SEMTOM ST-2620 User manual

BILL COUNTER

OPERATION MANUAL

BILL COUNTER

OPERATION MANUAL

Content

2.Self- check and fault diagnoses

1. Specification

3. Error codes and solutions

4.The instruction of the main parts

5.The introduction of the display and keys

6. The introduction of the parameter setting

7. Restore to the factory setting

8. Feeding clearance adjustment

9. Precaution for handling the machine

11. Maintenance

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

..................................................................................................................................................................

10.Cautions

..................................................................................................................................................................

introduction

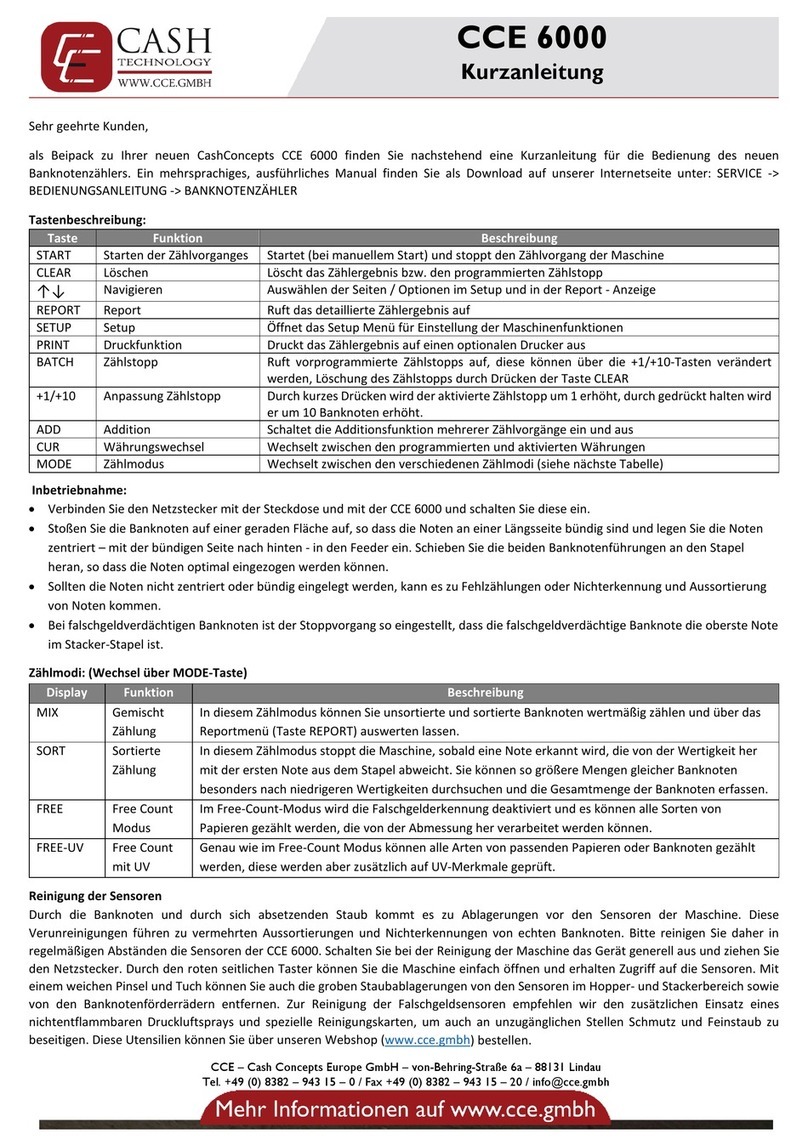

1. Specification

Rated voltage

/Frequency AC220V±10% 50Hz±5%

Power

consumption 110W(Max)

Counting range 4 digit

Counting speed ≥1000 pcs/min

Feeding system Roller Friction Type

Batch range 1-999pcs

Banknote size MIN:50×110mm MAX:90×180mm

Banknote thickness 0.075~0.15mm

Hopper capacity 150PCS

Stacker capacity 150PCS

Net weight 5.3KG

Dimension 260mm×308mm×178mm

2.Self- check and fault diagnoses

When turn on the machine, it will start self-check by itself. This function can check whether all the sensors and

relative circuit are in good working condition or not. When detecting a fault, the fault code will be showed in the

counting display:

Fault Code Reasons Solutions

L_Length Sensor Fault/

R_Length Sensor Fault Problem with the counting sensor Clean or replace the counting sensor

Problem with the relative circuit of the

counting sensor in the main board

Replace the main board or replace the

left/right length receiving board

Reset Sensor Fault Problem with the reset sensor Replace the reset sensor

Problem with the relative circuit of reset

sensor in the main board Replace the main board

Speed Sensor Fault Driving belt damaged or broken Replace the driving belt

Problem with the speed sensor or the

connector is not in the good connection

Replace the speed sensor or make the

connector in good connection

Problem with the main motor or the

connector is not in the good connection

Replace the main motor or make the

connector in good connection

The main board is damaged Replace the main board

L_Length Sensor Fault/

R_Length Sensor Fault

Reset Sensor Fault

Speed Sensor Fault

AC220V±10% 50Hz±5%

Start Sensor Fault There is something covered with the start

sensor Clean the start sensor

UV Sensor Fault Problem with the UV sensor Replace the UV sensor

L_IR Sensor Fault

R_IR Sensor Fault

Problem with the length sensor Replace the left/right length receiving

board

Problem with the relative circuit of the

length sensor in the main board

3. Error codes and solutions

The display may shows some error messages when counting, which means there are some problems with the

notes. Refer to the following diagram to find way to solve it.

Error Code Reasons Solutions

UV Suspicious note detected by UV detection Remove the suspicious note from the stacker;

press “RESET”to continue;

UV sensitivity level is too high Decrease the UV sensitivity level

MG Suspicious note detected by MG detection Remove the suspicious note from the stacker;

press “RESET”to continue;

MG sensitivity level is too high Decrease the MG sensitivity level

DBL Double note detected by the IR detection Remove the suspicious note from the stacker;

press “RESET”to continue;

IR sensitivity level is too high Decrease the IR sensitivity level

DD Different size(width) note detected by the DD

detection

Remove the suspicious note from the stacker;

press “RESET”to continue;

HALF Half note Remove the suspicious note from the stacker;

press “RESET”to continue;

CHAIN Chain note Remove the suspicious note from the stacker;

press “RESET”to continue;

SLANT Slant note Remove the suspicious note from the stacker;

press “RESET”to continue;

LEN Different size(length) note Remove the suspicious note from the stacker;

press “RESET”to continue;

DD sensitivity level is too high Decrease the DD sensitivity level

UV

MG

DBL

DD

L_Length Sensor Fault/

R_Length Sensor Fault

4.The instruction of the main parts

1.counting

guide 1.start sensor

2.handle 2.banknote

feeding wheel

3.main display

assembly

3.UV light

assembly

4.side display

4.banknote

transporting

wheel

5.banknote

receiving wheel

5.counting tube

frame assembly

6.transporting

platform 6.reset sensor

1.hopper fixing

screw

External display

(optional)

2.power socket

3.power switch

4.USB upgrade

port

5.external

display port

5.The introduction of the display and keys

5.1 The diagram of the main display and the keys

5.2 The introduction of the key function

introduction

Keys Function

Press this key to turn on/off the denomination clearance function(based on the first counting note).

Press this key to turn on/off the mix value counting.

Press this key to switch the AUTO/MUL counting mode.

Press this key to turn on/off the UV detection.

Press this key to turn on/off the UV detection.

1.Press this key to turn on/off the accumulation function.

2.In the sensitivity level setting, press this key to turn to the previous page.

1.In the BATCH mode, short press this key can increase the batch number one by one.

2.Long press this key, the batch number can be increased continuously, batch rang is 1-100.

1.In the BATCH mode, short press this key can decrease the batch number one by one.

2.Long press this key, the batch number can be decreased continuously, batch rang is 100-1.

1.Press this key can turn on the BATCH function, if press it again, the user can select among “100, 50, 20,

10, off”.

2.In the sensitivity level setting, press this key to go to the next page.

1.Press this key can clear all the fault message, then keeping counting.

2.In the sensitivity level setting, press this key to save and exit.

3.Long press this key for 3 seconds, after hearing the “beep”sound, then the machine is restored to the

factory setting.

5.3 The introduction of the side display panel and the key function

Key Function Side display

1.Press this key can clear all the fault message, then keeping

counting.

2.In the sensitivity level setting, press this key to save and exit.

3.Long press this key for 3 seconds, after hearing the

“beep”sound, then the machine is restored to the factory

setting.

Press this key to turn on/off the accumulation function.

Press this key to turn on/off the UV, MG detection.

1.Press this key can clear all the fault message, then keeping

counting.

2.In the sensitivity level setting, press this key to save and exit.

6. The introduction of the parameter setting

6.1 Sensitivity level setting

When the display shows some error codes during the counting, the user can adjust the according sensitivity level

to make the counting more smoothly.

In the normal state, this machine can enter into the sensitivity level setting by pressing the ”UV”and “MG”at the

same time, and press “ADD”or “BATCH”to check each page, then press “+”or “-”to adjust the sensitivity level, then

press the “RESET”to save and exit, the details showed as below:

6.1.1 Voice Switch(optional function):“0”is VOICE off, “1”is VOICE on;the default is “0”.

6.1.2 Fake Enable: fake note counted or not counted.“0”is fake note not counted, “1”is fake note counted; the

default is “0”.

6.1.3 Pcs Compare: showing the previous counting number and the current counting number at the same time.

“0”is off, “1”is on; the default is “1”.

6.1.4 External port Sel: external display port selection. “0”is computer communication, “1”is the 4 digit LED

side display + LCD external display; the default is “1”.

6.1.5 Slant: slant adjustment. “0”is no adjustment, “1”is medium adjustment, “2”is the senior adjustment;

the default is “1”.

6.1.6 Standby Time: the time of the LCD background automatically off, the default is 3 minutes.

6.1.7 Break Time: the time to stop counting. The range is 10-100ms; the default is 33ms.

6.1.8 Start Val: start sensor sensitivity value, ranging from 0 to 9(“0”is the lowest, “9”is the highest); the

default is “4”.

6.1.9 Reset Val: reset sensor sensitivity value, ranging from 0 to 9(“0”is the lowest, “9”is the highest); the

default is “4”.

6.1.10 Thcount Val: the threshold value of counting tube, ranging from 0-200; the default is 200.

6.1.11 Hole Time: the hole repairing time for the single counting tube.

6.1.12 Lcount Light: left counting tube emitting light value, ranging from 0-99; the default is “80”.

6.1.13 Rcount Light: right counting tube emitting light value, ranging from 0-99; the default is “80”.

6.1.14 UV Light: UV emitting light value, ranging from 0 to 99; the default is “60”.

6.1.15 Double Val: double note sensitivity value, ranging from 0 to 10 (“0”is off, “10”is the highest); the default

is “0”.

6.1.16 Chain Val: chain note sensitivity value, ranging from 0 to 5(“0”is off, “5”is the highest);the default is

“3”.

6.1.4 Ext Port Sel: external display port selection. “0”is computer communication, “1”is the 4 digit LED side

6.1.17 UV Val: UV detection sensitivity value, ranging from 0 to 10 (“0”is off, “10”is the highest); the default is

“4”.

6.1.18 MG INR val: MG detection sensitivity value for the INR, ranging from 0 to 30(“0”is off, “30”is the

highest); the default is “6”.

6.1.19 MG USD val: MG detection sensitivity value for the USD, ranging from 0 to 30(“0”is off, “30”is the

highest); the default is “6”.

6.1.20 Width Set: the note width sensitivity value, ranging from 30 to 90; the default is “63”.

6.1.21 Len500Max: the maximum of the Rs.500 length, ranging from 167 to 177; the default is “150”.

6.1.22 Len100Max: the maximum of the Rs.100 length, ranging from 157 to 167; the default is “162”.

6.1.23 Len50Max: the maximum of the Rs.50 length, ranging from 147 to 157; the default is “152”.

6.1.24 Len10Max: the maximum of the Rs.10 length, ranging from 137 to 147; the default is “142”.

6.1.25 Currency Sel: currency selection. “0”is for USD with UV/MG counting; “1”is for INR with mixed value

counting. The default is “1”.

7. Restore to the factory setting

Press “UV+MG+RESET”at the same time, meanwhile turning on the machine, after hearing “beep”sound, the

machine is restore to the factory setting.

8. Feeding clearance adjustment

8.1 The good feeding clearance condition: smooth feeding, accurate counting, good friction.

8.2 The bad feeding clearance condition: after a long time of usage, the roller and the rubber tape will be loose,

then it will result in inaccurate counting(generally the counting number will be less than the right notes number).

Adjustment operation: rotate the adjustment screw anticlockwise until the machine can count smoothly and

accurately. Do not rotate it too much, it will result in unsmooth counting or breaking the note.

6.1.18 MG INR val: MG detection sensitivity value for INR, ranging from 0 to 30(“0”is off, “30”is the

6.1.19 MG USD val: MG detection sensitivity value for USD, ranging from 0 to 30(“0”is off, “30”is the

length of Rs.500, ranging from 167 to 177; the default is “150”.

length of Rs.100, ranging from 157 to 167; the default is “162”.

length of Rs.50, ranging from 147 to 157; the default is “152”.

length of Rs.10, ranging from 137 to 147; the default is “142”.

9. Precaution for handling the machine

Damp and/or badly stained notes should be

avoided;

Check no other things(paper clip, rubber band,

pieces of paper etc.)mixed in the notes

Folded or curled notes should be straightened

before counting

As for the bundle of new notes, should bend

and flex before counting

The notes should be tidied up before counting,

or it will lead to the some problem when the

machine work

Damp and/or badly stained

note

Stack of notes mixed with

pieces of paper, clip or rubber

band

Curled note Folded note

10. Cautions

Please read all the instructions as below before using the machine, or it will lead to some danger and fault

——Avoid exposing the product to the sunlight.

——The product should have well earthing performance

——The product may affected by the wireless device interference(like phone, intercom etc.).

——Please use the qualified power cable.

——Turn off the machine or pull out the power plug before moving it.

——Do not put tools, hand, hair or cloth close to the rotating parts of the machine, in case of some danger

——Do not press the keys with something pointed.

——Keep the machine in the dry condition, this machine is not waterproof.

——Do not repair the machine by yourself, should ask qualified service person to repair and maintain it.

Warning:

Before cleaning the machine should pull out the power cable.

Don’t use the chemical cleaning agent to clean the machine.

11. Maintenance

The counting sensor and the feeding sensor are belong to the optical equipment. If there is some dust and dirty things

covering the sensor, it will lead to the fault when the machine is working. The user should clean the machine after

using.

For example, if there is some pieces of paper, dust or something else covering the reset sensor in the stacker, it

will result in fault when the machine is working. The user should clean the machine after using.

Table of contents