AL SERIES INSTALL OPERATION MAINTENANCE MANUAL |1

SAFETY

1.0 Introduction 3

1.1 General Safety Information 3

1.1.1 Handling The Unit 3

1.1.2 Positioning The Cooler 3

1.1.3 Wiring Electrical 3

1.1.4 Drainage 3

1.1.5 Occupational Health And Safety 4

1.1.6 Water Supply 4

1.1.7 Commissioning, Recommissioning, Decommissioning 4

1.1.8 Operational Safety 4

1.1.9 Safety Points To Consider 4

1.1.10 Legionnaires Disease 5

GENERAL INFORMATION

2.1 Unit Overview 6

2.2 Equipment Receipt 6

2.3 Factory Unit Test 6

2.4 Model Designation 6

2.5 Technical Specication 7

2.5.1 Construction 7

2.5.2 Blower 7

2.5.3 Fan Motors 7

2.5.4 Pulleys 7

2.5.5 Electrical Control And Connection 7

2.5.6 Supply Water Specication 7

2.5.7 Relief Area Calculation 7

2.5.8 Drainage 8

INSTALLATION INFORMATION

3.0 Installation Information 9

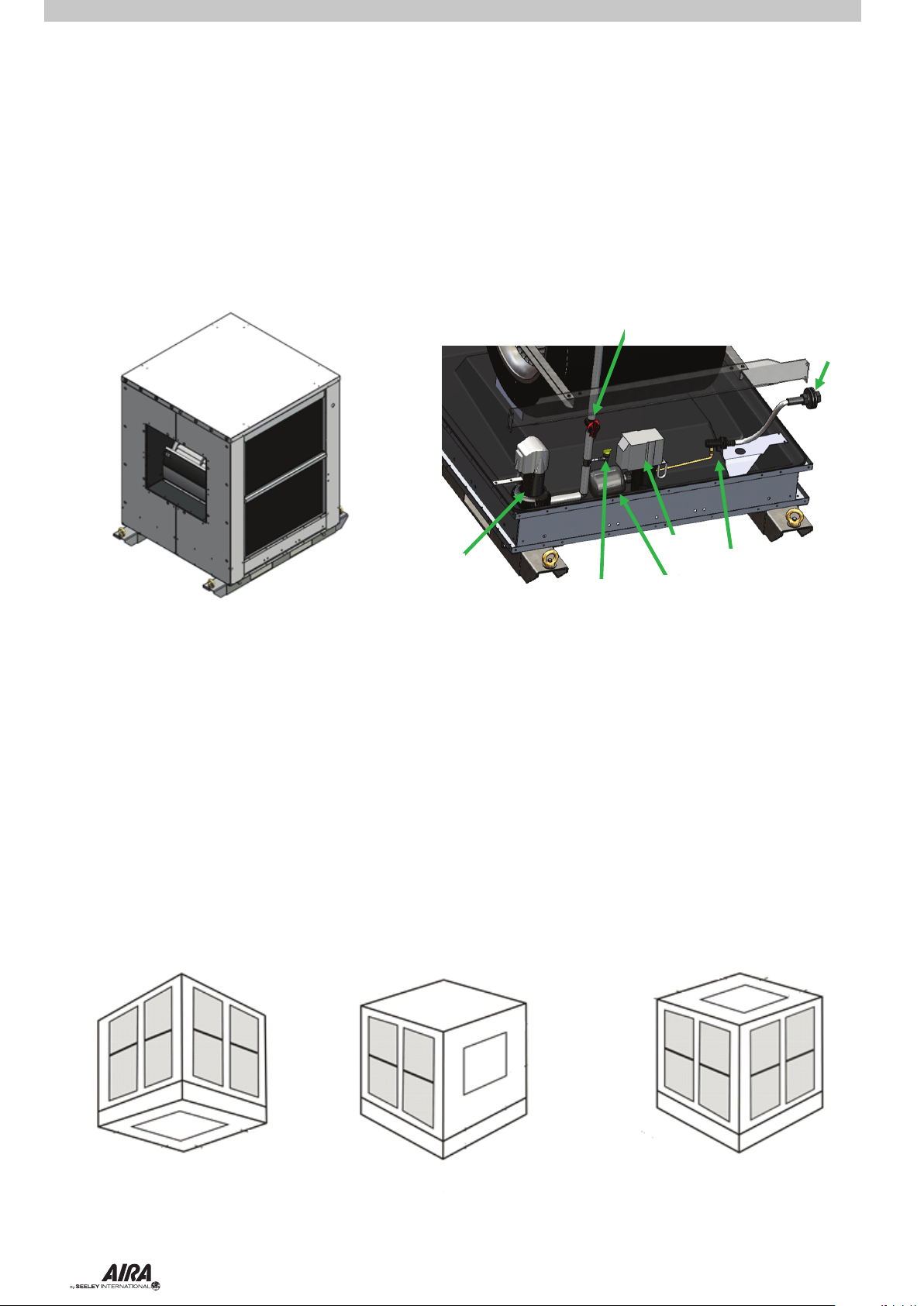

3.1 Model Variations And Dimensions 10

3.1.1 Cooler Dimensions (AL18, AL25, AL30, AL36) 11

3.1.2 Drain Location Dimensions (AL18, AL25, AL30, AL36) 12

3.2 Installation

3.2.1 Location 13

3.2.2 Clearance Around Unit 14

3.2.3 Plant Room 14

3.2.4 Roof Stands 14

3.2.5 Weight And Location 15

3.2.6 Lifting 15

3.2.7 Positioning And Securing 16

3.2.8 Duct Connections 16

3.3 Electrical Connections

3.3.1 Electrical Supply 17

3.3.2 User Control Conguration Options 17

3.4 Water Connections

3.4.1 Water Supply 18

3.4.2 Water Setup 18

3.4.3 Drain 19

3.4.4 Automatic Drain Valve 19

3.4.5 Bleed O Valve 19

3.4.6 Cooling Pads 20

COMMISSIONING INFORMATION

4.1 Unit Details 21

4.2 General Installation Check 21

4.3 Electrical Checks

4.3.1 Electrical Installation Checks 21

4.3.2 Blower Box Checks 21

4.4 Water Checks

4.4.1 Incoming Water Supply Checks 23

4.4 2 Internal Water Checks 23

4.5 Start Up Procedure 23

4.6 Setting Pad Saturation 24

4.7 Commissioning Results 24

OPERATING INSTRUCTIONS

5.1 Startup Single Speed To Provide Cool Air 25

5.2 Startup Single Speed To Provide Ventilation 25

5.3 Shutdown Single Speed Providing Cool Air 25

5.4 Shutdown Single Speed Providing Ventilation 25

5.5 Startup Dual Speed To Provide Cool Air 25

5.6 Startup Dual Speed To Provide Ventilation 25

5.7 Shutdown Dual Speed Providing Cool Air 25

5.8 Shutdown Dual Speed Providing Ventilation 25

5.9 BMS Startup And Shutdown 25

5.10 Operational Flowchart 26

MAINTENANCE

6.0 Service And Maintenance 27

6.1 Cooler Maintenance

6.1.1 Cooler Maintenance 27

6.2 Major Service/Component Replacement Process

6.2.1 Electrical Components

6.2.1.1 Electrical Wiring 28

6.2.1.2 Isolator Fitted And Operational 28

6.2.1.3 Single Or 3 Phase Power Test 28

6.2.1.4 Fan And Motor 28

6.2.1.5 Belts 29

6.2.1.6 Pulleys 29

6.2.1.7 Fan Direction 29

6.2.2 Water Components

6.2.2.1 Water Controls 30

6.2.2.2 Water Connection Visual Inspection 30

6.2.2.3 Water Isolation Fitted 30

6.2.2.4 Water Supply Pressure 30

6.2.2.5 Float Valve Operation 30

6.2.2.6 Overow And Drainage 30

6.2.2.7 Automatic Drain Valve 30

6.2.2.8 Bleed Valve 30

6.2.2.9 Cooling Pads

6.2.3 Casing Components

6.2.3.1 Weatherproof Casing Condition 30

6.2.3.2 Water Carry Over 30

6.2.3.3 Duct Condition 30

6.2.3.4 General Installation 31

6.2.4.5 Access To Unit 31

6.2.4.6 Maintenance Records 31

6.3 Fault Finding Cooler 32

6.4 Replacement Parts List 32

APPENDIX

Appendix A: Electrical Information

Appendix A1 - 3 Phase Wiring Diagram 33

Appendix A2 - 3 Phase Cooler Auto Drain Wiring Diagram 34

Appendix B: Commissioning Report 35

Appendix C: Maintenance

Appendix C1: Maintenance Schedule 37

Appendix C2: Monthly Maintenance Check 38

Appendix C3: Maintenance Checklist 39

Appendix D: Warranty Information

D1 - How To Register Your Product Warranty 41

D2 - Warranty Terms And Information 42

Appendix E: Release Information 45

CONTENTS