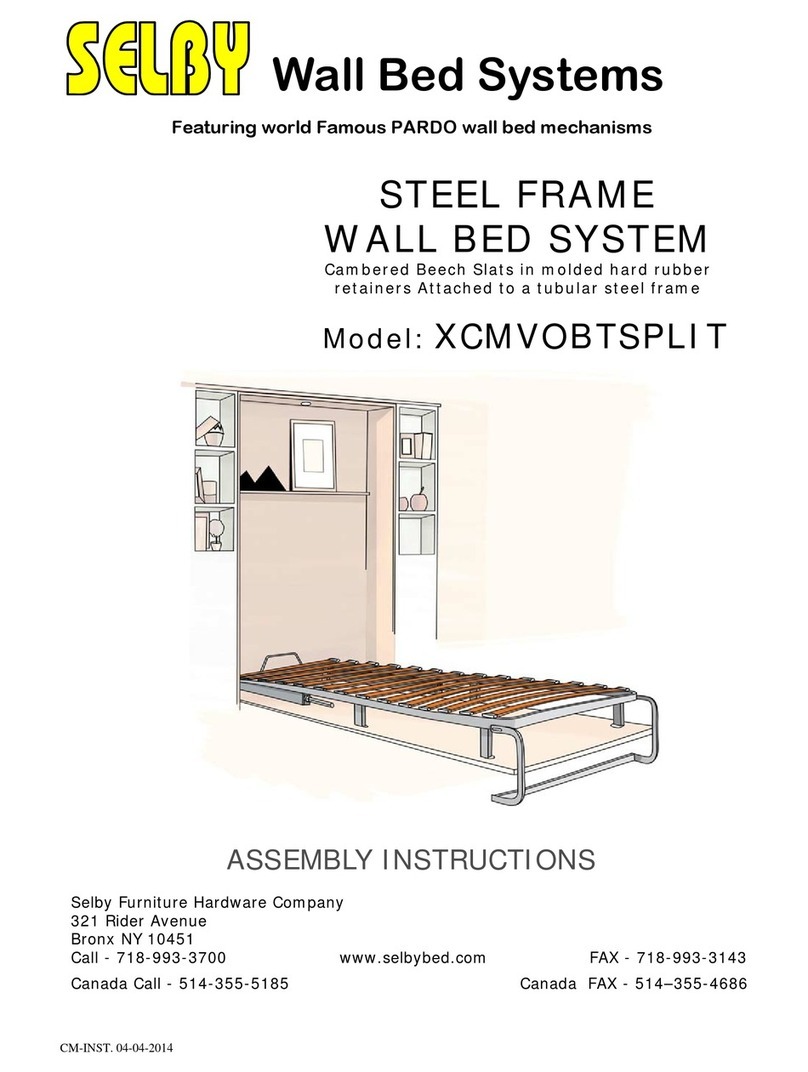

Selby XSMVO User manual

MECHANISMS For

Custom Wall Beds

Model: XSMVO

SM-INST. 090712 REV. 10-2-12

Wall Bed Systems

Featuring world Famous PARDO wall bed systems and wall bed mechanisms

Selby Furniture Hardware Company

321 Rider Avenue

Bronx NY 10451

Call - 718-993-3700 www.selbywallbedsystems.com FAX - 718-993-3143

Canada Call - 514-355-5185 Canada FAX - 514–355-4686

ASSEMBLY INSTRUCTIONS

OptionalBeechSlats&RetainersShown

SELBY Furniture Hardware Company

Selby type SM mechanisms for custom wall beds are intended for fabrication and installation by

professional cabinet and furniture makers. These Pardo patented systems and mechanisms are

available in a wide variety of styles and applications. Selby wall bed hardware is available for all

north American sized mattresses.

Carton Contents

1 Manual leg set

2 Counter Balance Mechanism

2 Pivot Mount Plates

1 Bag of hardware

8 Screws DIN 912 6x25

16 Nuts DIN 934 M-6

16 Countersink bushings

8 Screws DIN 912 6x60

If any parts are missing, contact your Selby Hardware Distributor immediately.

Check out these five points for a successful project

Mattress Size will determine the size of the bed frame and the weight capacity of the Pardo counter balance.

Standard mattress sizes will vary +/- 1” in length and width

The mattress thickness and height in the bed frame may determine the depth requirement of the wall cabinet.

Top of the mattress on a deployed bed frame should be 18”” to 28” off of the floor

Support the mattress on a platform or slats built into the bed frame

The combined height of frame components and mattress will effect the wall cabinet depth

You may choose concealed hardware or exposed hardware for aesthetic value or ease of access.

See chart Below

Material used for the construction of the bed fame will affect the Pardo counter balance capacity that is required.

Selby offers more different wall bed systems and mechanisms than any other manufacturer

Concealed Hardware Most aesthetically pleasing

Requires less wall space.

Reduced protrusion of panel

More difficult access to adjust

More likely to require a custom foundation,

platform or slats on cleats for mattress

support

Exposed Hardware Supports common foundations

Or “inner springs”

May accommodate a thicker

mattresses

Hardware is visible when bed is deployed

Wide door face interference when sitting

Requires about 3-1/4” wider wall space

PRO CON

SM-1

Handle

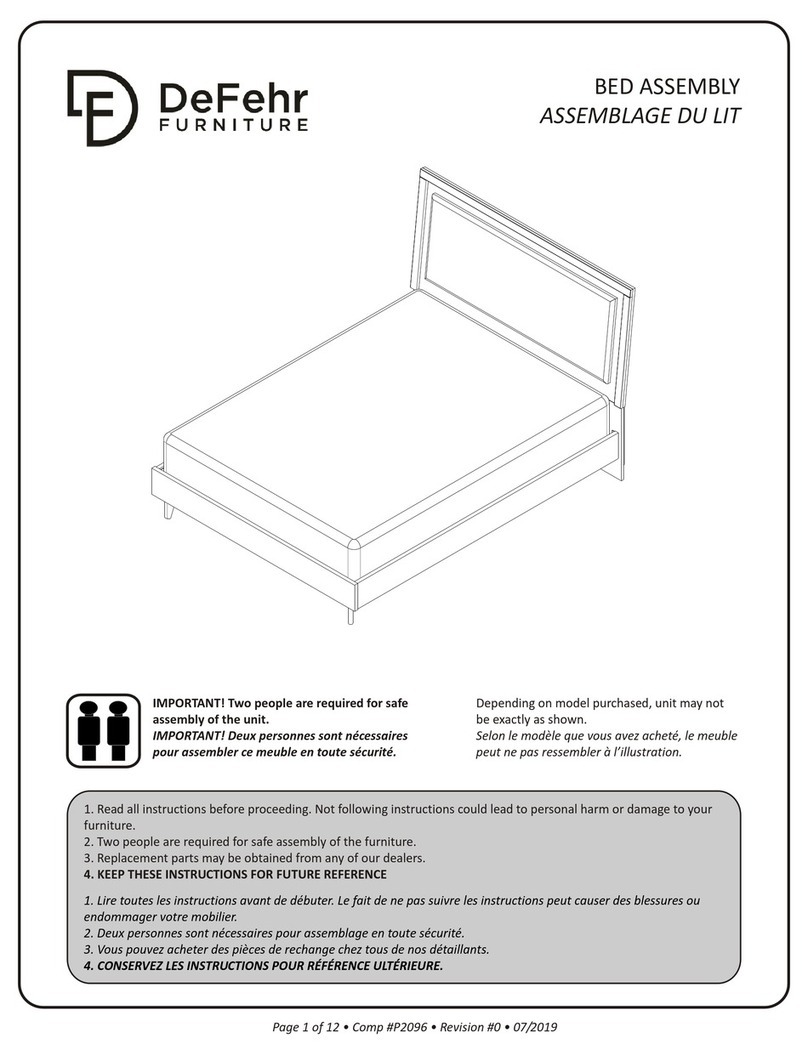

The following notes are intended as a guide for the construction of custom cabinets and installation of Pardo Euro-

pean wall bed hardware from Selby Furniture Hardware Company into those cabinets. Due to the many differences in

cabinet making styles and joinery techniques, it is suggested that a prototype cabinet be made using this guide, in order

to tailor these instructions to suit your individual requirements. Installation of the completed wall bed and adjustment of

the system will be found on pages 7 and 8 of this publication.

- · -

Local building codes will apply and if required by the municipality or state where the cabinetry will be installed, a

licensed contractor with wall bed experience may be required to complete the installation.

1.) Determine bed size and mechanism type, concealed or exposed, and weight capacity

2.) Select 3/4” inch plywood or lumber species to be used for cabinetry construction.

3.) Construct a wall cabinet (may be a two pier and bridge design) to later be firmly attached to a structurally sound

wall. See drawings and specifications on the following pages.

4.) Design and build a platform, bed frame & front panel door assembly, for the wall cabinet.

A foundation consisting of a commercial “inner spring” set, a frame and Bunkie board

foundation or a custom made foundation of slats & cleats. See drawings and specifications on following pages.

Selby Furniture Hardware Company offers “Tabloflex”, a bent steamed beech plywood and retainer

foundation system to fit most custom made bed frames.

5.) SM Mechanisms are supplied with two legs that require a wooden cross bar. The fabricator will cut and finish the

bar to match the door face in species and color

6.) We recommend a flush inset door panel that will “swing” into the cabinet at the bottom when activating the platform.

7.) Complete the wall cabinet with a door stop and door catch(s) (double ball or equal) to maintain a flush inset

condition even on a structural wall that is not plumb. Lighting with a positive “off”, sliding shelves and other

accessories may also be added.

8.) Fit the wall bed with accessories such as a head board, lights and pull out shelves as needed.

9.) Install and adjust the wall bed as detailed on the following pages.

10.) Adjust Allen screws in the square axel of the mechanism to register the door panel in the cabinet opening.

Mechanisms to activate vertical and/or horizontal descending beds ARE NOT interchangeable

The wall cabinet must be plumb and securely attached to a suitable wall

SM-2

ConcealedHardwareSystem

Bed Frame Detail

Bed Frame Detail

Case or Cavity Detail

SM-3

Door Panel may be left up to 3” long to eliminate the

toe kick

SM-4 – Revised 10-2-2012

The dimensions shown on this page are for the construction of cabinetry for Pardo brand wall beds from Selby Furniture Hardware Company

This grid was produced based on use of ¾” (.750”) finished material. If the use of 13/16” or other thickness for components is

necessary these dimensions must be replaced. The inside width of the wall cabinet must be 60mm greater than the O/A outside

width of the bed frame.

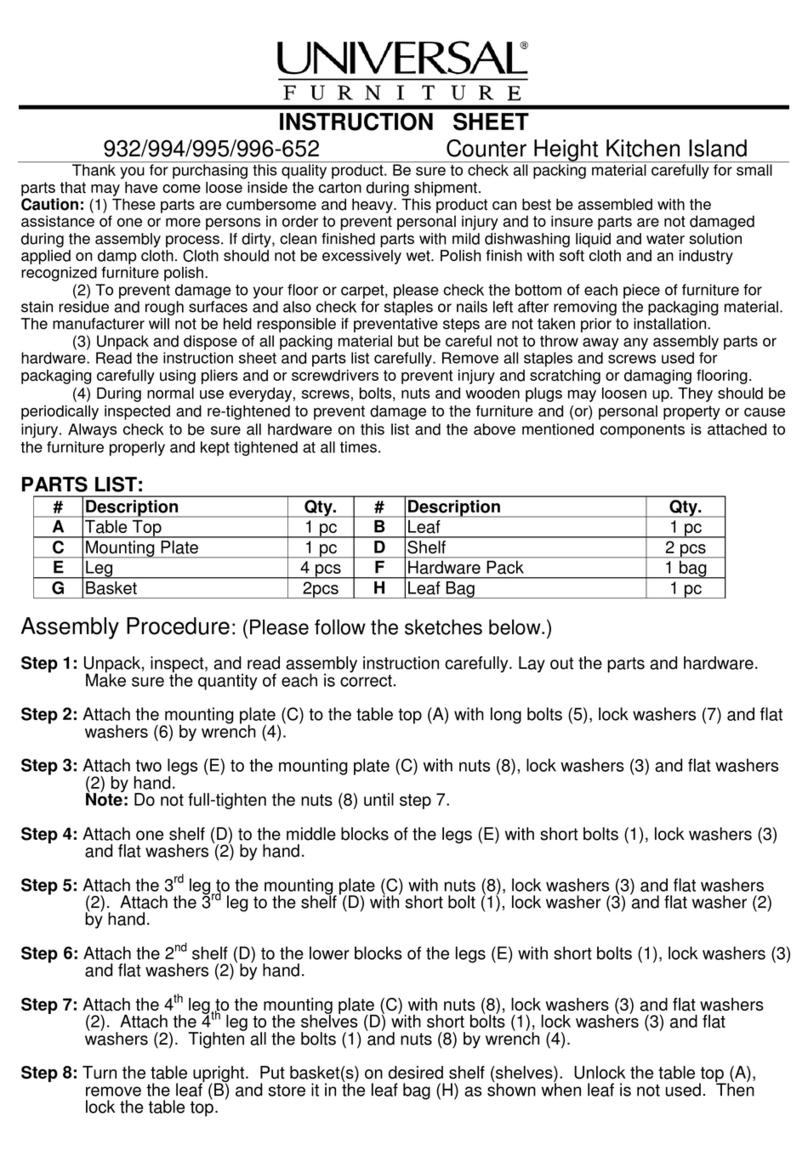

Cabinet Construction Dimensions Concealed Vertical Mechanism Exposed Vertical Mechanism

Width Dimensions Twin Double Queen E. King Twin Double Queen E. King

A– Inside Bed Frame Width 40” 55” 61” 77” 40” 55” 61” 77”

B– Outside Bed Frame Width 41-½” 56-½” 62-½” 78-½”

C– Outside Bed Frame & Mechanism 44-5/8 59-5/8 65-5/8 81-5/8

D- O/A Door Panel Width 43-3/8 58-3/8 64-3/8 80-3/8 46-11/16 61-11/16 67-11/16 83-11/16

G– Cabinet/Opening Inside Width 43-7/8 58-7/8 64-7/8 80-7/8 47-1/16 62-1/16 68-1/16 84-1/16

H – Cabinet Outside Width, Optional

Length Dimensions

1– Length Inside Bed frame 76 76 81 81 76 76 81 81

2– Length Outside Bed Frame 77-½ 77-½ 82-½ 82-½ 77-½ 77-½ 82-½ 82-½

3– Length Door Panel O/A 79-1/2 79-1/2 84-1/2 84-1/2 79-1/2 79-1/2 84-1/2 84-1/2

4– Toe Kick 4” 4” 4” 4” 4” 4” 4” 4”

6– Length Cabinet inside 83” 83” 88” 88” 83” 83” 88” 88”

7 – Length Cabinet O/A, Optional

Part Number 3950I5475I54110I54110I 3950X 5475X 54110X 54110X

Platform Design Weight Maximum Pounds 110* 165* 243* 260* 110* 165* 243* 260*

Mattress Manufacturers produce nominal sizes + / – 1”. The dimensions in this instruction are nominal size + 1”

* Platform Weight is inclusive of wood platform, mattress, foundation, etc. for the specified counter balance mechanism function.

Eastern King Nominal Mattress size is 76” X 80” Long (shown)– California King is 72” X 84” Long

Detail

Hole Locations

Countersink Bushings must be inserted into the wood cabinet

sides for added strength at stress points when the mechanism is

under tension. The M6 socket head machine screws are then

inserted through the countersink bushings and the mount plates

threaded into nuts that are then firmly tightened. (7.8FT.LB. Dry)

Measure 56mm from BACK of door to the

center of 35mm holes to accept back plates

Counter balance mechanisms are “handed” .

Right side shown.

Pivot Mount Plate

SM-5

FabricatorSupplies Bar

Technical Support:

On Line www.selbywallbedsystems.com

North America (602) 920-4337

7AM to 7PM CST

After the cabinet is assembled and attached to the wall a headboard arrangement can be assembled. This is a

simple arrangement but important for safety by stopping ‘things’ from falling down behind if the bed is lifted.

Cabinet Backs and Headboards

A cabinet back must be provided for cabinet integrity. A full 3/4” thick back of plywood or lumber, A partial back

that is full width and 24” +/- from the floor and a full length 4” wide or greater hang rail at the top of the wall cabi-

net or a 6” wide hardwood of veneer core plywood frame on the inside of the cabinet box.

SM-6

Mattress Height Mattress Height

SEMI

OPEN

BACK

SOLID

BACK FRAME

BACK

Selby wall bed installation

The descending platform on a wall bed may weigh hundreds of pounds and it will have very

little support when opening or closing, anchor the cabinet and all components securely!

The bed frame platform and front door assembly may be installed in a single wall cabinet of appropriate size or

may be installed between side cabinets or piers. It is critical to maintain a 30mm space between the outside of

the bed frame and the inside of the wall cabinet sides on both sides. The width of the bed frame must be 60mm

less than the inside of the wall cabinet. The door width will determine the gap between the door and the cabinet.

SM-7

REV.8-17-12

Use a 24mm

socket & ratchet

wrench to adjust

tension.

A flat wrench may

damage the

handle

Selby wall bed installation and adjustment.

Adjustment Procedure

Do Not Attempt to Adjust the Tension with the door panel in the full open position

1. With the cabinet secured to the wall you may start the adjustment procedure.

2. Lower the panel door to an approximate 15° angle (from vertical) and tighten by hand.

both left and right tension handles until they no longer turn without force. This means

that both sides are now evenly adjusted and that the springs are uniformly engaged.

3. Unwind the regulators an even 10 full turns each

4. Lower the panel door and carefully install the chosen mattress. Carefully release

the panel door to see if it will remain at this angle. With a foam mattress the panel door may

stay at this position but a spring mattress will require further adjustment.

5. Bring the bed back up to the original 15° angle (from vertical) At this point, uniformly hand tighten the

tensioning handle and then you must use a 24mm socket wrench to tighten both handles an equal number

of turns in multiples of 8 to 10 turns at a time. One side then the other. A ratchet wrench and 24mm socket is

recommended to avoid damage to the tension adjusting screw cover.

6. Lower the panel door until the bed is parallel to the floor. At this point, you may judge for

yourself the weight of the bed. If you feel it is to heavy, tighten the regulators further

(Always in the up-right position) to obtain the perfect setting.

7. Your new Selby wall bed is now ready for use.

Selby wall beds can be relocated by reversing the procedures shown on this page. A professional installer is advised

Adjust gap around door

Adjust tension and balance the bed platform

Secure the cabinet and bed firmly to a structural

wall of the building

To adjust the mechanism tension and balance

the bed platform; place the mattress in the bed

frame and position the door at 15° open. This is

the neutral position of the springs used to

balance the bed weight.

The handles may be turned “hand tight” after

which they must be sequentially tightened with a

24mm socket wrench

SM-8

SM-9

FAQ

Countersink Bearings Required Countersinks are supplied with the Selby wall bed system

hardware and MUST be inserted in counter bores to attach the cast mount plate to the wall

cabinet or piers and to attach the counter balance mechanisms to the bed frame with

appropriate machine screws and washers. The countersink bearings supply extra strength at

high-tension points when operating the bed

Installation, Baseboard – Installation of angle iron brackets at wall cabinet base will require

that the cabinet base is notched for clearance OR that the baseboard is cut away for a tight

connection to the base plate in the wall.

Installation, Attaching the Wall Cabinet or Piers & Bridge to a structure wall – A

minimum of # 10 X 3” wood screws must be placed through the connection rail of the wall

cabinet(s) at every wall stud and installation must conform to all applicable building codes.

Tool Choice – Tension the counter balance units of the system using a 24mm socket wrench.

Use of a flat wrench, adjustable wrench or end wrench is not advised and damage to the

tensioning screw handle should be expected.

Selby Socket and ratchet wrench set.

Mattress Support The mattress used on a wall bed requires support. Placing the mattress directly on the

backside of the front panel or door is not recommended! The three most common methods of supporting

the mattress are:

A commercial foundation or innerspring, lowered into the bed frame.

A grid and Bunkie board built into the bed frame or

A platform or slats built onto the rails of the bed frame.

Mattress and support system thickness and placement will be related to wall cabinet depth.

Selby Hardware offers a mattress support system of steamed curved beech slats and hard rubber

retainers for sale.

Selby Hardware Slat & Retainer.

IMPORTANT SAFETY INFORMATION:

The bed should only be operated by an adult.

Due to the risk of entrapment, children should not play with the bed in the sleeping or stored positions.

Ensure the bed cabinet is securely fixed to the wall (and adjoining units) before pulling the bed down.

Always manually control the bed by maintaining hand contact with the bed frame while in ascent and descent. Do not let the bed drop freely

or slam when opening / closing.

Fasten your bedding to the mattress using the straps, and secure to the bed before closing the cabinet. Insure that no bedding is

protruding, as it may cause damage to the mechanism. Secure the pillow under the foot strap.

Do not remove the mattress while the bed is in the horizontal position, unless the bed frame is being held by another person.

Bed and cabinet should be checked regularly for signs of wear.

lf you are relocating the bed, do not remove any of the fixings until the bed is in a vertical position. Bed relocation should be done by a

qualified installer.

Adjustable mechanisms should not be tampered with unless by a qualified fabricator.

We employ a policy of continuous development and therefore reserve the right to alter specifications or illustrations in this manual at any

time.

Accessories and Repair Parts

This is an excellent panel clamp that may be left in place for added

strength after the edge glued joint dries. The 35mm X 5/8” thick round

ends provide excellent surface contact. 5 or 6 recommended, drill 35mm

X 11/16” deep to bind and strengthen the front panel joint.

Selby Part # K52168 U

This ratchet and 24mm socket wrench will make adjusting the

counter balance mechanism fast, easy and certain even on a

concealed mechanism and without damage to the hex cover

Selby Part # XWRENCH24MM

Replacement legs for vertical wall bed platforms

Selby Part # XSMVOPARTLEG

Parts. 8-09-2012

Hardware parts bag: A complete assortment of fasteners for installation

of the Pardo counter balance system to a wood wall bed frame and

cabinet

Selby Part # XSMVO PARTBAG

Replacement handles for Pardo counter balance mechanisms

Selby Part # XSMVOADJHANDLE

Replacement pivot mount plates

Selby Part # XSMVOPARTPIVOT

Optional mattress strap sets are used to bind the mattress to the bed

frame in the vertical position.

Selby part # XSMVOMATSTRAP

Our solid brass extruded double ball catch, will insure a flush inset door,

even on a bed mounted on a wall that is not plumb. Don’t let the door

“pop” open an inch or two after you leave the installation site.

Selby Part # MKK240C - 2-3/4” X 1/2”

SM-10

TYPE

SM

TYPE

CM

TYPE

CE

Selby Furniture Hardware Company offers a wide variety of different styles of space saving

beds and bed mechanisms to suit the creative preferences of the most discerning design

professionals. Contact your local Selby distributor or sales representative for complete

details of the bed systems shown below. All system types are available in a configuration to

allow either vertical or horizontal opening .

TYPE

CA

TYPE

ST

Patented Pardo weight adjustable wall bed mechanism

Steel bed frame with front panel mounting brackets

Cambered beech plywood slats with hard rubber retainers

Automatic foot board deploys with the descending bed frame

Sizes to accommodate all North American standard size mattresses

Systems are available for vertical and horizontal deployment

Patented Pardo non adjustable swing away bed and mechanism

Mounts to wall of cabinet or fastens to closet or room floor

May be concealed in a cabinet or closet behind bi-fold doors

Perfect for beach house, ski lodge or hunting camp.

Use an economical standard size 4” thick foam mattress

Systems are available for vertical and horizontal deployment

Patented Pardo weight adjustable wall bed mechanism

Steel bed frame with front panel mounting brackets

Cambered beech plywood slats with hard rubber retainers

Manual combination leg and mattress retainer

Systems to accommodate all North American size mattresses

Systems are available for vertical and horizontal deployment

Patented Pardo weight adjustable wall bed mechanism only

Most popular hardware for custom cabinet and furniture makers

Mechanisms for all popular size and weight configurations

In stock at hardware distributors throughout North America

Systems are available for vertical and horizontal deployment.

System capacities for 50kg, 75kg, 80kg and 110 kg loads

Gas Piston assisted mechanism for beds with storage space

Rugged steel angle iron frame may be installed for vertical or

horizontal opening top

Toy box during the day, child's bed at night

Store valuables or excess bedding beneath you.

May be secured with cam locks

REV. 8-15-12

Other manuals for XSMVO

1

Table of contents

Other Selby Indoor Furnishing manuals