sedia systems FT20 User manual

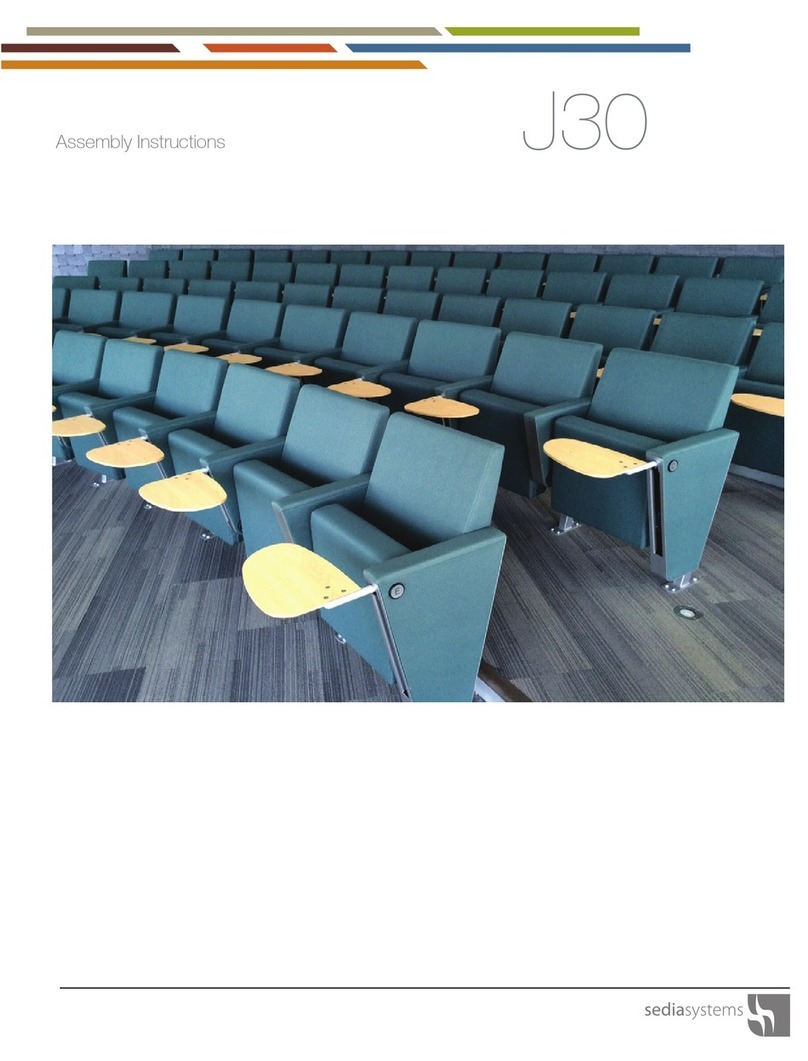

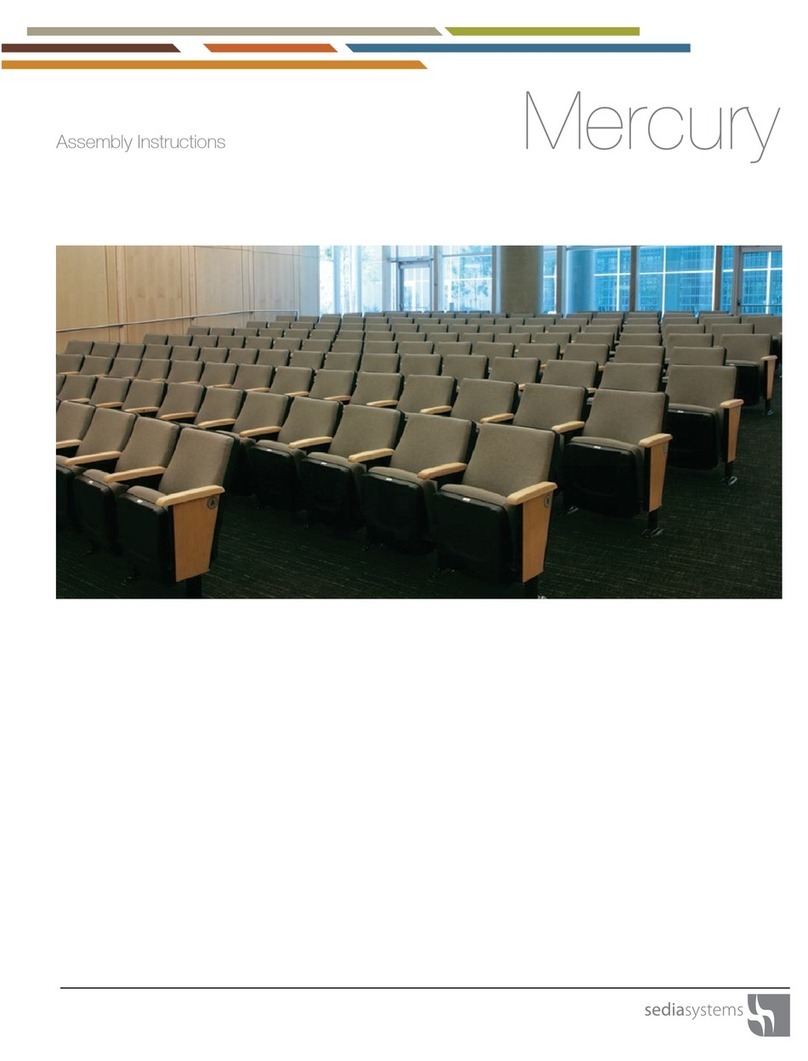

Assembly Instructions FT20

The FT20 auditorium seating system is intended to be used

in a commercial setting. The system consists of the

following components:

• Single Frame

• Beam Mount

• Riser Mount

• Seat

• Low Seat Back

• Mid Rise Seat Back

• High Seat Back

• Ultra Slim Seat Back

• Mesh Seat Back

• Power System

• Tablet Arm

Note: Read these assembly instructions carefully prior to

product installation. Electrically interconnected furnishings

must also be mechanically interconnected. Product failure

and personal injury may result if instructions are not

followed.

TOOLS REQUIRED

• Hammer drill and 1/4” masonary bit for concrete

anchor holes

• Drill and bit for pilot holes in wood floor

• #3 Phillips head screw driver

• #2 Phillips head screw driver

• Wrench Set

• Socket Set

• Allen Wrench

• 4’ Level

• 6-8’ Flexible straight edge 1/4 round or

equivalent

• 25 and 100’ Tape Measure

• Tailor’s Chalk

• FT20 Drill Template

IMPORTANT SAFETY INSTRUCTIONS

When using an electrical furnishing, basic precautions

should always be followed, including the following:

Read all instructions before installing the FT20 Chair

WARNING:

1. Risk of Electrical Shock - Connect this furnishing

to a properly grounded outlet only.

See Grounding Instructions.

2. Do not use outdoors.

3. Use this furnishing only for its intended use

described in these instructions. Do not use

attachments not recommended by the

manufacturer.

4. The maximum intended load for this seat is 300

pounds (102 Kilograms).

5. Functional Tablet Load - 20 Pounds (9 kg)

GROUNDING INSTRUCTIONS

This product must be connected to a grounded metal,

permanent wiring system, or an equipment-grounding

conductor must be run with the circuit conductors and

connected to the equipment-grounding terminal or lead

on the product.

Note: The power infeeds are to be connected to the

power source by a qualified electrician who must also

check the electrical integrity of the finished system

installation.

SAVE THESE INSTRUCTIONS

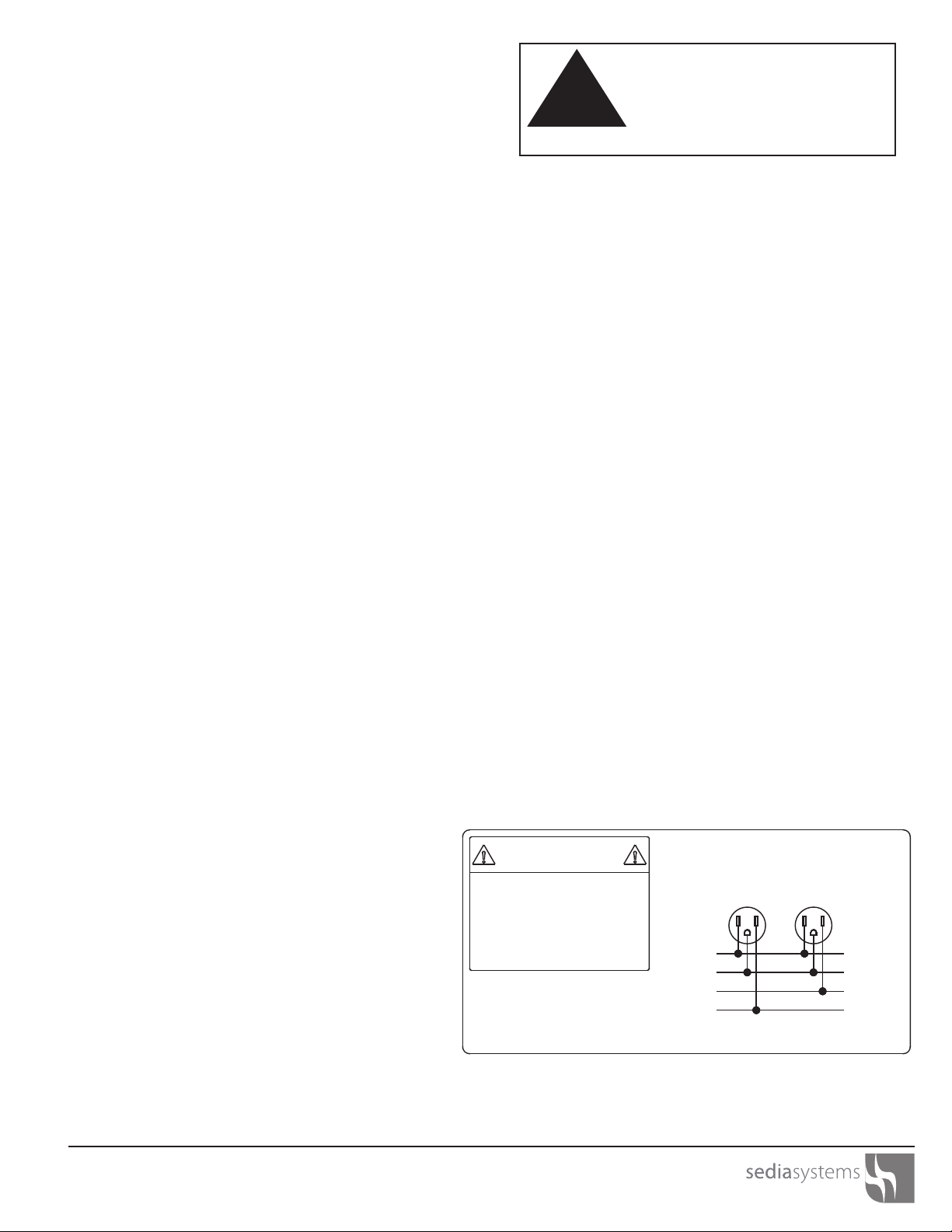

WHITE

GREEN/BARE

RED

BLACK

GROUND

HOT-2

HOT-1

NEUTRAL-1

CIRCUIT 1

I

CIRCUIT 2

II

WARNING

RISK OF FIRE OR ELECTRIC

SHOCK. DO NOT

ELECTRICALLY CONNECT

TO MORE THAN ONE SOURCE

OF SUPPPLY. ALL SOURCES

MUST BE DISCONNECTED

PRIOR TO ANY SERVICING

SEDIA SYSTEMS, INC.

CHICAGO, IL

*NOT FOR INTERRUPTING CURRENT*

FT20 Auditorium Seating

Assembly Instructions

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

INTRODUCTION

2

Wood Floors

• Minimum two layers of 3/4” thick plywood

• APA rated grade plywood

• Allow minimum embedment 1-1/2” with lag screws

• Use toggle bolt if less than 1-1/2” embedment

Concrete Floors

• 3000 psi concrete compressive strength

• 3“ thick free of obstruction for 1-1/2”

• Minimum anchor embedment 1-1/2”

Note: Warranty null and void if Sedia Systems FT20

seating product line is installed on flooring that does not

meet the minimum structural requirements stated above.

FLOOR FASTENER REQUIREMENTS

Wood Floors

• 3/8” x 2-1/2” lag bolts

• 3/8” flat washers

• (4) Bolt assemblies required per seat pedestal

Concrete Floors

• 1/4” x 2-5/8” concrete anchors

• 3/8” flat washers

• (4) Bolt assemblies required per seat pedestal

Site Preparation

1. Read and review the assembly instructions.

2. Review project drawings and layouts.

3. Locate floor center.

4. Locate row size line.

5. Draw size line for straight or radius rows.

6. Mark hole centerline for first chair.

7. Mark incremental hole centerline locations.

8. Use drill template to mark hole locations.

9. Use carpet punch at each hole location.

10. Locate and drill anchor holes into floor.

11. Vacuum holes to remove debris.

Chair Installation

12. Mount base to the floor with anchor bolts.

13. Align seat back bracket to base and slide to side.

14. Tighten seat attachment bolts with wrench.

15. Assemble seat by aligning pins with pivot disc slot.

16. Install seat pivot cap with seat in the down position.

17. Slide foot cover around post with slot facing front,

snap small cover onto base clip to lock in place.

Steps for Installing Power Option

Before Assembling Seat:

1. Drill pilot holes onto both sides of seat post as per

dimensions on layout.

2. Attach the raceway brackets to seat post.

3. Attach the raceway to the brackets.

4. Place the power whip into the raceway.

5. Attach the duplex outlet to the whip or jumper.

6. Attach the raceway end caps to each side.

7. Attach the raceway cover so the outlet module fills

the outlet opening in the cover.

8. Assemble seat by aligning pins with pivot disc slot.

9. Install seat pivot cap with seat in the down position.

10. Connect electrical whip to the main power source.

11. Mount row and seat numbering (optional).

12. Clean product and site for walk through.

Note: Dimensional spacing referenced is centerline to

center line unless otherwise noted.

FT20 Auditorium Seating

Assembly Instructions !

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

3

CAUTION

CAUTION

!

All power modules rated at 15A 120V 60HZ.

System capacity to be limited to 15A per

circuit.

No more than 12 outlets should be supplied by

one circuit.

1. All parts are lubricated for life.

2. Any service should be conducted by an authorized

service representative.

3. Perform periodic inspections for loose or broken parts.

LAMINATE:To clean the surface, use a damp cloth or

sponge and a mild soap or detergent. Difficult stains such

as coffee or tea can be removed using a mild household

cleaner and baking soda; mixing to achieve a paste

consistency. Use a stiff nylon bristle brush, scrubbing

(approx. 15-20 strokes) the affected area. Do not scrub so

as to mar (damage, scratch) the surface finish. Stubborn

stains that resist any of the above cleaning methods may

require the use of undiluted household bleach or nail polish

remover. Use a cotton ball saturated with bleach or nail

polish remover (acetone); gently rub the stain for up to two

minutes. Rinse thoroughly with warm water and wipe dry

using a soft cloth. This step may be repeated if the stain

appears to be going away and the color of the laminate

has not been affected.

CAUTION:

Prolonged exposure of the laminate and powder coat

surfaces to bleach will cause discoloration. Always rinse

laminate and powder coat surfaces after cleaning! Failure

to rinse after cleaning can cause damage; even if a small

amount of cleaning solution remains on the surface. A dry

residue may be invisible; however, moisture from cups or

drinks can reactivate it, and result in permanently etched

scars or stains over time.

Recommended Household Cleaners:

• Clorox®* • Formula 409® • Dawn® • Fantastik®

• Dow Bathroom Cleaner with Scrubbing Bubbles™

• Favor® • Windex® • Lestoil® • Glass Plus®

• Pledge® • Grease Relief® • Mr. Clean® • TOP JOB®

• Lysol® Brand Disinfectant Basin/Tub/Tile Cleaner

* Prolonged exposure can mar the surface

CAUTION:

Acidic or abrasive cleaners can damage laminate and

powder coat surfaces; do not use them. Drain cleaners

containing lye will permanently damage the laminate

surface. If you spill a drain cleaner, wipe it up immediately

and rinse several times with water. Hair, textile and food

dyes can cause permanent stains. If dye should happen to

spill, wipe it up immediately with dishwashing detergent or

an all-purpose cleaner. Wipe spills away promptly and rinse

several times with water.

Rust removers contain harsh chemicals, which will quickly

cause permanent damage. If a spill occurs, wipe off all

residues immediately, wash thoroughly with soapy water

and rinse several times. Steel wool and other abrasive pads

will damage the laminate and powder coat face. Do not use

them for cleaning and don’t store steel wool pads on your

countertop; the metal can rust and leave stains. Toilet bowl

cleaners contain harsh chemicals that can cause permanent

damage. If spills occur, wipe up immediately, wash surface

with soapy water and rinse several times.

The cleaners listed below can cause damage to the surface

of laminate:

Chemical Ingredient Synonymous Names

Hydrochloric Acid Muriatic Acid

Hydrogen Chloride

Sulfuric Acid Oleic Acid

Oil of Vitriol

Oleum

Hydrofluoric Acid Rust Remover

Phosphoric Acid Rust Remover

Sodium Hydroxide Caustic Soda

Caustic Soda Lye

Lye

Pumice (abrasive)

Remember, sharp objects can damage the surface of

laminate and powder coat surfaces, marring its beauty and

lowering wear and stain resistance. Although the laminate

and powder coat surfaces are somewhat resistant to

scratch and marring, they can be damaged, even under

normal use.

Laminate and powder coat surfaces may need occasional

dusting depending on where it’s used. To keep the surface

beautiful, use a non-oily furniture spray. (Remember to clean

the spray off several times a year to prevent build-up.)

Furniture polish can also help hide fine scratches in the

surface.

UPHOLSTERED FABRIC: Clean with water-based cleaning

agents, foam or pure water-free solvents. Vacuuming or light

brushing is recommended to prevent dust and soil buildup.

For answers to additional questions regarding care or

cleaning please contact Sedia Systems.

CAUTION

ROUTINE CARE AND MAINTENANCE

FT20 Auditorium Seating

Assembly Instructions !

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

4

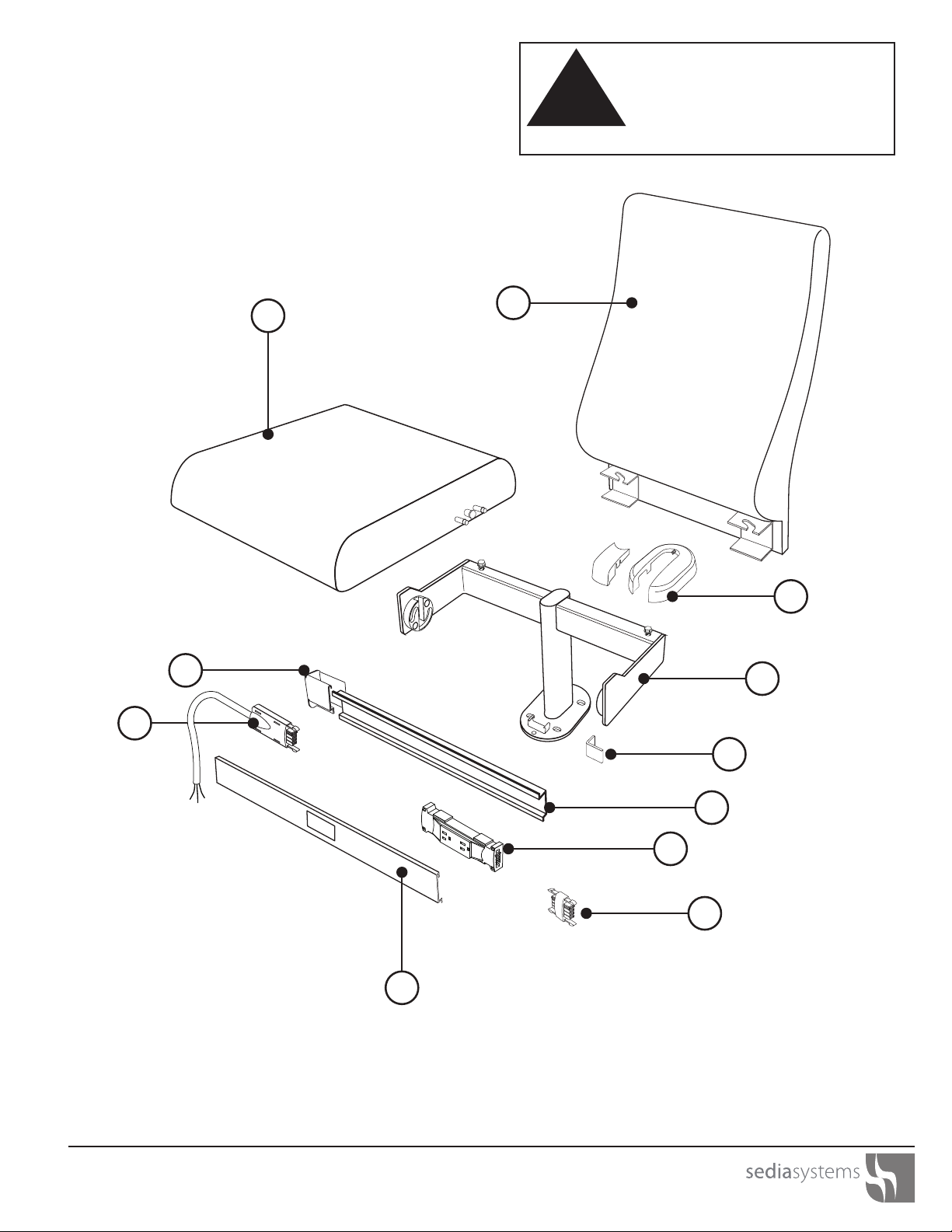

CAUTION

11

3

4

5

6

9

2

1

10

7

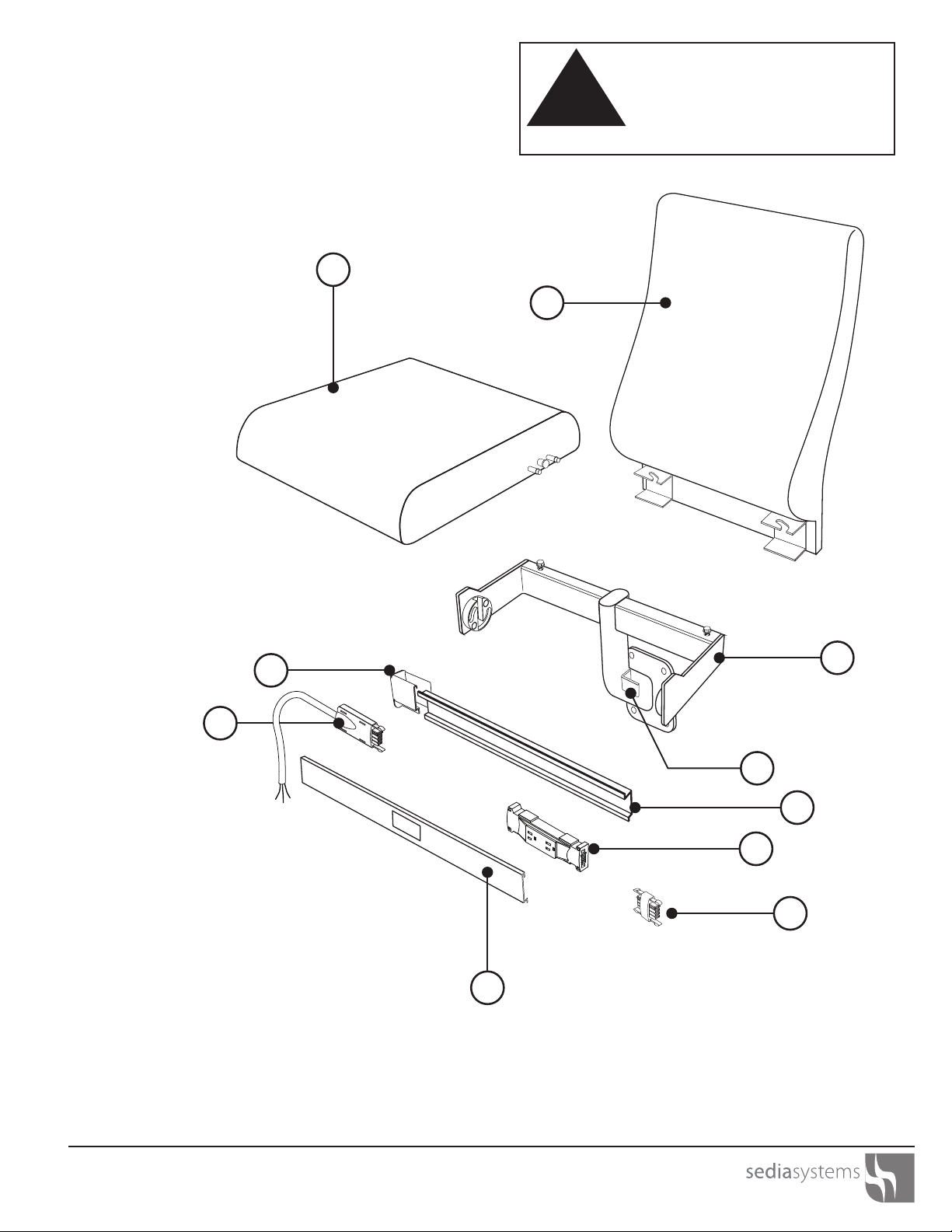

1. Seat

2. Seat Back

3. Foot Cover Assembly

4. Chair Base

5. Raceway Bracket

6. Raceway

7. Duplex Power Module

8. Duplex End Plug

9. Raceway Cover

10. Power Whip

11. Raceway End Cap

8

Standard Floor Mounted Chair CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

5

FT20 Auditorium Seating

Assembly Instructions

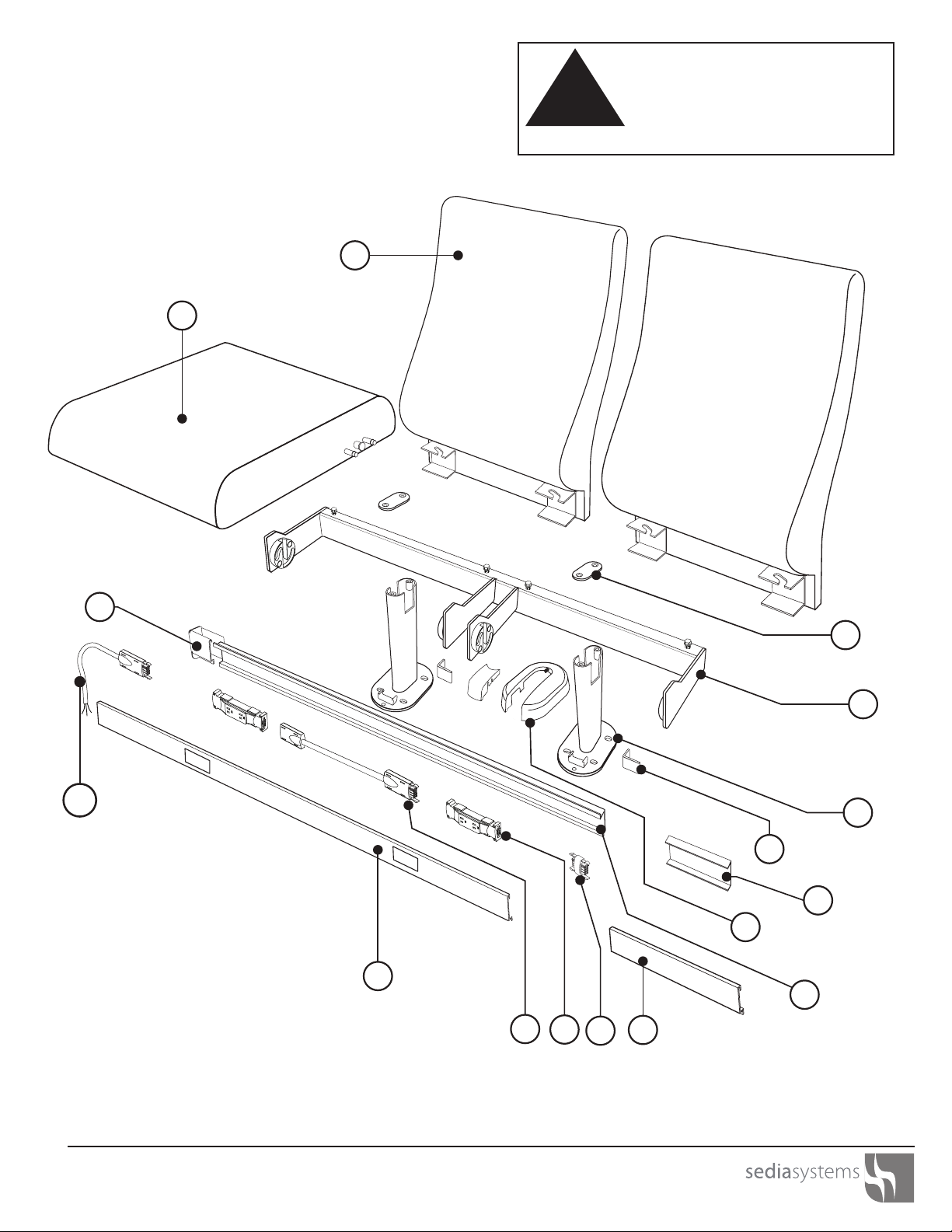

1. Seat

2. Seat Back

3. Riser Mount Assembly

4. Raceway Bracket

5. Raceway

6. Duplex Power Module

7. Duplex End Plug

8. Raceway Cover

9. Power Whip

10. Raceway End Cap

1

2

3

4

5

6

7

8

9

10

Standard Riser Mounted Chair CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

6

FT20 Auditorium Seating

Assembly Instructions

1

2

3

4

6

5

7

9

10

11

14

16

8

1213

1. Seat

2. Seat Back

3. Beam Clamp

4. Beam Assembly

5. Pedestal Base

6. Raceway Bracket

7. Raceway Splicer

8. Foot Cover Assembly

9. Raceway

10 Raceway Spacer

11. Duplex End Plug

12. Duplex Power Module

13. Jumper Cable

14. Raceway Cover

15. Power Whip

16. Raceway End Cap

15

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

7

Standard Beam Mounted Chair

FT20 Auditorium Seating

Assembly Instructions

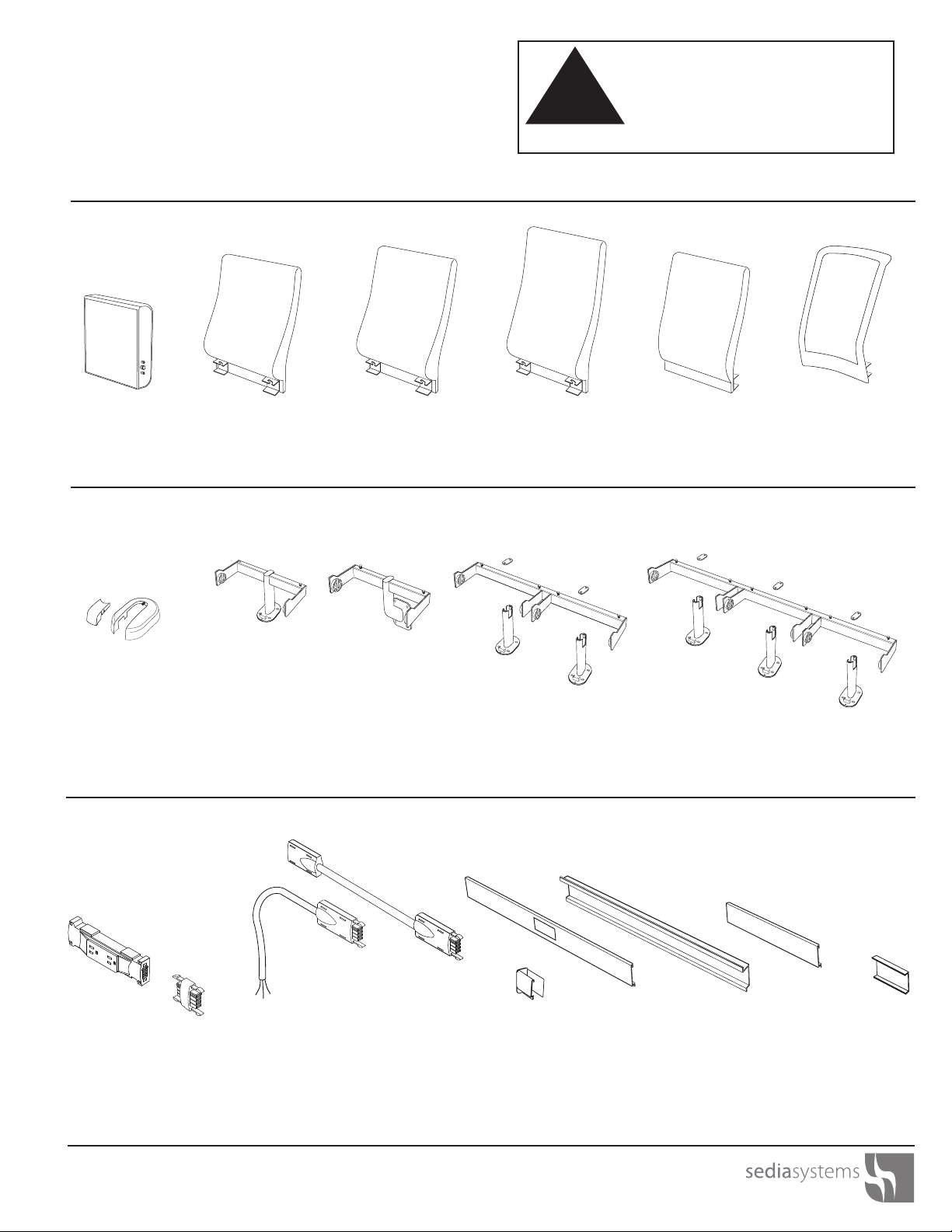

System Components

Jumper Cable

Lengths Based

on Layout Drawing

8 - 300 Inches

Cover

Lengths Based

on Layout Drawing

10 - 48 Inches

Raceway

Lengths Based

on Layout Drawing

17 - 72 Inches

Power Whip

72 - 300 Inches

Seat

20-26 inch widths

Low Back Mid Back (STD) High Back Ultra Slim Back

Single BaseFoot Cover Riser Mount Dual Beam Triple Beam

Duplex Module End CapEnd Plug

Mesh Back

SplicerSpacer

System Components CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

8

FT20 Auditorium Seating

Assembly Instructions

Site Preparation

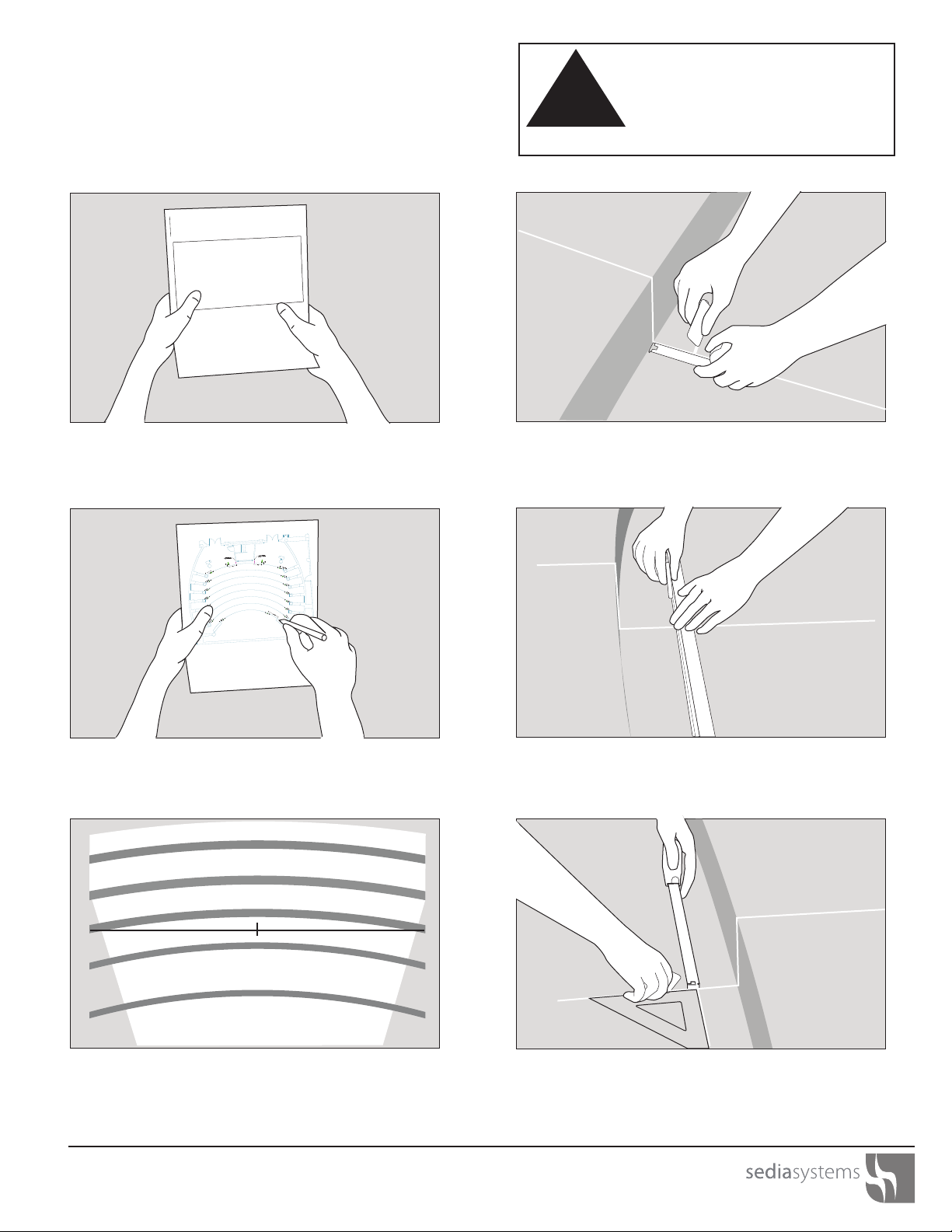

Step 2: Refer to layout drawings and verify room

dimensions.

Step 3: Use tape measure to locate room center and

other reference dimensions and mark with chalk

Step 4: Use layout drawing to locate row size line from

back of riser and mark with chalk.

Step 5: Draw the size line. For radius floor, use

1/4 round or equivalent to get the radius size line.

Step 6: Mark hole locations of the first chair symmetric

the center line and according to the drawing.

FT20 AUDITORIUM SEATING

Assembly Instructions

May 2017

Step 1: Read and review the assembly instructions.

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

9

FT20 Auditorium Seating

Assembly Instructions

Site Preparation

Step 10: Drill holes using 1/4” x 4” concrete drill bit.

Concrete Floor - 4 holes, Wood Floor - 4 pilot holes

only.

Step 7: Mark all hole locations by incrementing

dimensions sequentially as per drawing.

Step 9: Punch carpet using hammer and punch.

Remove thread material and ensure drill area is free of

debris.

Step 8: Center drill template and mark hole locations. Step 11: Vacuum holes to remove wood/concrete

particles.

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

10

FT20 Auditorium Seating

Assembly Instructions

Chair Installation

Step 12: Align base and fasten with wood/

concrete anchors. Concrete Floor - 4 Bolts.

Wood Floor - 4 Bolts.

Step 13: Assemble back by sliding bracket onto frame

from rear side and sliding to the left.

Step 14: Tighten seat attachment bolts with box end

wrench.

Step 15: Assemble seat by positioning pins over the

slot in the pivot and lowering the seat.

Step 16: With the seat in the down position, insert the

pivot cap into the pivot disc so the notch is filled and

the cap snaps into place.

Step 17: Assemble the foot cover so the pin engages

the hole on the rear of the tube. Snap the cover clip

into place.

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

11

FT20 Auditorium Seating

Assembly Instructions

Power System Installation

Step 1: Before the seat is assembled, drill pilot holes

for the support brackets on side of tube. Dimensions

will be defined by the layout drawings.

Step 2: Assemble the brackets with metal cutting

screws and a phillips head screw driver.

Step 3: Center the raceway and assemble to the

brackets with #10-32 screws.

Step 4: Assemble the power whip into the raceway

through the hole in the back of the raceway.

Step 5: Attach the duplex outlet to the power whip

and add the end plug.

Step 6: Assemble the end caps to each side of the

raceway with #8x1/2” screws.

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

12

FT20 Auditorium Seating

Assembly Instructions

Power System Installation

Step 8: Assemble seat by positioning pins over the slot

in the pivot and lowering the seat.

Step 9: With the seat in the down position, insert the

pivot cap into the pivot disc so the notch is filled and

the cap snaps into place.

Step 7: Assemble the raceway cover so the duplex

outlet fills the hole. Attach with #8x1/2” screws.

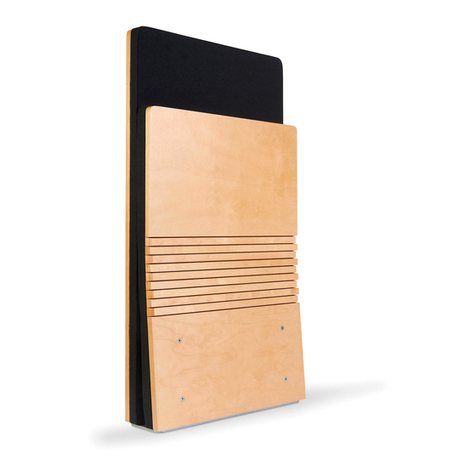

Installing the Wrimatic Tablet Arm Option:

Assemble the Wrimatic arm to the post by attaching

the clamp plate to the bottom of the arm with (2)

provided M6 x 25mm socket head cap screws.

Tighten the screws to clamp the arm onto the post.

CAUTION

!

Assemble units only as described herein. Failure to

do so may result in instability or assembly failure. All

screws, nuts and bolts must be tightened securely

and must be checked periodically after assembly.

Failure to assemble properly, or to secure parts may

result in personal injury.

13

FT20 Auditorium Seating

Assembly Instructions

Table of contents

Other sedia systems Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

modway

modway EEI-3348 manual

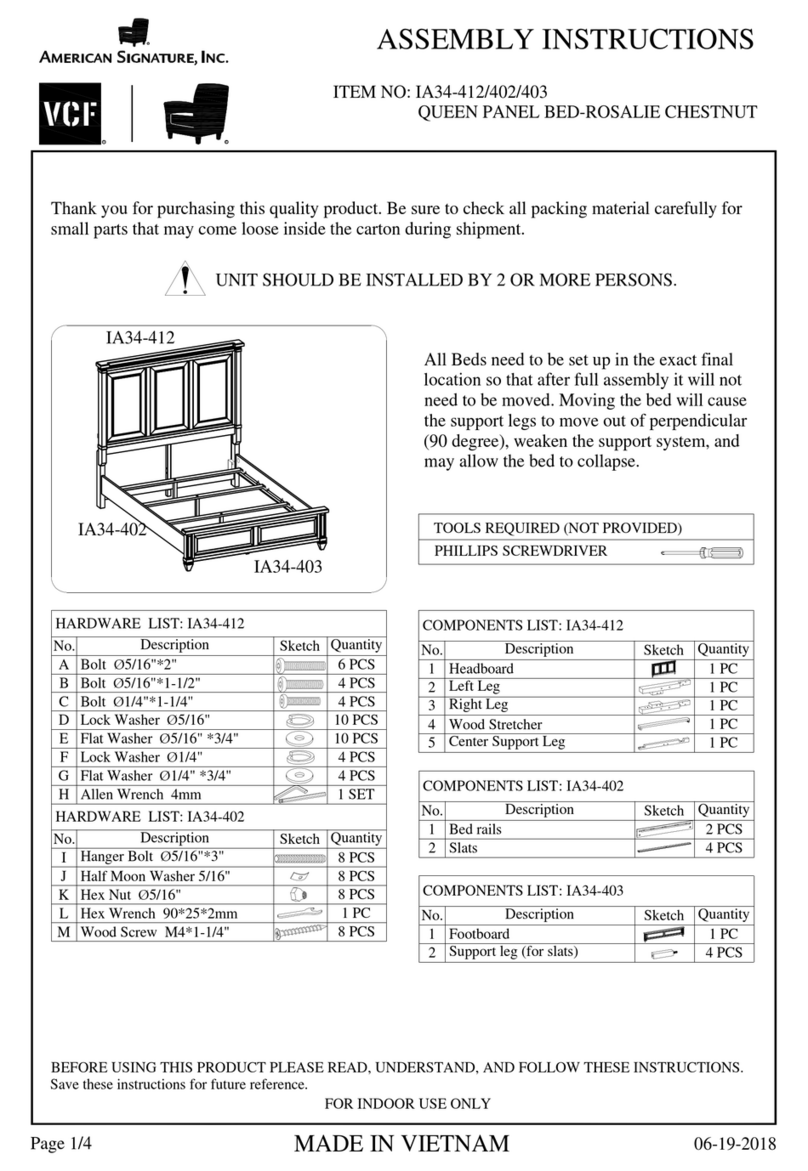

American Signature

American Signature VCF IA34-455 Assembly instructions

Manual Thinking

Manual Thinking MT-WT L55 Assembly instructions

SHOR-LINE

SHOR-LINE Blue-Line 903.1530.04 Guide

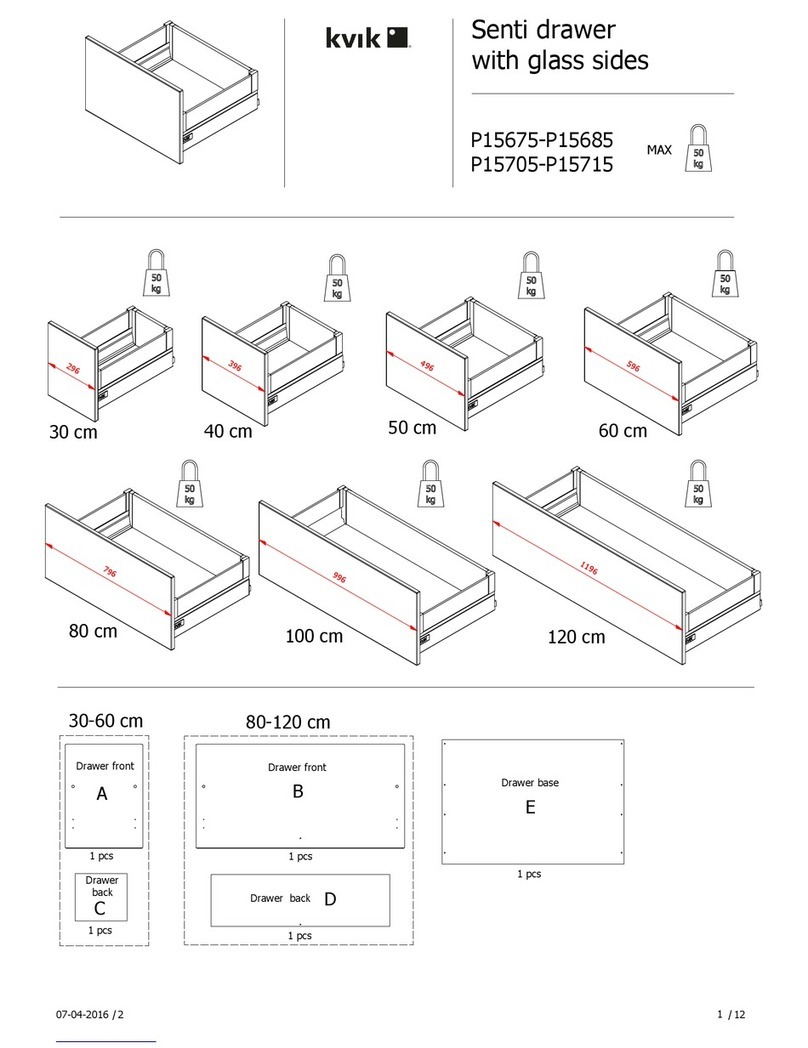

Kvik

Kvik P15675 Assembly instructions

FMD Furniture

FMD Furniture MEGA 2 248-002 Assembly instructions

modway

modway KING BED FRAME MOD-5433 Assembly instructions

Universal Furniture

Universal Furniture 628355 instruction sheet

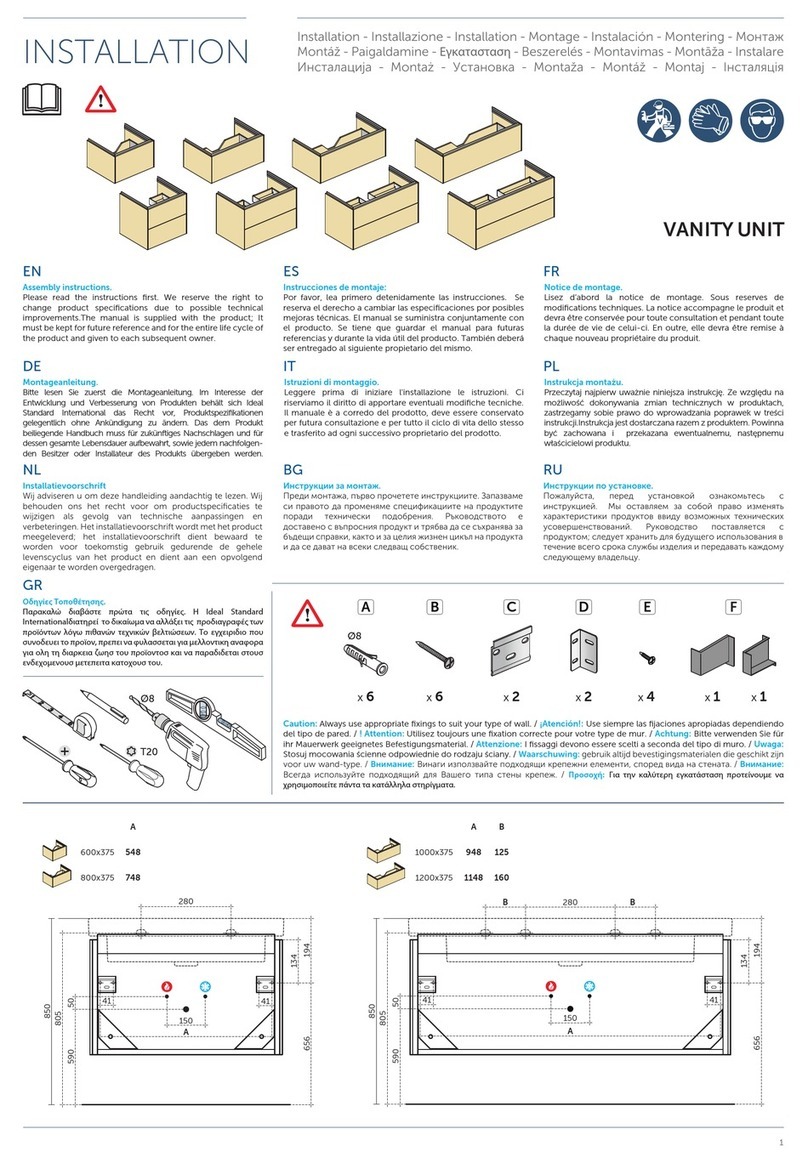

Balmani

Balmani Fila Wall Unit installation guide

Broyhill

Broyhill LEGACY CASTLE PINES KVS9433 Assembly instruction

Ideal-Standard

Ideal-Standard Conca T4580Y1 Installation

Venjakob

Venjakob NEXT LEVEL 3000 Assembly instruction