4 |CW-H10, H15, H15S, H15S Plus 859749-A

IMPORTANT SAFETY INSTRUCTIONS

READ AND SAVE THESE INSTRUCTIONS

FOR FUTURE REFERENCE.

FOR EUROPE

This appliance can be used by children aged

from 8 years and above and persons with

reduced physical, sensory or mental capabilities

or lack of experience and knowledge if they

have been given supervision or instruction

concerning use of the appliance in a safe way

and understand the hazards involved. Children

shall not play with the appliance. Cleaning and

user maintenance shall not be made by children

without supervision.

FOR AUSTRALIA, NEW ZEALAND & OTHER

NON-EUROPEAN COUNTRIES

This appliance is not intended for use by

persons (including children) with reduced

physical, sensory or mental capabilities, or

lack of experience and knowledge, unless they

have been given supervision or instruction

concerning use of the appliance by a person

responsible for their safety. Children should be

supervised to ensure that they do not play with

the appliance.

Means for all pole disconnection must be

incorporated in the xed wiring in accordance

with the wiring rules, adjacent to or on the

cooler cabinet. If mounting on the cooler

cabinet, take care not to puncture the water

reservoir.

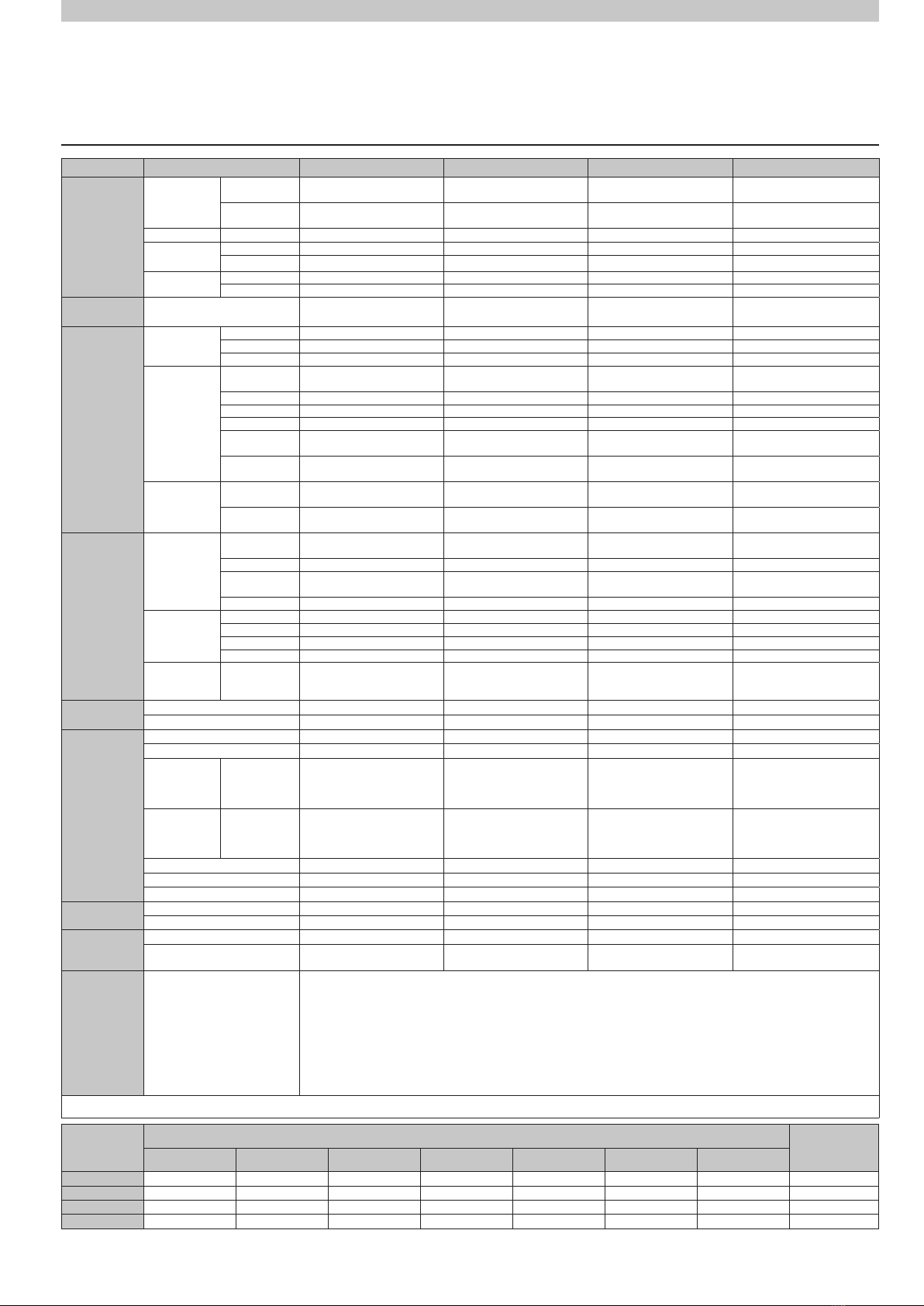

The following specications for the cooler water

supply are required:

Water Connection ½” BSP (Aus/Eur), ½” NPT

(USA)

Min Water Pressure 100kPa (15psi)

Max Water Pressure 800kPa (115psi)

Max Water Flow 20 L/min (5.3 gallons/min)

Max Water Temperature 40°C (104°F)

New hose sets supplied with the appliance are

to be used and old hose-sets should not be re-

used.

If the supply cord is damaged, it must be

replaced by the manufacturer, its service agent

or similarly qualied persons in order to avoid a

hazard.

CAUTION: In order to avoid a hazard due to

inadvertent resetting of the thermal cut-out,

this appliance must not be supplied through an

external switching device, such as a timer, or

connected to a circuit that is regularly switched

on and o by the utility.

FOR AUSTRALIAN BUSHFIRE PRONE

AREAS

WARNING If this evaporative cooler is installed

in a BAL-12.5 to 29 area the evaporative cooler

dropper duct and ashings shall be adequately

sealed at the roof to prevent gaps greater than

3mm. The dropper duct and ashings shall be

non-combustible.

WARNING: This cooler is NOT APPROVED

for installation in any bushre zoned area/

property (BAL-12.5 to BAL-FZ).

WARNING - TO REDUCE THE RISK OF

FIRE, ELECTRIC SHOCK, OR INJURY TO

PERSONS, OBSERVE THE FOLLOWING:

a) Use this unit only in the manner intended

by the manufacturer. If you have ques-

tions, contact the manufacturer.

b) Before servicing or cleaning unit, switch

power o at service panel and lock the

service disconnecting means to prevent

power from being switched on accidentally.

When the service disconnecting means

cannot be locked, securely fasten a prom-

inent warning device, such as a tag, to the

service panel.

c) Installation work and electrical wiring must

be done by qualied person(s) in accor-

dance with all applicable codes and stan-

dards, including re-rated construction.

d) When cutting or drilling into wall or ceiling,

do not damage electrical wiring and other

hidden utilities.

e) Do not use this fan with any Solid-State

Speed Control device.

f) Ducted fans must always be vented to the

outdoors.

EMPLOYER AND EMPLOYEE

RESPONSIBILITIES

The installation and maintenance of evaporative

coolers at height has the potential to create Oc-

cupational Health and Safety issues for those

involved. Installers are advised to ensure they

are familiar with the relevant State and Federal

legislation, such as Acts, Regulations, approved

Codes of Practice and Australian Standards,

which oer practical guidance on these health

and safety issues. Compliance with these reg-

ulations will require appropriate work practices,

equipment, training and qualications of work-

ers.

Seeley International provides the following in-

formation as a guide to contractors and employ-

ees to assist in minimising risk whilst working at

height.