation screen

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 9

Operating Instructions

1. Click on Select Columns

2. Click the checkmarks shown in Sect Columns to Display. Click Ok

3. Click on Download Data

3a. Choose the Record Date Range you wish to download

3b. Click on “All Records”.

3c. Click on Start Download

3d. Data will be shown in IMS.

3e. To download data in Excel:

10

3e.To download data in Excel:

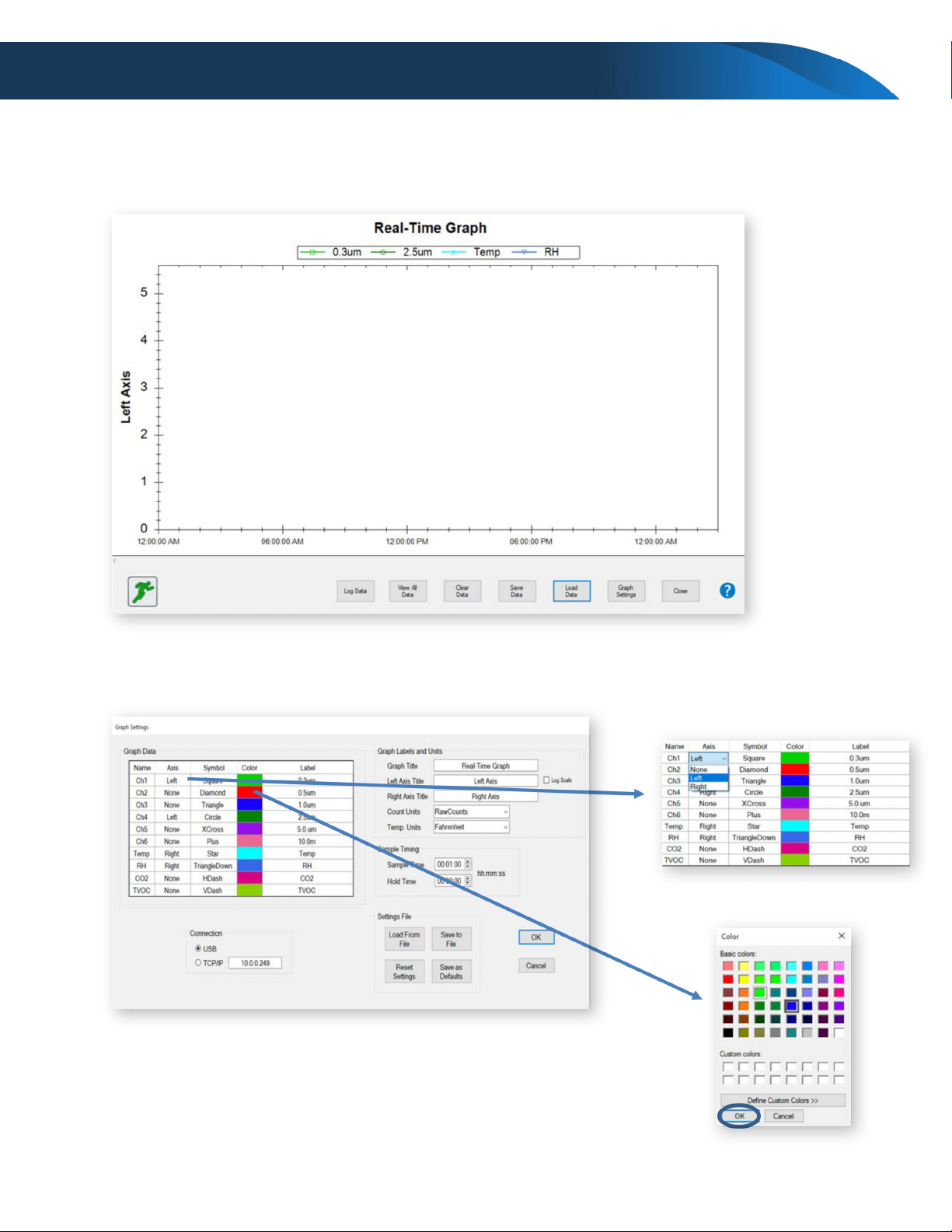

Real-Time Graph (RTG) and Settings

When running the Real Time Graph Mode, it must be set up independent

of the recipes in the AQM-150.

1. Connect using the USB Cable provided.

a. Connect the USB cable to the instrument and to the PC

b. Click on the Real-Time Graph button.

The Real-Time Graph will collect and save the information from the remote operation session but will only

save this information as graph data. For the complete data download you must pull the data from the

AQM 150 using a USB memory stick or by connecting directly with the USB cable and running the

Download Data function. A step by step example is provided in Appendix A.

The Real-Time Graph feature for remote operation and visual display of sample data in real time is able to

be customized to user preferred settings. It is also the screen for setting up the communications mode the

instrument and software will use to communicate.

Operating Instructions

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 11

Corresponding Graph Settings:

1. Axis – Turn on/o channel/sensor data or set to display on left or right axis.

2. Symbol – Choose the symbol for the data point for that channel/sensor.

3. Color – Choose the color for the channel/sensor data to use on the graph.

4. Label – Create custom label for specic channel or sensor.

5. Graph Title – Change the graph title.

6. Left Axis Title – Change the left axis title.

7. Right Axis Title – Change the right axis title.

8. Count Units – Select Raw Count, Count per M³, Count per Ft³, or PM.

9. Temp. Units – choose the temperature units (Celsius or Fahrenheit).

10. Sample Time – Amount of time set for sample (hh:mm:ss).

11. Hold Time – Amount of time set for delay before next sample begins (hh:mm:ss).

12. Log Scale – Turns on feature for values to display in Log Scale on graph.

13. Connection Type – Select USB or TCP/IP for connection method to instrument.

14. Enter IP address of instrument (default IP address is 10.0.0.249).

15. Load From File – Previously saved settings can be loaded from a le.

16. Reset Settings – Resets all settings on screen to factory default.

17. Save to File – Saves the current settings to a le for later use.

18. Save as Default – Saves the current settings to be default when started.

19. OK – Acknowledges and accepts the current settings and returns to RTG screen.

20. Cancel – Cancels the current settings page and returns to the RTG Screen.

Operating Instructions

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-00112

Purge Filter Procedure for “Zero” Count Testing

The Purge Filter procedure is used to verify that the AQM-150’s internal sensor is clean and free from any

built-up debris. In addition, this veries that the monitor has been recalibrated to a conrmed “Zero”

particle reading. It is recommended that this procedure be performed at least 3X per year or when an

important analysis is performed, i.e., a hospital operating room study.

Purge Filter Use and Procedure:

1. Unscrew the Isokinetic Probe and replace it with the 0.1-micron Purge Filter.

2. Run unit until all counts at 0.3u have reached a Zero (0) value.

(This should take no longer than 5 minutes.)

3. Remove the 0.1-micron Purge Filter and re-attach the Isokinetic Probe.

The AQM-150 is clean and ready for re-use.

Operating Instructions

Isokinetic Probe

4.3” Touch Screen

Touch Screen Stylus

Power Switch & One

Touch Sample Button

FRONT

Important Notes:

1. Always keep the Cap on Isokinetic Probe

when the AQM-150 is not in operation.

2. Never keep Cap on Isokinetic Probe when

the AQM-150 is in operation.

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-001 13

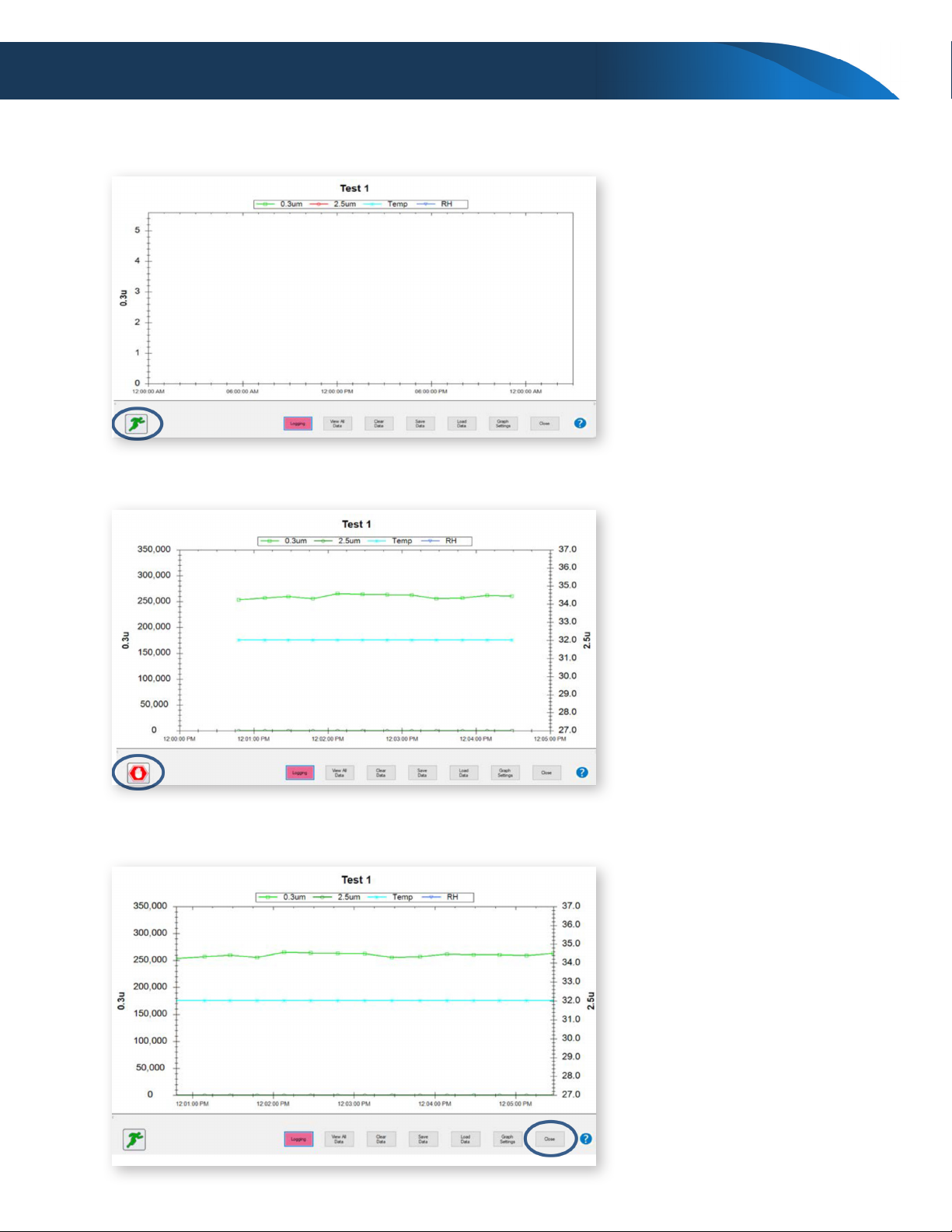

Appendix A

Downloading data from the Real-Time Graph Function

Selecting Axis, Symbol and Color

Appendix A

www.secureaire.com | Proudly made in the U.S.A. | AQM-150 Operating Guide | April 2022 | Part Number D-00114

Appendix A

Saving File by Name

Detailing Test Parameters

Fill in

15

Appendix A

Running the Test

Completing the Test

Closing the Test File

SecureAire Technologies, LLC

1968 Bayshore Boulevard, Dunedin, FL 34698

813.300.6077 | www.secureaire.com

© 2022 SecureAire Technologies, LLC. All rights reserved. Made in USA. 4.22

Appendix A

Saving the Data

Naming the File

About SecureAire: SecureAire is headquartered in Dunedin, Florida. The Company is the industry leader

in Active Particle Control™, which is based upon technologies developed and employed in Semiconductor

Cleanrooms. SecureAire has advanced and developed highly sophisticated air purication technologies that

make air ow the dominant transport mechanism for airborne contamination.

Please contact SecureAire at 813-300-6077 with any questions or concerns.

For more information please visit us at our website www.secureaire.com.

Table of contents

Popular Measuring Instrument manuals by other brands

Endress+Hauser

Endress+Hauser Proline Fieldcheck operating instructions

MIB

MIB Flowmax 54i operating manual

Ludlum Measurements

Ludlum Measurements 3003 user manual

Copper mountain

Copper mountain Planar TR5048 Programming manual

Sper scientific

Sper scientific 800015 instruction manual

Onicon

Onicon System-10 BTU Meter installation guide