seikoh giken SFP-550 User manual

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

SFP-550

Polishing Process Manual

296-1, Matushidai, Matsudo-Shi, Chiba 270-2214 Japan

TEL: +81-47-388-6111 FAX: +81-47-388-4477

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

1/20

INTRODUCTION

This manual covers polishing conditions and procedures with SFP-550

Polishing Machine. The polishing conditions in this manual are standard

and recommendable for the polishing applicable to our optical Zirconia

ferrule. Polishing conditions need to be changed applying to each

connector type, ferrule shape and material.

NOTE

Before polishing, also read Operating Manual and Maintenance Manual

of SFP-550 along with this manual.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

2/20

---------------------------Table of Contents---------------------------

§1 Introduction of IPC Holder 3

§2 Instruction of Polishing Film / Pad 4

Standard IPC Holder Process

§3 D 2.5mm Pre-radius Ferrule, HPC Convex Polishing 6

§4 D 1.25mm Ferrule, HPC Convex Polishing 7

§5 D 2.5m Ferrule APC Polishing (w/o Tuning) 8

§6 LC / MU Plug APC Polishing (w/o Tuning) 9

Mega-axis Holder Process

§7 Instruction of Mega-axis IPC Holder 11

§8 D2.5mm Pre-radius Ferrule, HPC Convex Polishing 12

§9 D1.25mm Ferrule, HPC Convex Polishing 13

§10 SC Plug APC Polishing (w/o Tuning) 14

§11 LC Plug APC Polishing (w/o Tuning) 15

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

3/20

§1 Introduction of IPC Holder

Please make sure that Zr ferrule does not have any epoxy or debris on side

face. These epoxy or debris may affect polishing performance because of

changing spring pressure from IPC (Independent Pressure Control) system.

In addition, to clean ferrule insertion hole is necessary as regular maintenance

to avoid debris to stick inside the hole. Please use HCB-250 (for 2.5mm hole)

or HCB-125 (for 1.25mm hole) brush with IPA for cleaning. After brushing,

brow compressed air to the cleaned insertion hole.

* Cleaning Method Using HCB-250 / 125

1) Insert the brush into the hole from upper side of the holder. (Pic.1).

2) Keep inserting the brush to the other side (Pic. 2).

3) Repeat this cleaning method several times until the hole is cleaned up. Try

to put alcohol to the brush for cleaning if foreign substances are still

adhered in spite of many trials.

Pic. 1 Pic. 2

Using brush for cleaning Viewed from bottom

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

4/20

§2 Instruction of Polishing Film / Pad

2-1) Rubber pad (PR5X-500-**)

To avoid pealing problem during polishing, please follow the instruction

below when you attach polishing film to rubber pad.

1) Place rubber pad on flat & solid object such as glass plate (Pic. 3).

2) Place a few drops of PURIFIED WATER (Pic. 3) and wipe with lint-free

tissue to remove moisture (Pic. 4).

3) Place the polishing film on the rubber pad and remove bubbles

between the pad and the film by roller (Pic. 5).

Pic. 3 Pic. 4

Pic. 5

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

5/20

2-2) Sponge pad (PS5X-500-00)

Sponge pad is necessary for adhesive removal step to reduce the

grinding pressure to avoid a fiber crack problem. We recommend using

“repositionable spray glue” to attach polishing film to the sponge pad.

The spray glue is durable and can be used several times with one spray

brow.

Pic. 6 Pic. 7

Pic. 8

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

6/20

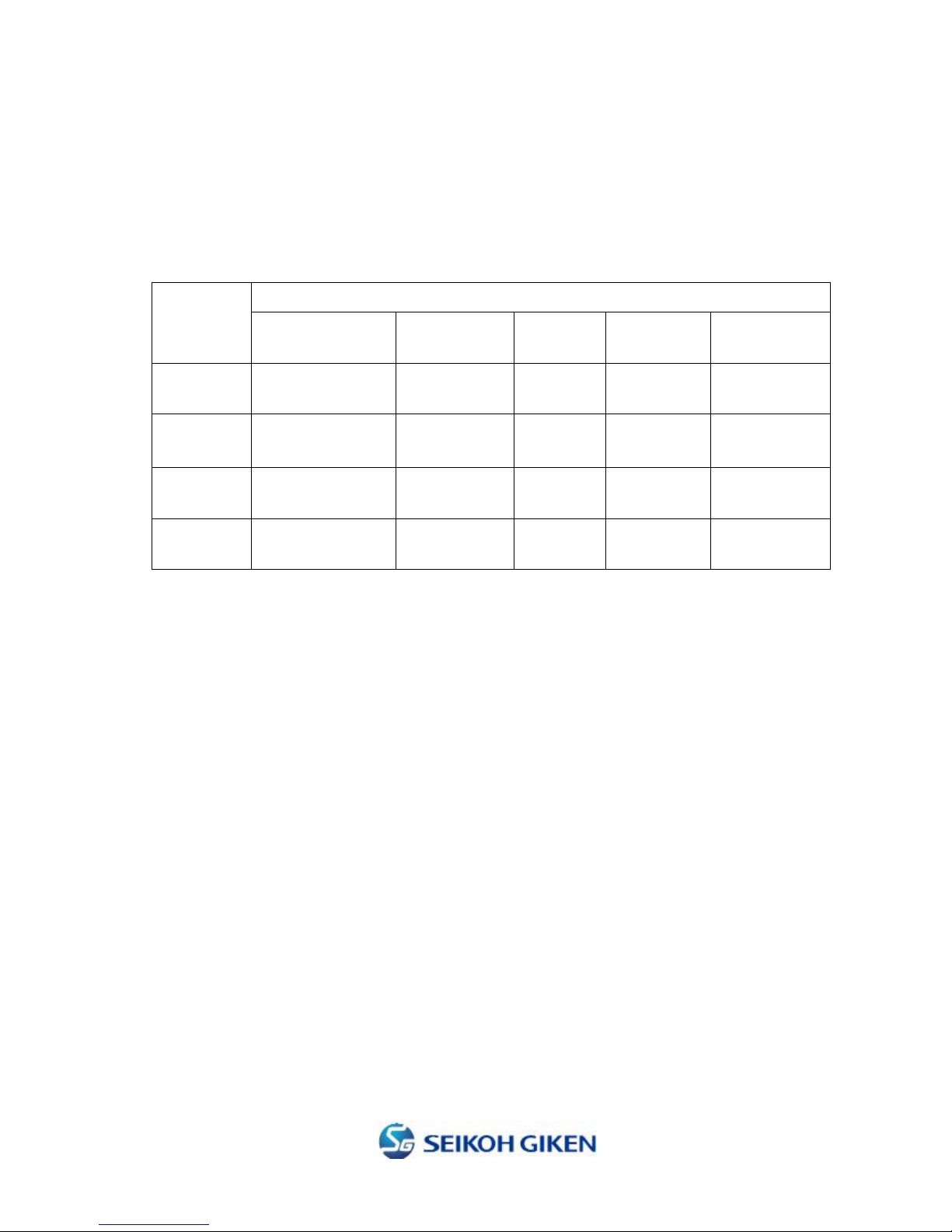

§3 D 2.5mm Pre-radius Ferrule, HPC Convex Polishing

Polishing Holder (Standard IPC Holder):

PH55-FF-20 (D 2.5mm Ferrule)

PH55-FP-20 (FC Plug)

PH55-CP-20 (SC Plug)

PH55-SP-20 (ST Plug)

POLISHING CONDITIONS

POLISHING

PROCESS POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min) PRESSURE

ADHESIVE

REMOVAL PS5X-500-00 GA5D

(5) NONE 0.5 NONE

FIRST

POLISHING

PR5X-500-80 DR5D-9u

(30)

PURIFIED

WATER 0.5

AFTER 10

TURNTABLE

REVOLUTIONS

SECOND

POLISHING

PR5X-500-80 DJ5D-1u

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-80 XF5D

(7)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note: All polishing times will be half of the above when the number of attached ferrules is 5

or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

7/20

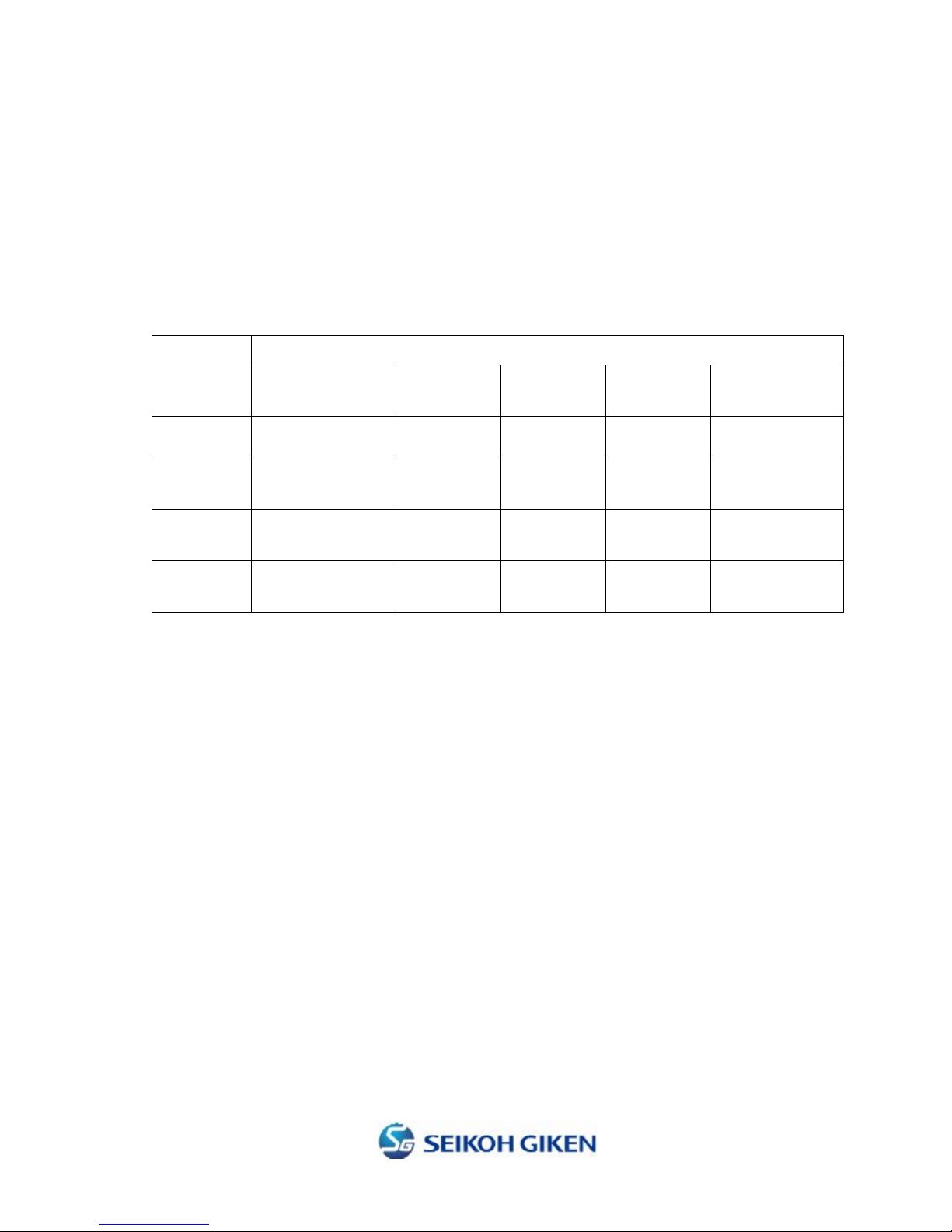

§4 D 1.25mm Ferrule, HPC Convex Polishing

Polishing Holder (Standard IPC Holder):

PH55-FLM-24 (LC / MU Ferrule, Coupling nut type)

PH55-FLM-16 (LC / MU Ferrule, Post-type)

PH55-PL-24 (LC Plug)

PH55-PM-24 (MU Plug)

POLISHING CONDITION

POLISHING

PROCESS POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min.) PRESSURE

ADHESIVE

REMOVAL PR5X-500-90 GA5D

(5) NONE 0.5 NONE

FIRST

POLISHING

PR5X-500-85 DH5D-3μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

SECOND

POLISHING

PR5X-500-85 DJ5D-1μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-85 XF5D

(10)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note: All polishing times will be half of the above when the number of attached ferrules is 5

or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

8/20

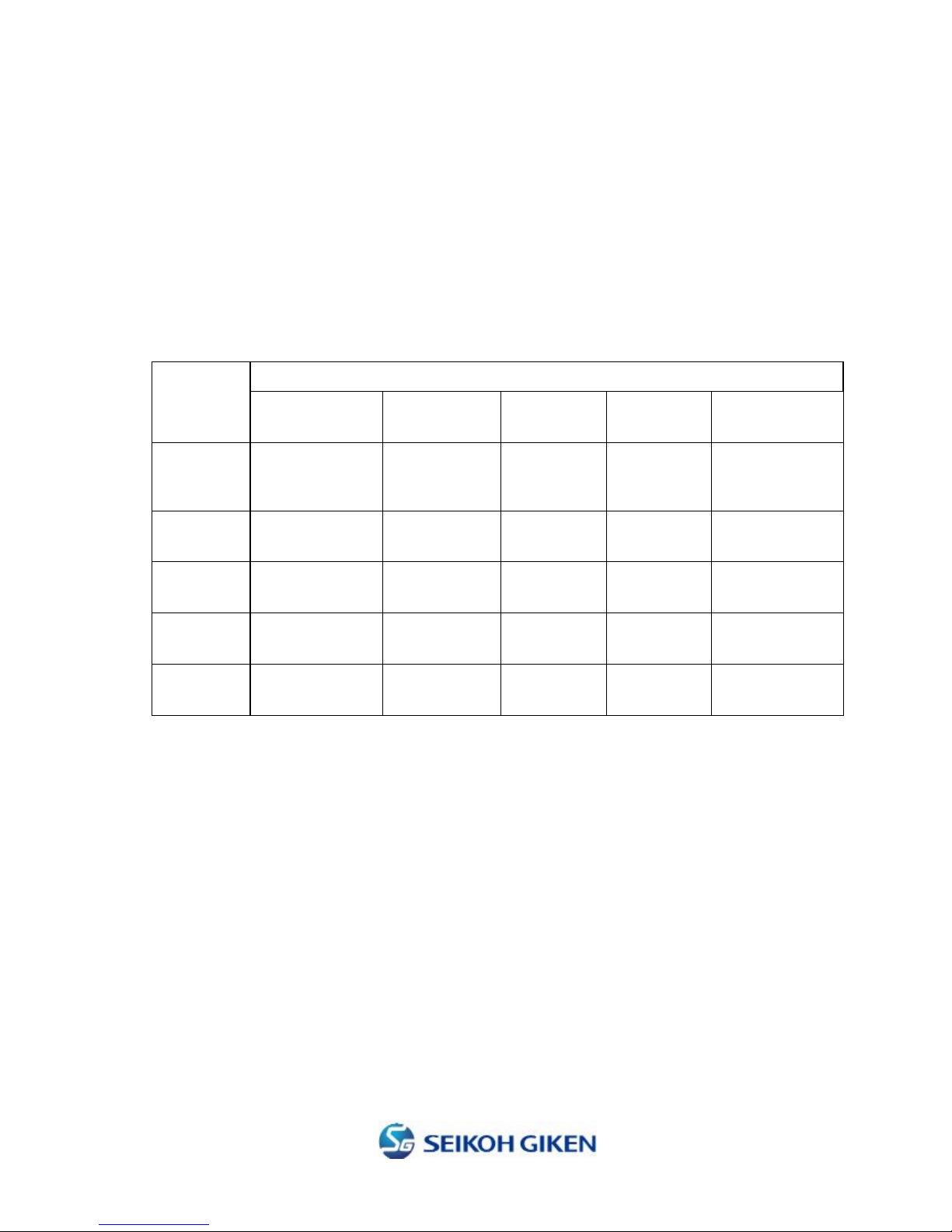

§5 D 2.5mm Ferrule APC Polishing (w/o Tuning)

Polishing Holder (Standard IPC Holder):

Connector

Type APC

Type Pedestal

Diameter Key

Width Chamfer

Angle

PH55-FF8A-18-1.3 APC Ferrule Step 1.4mm 1.3mm ---

PH55-FF8A-18-1.5 APC Ferrule Step 1.4mm 1.5mm ---

PH55-FF8C-18-1.3 APC Ferrule Conical 1.0mm 1.3mm 35 degree

PH55-FF8C-18-1.5 APC Ferrule Conical 1.0mm 1.5mm 35 degree

PH55-FP8R-18-I FC/APC Step 1.4mm 2.00mm ---

PH55-FP8N-18-I FC/APC Step 1.4mm 2.14mm ---

PH55-FP8RC-18-I FC/APC Conical 1.0mm 2.00mm 35 degree

PH55-FP8NC-18-I FC/APC Conical 1.0mm 2.14mm 35 degree

PH55-CP8A-18 SC/APC Step 1.4mm --- ---

PH55-CP8C-18 SC/APC Conical 1.0mm --- 35 degree

POLISHING CONDITION

POLISHING

PROCESS

POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min.)

PRESSURE

ADHESIVE

REMOVAL

CONVEX

FORMING

PR5X-500-75 GA5D

(1)

PURIFIED

WATER 1.0

AFTER 10

TURNTABLE

REVOLUTIONS

FIRST

POLISHING

PR5X-500-75 DA5D

(30)

PURIFIED

WATER

1.0 to 1.5

(Note 1)

AFTER

REVOLUTION

STARTS

SECOND

POLISHING

PR5X-500-75 DR5D-9μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

THIRD

POLISHING

PR5X-500-75 DJ5D-1μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-75 XF5D

(10)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note 1: Polishing time for DA5D is 1.0 min. up to 15 times and 1.5 min. after 15 times

Note 2: All polishing times will be half of the above when the number of attached ferrule

is 5 or less.

Note 3: For conical ferrule, the above holders might cause apex offset depending on

conical ferrule tip dimension. Then you need to have custom design holder as

per ferrule tip dimension.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

9/20

§6 LC / MU Plug APC Polishing (w/o Tuning)

Polishing Holder (Standard IPC Holder):

PH55-PL8A-20 (LC/APC Plug)

PH55-PM8A-20 (MU/APC Plug)

APC POLISHING CONDITION

POLISHING

PROCESS

POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min)

PRESSURE

ADHESIVE

REMOVAL

CONVEX

FORMING

PR5X-500-70 DA5D

(30)

PURIFIED

WATER

0.5 to 1.0

(Note 1)

AFTER 20

TURNTABLE

REVOLUTIONS

FIRST

POLISHING

PR5X-500-70 DR5D-9μ

(30)

PURIFIED

WATER 0.5

AFTER

REVOLUTION

STARTS

SECOND

POLISHING

PR5X-500-70 DJ5D-1μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-70 XF5D

(10)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note 1: Continue polishing until convex is completely formed

Note 2: All polishing times will be half of the above when the number of attached ferrules

is 5 or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

10/20

Polishing Process for Mega-axis Holder

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

11/20

§7 Instruction of Mega-axis IPC Holder

Please make sure that Zr ferrule does not have any epoxy or debris on side

face. These epoxy or debris may affect polishing performance because of

changing spring pressure from IPC (Independent Pressure Control) system.

In addition, to clean ferrule insertion hole is necessary as regular

maintenance to avoid debris to stick inside the hole. Please use HCB-250

(for 2.5mm hole) or HCB-125 (for 1.25mm hole) brush with IPA for cleaning.

After brushing, brow compressed air to the cleaned insertion hole.

Pic. 1 Pic. 2

Pic. 3

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

12/20

§8 D 2.5mm Pre-radius Ferrule, HPC Convex Polishing

Polishing Holder (Mega-axis IPC Holder):

PH55-FF-40N (D 2.5mm Ferrule)

PH55-CP-32N (SC Plug)

PH55-SP-28N (ST Plug)

POLISHING CONDITIONS

POLISHING

PROCESS POLISHING PAD

POLISHING

FILM

(service life)

POLISHIN

G LIQUID

POLISHING

TIME (min) PRESSURE

ADHESIVE

REMOVAL PS5X-500-00 GA5D

(5) NONE 0.5 NONE

FIRST

POLISHING

PR5X-500-75 DR5D-9u

(30)

PURIFIED

WATER 0.5

AFTER 10

TURNTABLE

REVOLUTION

SECOND

POLISHING

PR5X-500-75 DJ5D-1u

(15)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-75 XF5D

(5)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note: All polishing times will be half of the above when the number of attached ferrules is

5 or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

13/20

§9 D 1.25mm Ferrule, HPC Convex Polishing

Polishing Holder (Mega-axis IPC Holder):

PH55-PL-40N (LC Plug)

PH55-PM-40N (MU Plug)

PH55-FLM-40N (LC / MU Ferrule) *

*Note: For LC ferrule polishing, please insert 4pcs of 0.6mm spacers between

the holder plate and the spring plate. The spacers come with the holder.

POLISHING CONDITION

POLISHING

PROCESS POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min.) PRESSURE

ADHESIVE

REMOVAL PR5X-500-90 GA5D

(5) NONE 0.5 NONE

FIRST

POLISHING

PR5X-500-85 DH5D-3μ

(20)

PURIFIED

WATER 1.0

AFTER

REVOLUTIONS

STARTS

SECOND

POLISHING

PR5X-500-85 DJ5D-1μ

(20)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-85 XF5D

(5)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note: All polishing times will be half of the above when the number of attached ferrules is

5 or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

14/20

§10 SC Plug APC Polishing (w/o Tuning)

Polishing Holder (Mega-axis IPC Holder):

PH55-CP8A-32N (SC/APC Plug with Step ferrule, Pedestal D 1.4mm)

PH55-CP8C-32N (SC/APC Plug with Conical ferrule, Pedestal D 1.0mm,

Chamfer angle 35-deg)

PH55-FF8C-40N-1.3 (Conical ferrule 8-deg APC, Pedestal D 1.0mm,

Chamfer angle 35-deg, Key width 1.3mm)

POLISHING CONDITION

POLISHING

PROCESS

POLISHING PAD

POLISHING

FILM (service

life)

POLISHING

LIQUID

POLISHING

TIME (min.)

PRESSURE

ADHESIVE

REMOVAL

CONVEX

FORMING

PR5X-500-75 GA5D

(1)

PURIFIED

WATER 1.0

AFTER 10

TURNTABLE

REVOLUTIONS

FIRST

POLISHING

PR5X-500-75 DA5D

(30)

PURIFIED

WATER

1.0 to 1.5

(Note 1)

AFTER

REVOLUTION

STARTS

SECOND

POLISHING

PR5X-500-75 DR5D-9μ

(30)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

THIRD

POLISHING

PR5X-500-75 DJ5D-1μ

(15)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-75 XF5D

(5)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note 1: Polishing time for DA5D is 1.0 min. up to 15 times and 1.5 min. after 15 times

Note 2: All polishing times will be half of the above when the number of attached ferrules

is 5 or less.

Note 3: For conical ferrule, the above holders might cause apex offset depending on

conical ferrule tip dimension. Then you need to have custom design holder as

per ferrule tip dimension.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

15/20

§11 LC Plug APC Polishing (w/o Tuning)

Polishing Holder (Mega-axis IPC Holder):

PH55-PL8A-40N (LC/APC Plug)

APC POLISHING CONDITION

POLISHING

PROCESS

POLISHING PAD

POLISHING

FILM

(service life)

POLISHING

LIQUID

POLISHING

TIME (min)

PRESSURE

ADHESIVE

REMOVAL

CONVEX

FORMING

PR5X-500-70 DA5D

(30)

PURIFIED

WATER

0.5 to 1.0

(Note 1)

AFTER 20

TURNTABLE

REVOLUTIONS

FIRST

POLISHING

PR5X-500-70 DR5D-9μ

(30)

PURIFIED

WATER 0.5

AFTER

REVOLUTION

STARTS

SECOND

POLISHING

PR5X-500-70 DJ5D-1μ

(15)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

FINAL

POLISHING

PR5X-500-70 XF5D

(5)

PURIFIED

WATER 1.0

AFTER

REVOLUTION

STARTS

Note 1: Continue polishing until convex is completely formed.

Note 2: All polishing times will be half of the above when the number of attached ferrules is

5 or less.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

16/20

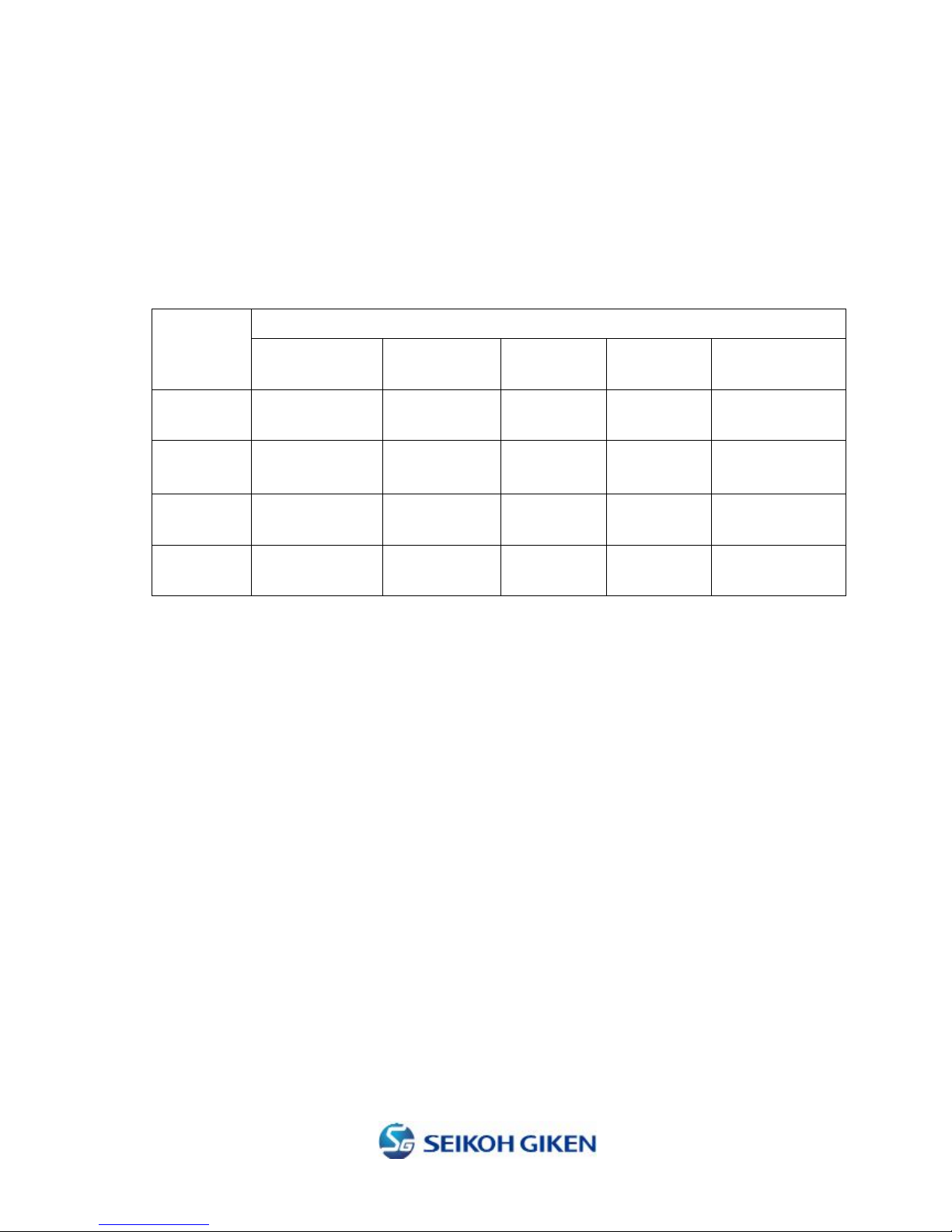

§12 Service Life of Polishing Films

Polishing Films Application Service Life

(Usable

times)

Polishing

Material

Diameter

of polishing

particles

GA5D Adhesive Removal,

Rough Polishing 1-5

GC5D Adhesive Removal,

First Polishing 1

GI5D Second Polishing 1

GK5D Second Polishing 1

S i C

Large

│

│

│

│

↓

Small

DA5D Rough Polishing 15-30

DR5D-9μ First Polishing 15-30

DG5D-5μ First Polishing 15-30

DH5D-3μ Second Polishing 15-30

DJ5D-1.5μ Second Polishing 15-30

Diamond

Large

│

│

│

│

↓

Small

AR5D First Polishing 1

AJ5D Second Polishing 1

SF5D Final Polishing 1

AO5D Final Polishing 1

Alumina

Large

│

│

│

↓

Small

XF5D Final Polishing 5-10 SiO2 Fine

EF5D Final Polishing 1 CeO2 Fine

CF5D Cleaning 30

BX5D Polishing 3 Polishing Pad

Note 1: Service life of films may change depending on conditions of storage or usage

Note 2: Wipe and clean the polishing films to remove polishing remaining and

moisture after polishing and storage them in low humidity condition.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

17/20

§13 Polishing Process

Polishing process is depending on each ferrule shape, material, and connector type.

Polish ferrules by an appropriate polishing condition described in the former sections.

The following Polishing Process is regarding to general ferrule polishing using SFP-550S

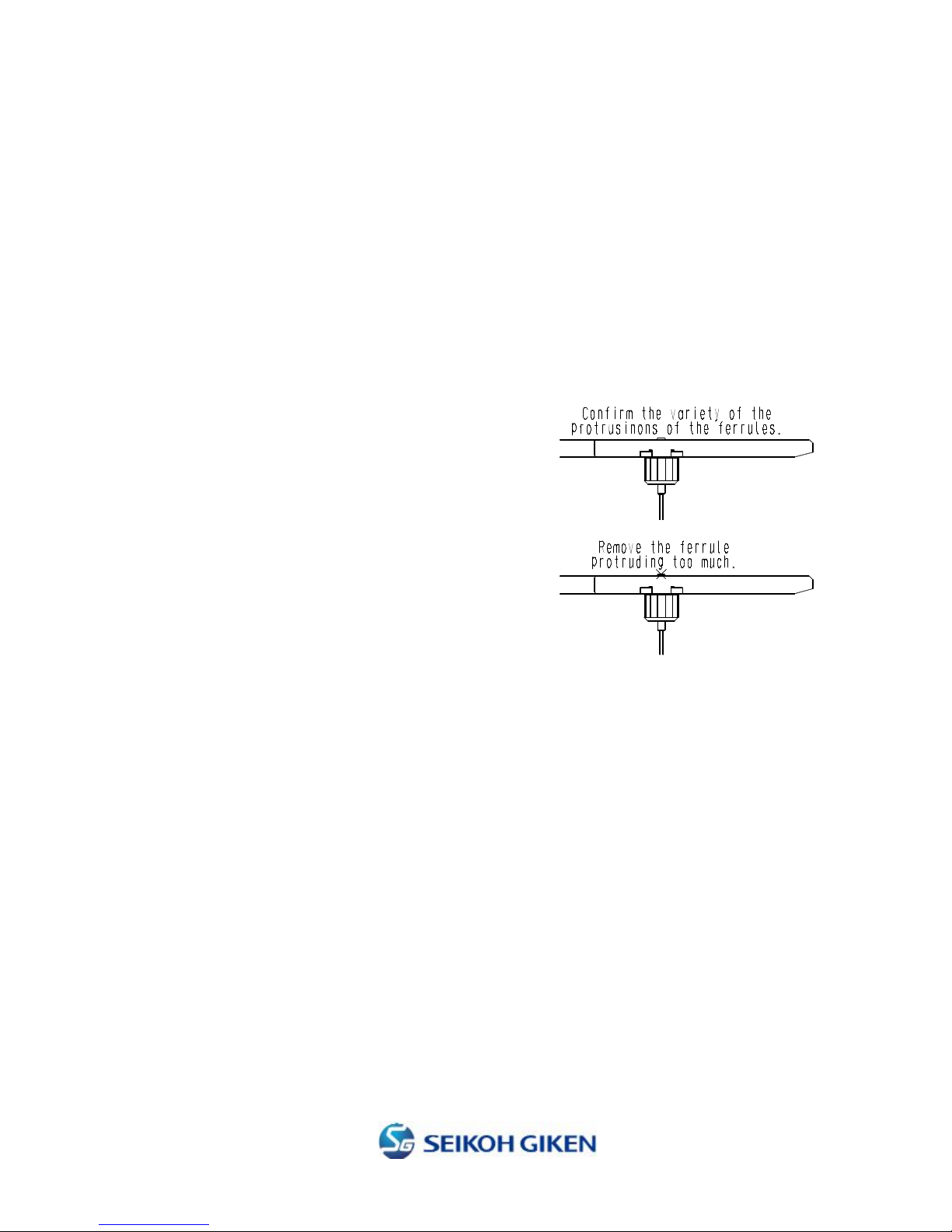

13.1 Ferrule Mounting Check

When ferrules are mounted to the polishing holder, please make sure that the tip of

ferrules protrude uniformly from the bottom of the holder.

A variety of the protrusions influence the quality of

polishing. Confirm the protrusion of the ferrules

after mounting, remove the ferrule if its protrusion

length is larger or shorter than others. Especially

the ferrule of short protrusion may not be mounted

completely because of adhesive on the side of the

ferrule. Clean the ferrule well and mount it to the

holder again. Do not remove the ferrules during

polishing processes.

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

18/20

13.2 Adhesive Removal Process

Use of sponge pad in adhesive removal step helps reducing fiber crack and damages in

polishing film. Adhesive removal process shall be done until adhesive is completely

removed. If there is adhesive left on ferrule endface, it might lead to polishing film

breakage or affect to polished endface geometry.

Pic. 10 Fiber crack

Example: amount of adhesive

Pic. 11 Not enough Pic. 12 Decent amount Pic. 13: Too much

SFP-550 Polishing Process Manual

FP-PM55 (Rev. 6.3)

19/20

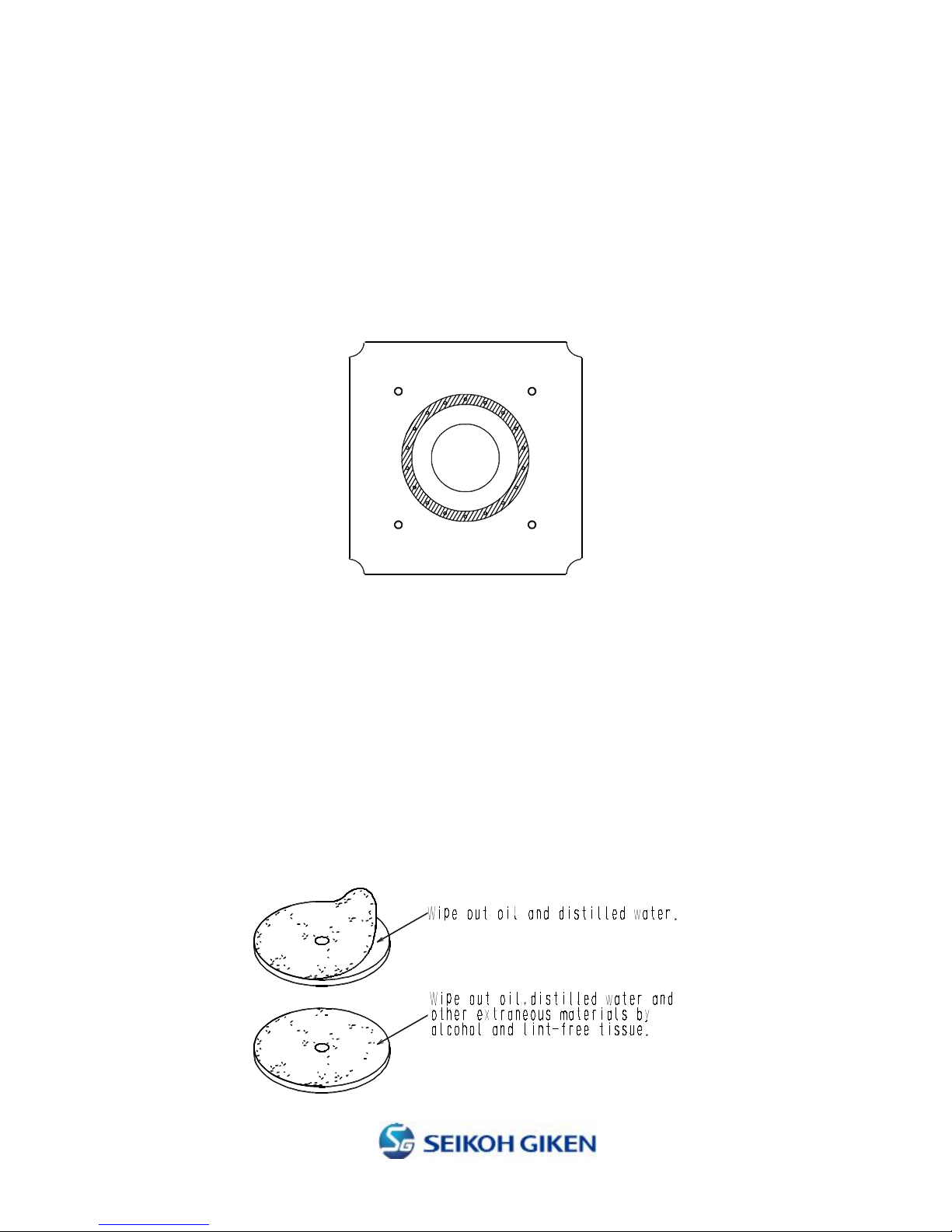

13.3 Cleaning of Polishing Holder

Polishing particles stuck to the polishing holder at the former polishing step may be a

cause for the damage of a polishing film and scratches of the ferrule tip at the latter

polishing step. After every polishing step, wipe the bottom side of the polishing holder,

especially the area around the ferrule tips shown the shaded part in the bottom figure, by

PURIFIED WATER and lint-free tissue.

13.4 Cleaning of Polishing Film and Polishing Pad

For polishing film, which has service life more than once, shall be wiped and cleaned

by purified water and lint-free tissue after every use. Because remain of polished

residue may cause bad polishing result. Also, when polishing liquid between the

polishing pad and the film is found, clean the area between the polishing pad and film

and keep the area free from the extraneous materials. Because polishing liquid

between the polishing pad and the polishing film may accelerate the polishing film

peeling and be cause for the bad polishing result or damage of the polishing film.

The following figure shows the area focusing on cleaning.

DM

DR

Other manuals for SFP-550

1

Table of contents