sematic SDS User manual

Drive - Instruction Manual

8XX

E 2016-03-25

SDS Drive DC-PWM

Compatible

811-000-000

ENGLISH

3

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

ENGLISH

www.sematic.com

Changes can be made without notice

1 Preface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2 What is the Sematic DC-PWM Drive System© Compatible? . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

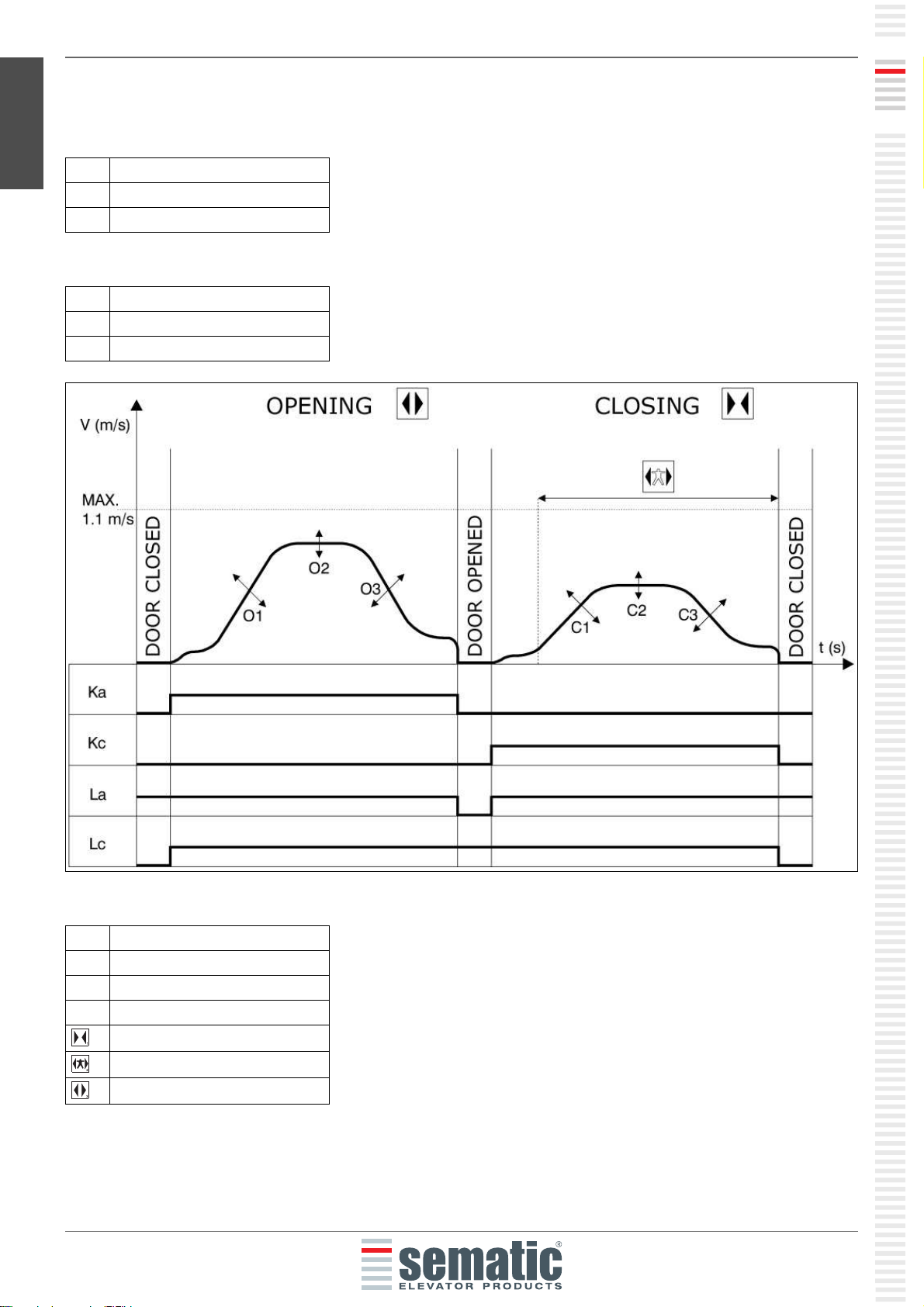

2.1 Speed profile 10

General Features . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

3.1 Technical information 11

3.2 Sematic Drive System© Door Controller (DC-P M) 11

4 Signals to/from the door controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1 Sematic Drive System© (DC-P M) COMPATIBLE connections 12

4.2 Sematic Drive System© set-up and incoming/outgoing signals from the door controller 13

4.3 Detector/Photocell/Barriers: Signal-Only Connection to the Door Controller (Direct Connection) 15

4.4 Detector/Photocell/Barriers: Complete Connection to the Door Controller 15

4.5 Magnetic Switches 17

5 Instruction without handset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.1 Automatic Mode “AUTO” 18

5.2 Manual Mode “MAN” 18

5.3 Programming Mode “PROG” 19

6 Functions available . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1 Reversing system force setting 21

6.2 Reversing System choice: INTERNAL or EXTERNAL 21

6.3 Limited Door Reversal 21

6.4 Main Lift Controller Test 21

6.4.1 No MLC Signal 21

6.4.2 Main Lift Controller Input Alarm 21

6.5 Car Door Locking Device (USA = Restrictor) 21

6.6 Full or framed Glazed Paneled Doors 21

6.7 Aux Output Relay 22

6.7.1 Space Percentage 22

6.7.2 Gong hile Opening 22

6.8 Forced Closing (Nudging) 22

6.9 Protective Device Logic Kn 22

6.10 Emulation Type 22

6.11 Alarms 23

7 Instruction with handset . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.1 Handset (optional) 24

7.2 User Handset menus and submenus 25

7.3 Reversing System Force setting by means of the handset 26

7.4 Speed Profile and High Speed adjustments by means of the Handset 26

7.4.1 Option “Fast settings” 26

7.5 Option “Advanced Settings” 27

7.5.1 Option “Opening Parameters” 27

7.5.2 Option “Closing Parameters” 28

7.5.3 Option “Change Password” 28

7.5.4 Option “Reset speed” 28

7.5.5 Option “Input levels logic” 28

7.5.6 Option “Opening slow down delay to opening rest current” (Only for digidoor emulation) 29

7.5.7 Option “Closing limit delay to closing rest current” (Only for digidoor emulation) 29

7.6 Option “Reserved Area” 29

8 General option . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0

8.1 Reversing System Setting by means of the Handset 30

8.2 Activation of the Main Lift Controller Test by means of the Handset 30

8.3 Activation of the Main Lift Failure by means of the Handset 30

8.4 Main Lift Controller Alarm - (MLC Input Alarm) 31

8.5 Limited door reversal Activation by means of the handset 31

8.6 Activation of the Car Door Locking Device setting by means of the Handset 31

8.7 Activation of the Glazed Paneled doors setting by means of the Handset 31

8.8 AUX Output Relay setting by means of the Handset 32

8.9 Protective Device Logic Kn setting by means of the Handset 32

8.10 Emulation Type 32

4

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

ENGLISH

www.sematic.com

Changes can be made without notice

9 Maintenance Menu - diagnostics and alarm management . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Consulting the Maintenance Menu with the Handset 33

10 Controller software upgrade . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

11 Upgrade from controllers previous to F28/F29 controller (Controller type: ASC 10/20, ADC10/11, SEM10/11, LMDC 10/11) F28/29 B . . . . 6

12 Upgrade from F28/F29 and LMDC 2010/2011/DIGIDOOR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

1 Upgrade from F28/F29 controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

14 Upgrade from F28/F29 controller rel. 2.0 Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

15 Upgrade from LMDC 2010/11 controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

16 Upgrade from Digidoor Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

17 Door operator maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

18 Spare parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

ENGLISH

www.sematic.com

Changes can be made without notice

5

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

Confidentiality agreement Disclaimer

The software/hardware “Sematic Drive System©” and all the relevant information, ideas, concepts and know-how

are confidential and the exclusive property of Sematic.

All information relevant to this instruction manual and any other support supplied by Sematic must be kept

confidential and proprietary to Sematic and shall not to be copied or reproduced in any form whatsoever.

Any information contained in the “Sematic Drive System©” shall not be disclosed to anyone, without Sematic's

written consent apart from authorized representatives employed by the user which commits itself to the

confidentiality clause.

The Company that makes use of the Sematic Drive System©, binds itself not to use confidential informations

owned by Sematic and not to compile or reingineer the Sematic Drive System© and any information in it

contained.

© Sematic Spa. All rights reserved.

Sematic regards all the information contained in this instruction manual to be correct at the time of printing. This information does not constitute any obligation to Sematic

and can be modified without prior notification. Sematic cannot be held responsible for any possible damages or claims caused to items or persons due to errors or

misunderstandings within the contents of this instruction manual.

Please dispose of the

controller correctly.

Bitte entsorgen Sie das

Türsteuergerät auf korrekte Weise.

Si prega di differenziare

correttamente il controller.

Prière de distinguer

correctement le controller.

Rogamos diferenciar la controla

corectamente.

cod. 1020211-263

ENGLISH

www.sematic.com

Changes can be made without notice

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

-

Sematic Group:

we care about your integrated solution!

OMPONENT SYSTEMS

• Automatic lift doors

• Frame and frameless glass doors

• Enhanced car door operator solutions

• Complete cabins

• Car Frames

• Custom integrated packages

• Special lift doors, cabins and car frames

ELEVATOR SYSTEMS & SUBSYSTEMS

• Rope traction elevators

• Machineroomless roped elevators

• Modular hydraulic elevators

• Hydraulic elevators

• Panoramic elevators

• Hospital elevators

• Special executions

ENGLISH

www.sematic.com

Changes can be made without notice

Preface

7

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

1 PREFA E

This manual has been drafted taking into account that the Company installing genuine Sematic products will

comply with the following necessary requirements:

• personnel responsible for the installation and/or maintenance of the doors must be familiar with the General

and Specific regulations in force on the subjects of work safety and hygiene (89/391/CEE - 89/ 54/CEE - 89/

5 /CEE);

• personnel responsible for the installation and/or maintenance must be familiar with the Sematic product and

must have been trained by Sematic or by an authorized Sematic agent;

• installation equipment used must be in good working order with all measuring instruments calibrated (89/ 55/

CEE).

Sematic:

• undertakes to update the present manual and send the customer copies of all new updates together with

material;

• within its continuous product improvement policy, reserves the right to make changes to the designs and

materials of its products. Sematic will give an agreed reasonable time to all its customers to allow them to

adapt to the new changes their complementary current constructions;

• guarantees a good performance only of the original parts sold directly and correctly installed.

Therefore:

parts manufactured and/or added to the Sematic product without having it checked by Sematic, or non-original

parts based upon a Sematic design (even if supplied by authorised agents) cannot be considered under guarantee

since the following conditions have not been ensured:

1. Quality control of raw material supply

2. Process control

3. Product control

4. Conformity tests according to Sematic specifications

Furthermore, Sematic

• guarantees the performance life of its products only if correctly stored (indoors storage at temperatures

ranging between -10 and + 0 °C out of direct sunlight) and correctly installed;

• guarantees the perfect performance of the products installed in environments with temperatures between -10

and + 0 °C and with a non-condensing, relative humidity level inbetween 20% and 80%. (Special note: for

temperatures and humidity rates outside these ranges, please consult our Technical Dept.)

The present document has been drafted in accordance with the following EU Directives:

• 98/37/CE Machinery Directive and subsequent modifications (when applicable)

• 95/1 /CEE Lifts Directive

• 2014/33/EU Lifts Directive

• 93/ 8/CEE Markings

• 90/2 9/CEE Heavy loads handling

• Noise (Acoustic emission) 8 /188/CEE modified according to Directive 98/24/CEE

• Electromagnetic compatibility 89/33 /CEE

and with the following particular standards:

• EN81-1/2;

• EN81-20/50;

• AS17535;

• EN12015/EN1201 ;

• EN13015

Taking into account, during all project planning, the Risk Assessments relating to:

a. RISKS OF ME HANI AL HAZARDS

• Squeezing during operations

• Squeezing after Trapping caused by friction (glass panels)

• Cuts caused by sharp edges, or static sharp pieces

8

ENGLISH

www.sematic.com

Changes can be made without notice

Preface

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

b. RISKS OF ELE TRI AL HAZARDS

• Persons in contact with energized parts (direct contact)

• Persons in contact with parts that become energized due to a fault (indirect contact)

c. RISKS OF OVERHEATING

d. RISKS GENERATED BY NOISE

e. RISKS GENERATED BY VIBRATION

f. RISKS GENERATED BY MATERIALS AND SUBSTAN ES

ENGLISH

www.sematic.com

Changes can be made without notice

What is the Sematic DC-PWM Drive System© Compatible?

9

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

2 WHAT IS THE SEMATI D -PWM DRIVE SYSTEM© OMPATIBLE?

The System consists of:

• a Car Door Operator (1)

• a microprocessor-based Door Controller (2)

• DC Motor (3)

• Megnetic Switches with activation magnets (4)

The Sematic Drive System© automatically controls the opening and closing of the lift doors, monitoring the

timing, current variations, speeds (high, low, acceleration and deceleration curves), various safety systems

(reversing system, Limited Door Reversal etc.) and faults (high voltage, signal failure, ...).

There are two independent speed curve profiles for the opening and closing cycles (5) which can be modified by

means of the door controller push buttons or by means of the Sematic handset (an optional 8 digit keypad and

display accessory which can be connected to the card by an RJ45 plug).

The handset ( ) is a key pad that allows viewing and modification of the function parameters stored in the

controller.

It is important to use the Sematic handset for installation or maintenance, as it enables viewing and/or variation

of the controller parameters, systems, and operation errors.

Furthermore, it is possible to use the Sematic handset directly from the inside of the car (7).

Making it possible to monitor and modify the door operating parameters from a completely safe position, and also

to control the movement of the coupled car and landing doors during their effective operating cycle.

Note: the pictures on this document are examples only; real components appearances may differ according to

supplied configuration of door operator and motor.

10

ENGLISH

www.sematic.com

Changes can be made without notice

What is the Sematic DC-PWM Drive System© Compatible?

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

2.1 SPEED PROFILE

Opening cycle

losing cycle

Key

O1 Opening acceleration

O2 Opening hight speed

O3 Opening deceleration

C1 Closing acceleration

C2 Closing hight speed

C3 Closing deceleration

Ka Door opening

Kc Door closing

La Open Limit

Lc Close limit

Closing cycle

Active reversing system

Opening cycle

ENGLISH

www.sematic.com

Changes can be made without notice

General Features

11

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

3 GENERAL FEATURES

3.1 TE HNI AL INFORMATION

3.2 SEMATI DRIVE SYSTEM© DOOR ONTROLLER (D -PWM)

1. Power ON button

2. Power OFF button

3. Display

4. Manual mode buttons

5. RJ45 Connection port (Handset)

. poles motor and auxiliary EOD battery power supply connector (cod. E0 AARX-05)

7. RJ45 Connection port (Motor optical Encoder)

8. 4 poles detector / photocells connector (cod. E0 AARX-0 )

9. poles Main Lift Controller signals connector (cod. E0 AARX-03)

10. poles Main Lift Controller signals connector (cod. E0 AARX-04)

11. 10 poles Main Lift Controller signals connector (cod. E0 AARX-07)

MAIN SUPPLY VOLTAGE 90-290 Vac (115 V-20%, 230V+2 %), 50- 0 Hz

TYPICAL POWER CONSUMPTION 200 VA

PEAK POWER CONSUMPTION 300 VA

MOTOR OVERLOAD PROTECTION @In <15 minutes

@2In <3 minutes

OPERATIONAL TEMPERATURE

RANGE

from -10°C to + 0°C

HUMIDITY non-condensing between 20% and 80%

PROTECTION rapid cartridge fuse [5x20, 4 A]

battery fuse [5x20, 8 A]

PERFORMANCE SPEED separately adjustable for opening and closing

REVERSAL SENSITIVITY Variable, only operational on door closing cycle

12

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

4 SIGNALS TO/FROM THE DOOR ONTROLLER

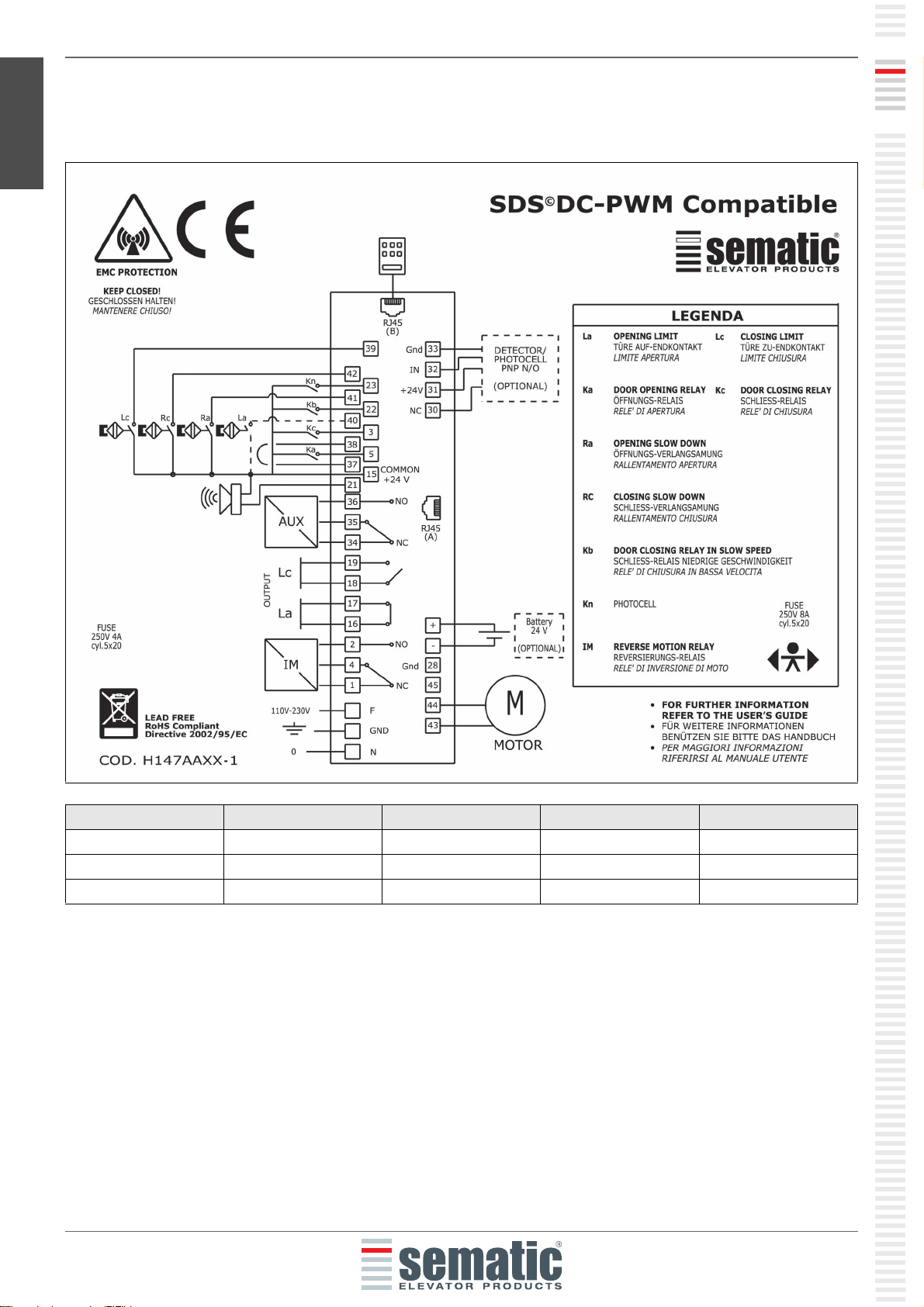

4.1 SEMATI DRIVE SYSTEM© (D -PWM) OMPATIBLE ONNE TIONS

DOOR POSITION L SWIT H STATE R SWIT H STATE RA SWIT H STATE LA SWIT H STATE

Door closed OPEN CLOSED OPEN CLOSED

Door mid travel CLOSED OPEN OPEN CLOSED

Door open CLOSED OPEN CLOSED OPEN

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

13

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

4.2 SEMATI DRIVE SYSTEM© SET-UP AND IN OMING/OUTGOING SIGNALS FROM THE DOOR

ONTROLLER

1 Magnetic switches

2 Safety chains

3 Main Lift Controller

4 Photocells or Detector

14

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

-

Note: Sematic Drive System© controller may be used also with incoming signal from the Main Lift Controller with

voltage range between and 24 Vdc.

To use this feature:

• Remove the shunt between 37-38 connector pins

• Connect the 38 connector pin at the 0V DC external incoming signal Power supply

IN OMING SIGNALS FROM THE DOOR ONTROLLER

Signal Connector Pins Contact type & normal state Note

Opening control Ka

(coming from the Main Lift

Controller)

Connector pins

5-15

These connections require dry

(voltage free) contacts (contact

open when inactive)

When the Door Controller is

installed on a Front & Rear

entrance car, it is important that

the opening and closing

commands have no common

contacts between the two doors.

Shielded, Grounded Wire Highly

Recommended

Closing control Kc

(coming from the Main Lift

Controller)

Connector pins

3-15

These connections require dry

(voltage free) contacts (contact

open when inactive)

Forced closing control at low

speed Kb

Connector pins

15-22

These connections require dry

(voltage free) contacts (contact

open when inactive)

The main lift controller may signal

the forced closing when the

photocell (or similar device) shall

be made inoperative due to a

failure, or after several door

closing failures.

Re-opening control Kn Connector pins

15-23

These connections require dry

(voltage free) contacts (both

logics available)

See 4.1 & 4.2 for the connection

to the door controller

Closing limit switch contact Lc Connector pins

15-39

These connections require dry

(voltage free) contacts (contact

open when door is closed)

From the operator closing limit

magnetic switch

Closing slow down contact La Connector pins

15-42

These connections require dry

(voltage free) contacts (contact

open when door is open)

From the operator closing limit

magnetic switch

Opening limit switch contact Rc Connector pins

15-40

These connections require dry

(voltage free) contacts (contact

open when inactive)

From the operator opening limit

magnetic switch (Nnot used for

DIGIDOOR compatibility).

Opening slow down contact Ra Connector pins

15-41

These connections require dry

(voltage free) contacts (contact

open when inactive)

From the operator opening slow

down magnetic switch

Handset (Optional) Connector RJ45 (B)

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

15

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

-

• For the Door Operator mechanical installation refer to the “Installation and maintenance of Sematic doors”

manual.

• Warning: to avoid possible induced currents within field wiring, it is recommended to shield the Ka and Kc

signals (connector pins 3, 5 and 15) with grounded, shielded cables.

• Changes made to the factory wiring length or position can damage the EMC system characteristics and is not

recommended.

4.3 DETE TOR/PHOTO ELL/BARRIERS: SIGNAL-ONLY ONNE TION TO THE DOOR ONTROLLER

(DIRE T ONNE TION)

This connection requires a dry (voltage free) external relay contact connected to the Door Controller Connector

pins 15 & 23.

If desired, it is possible to connect the single output signal from a photocell (or similar device) formed by a voltage

free contact, so that the door controller will directly receive the command to re-open.

The photocell (or similar device) has therefore an independent power supply and sends only its outgoing signal to

the Sematic Drive System© controller.

Reopening is operated according to the REVERSING SYSTEM, LIMITED DOOR REVERSAL EFFECT and PROTECTIVE

DEVICE LOGIC settings (see sections § .2 (pg. 21), § .3 (pg. 21) and § .9 (pg. 22)).

4.4 DETE TOR/PHOTO ELL/BARRIERS: OMPLETE ONNE TION TO THE DOOR ONTROLLER

Complete Connection means that the device draws its power supply from and sends the re-open signal directly

and only to the Sematic Drive System© controller.

It is possible to have the complete connection of detectors or photocells with a 24 Vdc max 100 mA supply and a

PNP N/O or N/C output, through the connector pins:

OUTGOING SIGNALS FROM THE DOOR ONTROLLER

Signal Connector Pins Contact type & Normal state Notes

Opening limit switch contact La Connector pins

1 -17

These connections provide dry

(voltage free) contact.

The contact is open when the door

is fully open.

Contact rating: 3A 250Vac 30Vdc

Closing limit switch contact Lc Connector pins

18-19

These connections provide dry

(voltage free) contact.

The contact is open when the door

is fully closed.

Contact rating: 3A 250Vac 30Vdc

Reversing system signal IM Connector pins

1-4

These connections provide dry

(voltage free) contact.

(contact normally closed)

This signal is generated by dry

(voltage free) Form C contacts

(relay within the Door Controller)

and is activated only when either

a mechanical obstacle (excessive

force) prevents the doors from

closing, or a signal is received

from an external safety device

that is connected to the door

controller.

It is used to signal the main lift

controller to interrupt the door

close command and give a door

open signal. Contact rating: 3A

250Vac 30Vdc

Connector pins

2-4

(contact normally open)

Auxliary autput signal AUX Connector pins

34-35

These connections provide dry

(voltage free) contact.

(contact normally open

These contacts can be used to

signal that a particular (pre-set)

door opening distance has been

achieved, or as a Gong or Buzzer

while the door is opening or as a

Thermic alarm signal.

Contact rating: 3A 250Vac 30Vdc.

Connector pins

35-3

(contact normally closed)

Motor Connector pins

43-44-45

Factory-prewired connector

Acoustic alarm (BUZZER)

Optional

Connector pins

15-21

These connections provide a

24Vdc, 100ma contact. Contact is

open when not active.

1

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

Connector pin 30 can be used as a pass-through (dummy) connector pin for connections between the detector

system components.

The operating reopening modes depend upon the setting of the REVERSING SYSTEM, LIMITED DOOR REVERSAL

EFFECT and PROTECTIVE DEVICE LOGIC settings (see sections § .2 (pg. 21), § .3 (pg. 21) and § .9 (pg. 22))

1 Example of photocells/barriers with transmitter and receiver connected between themselves through the dummy

free connector pin 30

33 GND ground connector pin

32 IN PNP N/O or N/C signal from

detector/photocell/barrier

31 + 24 Vdc Vdc power supply to

detector/photocell/barrier

30 NC dummy free connector pin

(it can be used as a dummy connector for connection

between the detectors system components).

ENGLISH

www.sematic.com

Changes can be made without notice

Signals to/from the door controller

17

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

4.5 MAGNETI SWIT HES

Verify that the magnet (1) has the countersink for the self-threading screw on the side of the magnetic switch (2).

Open and close the door by means of the controller or manually and make sure that the magnetic switches work

correctly.

For K1-2-3R

For K1-2-3L and K2-4-6

These are the operations of the magnetic switches:

•losed door - the door close limit (pre-adjusted by the manufacturer) must operate when the carriage has

already stopped but the retractable skate is not closed;

•Open door - the door open limit (pre-adjusted by the manufacturer) must operate approx 5 mm before the

door is totally open; (note: not used for DIGIDOOR operator compatibility);

• The closing slow down limit causes the doors to slow down before they are totally closed;

• The opening slow down limit causes the doors to slow down before they are totally open.

Attention: the distance between the slowing limits can be adjusted according to specific needs.

Fig. 1 Looking from the landing the switches are marked this way.

18

ENGLISH

www.sematic.com

Changes can be made without notice

Instruction without handset

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

5 INSTRU TION WITHOUT HANDSET

Display in Automatic and Manual Mode

5.1 AUTOMATI MODE “AUTO”

• When the Door Controller is working in automatic mode the “AUTO” red led is on, whereas the other two red

leds are off.

• When the Door Controller is switched on, or after a self-resetting, it starts directly in the automatic mode.

• All the signals sent by the main lift controller and by the external devices (barriers, photocells, etc.) are active

in this mode.

• Keys 2 and 3 are not functional during automatic mode.

• When Key 4 is kept pressed for a while, the Door Controller (ca. 3 sec.), switches to the manual mode “MAN”.

5.2 MANUAL MODE “MAN”

• When the Door Controller is working in manual mode the “MAN” red led is on, whereas the other two red leds

are off.

• All signals coming from the main lift controller and from other external devices are ignored.

• The IM contact is deactivated, therefore the Door Controller does not recognize any signal coming from the

external devices to reverse door movement, such as photocells or barriers.

• Opening and Closing commands may be manually input by pushing Key 2 (open) or Key 3 (close).

• When key 4 is kept pressed for a while (Appx. 3 sec.), the Door Controller switches to the automatic mode

“AUTO”.

• If no keys are pressed for at least 10 minutes, the Door Controller will switch to the “automatic mode “AUTO”.

Both in automatic and manual mode the Door ontroller will show the following display:

Door opening (Flashing Display)

Door open

Door closing (Flashing Display)

Door closed

Forced closing

It signals an alarm and flashes giving the code of the

recognised alarm. See § 10 (pg. 35).

Reversing system on

ENGLISH

www.sematic.com

Changes can be made without notice

Instruction without handset

19

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

5.3 PROGRAMMING MODE “PROG”

• When the Door Controller is working in “programming mode” the “PROG” red led is on whereas the other two

red leds are off.

• Press contemporaneously Key 1 and Key 4 for few seconds to enter the programming mode. The display on

the Door Controller will show “P” and “00” flashing alternately.

• When the Door Controller is in the programming mode, all signals coming from the main lift controller and

from the external devices (barriers, photocells,…) are ignored.

• The parameter to be modified is selected by means of the increasing and decreasing KEYs, respectively the

buttons 2 and 3; this parameter is then confirmed by pushing the key 1, ENTER.

• After confirming the parameter to be modified, the display shows the relevant numeric value.

• Modify the chosen parameter using the key 2, increase, and 3, decrease, and confirm the changes by pressing

key 1 ENTER.

• At the end of the necessary configurations, using the key 4 press to select the required operating mode

(manual “MAN” or automatic “AUTO”).

20

ENGLISH

www.sematic.com

Changes can be made without notice

Instruction without handset

811-000-000 SDS© DC-PWM Compatible • Edition 25 March 201

-

The following table contains the available parameters, the relevant codes, the description and the

allowed modification range:

Param. codes Default Parameter Range Note

00 00 Reversing system choice 00, 01 00-> Internal

01-> External

01 00 Main Lift Controller Test 00, 01, 02 00-> When moving

01-> Moving + Parking

02-> Off

02 00 No MLC signal 00, 01, 02 00 -> Instant Stop

01 -> Low Speed to Stop

02-> Low speed Cycle

03 00 MLC Input Alarm 00, 01 00 -> Off

01 -> On

04 00 Limited Door Reversal Effects 00, 01 00 -> Off

01 -> On

05 00 Car door locking device 00, 01 00 -> Off

01 -> On

0 00 Glass doors 00, 01 00 -> Off

01 -> On

07 00 Aux Output Relay 00, 01, 02,

03

00 -> Off

01 -> Gong While opening

02 -> According to % of space

03 -> Termic Alarm signal

08 00 Space Percentage (Percentage of

the available space

to operate the AUX relay)

00...99 00..99% (00 = closing limit)

09 Reversing force setting 00...99 10-150 N (10-135 N U.S. version)

10 33 Opening High Speed 01...99

11 50 Opening Low Speed 01...99

12 50 Opening "comfort" 01...99

13 30 Closing High Speed 01...99

14 50 Closing Low Speed 01...99

15 80 Closing "comfort" 01...99

1 - Not Used -

17 - Not Used -

18 - Not Used -

21 00 Protective Device Logic Kn 00, 01 00 -> N/O, on obstruction closed

01 -> N/C, on obstruction open

22 01 Emulation Type 01, 02, 03,

04, 05, 0

01 ->Emulation F28

02 -> Emulation F29

03 -> Emulation Digidoor 1 Nm

04 -> Emulation Digidoor 2 Nm

05-> Emulation LM-DC 2010

0 -> Emulation LM-DC 2011

23 00 Ka, Kc, Kb inputs logic (see also §

7. (pg. 29))

00, 01 00 -> Ka, Kc, Kb inputs activated

by +24V (high level logic)

01 ->Ka, Kc, Kb inputs activated

by 0V (low level logic)

Table of contents

Popular DC Drive manuals by other brands

Becker

Becker R8/17PS operating instructions

Dover

Dover DESTACO CAMCO 900P General service manual

ABB

ABB ACS580-01 drives installation guide

Anaheim Automation

Anaheim Automation DPN10601 user guide

Applied Motion Products

Applied Motion Products PDO 2035 user manual

Lenze

Lenze L-force 8400 Series Mounting instructions