Senix CSPE6.5-M User manual

8458-4347007-001

Electric Pole Saw

Operator’s manual

Model: CSPE6.5-M

For customer support, please call 1-800-261-3981 or send email to:

SAVE THIS MANUAL FOR FUTURE REFERENCE.

2WWW.SENIXTOOLS.COM

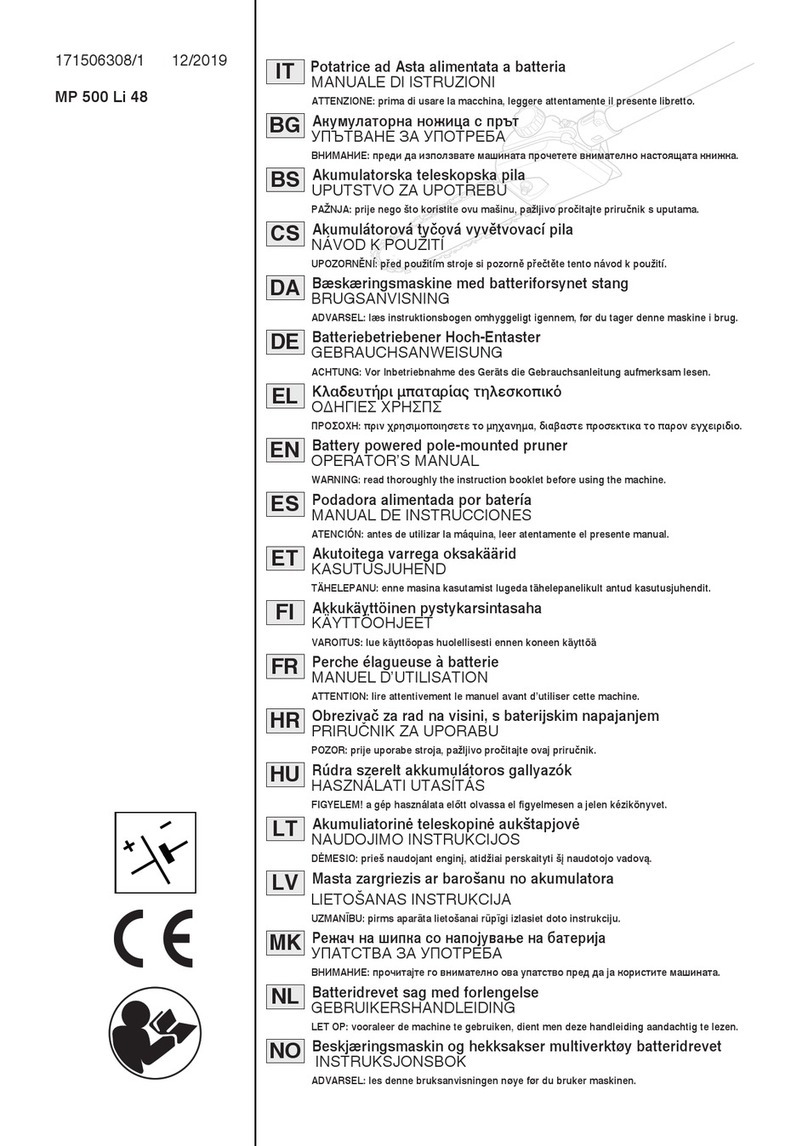

• SAFETY & INTERNATIONAL SYMBOLS •

This operator’s manual describes safety and international symbols and pictographs that may appear on this product.

Read the operator’s manual for complete safety, assembly, operating and maintenance and repair information.

To reduce the risk of injury, user must read

instruction manual.

Contact of the guide bar tip with any object

should be avoided.

Always use two hands when operating the

pole saw.

Hot surface. Do not touch a hot motor.

You may get burned. The motor get

extremely hot from operation. It remains hot

for a short time after the unit is turned off.

Thrown objects can ricochet and result in

personal injury or property damage.

Keep all bystanders at least 50 ft. away.

DANGER!

Risk of electrocution!

The chain must be continously coated with

oil to function correctly. Verify oil level before

each use.

Wear hand protection.

Wear non-slip safety footwear.

Failure to keep your hands away from the

blade will result in serious personal injury.

Avoid power lines, use in dry conditions.

Do not expose to rain.

Indicates danger, warning or caution.

Precautions that involve your safety.

Thrown objects and loud noise can cause

severe eye injury and hearing loss. Wear

eye protection meeting current ANSI Z87.1

standards and ear protection when operating

this unit. Wear head protection when

operating this unit. Fallen objects can cause

severe head injury. Use a full face shield

when needed.

3WWW.SENIXTOOLS.COM

TABLE OF CONTENTS

SAFETY..........................................................................................3

KNOW YOUR UNIT........................................................................7

SPECIFICATIONS*.........................................................................7

ASSEMBLY.....................................................................................8

OPERATION..................................................................................11

MAINTENANCE............................................................................14

TROUBLESHOOTING..................................................................17

PARTS...........................................................................................18

PARTS LIST..................................................................................19

WARRANTY...................................................................................20

1. Avoid Dangerous Environment – Don’t use

appliances in damp or wet locations.

2. Don’t Use In Rain.

3. Keep Children Away – All visitors should be kept at a

distance from work area.

4. Dress Properly – Do not wear loose clothing or

jewelry. They can be caught in moving parts.

Use of rubber gloves and substantial footwear

is recommended when working outdoors. Wear

protective hair covering to contain long hair.

5. Use Safety Glasses – Always use face or dust mask

if operation is dusty.

6. Use Right Appliance – Do not use appliance for any

job except that for which it is intended.

7. Ground Fault Circuit Interrupter (GFCI) protection

SAFETY

Some dust created by power sanding, sawing, grinding,

drilling and other construction activities contains

chemicals known to the state of California to cause

cancer, birth defects or other reproductive harm. Some

examples of these chemicals are: Lead from lead-

based paints, crystalline silica from bricks and cement

and other masonry products, and arsenic and chromium

from chemically treated lumber.

Your risk from these exposures varies, depending on

how often you do this type of work. To reduce your

exposure to these chemical: Work in a well ventilated

area and work with approved safety equipment,such

as dust masks that are specially designed to lter out

microscopic particles.

This product can expose you to chemicals including

lead, a chemical known to the State of California to

cause cancer and birth defects or other reproductive

harm. For more information go to

www.P65Warnings.ca.gov.

When using electric gardening appliances, basic safety

precautions should always be followed to reduce

the risk of re, electric shock, and personal injury,

including the following:

WARNING!

WARNING!

WARNING!

should be provided on the circuit(s) or outlet(s) to be

used for the gardening appliance. Receptacles are

available having built-in GFCI protection and may be

used for this measure of safety.

8. Warning – To reduce the risk of electric shock, use

only with an extension cord intended for outdoor

use, such as an extension cord of cord type SW-

A, SOW-A, STW-A, STOW-A, SJW-A, SJOW-A,

SJTW-A. or SJTOW-A.

9. Avoid Unintentional Starting – Don’t carry plugged-in

appliance with nger on switch. Be sure switch is off

when plugging in.

10. Don’t Abuse Cord – Never carry appliance by cord

or yank it to disconnect from receptacle. Keep cord

from heat, oil, and sharp edges

11. Don’t Force Appliance – It will do the job better and

with less likelihood of a risk of injury at the rate for

which it was designed.

12. Don’t overreach – Keep proper footing and balance

at all times.

13. Stay Alert – Watch what you are doing. Use

common sense. Do not operate appliance when you

are tired.

14. Disconnect Appliance – Disconnect the appliance

from the power supply when not in use, before

servicing, when changing accessories such as

blades, and the like.

15. Store Idle Appliances Indoors – When not in use,

appliances should be stored indoors in dry, and high

or locked-up place – out of reach of children.

16. Maintain Appliance With Care – Keep cutting edge

sharp and clean for best performance and to reduce

the risk of injury. Follow instructions for lubricating

and changing accessories. Inspect appliance cord

periodically, and if damaged, have it repaired by an

authorized service facility. Inspect extension cords

periodically and replace if damaged. Keep handles

dry, clean, and free from oil and grease.

17. Check Damaged Parts – Before further use of the

appliance, a guard or other part that is damaged

should be carefully checked to determine that it will

operate properly and perform its intended function.

Check for alignment of moving parts, binding of

moving parts, breakage of parts, mounting, and any

other condition that may affect its operation. A guard

or other part that is damaged should be properly

repaired or replaced by an authorized service center

unless indicated elsewhere in this manual.

Read All Instructions

4WWW.SENIXTOOLS.COM

• Always disconnect the appliance from the power

supply before assembling, adjusting or cleaning, and

before leaving the machine unattended for any period.

SAVE THESE INSTRUCTIONS

ELECTRICAL SAFETY

SPECIFIC SAFETY RULES FOR POLE

PRUNERS

EXTENSION CORDS

1. Wear head, and eye protection and personal

protective equipment (PPE), including correct

clothing.

2. Keep bystanders, especially children at a safe

distance during operation of the saw chain pole

pruner.

3. Keep all parts of the body away from the saw chain.

Do not remove cut material or hold material to be cut

when blades are moving. Make sure the switch is off

when clearing jammed material. Saw chain continues

to move after the switch is turned off. A moment of

inattention while operating the extended-reach pruner

may result in serious personal injury.

4. Carry the extended-reach pruner by the handle with

the saw chain stopped. When transporting or storing

the extended-reach pruner, always t the saw chain

device cover. Proper handling of the extended-reach

pruner will reduce possible personal injury from the

saw chain.

5. Hold the extended-reach pruner by insulated gripping

surfaces only, because the saw chain may contact

hidden wiring. A saw chain contacting a ″live″wire

may make exposed metal parts of the extended-

reach pruner ″live″ and could give the operator an

electric shock.

6. Keep cable away from cutting area. During operation

the cable may be hidden in shrubs and can be

accidentally cut by the saw chain.

7. Do not use the extended-reach pruner in bad

weather conditions, especially when there is a risk of

lightning. This decreases the risk of being struck by

lightning.

8. To reduce the risk of electrocution, never use near

any electrical power lines. Contact with or use near

power lines may cause serious injury or electric

shock resulting in death.

9. Always use two hands when operating the extended-

reach pruner. Hold the extended-reach pruner with

both hands to avoid loss of control.

10. Always use head protection when operating the

extended-reach pruner overhead. Falling debris can

result in serious personal injury.

1. Double insulated tools are equipped with a polarized

plug (one blade is wider than the other and will

require the use of a polarized extension cord. The

Pole Saw’s plug will t into a polarized extension

cord only one way. If the plug does not t fully into

the extension cord, reverse the plug. If the plug still

does not t, obtain a correct polarized extension

cord. A polarized extension cord will require the use

of a polarized wall outlet. This plug will t into the

polarized wall outlet only one way. If the plug does

not t fully into the wall outlet, reverse the plug. If the

plug still does not t, contact a qualied electrician

to install the proper outlet. Do not change or alter

the equipment plug, extension cord receptacle, or

extension cord plug in any way.

2. Double insulation eliminates the need for the three-

wire grounded power cord and grounded power

supply system. Applicable only to Class II (double-

insulated) tools. This Pole Saw is a double insulated

tool.

• Checking the completeness, assembly and setting

of the tool (see details below) before start to work.

Repeat the checking regularly during your work.

• Always use the harness to carry the tool weight on

the shoulder. If you use the harness cross your body,

please learn how to use the quick release clamper on

the harness and keep it in front of your body.

• It is recommended that the unexperienced user

should have practical instruction in the use of the

pole saw and the protective equipment from an

experienced operator. The initial practice should be

cutting logs on a saw horse or cradle.

• This tool is not intended for use by persons (including

children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge,

unless they have been given supervision or

instruction concerning use of the appliance by a

person responsible for their safety. Children should

be supervised to ensure that they do not play with the

appliance.

• Children and juveniles, with the exception of

apprentices older than 16 years and under

supervision, may not operate the product. The same

applies for persons who do not or do not sufciently

know how to handle the product.

• The operating instructions should always be ready to

hand. Persons unt or tired must not operate the tool.

• Wait until the chain has come to a standstill completely

before placing it down.

• Any servicing should be performed by an authorized

service representative.

Do not permit ngers to touch the terminals of plug

when installing or removing the extension cord from the

plug.

Use a proper extension cord. ONLY use cords

listed by underwriters Laboratories (UL). Other

extension cords can cause a drop in line voltage,

WARNING!

Do not operate near electrical power lines. The unit has

not been designed to provide protection from electric

shock in the event of contact with overhead electric

lines, Consult local regulations for safe distances from

overhead electric power lines and ensure that the

operating position is safe and secure before operating

the saw chain pole pruner.

WARNING!

ADDITIONAL SAFETY WARNINGS FOR

OPERATION

5WWW.SENIXTOOLS.COM

• Damage to lungs if an effective dust mask is not worn.

• Damage to hearing if effective hearing protection is

not worn.

• Health defects resulting from vibration emission if the

unit is being used over long periods of time or not

adequately managed and properly maintained.

RESIDUAL RISKS

CAUTION:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

resulting in a loss of power and overheating of tool.

For this tool an AWG (American Wire Gauge) size of

a least 14-gauge is recommended for an extension

cord of 25-ft. or less in length. Use 12-gauge for an

extension cord of 50-ft. Extension cords 100-ft. or

longer are not recommended. Remember, a smaller

wire gauge size has greater capacity than a larger

number (14-gauge wire has more capacity than

16-gauge wire; 12-gauge wire has more capacity than

14-gauge). When in doubt use the smaller number.

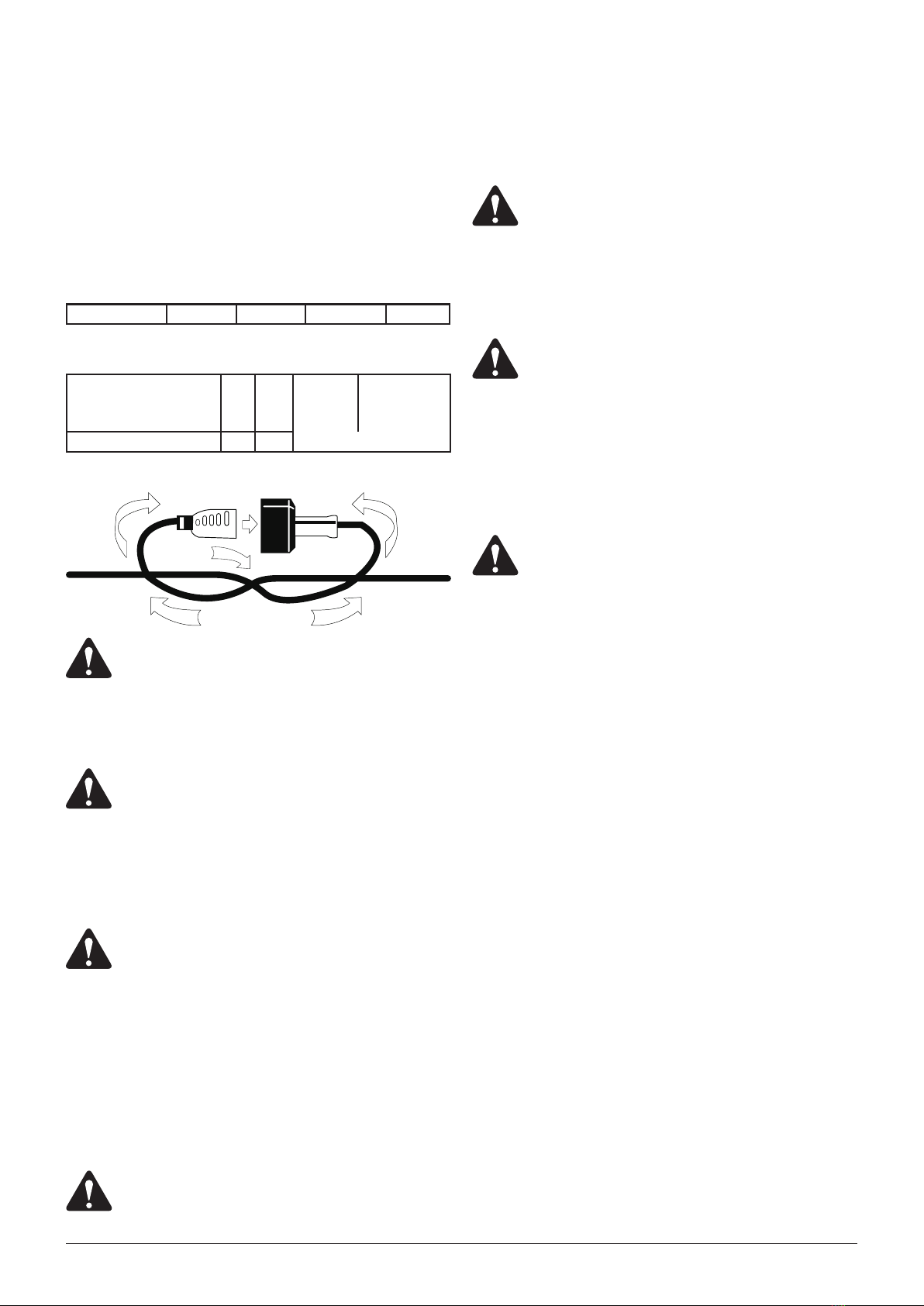

Minimum gauge for extension cords

Ampere Rating

Volts Total length of cord in feet

More than/Not more than AWG

120 V 25 50 100 150

0-6

6-10

10-12

18

18

16

16

16

16

16

14

14

14

12

12

12-16 14 12 Not recommended

Securing extension cord

Keep the extension cord clear of the work area. Position

the cord so that it will not get caught on bushes,

hedges, tree trunks, lawnmowers or other obstructions

while you are working with the pole saw.

Check extension cords before each use. If damaged

replace immediately. Never use tool with a damaged

cord since touching the damaged area could cause

electrical shock, resulting in serious injury.

Even when the unit is used as prescribed it is not

possible to eliminate all residual risk factors. The

following hazards may arise in connection with the unit’s

construction and design:

This unit produces an electromagnetic eld during

Inspect unit before each use. Replace damaged parts.

Make sure all fasteners are in place and secure.

Replace parts that are cracked, chipped, or damaged in

any way. Make sure the cutting attachment is properly

installed and securely fastened.

Do not operate the unit inside a closed environment,

such as a room or building.

operation. This eld may, under some circumstances,

interfere with active or passive medical implants. To

reduce the risk of serious or fatal injury, we recommend

persons with medical implants to consult their physician

and the medical implant manufacturer before operating

this unit.

Kickback can occur when the tip of the guide bar

touches an object or when the wood closes in and

pinches the saw chain inside of the cut. Tip contact can

kick the guide bar up and back towards the operator.

Pinching the saw chain along the top of the guide bar

can push the bar rapidly towards the operator. Either of

these reactions may cause a loss in control of the saw,

increasing the chances of serious personal injury. Do

not rely on the safety devices built into the saw.

Kickback is the result of tool misuse and/or incorrect

operating procedures. These conditions can be

minimized with the following steps:

REDUCING KICKBACK

WARNING:

The danger of a kickback is greatest when attempting

to cut near or with the guide bar tip. Always apply the

saw as atly as possible in order avoid a loss of control

during operation.

1. Maintain a rm grip, with thumbs and ngers

encircling the pole saw handles. Both hands should

be on the saw with your body and arms in a position

to resist kickback forces.

2. Do not overreach and keep the work area free from

obstructions.

3. Only use replacement bars and chains specied by

Senix. Replace dull blades as necessary.

4. Do not let the tip of the guide bar contact any

surfaces.

5. Keep proper tension on the blade at all times. Check

the tension at regular intervals.

6. Cuts should only take place while the chain is moving

at full speed. Do not turn the saw ON or OFF in

the middle of a cut. Use extreme caution when re-

entering a previous cut.

7. Cut one branch at a time. Do not attempt plunge or

bore cuts. Watch for shifting logs or other external

forces that could close a cut and pinch the chain.

8. Make a precut on the opposite side of the log to

avoid the blade from being pinched during operation

as another safeguard against kickback.

6WWW.SENIXTOOLS.COM

SAWING TECHNIQUES

• Saw off the lower branches on the tree rst. By doing

so, it is easier for the cut branches to fall to the

ground.

• At the end of the cut, the weight of the saw suddenly

increases for the user since it is no longer being

supported by a branch. There is a risk of losing

control of the saw, so make sure to stay alert during

the entire sawing operation.

• Only pull the saw out of a cut while the saw is

running. By doing so, you prevent the chain from

jamming in the wood.

• Do not saw with the tip of the guide bar. Do not saw

into the branch formations (where the tree branches

outwards). This will impede the tree’s ability to heal.

• For sawing off smaller branches, place the stop face

of the saw on the branch. This prevents unwanted

movements of the saw at the beginning of the cut.

While applying light pressure, guide the saw through

the branch from top to bottom.

• For sawing off larger branches, rst make a relief

cut. Saw through 1/3 of the branch diameter from the

bottom to top using the top side of the guide bar. Then

saw from top to bottom for the other 2/3 using the

bottom side of the guide bar.

• Saw off longer branches in sections in order to

maintain control over the location of impact.

• When working on an incline, always stand above or

to the side of the branch being sawed. Hold the tool

as close as possible to your body. By doing so, you

maximize your balance.

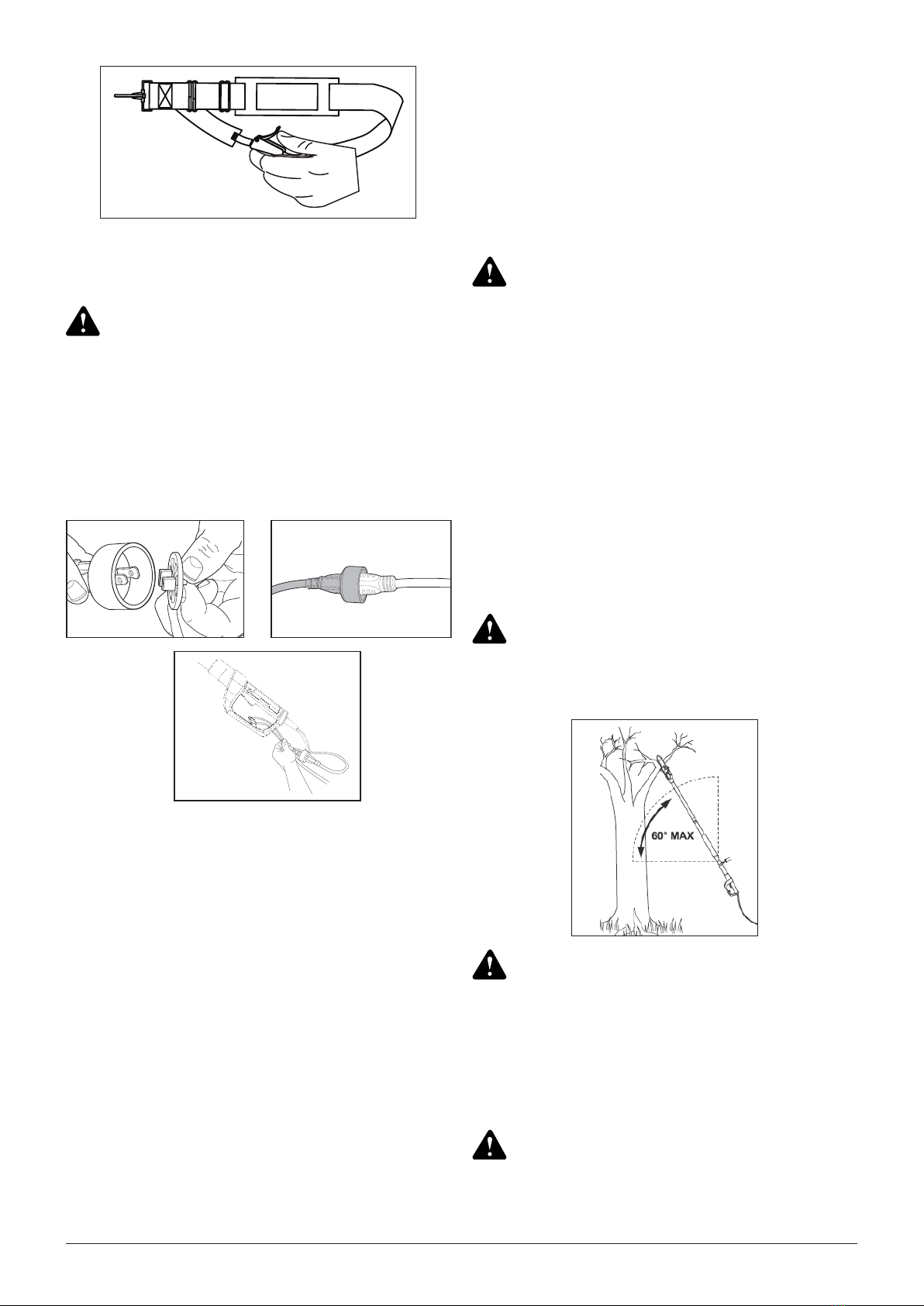

WARNING:

When removing branches, hold the pole saw at an

angle ranging from 0 to 60° in order to avoid being

struck by a falling branch. The saw should never be

operated directly above head.

7WWW.SENIXTOOLS.COM

As a pole saw:

• Cutting small limbs

• General tree pruning

Rated Voltage ............................................................................................................................................120V~ 60Hz

Rated current.......................................................................................................................................................... 6.5A

Motor type............................................................................................................................................. Universal Motor

No load speed ...............................................................................................................................................5200 RPM

Oil tank capacity ....................................................................................................................................2.04 oz. (60 ml)

Saw chain ......................................................................................................... 8 inch (203 mm), Oregon, 91PJ033X

Guide bar....................................................................................................... 8 inch (203 mm), Oregon, 080SDEA041

Weight .................................................................................................................................................. 6.8 lbs. (3.1 kg)

* All specications are based on the latest product information available at the time of printing. We reserve the right

to make changes at any time without notice.

APPLICATIONS

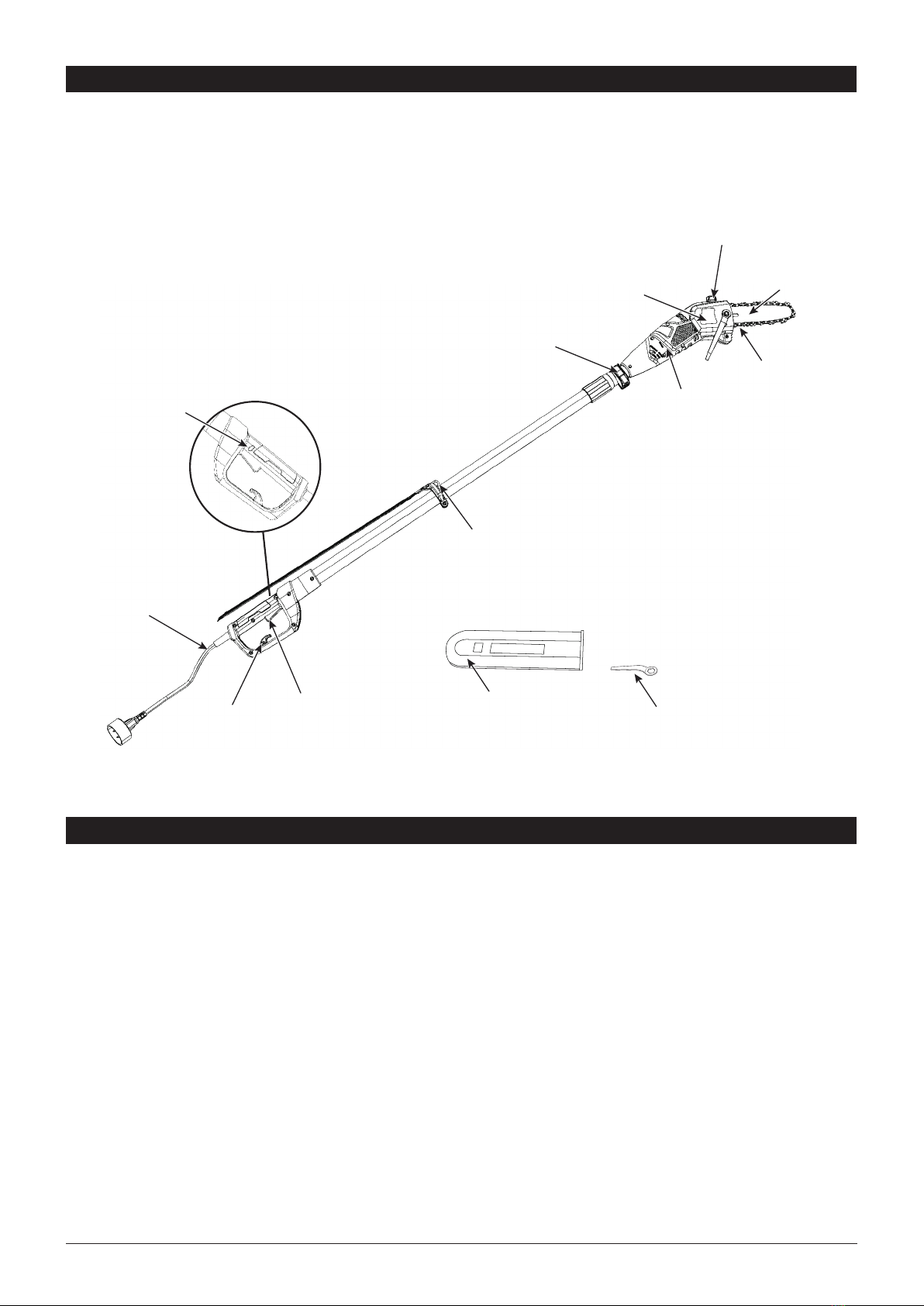

KNOW YOUR UNIT

SPECIFICATIONS*

Power Cord

& Plug

Sprocket

Cover

Harness Attachment

Guide Bar

Saw Chain

Oil

Tank

Cap

Wrench

Chain/Bar/Blade

Protective Cover

Switch

Trigger

ON/OFF

Chain Cover

Nut

Safety

Switch

Safety Cord

Retainer

Telescoping

Release

Lever

8WWW.SENIXTOOLS.COM

Locking Nut/

Step Washer

Wrench

Cover

USING THE RIGHT OIL

INSTALL THE CHAIN BAR AND CHAIN

ASSEMBLY

INCLUDED PARTS

This product requires assembly. Carefully remove the

product and any accessories from the box. Make sure

that all items listed in the packing list are included.

Inspect the product carefully to make sure no breakage

or damage occurred during shipping.

Do not discard the packing material until you have

carefully inspected and satisfactorily operated the

product. If any parts are damaged or missing, please

call 1-800-261-3981 for assistance.

Do not use this product if any parts on the packing

list are already assembled to your product when you

unpack it. Parts on this list are not assembled to the

product by the manufacturer and require customer

installation. Use of a product that may have been

improperly assembled could result in serious personal

injury.

o prevent an accidental start that could cause serious

personal injury, always disconnect the motor spark plug

wire from the spark plug when assembling parts.

Never install, remove, or adjust any attachments while

power head is running. Failure to stop the motor can

cause serious personal injury.

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a

second is sufcient to inict serious injury.

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

If any part of the pole saw is missing or damaged, do

not connect to power source or operate the pole saw

until the damaged part is repaired or replaced.

Disconnect the spark plug wire before performing

maintenance or assembly procedures.

Cutting edges on chain are sharp.

Use protective gloves when handling chain.

ALWAYS maintain proper chain tension. A loose chain

will increase the risk of kickback. A loose chain may

jump out of chain bar groove. This may injure operator

and damage chain. A loose chain will cause chain,

chain bar, and sprocket to wear rapidly. The chain

life of the saw chain mainly depends upon sufcient

lubrication and correct tensioning. Avoid tensioning the

chain if it is hot, as this will cause the chain to become

over tensioned when it cools down.

1. Place the saw body on a rm and level surface.

2. Using the supplied wrench, turn the bar adjustment

locking nut counter-clockwise to loosen it. Remove

the locking nut, step washer, and cover.

DO NOT discard box or packing material until all parts

are examined.

NOTE: Chain and Bar Oil is not included. You must ll

the Pole Saw with SAE30 oil BEFORE use.

NOTE: Remove the Chain/Bar/Blade Protective Cover

before use.

Quantity Item

1Operator’s manual

1Chain protective cover

1Bar nut wrench

1Harness

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

Internal Bolt

Sprocket Chain Tensioning Pin

9WWW.SENIXTOOLS.COM

SAW CHAIN LUBRICATION

FILLING THE OIL TANK

The saw chain must be tensioned properly in order to

ensure safe operation.

Make sure that no dirt gets into the oil tank to prevent

clogging in the oil nozzle.

Because the saw chain heats up during operation, its

length can uctuate. Check the chain tension every

10 minutes of operation and adjust as necessary,

particularly for new saw chains.

The pole saw features automatic chain lubrication.

Never operate the pole saw without saw chain oil. The

use of the pole saw without enough saw chain oil will

damage the unit.

1. Place the saw on a level surface. Clean the area

around the oil tank cap and then open it.

IMPORTANT: Only use SAE300 saw chain oil. Other

oils will run the risk of damaging the unit and voiding the

warranty. Take note of temperature conditions. Using

the saw at various temperatures requires the use of

differing oils. To ensure a sufcient layer of lubricant at

lower temperatures, use liquid oil (low viscosity).

TIP: The saw chain shortens when cooling down.

Loosen the saw chain after work is completed to

elongate the chain’s life and prevent possible damage.

3. Wearing protective gloves, wrap the saw chain

around the chain bar, making sure that the teeth are

aimed in the direction of rotation. The chain should

be properly set in the slot running along the entire

outside edge of the chain bar.

4. Place the saw chain around the sprocket while lining

up the slot in the chain bar with the internal bolt at the

base of the saw and the chain tensioning pin in the

chain bar’s pin hole. The chain tensioning pin may

need adjustment to properly align with the hole in the

chain bar. Use a at-blade screwdriver to turn the

chain tensioning screw to adjust the location of the

pin until it ts in the chain bar.

5.Turn the chain tensioning screw clockwise to

preliminarily tighten the chain bar enough that it stays

in place.

6. Install the step washer and locking nut. Using the

supplied wrench, turn the locking nut clockwise to

tighten it. DO NOT overtighten.

2. Fill the oil tank with 2.04 oz. (60 ml) of saw chain and

bar oil.

3. Close the oil tank cap.

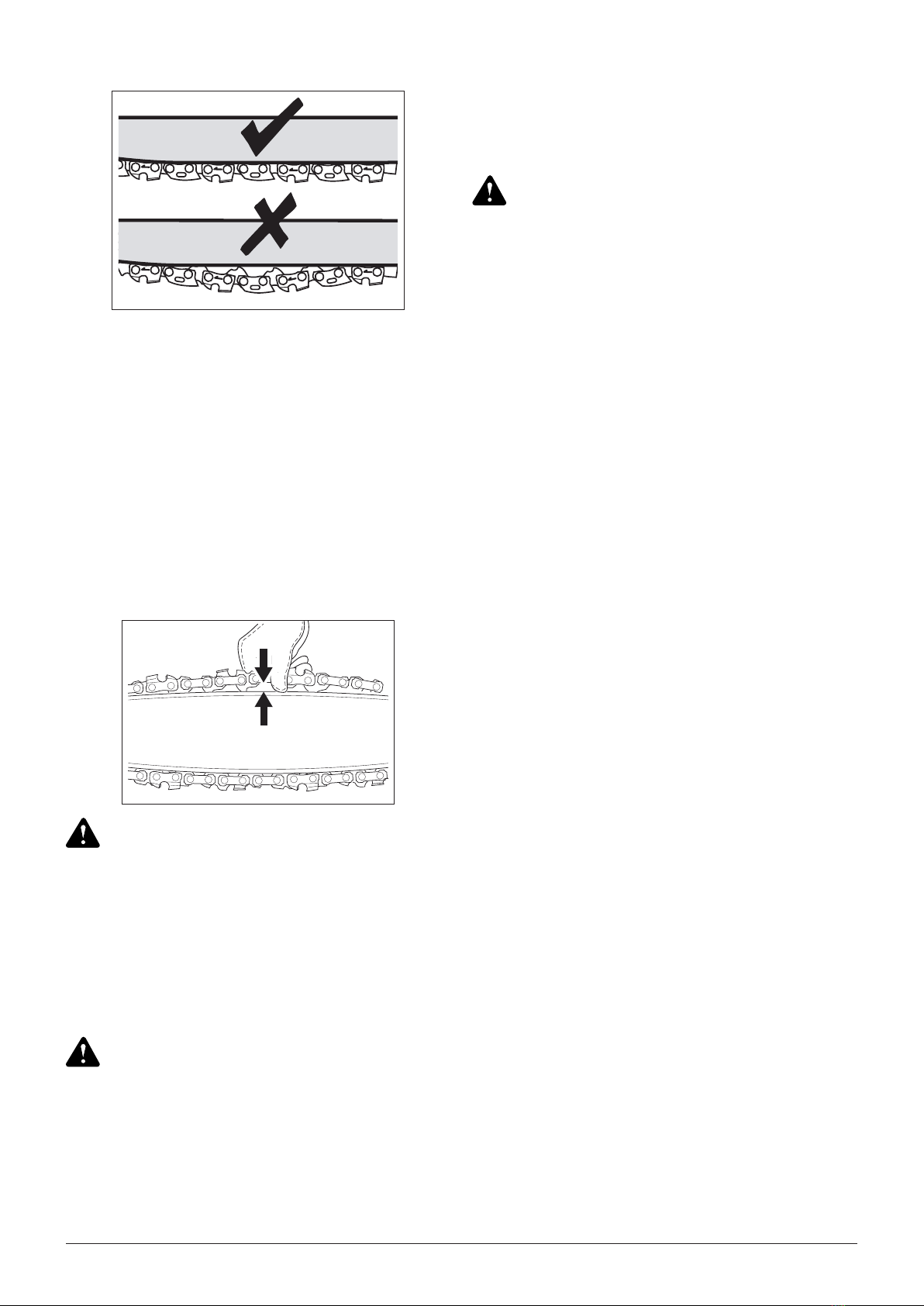

7. Check the chain tension by pulling the saw chain

away from the chain bar. A properly tensioned chain

should have roughly 0.08 inch (2 mm) of distance

between itself and the bar guide.

8. If adjustments are needed, loosen the bar adjustment

locking nut one full turn.

9. To adjust the saw chain tension, turn the chain

tensioning screw. Turning the screw clockwise

increases the tension while turning it counter-

clockwise decreases tension. A properly tensioned

chain should have no sag and should only be able to

be pulled 0.08 inch (2 mm) away from the chain bar

of the saw.

10. Once the chain is properly tensioned, tighten the bar

adjustment locking nut. DO NOT over-tension the

chain: this will lead to excessive wear and reduces

the life of both the bar and chain.

CAUTION:

CAUTION:

Chain

Tensioning

Screw

Chain Tensioning

Screw

0.08” (2 mm)

Oil tank cap

10 WWW.SENIXTOOLS.COM

INSTALL THE HARNESS

The harness with quick release function can be hooked

behind the rear hand if needed.

NOTE: Harness use is optional.

11WWW.SENIXTOOLS.COM

OPERATION

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

Operate this unit only in a well-ventilated outdoor area.

Do not overwork yourself. Take regular breaks and

change working position to ensure you can concentrate

on the work and have full control over the product.

Maintain rm footing and balance during operation.

Inspect unit before each use. Replace damaged parts.

Check for fuel leaks. Make sure all fasteners are in

place and secure.

Motor housing can become hot during pole saw

operation. Do not rest or place your arm, hand, or any

body part against the motor housing. Extended contact

with the motor housing can result in burns or other

injuries.

Always position the unit on the operator’s right side. The

use of the unit on the operator’s left side will expose

the user to hot surfaces and can result in possible burn

injury. To avoid burns from hot surfaces, never operate

unit with the bottom of the motor above waist level.

Do not allow familiarity with this product to make you

careless. Remember that a careless fraction of a

second is sufcient to inict serious injury.

Always wear eye protection with side shields marked to

comply with ANSI Z87.1, along with hearing protection.

Failure to do so could result in objects being thrown into

your eyes and other possible serious injuries.

Do not use any attachments or accessories not

recommended by the manufacturer of this product. The

use of attachments or accessories not recommended

can result in serious personal injury.

Operation of this equipment could create sparks that

can start res around dry vegetation. The operator

should contact local re agencies for laws or regulations

relating to re prevention requirements.

WARNING:

WARNING:

CAUTION:

CAUTION:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

WARNING:

PREPARATION

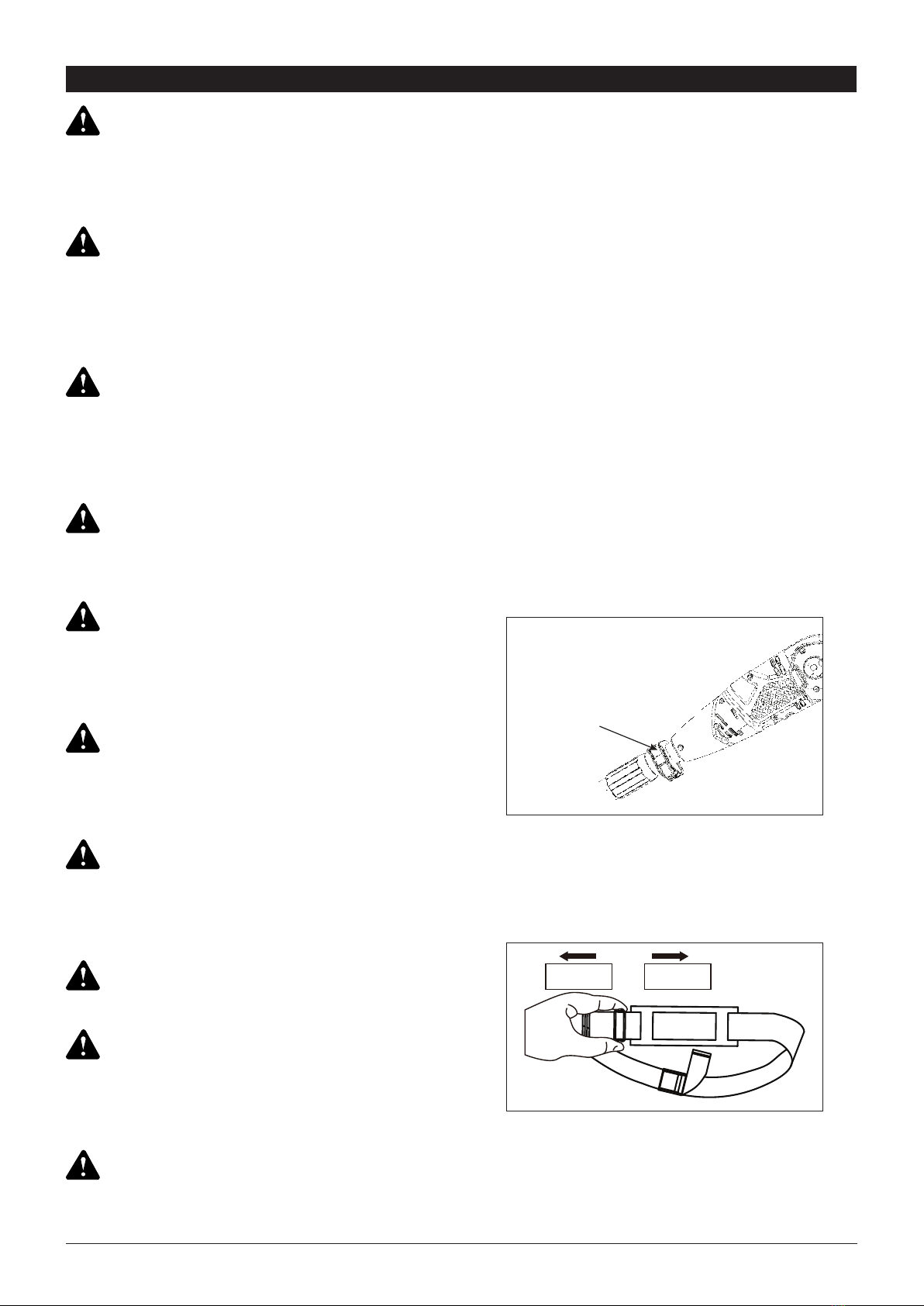

ADJUSTING THE TELESCOPING HANDLE

ADJUSTING THE HARNESS

Before each use, check the following items to ensure

safe working conditions.

POLE SAW: Before beginning work, inspect the pole

saw for damage to the housing, the saw chain and the

guide bar. Never use a damaged machine.

OIL TANK: Check the ll level of the oil tank. Also check

whether there is sufcient oil available while working.

Never operate the saw if there is no oil or the oil level is

not visible in order to prevent damage to the pole saw.

SAW CHAIN: Check the tension of the saw and the

condition of the blades. The sharper the saw chain is,

the easier and more manageable operations will be.

The same applies to chain tension.

Check the tension every 10 minutes of operation

to maximize safety. New saw chains in particular

are subject to changes due to the heat created by

operation.

PROTECTIVE CLOTHING: make sure to wear the

appropriate close- tting protective clothing such as

hainsaw-protective pants, gloves and safety shoes.

Wear a safety helmet with integrated hearing protection

and a face guard to provide protection against falling

and recoiling branches.

Telescoping

Release

Lever

1. Unlock the telescope release lever so that the pole

can freely extend outwards and inwards.

2. Extend it to the desired length and lock the telescope

release lever to hold it in place.

Adjust the harness to a length which is suitable for your

operation.

Always use the harness to carry the product weight on

your shoulder (on the same side of tool or cross your

body). Ensure that the quick release is on your chest

(NOT on your back).

Short Long

12 WWW.SENIXTOOLS.COM

HANDLING POLE SAW

• Hold the Pole Saw with both hands using the soft

grip.

• Fully grip both handles at all times during operation.

• Hold the Pole Saw at a max. angle of 60° from the

horizontal level.

• Maintain a minimum distance of thirty feet to

bystanders.

Do not operate Pole Saw using only one hand.

Do not stand directly under the limb you are sawing.

Objects may fall different than expected. Position

yourself well out of the path of falling limbs. Keep

bystanders away from cutting end of garden power tool

and a safe distance from the work area.

Do not stand on a ladder or other support while using

Pole Saw.

WARNING:

WARNING:

WARNING:

ATTACHING THE EXTENSION CORD

Open the quick release clamp if it is necessary to open

the harness quickly.

You should only use extension cords for outdoor use,

PVC or rubber cord ordinary duty with a cross sectional

area not less than 1.5 mm. Before and during use,

check the supply and extension cords for damage. Do

not use the appliance if the cord is damaged or worn.

Keep extension cord away from cutting elements. If the

cord is damaged during use, disconnect the cord from

the supply immediately. Do not touch the cord before

disconnecting the supply.

WARNING:

HOLDING THE UNIT

AVOIDING KICKBACK DURING USE

Remove the plug safety cap. Insert the extension cord

socket into the pole saw plug. An extension cord retainer

is attached to the handle to reduce strain on the cord.

To use the cord retainer, double the extension cord as

shown, about a foot from the end, and insert it into the

end of the retainer. Place the

loop formed by doubling the cord over the hook. Gently

tug on the cord

to ensure that it is rmly situated in the retainer.

Keep the extension cord clear of operator, unit, and any

obstacles at all times. Do not expose the cord to heat, oil,

water, or sharp edges.

When kickback occurs, the pole saw can react

unpredictably and cause severe injures to the operator

or bystanders.

To avoid kickback:

Kickback occurs when the chain (at the tip of the guide

bar) comes in contact with a log or wood, or when

the saw chain becomes jammed, often when sawing

sideward, slanted or during lengthwise cuts.

WARNING:

• Stand in the operating position Stand up straight. Do

not bend over.

• Keep feet apart and rmly planted.

• Hold the shaft grip with the right hand. Keep the right

arm slightly bent.

• Hold the handle with the left hand. Keep the left arm

straight.

• Hold the unit at waist level.

• Saw with guide bar at a at angle

• Do not work with a loose, overstretched or worn out

chain

• Ensure chain is sharpened correctly

• Do not work with the tip of the guide bar

• Hold the pole saw rmly with both hands

• Use a low kickback chain

• Ensure correct chain tension.

• Position the cutting head a few inches above the

ground.

• Do not over-reach; Keep all parts of your body away

from the rotating cutting attachment and hot surfaces.

13WWW.SENIXTOOLS.COM

CUTTING THIN BRANCHES

STARTING AND STOPPING

IF ASSISTANCE IS REQUIRED FOR THIS PRODUCT:

CUTTING THICK BRANCHES

• Thin branches can be cut off with a single cut.

• To prevent the branch from slivering and buckling, cut

the branch off in several pieces.

When cutting larger branches, the following four cuts

are necessary:

• First cut into the branch from below, outside of the

location where you intend to cut off the branch.

• The cut should go one third to halfway through the

branch (1).

• Cut into the branch from the top, making sure it’s

outside from where the branch is to be sawed (2).

• To keep stump and branch from splintering, do a stub

undercut below branch (3).

• Cut off the stump with one clean cut from top to

bottom. If desired, seal the cut with a suitable

compound (4).

• When nished cutting, turn off the Pole Saw and

disconnect its power supply after use.

• Clean, then store the appliance indoors out of

children’s reach.

• Make sure the power cord is located to the rear, away

from the chain and wood, and kept free of branches

during cutting.

• Hold the Pole Saw to the side of your body.

• Keep a rm, steady pressure on the Pole Saw while

working. Do not try to force the Pole Saw through

the wood, let the chain do the work. Use the gripping

teeth to apply minimal leverage pressure.

• Use caution when reaching end of cut. The Pole

Saw’s weight may change unexpectedly as it cuts free

from the wood. Always remove the Pole Saw from a

wood cut while it is running.

Do not operate the Pole Saw with arms fully extended

or attempt to saw areas that are difcult to reach.

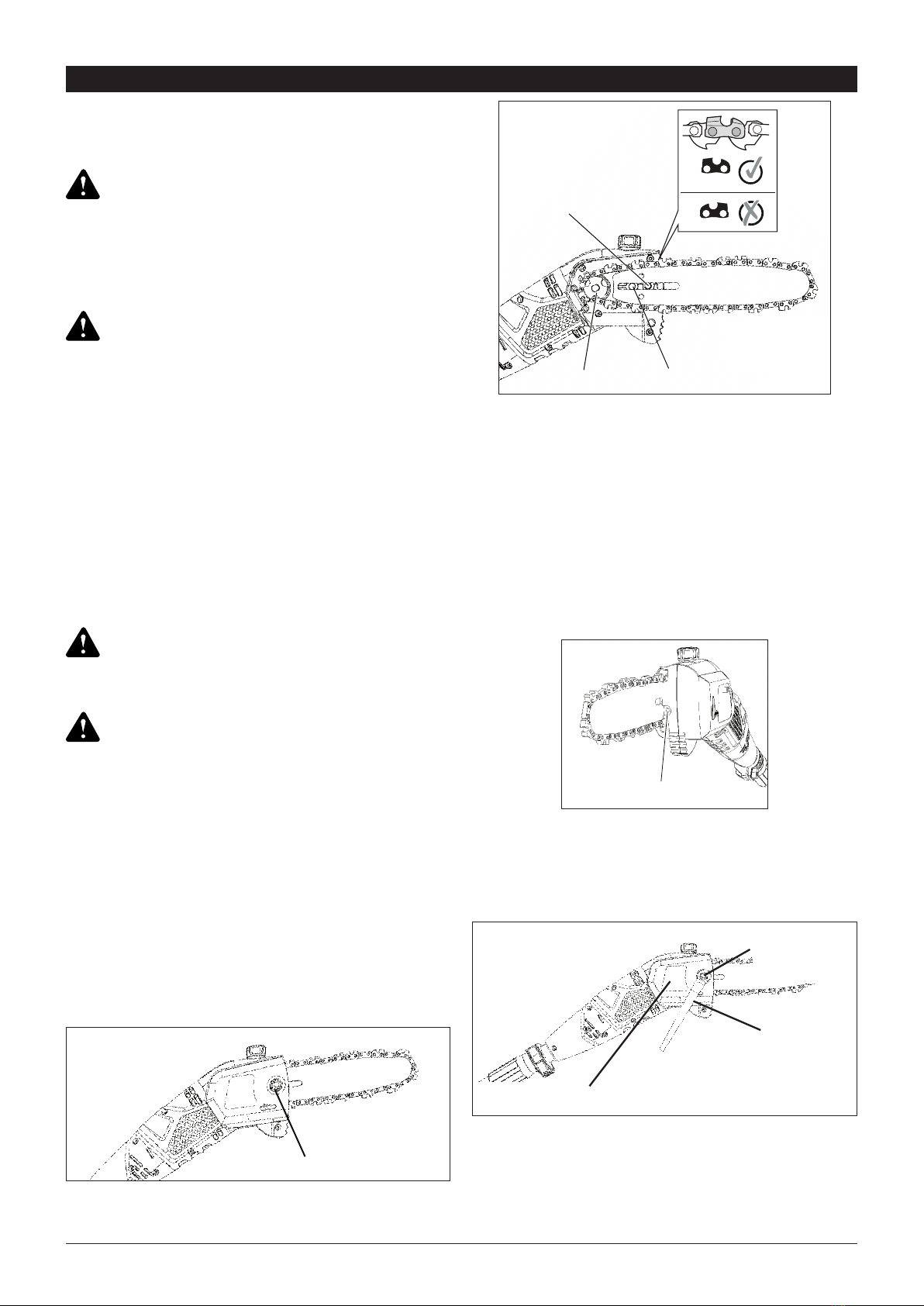

To turn ON, hold the pole saw rmly with both hands.

Press and hold the safety switch located on the left-

hand side of the rear handle above the main power

trigger.

Press the trigger to turn it ON. The safety switch can

now be released. To turn OFF, release the ON/OFF

trigger switch.

Do not return this product to the retail store where it

was purchased. Please call our Customer Service

Department for any issues you may have. For Help Call:

1-800-261-3981

WARNING:

Trigger

Safety switch

14 WWW.SENIXTOOLS.COM

Locking Nut/

Step Washer

Wrench

Cover

MAINTENANCE

To avoid serious personal injury, always stop the motor

and allow it to cool before cleaning or maintaining the

unit. Never perform cleaning or maintenance while

the unit is running. Disconnect the spark plug wire to

prevent the unit from starting accidentally.

Wear protective clothing and observe all safety

instructions to prevent serious personal injury.

Only use replacement bar/chain combination listed. DO

NOT use any other bar/chain combination.

Replace chain when cutters are too worn to sharpen or

when chain breaks. Only use replacement chain noted

in this manual. Always include new drive sprocket when

replacing chain. This will maintain proper driving of

chain.

When handling saw chains, always wear protective

gloves.

Guide bar: 8 inch (203 mm), 080SDEA041, Oregon

Saw chain: 8 inch (203 mm), 91PJ033X, Oregon

Use a small brush to clean the outside of the unit. Do

not use strong detergents. Household cleaners that

contain aromatic oils such as pine and lemon, and

solvents such as kerosene, can damage plastic. Wipe

off any moisture with a soft cloth.

Correct and regular cleaning is not only important for

the safe use of this product, but also extends its life

span.

When servicing, use only identical replacement parts.

Use of any other parts could create a hazard or cause

product damage.

WARNING:

WARNING:

WARNING:

WARNING:

CLEANING

REPLACING THE SAW CHAIN AND CHAIN

BAR

1. Place the saw body on a rm and level surface.

2. Using the supplied wrench, turn the chain sprocket

cover nut counter-clockwise to loosen it. Remove the

nut and cover.

3. Wearing protective gloves, wrap the saw chain around

the chain bar, making sure that the teeth are aimed in

the direction of rotation. The chain should be properly

set in the slot running along the entire outside edge of

the chain bar.

4. Place the saw chain around the sprocket while lining

up the slot in the chain bar with the internal bolt at

the base of the saw and the chain tensioning pin in

the chain bar’s pin hole. The chain tensioning pin may

need adjustment to properly align with the hole in the

chain bar. Use a at-blade screwdriver to turn the

chain tensioning screw to adjust the location of the pin

until it ts in the chain bar.

5. Turn the chain tensioning screw clockwise to

preliminarily tighten the chain bar enough that it stays

in place. While holding the bar still, place the cover

back onto the saw. Make sure the tab properly lines

up with the slot on the body of the saw.

6. Install the collar and locking bolt. Using the supplied

wrench, turn the locking nut clockwise to tighten it. DO

NOT overtighten. Adjust the chain tension.

Chain Cover Nut

Internal Bolt

Sprocket Chain Tensioning Pin

Chain

Tensioning

Screw

Chain Tensioning

Screw

15WWW.SENIXTOOLS.COM

The saw chain must be tensioned properly in order to

ensure safe operation.

Install the guide bar cover when transporting to prevent

personal injury.

Install the guide bar cover when transporting to prevent

personal injury.

If the supply cord of this power tool is damaged, it must

be replaced by a specially prepared cord. Inspect the

power cord and plug often. If damaged, have replaced

by a qualied service dealer.

Examine the unit thoroughly for worn, loose or damaged

parts. If you need to repair or replace a part, contact

Senix customer service at 1-800-261-3981.

Transport the unit in a horizontal position. If not

possible, transport the unit vertically with the motor at

the top. Secure the pole saw to prevent damage during

transportport.

CAUTION:

CAUTION:

CAUTION:

TENSION THE CHAIN

REPLACING THE POWER CORD

STORAGE

TRANSPORTATION

1. Check the chain tension by pulling the saw chain away

from the chain bar. A properly tensioned chain should

have roughly 0.08 inch (2 mm) of distance between

itself and the bar guide.

2. If adjustments are needed, loosen the bar adjustment

locking nut one full turn.

3.Toadjustthesawchaintension,turnthechaintensioning

screw. Turning the screw clockwise increases the

tension while turning it counter-clockwise decreases

tension. A properly tensioned chain should have no

sag and should only be able to be pulled 0.08 inch (2

mm) away from the chain bar of the saw.

4. Once the chain is properly tensioned, tighten the bar

adjustment locking nut. DO NOT over-tension the

chain: this will lead to excessive wear and reduces the

life of both the bar and chain.

• Clean the unit before storing.

• Store the unit with the chain protective cover installed.

• Store the tool out of reach for children and other

0.08” (2 mm)

unauthorized persons in a well-ventilated, dry and

frost-free environment.

• Protect the machine against dust and moisture.

• Cover it in order to provide added protection.

16 WWW.SENIXTOOLS.COM

Unplug unit from power source before servicing. Severe

injury or death could occur from electrical shock or body

contact with moving chain. Cutting edges on chain are

sharp. Use protective gloves when handling chain.

WARNING:

SHARPENING THE SAW CHAIN

Keep chain sharp. Your saw will cut faster and more

safely. A dull chain will cause undue sprocket, guide

bar, chain, and motor wear. If you must force chain into

wood and cutting creates only sawdust with a few large

chips, then chain is dull.

Purchase a new chain, have your chain sharpened

professionally at a qualied service center, or sharpen

the chain yourself using a proper sharpening kit. The

height difference between the cutting tip and the ridge is

the depth gauge setting.

When you sharpen the cutting tip, the depth gauge

setting between the tip and the side plate ridge will

decrease. To maintain optimal cutting performance, the

ridge has to be led down to achieve the recommended

depth gauge setting.

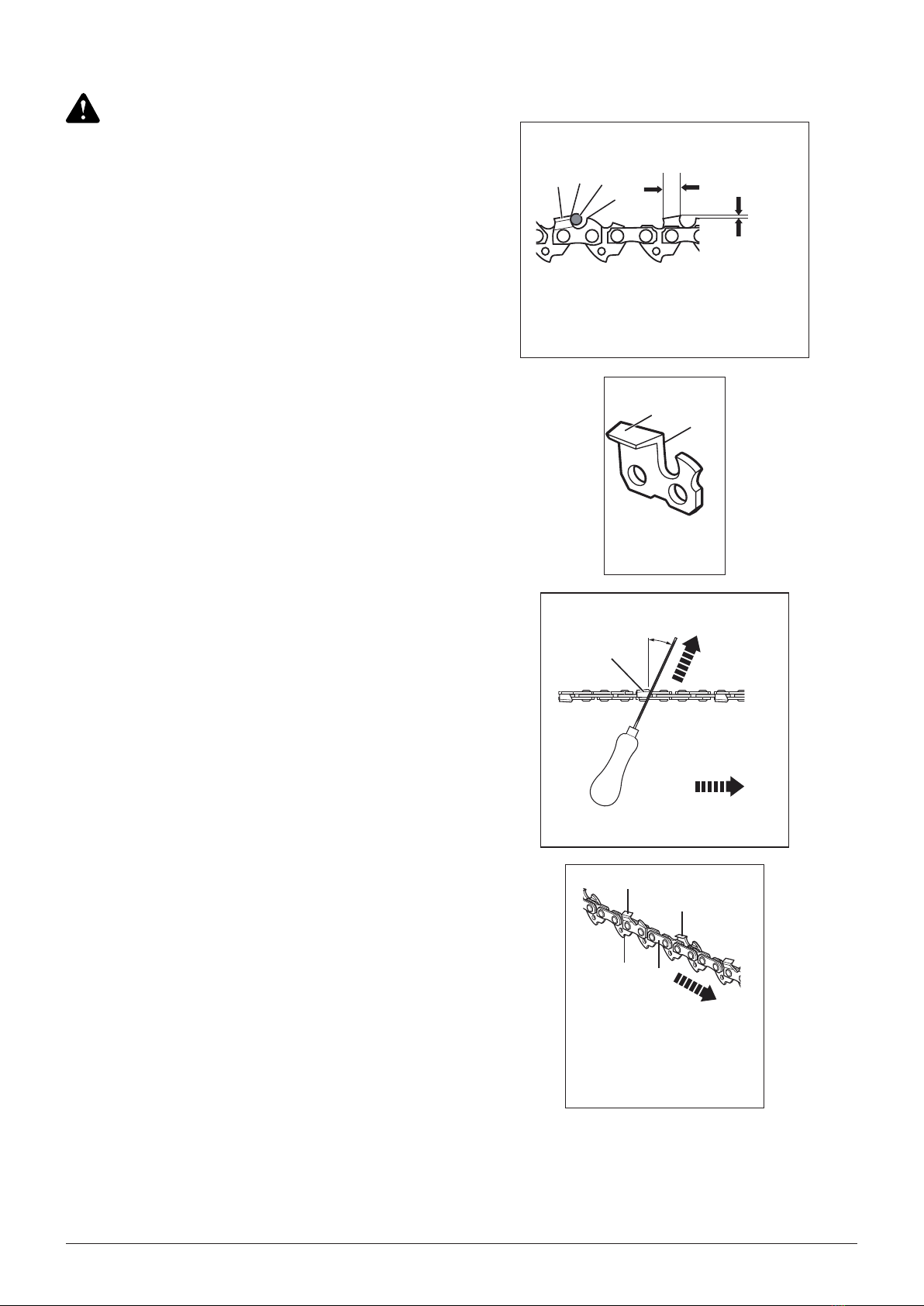

To sharpen the chain:

1. Using protective gloves, ensure the chain is correctly

tensioned on the guide bar.

2. Use a round le with a diameter 1.1 times the cutting

tooth depth. Make sure 20% of the le diameter is

above the cutter’s top plate.

NOTE: A le guide is available from most pole saw

retailers and is the easiest way to hold the le at the

correct position.

3. File at an angle perpendicular to the bar, and at an

angle of 25˚ to the direction of travel.

4. File each tooth from the inside towards outside only.

File one side of the chain rst then turn the saw around

and repeat the process.

• Sharpen each tooth equally by using the same

number of strokes.

• Keep all cutter lengths equal. Each time the cutting tip

is sharpened the cutting length is reduced. When the

cutter length is reduced to 0.16 inch (4 mm), the chain

is worn out and should be replaced.

• The depth gauge setting is also reduced with each

sharpening.. Every 5 sharpenings use a depth gauge

measuring tool to check the height between the

cutting tip and the ridge. When necessary, use a at

le to le down the ridge to achieve the .025 inch

depth gauge setting. Depth gauge measuring tools

are available from most pole saws retailers.

• If the saw is not functioning properly, take it to a

qualied pole saw service center to have the saw

inspected. Use only identical parts as listed in this

manual.

ABC

D

Cutter

Length

Depth Gauge

Setting 0.025 in.

A - Top Plate

B - Cutting Tip

C - File Position

D - Ridge

B

A

A - Top Plate

B - Side Plate

25°

A

SA

W CHAIN DIRECTION

Sharpening Angle

FILE

DIRECTION

Outside

Inside

A - Left-hand Cutter

A

B

CD

A - Right-hand Cutter

B - Left-hand Cutter

C - Bumper Drive Link

D - Tie Strap

SA

W CHAIN DIRECTION

17WWW.SENIXTOOLS.COM

TROUBLESHOOTING

SYMPTOM POSSIBLE CAUSE Fill the fuel tank with fresh fuel

Motor stops while cutting

Chain pinched in cut. Undercut limb to relieve pressure on limb.

Overheating of control system. Let the unit cool down.

Safety switch not pressed. Press the safety switch before squeezing the

trigger switch.

Debris in side cover. Remove chain sprocket cover and clean out

debris.

Overheating of motor. Let the motor cool down.

Motor runs, but saw

chain does not rotate

Chain not engaging drive sprocket. Reinstall the chain, making sure the drive

links on the chain are fully seated on the

drive sprocket.

Guide bar nose sprocket is not turning. Replace the guide bar.

Pole saw does not cut

properly

Insufcient chain tension. Tension the chain.

Dull chain. Sharpen or replace the chain.

Chain installed backwards. Install the chain with the teeth facing the

correct direction.

Worn chain. Replace the chain.

Dry or excessively stretched chain. Check the oil level. Rell oil reservoir if

necessary.

Chain not in bar groove. Reseat chain onto groove.

18 WWW.SENIXTOOLS.COM

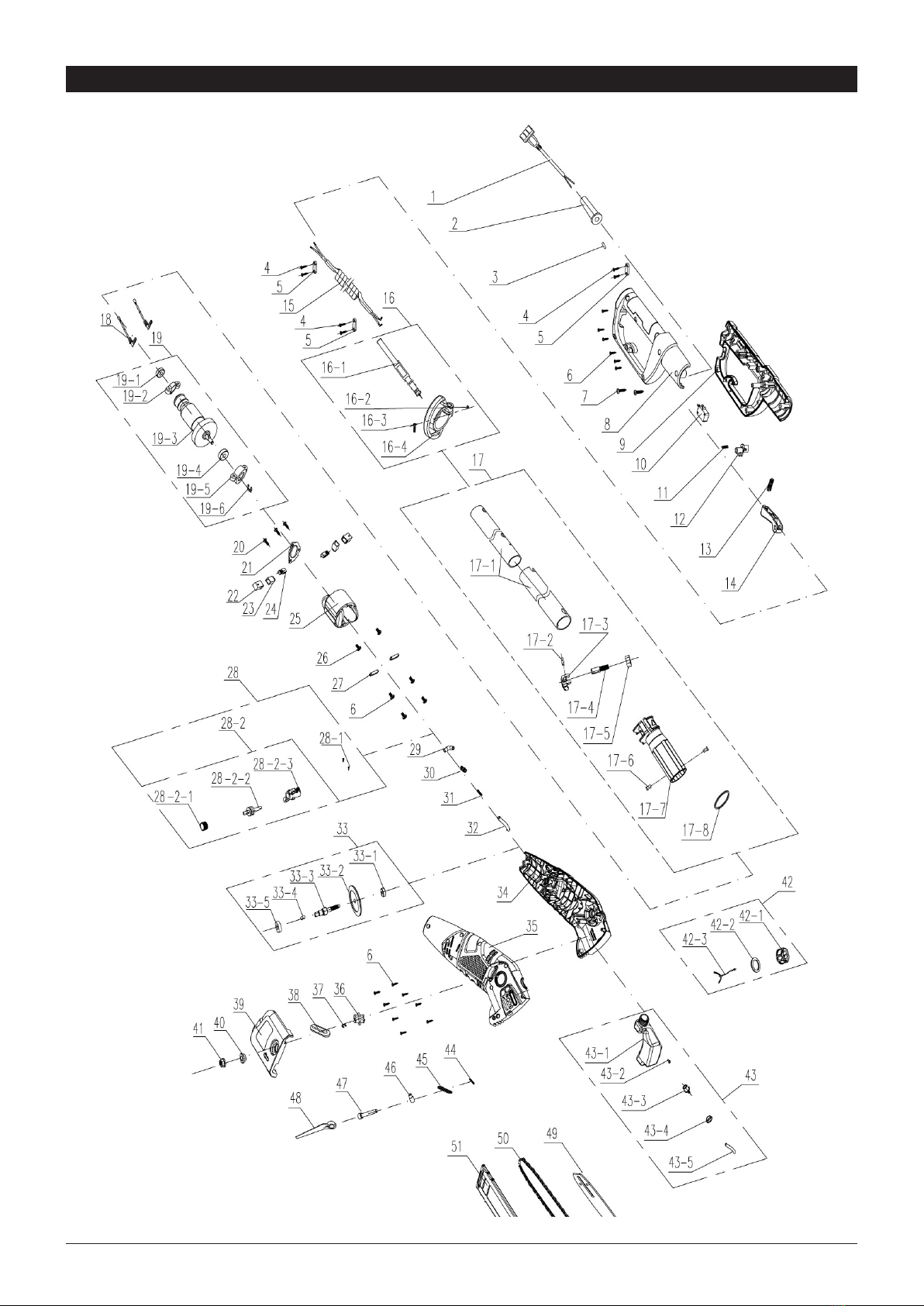

PARTS

19WWW.SENIXTOOLS.COM

PARTS LIST

No. Part # Description

1203002000015 Cable/Plug

2207099900006 Cable sheath

3301200005 Heat shrinkable tube

4207310100041 Self tapping screw

5207089900001 Cable clamp

68SJAB40-14D Self tapping screw

7207310100073 Self tapping screw

8202024002424 Right handle

9202024002423 Left handle

10 207180800008 Control switch

11 207019900024 Anti lock button spring

12 202003001777 Lock off button

13 207019900315 Switch spring

14 202003001776 Switch button

15 207039900469 Spring connection

16 199007000045 Backband Ring Component

16-1 208008000004 Backband

16-2 207320100008 Nut

16-3 207310100704 Screw

16-4 202040000031 Backband Ring

17 199060000507 Tube assembly

17-1 199060000347 Tube assembly

17-2 207199900054 Cylindrical pin

17-3 202026000219 Adjust the button

17-4 207229900169 Quick clamping adjusting bolt

17-5 207320100050 Lock nut

17-6 207199900110 Fixed pin

17-7 202031000164 Connecting bracket

17-8 207269900014 Big Split washer

18 207039900040 Carbon brush connection

wire

19 199133000044 Rotor component

19-1 207390100018 Bearing 607

19-2 202032000013 Bearing sleeve

19-3 106001000088 Rotor assembly

19-4 207390100069 Bearing 6000

19-5 202032000015 Bearing sleeve

19-6 207340100049 Split washer

20 207310100148 Countersunk head tapping

screws

21 201057000095 Bearing Pressure plate

22 207129900022 Bushing

23 207119900044 Carbon brush

24 202016002615 Brush shell

25 107001000061 Stator

26 207310100022 Self tapping screw

No. Part # Description

27 299999000054 Pressure plate

28 199010000040 Oil pump assembly

28-1 207310100324 Flange tapping screw

28-2 199010000147 Oil pump assembly

28-2-1 202001000002 worm gear

28-2-2 201004000103 Worm gear tooth

28-2-3 202999001599 Pump body

29 202019000177 Rubber joint

30 202019000171 Pipe connection connector

31 207019900001 Tubing setting spring

32 302000002 Transparent oil tube

33 199101000045 Output shaft assy

33-1 207390100011 Bearing 606

33-2 201004000091 Big gear

33-3 201999000724 Woodruff key

33-4 201025000118 Output shaft

33-4 207390100180 Bearing 6900

34 202016003791 Left housing

35 202016003790 Right housing

36 201035000003 Sprocket

37 207340100049 Split washer

38 207279900043 End cap seal ring

39 202011000543 End cover

40 207289900054 Axle sleeve

41 207320100061 Hexagon ange nut

42 199123000363 Oil box cap assy

42-1 202165000571 Oil box cap

42-2 207279900031 Oil box cap seal rings

42-3 202014000001 Prevent loss hook

43 199124000015 Oil box assembly

43-1 202164000013 Oil box

43-2 202074000003 Valve

43-3 199071000126 Oil-out connector assembly

43-4 207279900050 Oil outlet sealing ring

43-5 302000000 Transparent oil tube

44 207019900002 Tubing setting spring

45 207279900050 Oil outlet sealing ring

46 207169900011 Tighten the nut

47 207229900133 Tighten the screws

48 207179900012 Spanner

49 202009000201 Knife set

50 205001000003 Chain

51 205001000090 Chain board

20 WWW.SENIXTOOLS.COM

WARRANTY

2-year limited warranty on all Senix E series outdoor electric powered equipment.

FOR TWO YEARS from the original date of retail purchase this Senix product is warranted against defects in

materials or workmanship on power tools. Defective product will receive free repair.*

This warranty does not cover normal wear of parts and components such as cutting chain, line or blades nor does

this warranty cover product transportation cost for warranty or service.

Any implied warranty granted under state law, including warranties of merchantability or tness for a particular

purpose, are limited to three years from the date of purchase on power tools and chargers and seven years on

batteries. The manufacturer is not responsible for direct, indirect, incidental or consequential damages. Some

states and provinces do not allow limitations on how long an implied warranty lasts and/or do not allow the

exclusion or limitation of incidental damages, so the above limitations and exclusions may not apply to you. This

warranty gives you specic legal rights, and you may also have other rights which vary from state to state or

province to province.

The YAT USA declines any responsibility in regard to civil liability arising from abusive use or not in conformity with

proper use and maintenance of the machine as described in the operator’s manual.

YAT USA is not responsible for direct, indirect, incidental or consequential damages.

After the purchase, the manufacturer recommends proper maintenance of the machine and to read the operator’s

manual before using the machine.

*Original purchase receipt may be required for proof of purchase

For customer service contact us toll free at 1-800-261-3981 or Senixtools.com.

YAT USA, Inc. 9048 E Bahia Dr, suite 105, Scottsdale, AZ 85260

LIMITED TWO-YEAR WARRANTY

Additional Limitations

Warranty is subject to the following conditions:

• Warranty applies to the original purchaser at retail and is not transferrable*

• Warranty Registration at www.senixtools.com

• The tool has not been misused, abused, neglected, altered, modied or repaired by anyone other than an

authorized servicecenter

• Only genuine Senix accessories have been used with or on this product

• The tool has been subjected to normal wear and tear

• The tool has not been used for trade or professional purposes

• The tool has not been used for rental purposes

• This warranty only covers defects arising under normal usage and does not cover any malfunction, failure or

defect resulting from misuse, abuse (including overloading the product, exposure to water or rain) accidents,

neglect or lack of proper installation and improper maintenance or storage.

To locate your nearest Senix service provider call toll free at 800-261-3981 or email us at [email protected].

Table of contents

Languages:

Other Senix Pole Saw manuals