Sens SuperTorque 8Z User manual

SENS SuperTorque™8Z Technical Manual

1

SENS Part Number: 101341

Document Revision: A

DCN Number: 108283

Date: April 29, 2023

PATENTED US 9,270,140; 9,385,556; 9,413,186; 9,509,164;

9,466,995

Installation or service questions?

Call SENS between 8 a.m. and 5 p.m. (Mountain Time),

Monday through Friday, or visit our website.

Copyright © Stored Energy Systems LLC 2023

The SENS name / logo and Dynamic Boost are trademarks of Stored Energy Systems LLC

Installation & Operation Manual

SuperTorque™8Z

Genset Starting System

Super High-Performance Battery + Integrated Charger System

1840 Industrial Circle

Longmont, CO 80501

Phone: 303.678.7500

800.742.2326

Fax: 303.678.7504

Email: service@sens-usa.com

Web: www.sens-usa.com

SENS SuperTorque™8Z Technical Manual

2

TABLE OF CONTENTS

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR ............................................................ 4

2MODEL NUMBER BREAKOUT.............................................................................................................................. 6

3PERFORMANCE SPECIFICATIONS........................................................................................................................ 7

4SYSTEM OVERVIEW............................................................................................................................................. 9

4.1. Physical Overview ......................................................................................................................................9

4.2. Functional Overview ................................................................................................................................ 10

5MOUNTING INSTRUCTIONS.............................................................................................................................. 11

5.1. Mounting..................................................................................................................................................11

6SETUP AND WIRING .......................................................................................................................................... 12

6.1. Wire Ratings.............................................................................................................................................12

6.2. Grounding Instructions ............................................................................................................................ 12

6.3. Sleep and Wake Up Buttons.....................................................................................................................12

6.4. DC Connection.......................................................................................................................................... 13

6.5. AC Connection..........................................................................................................................................14

6.6. AC Pass-through.......................................................................................................................................14

6.7. Alarm Connections................................................................................................................................... 14

6.8. RS-485 Connection................................................................................................................................... 15

6.9. Ethernet or SAE J1939.............................................................................................................................. 17

6.10. SENSbus Connection ................................................................................................................................18

6.11. USB Connection........................................................................................................................................19

6.12. Verify Connections ...................................................................................................................................19

7START-UP PROCEDURE ..................................................................................................................................... 20

7.1. Connect DC Output ..................................................................................................................................20

7.2. Apply AC Power........................................................................................................................................20

7.3. Connect Alarms and Communications.....................................................................................................20

8ALARMS, LEDS AND DISPLAY ............................................................................................................................ 21

8.1. LED Indicators...........................................................................................................................................21

8.2. Individual Alarm Relay Contacts...............................................................................................................21

8.3. LCD Panel .................................................................................................................................................21

8.4. Latched Alarms.........................................................................................................................................22

8.5. Alarm Definitions .....................................................................................................................................22

9OPERATION ....................................................................................................................................................... 26

9.1. Charging Algorithms.................................................................................................................................26

9.2. Float Mode............................................................................................................................................... 26

9.3. Dynamic Boost™Mode ............................................................................................................................26

9.4. Battery Check ........................................................................................................................................... 26

9.5. Restore Factory Defaults..........................................................................................................................27

9.6. Keypad Operation—Optional...................................................................................................................27

9.6.3. Menu Options ..........................................................................................................................................27

9.7. Configuration and Monitoring with SENS Setup Utility ...........................................................................33

9.8. Temperature Compensation....................................................................................................................33

9.9. Parallel/Load Share Operation................................................................................................................. 33

9.10. Remote Alarm/Communications Panel Accessory................................................................................... 33

10 SERVICE AND MAINTENANCE ........................................................................................................................... 34

10.1. Recommended Annual Maintenance....................................................................................................... 34

10.2. Service......................................................................................................................................................34

11 J1939 COMMUNICATIONS ................................................................................................................................ 34

11.1. J1939 Data Messages...............................................................................................................................34

12 MODBUS COMMUNICATIONS .......................................................................................................................... 35

12.1. TCP/IP Modbus—Optional .......................................................................................................................35

12.2. Modbus RS-485—Optional....................................................................................................................... 35

12.3. Modbus Holding Registers ....................................................................................................................... 36

12.4. Basic Charging Alarms Bit Definition........................................................................................................ 37

12.5. Charging Status Bit Definition ..................................................................................................................38

SENS SuperTorque™8Z Technical Manual

3

12.6. Charging Alarms Extended Bit Definition.................................................................................................39

12.7. Charging AC Alarms Bit Definition............................................................................................................ 39

12.8. Accessory Channel Alarms Bit Definition .................................................................................................39

12.9. Accessory System Alarms Bit Definition...................................................................................................40

12.10. Accessory Assigned Channel Alarms Bit Definition..................................................................................40

12.11. Writable Control Flags (Coils)...................................................................................................................40

13 TROUBLESHOOTING/ERROR CODES................................................................................................................. 41

13.1. Configuration Error Codes........................................................................................................................41

13.2. Troubleshooting .......................................................................................................................................42

14 RECYCLING......................................................................................................................................................... 45

15 GLOSSARY.......................................................................................................................................................... 46

SENS SuperTorque™8Z Technical Manual

4

1IMPORTANT SAFETY INSTRUCTIONS FOR INSTALLER AND OPERATOR

1.1. SAVE THESE INSTRUCTIONS –This manual contains important safety and operating instructions for

SuperTorque 8Z genset starting systems.

Conserver ces instructions. Ce manuel contient des instructions importantes concernant la sécurité et le

fonctionnement.

1.2. Before using genset starting system, read all instructions and cautionary markings on product.

1.3. Do not expose to rain or snow.

1.4. Use of an attachment not recommended or sold by the manufacturer may result in a risk of fire, electric

shock, or injury to persons.

1.5. This genset starting system is intended for commercial and industrial use. ONLY TRAINED AND QUALIFIED

PERSONNEL MAY INSTALL AND SERVICE THIS UNIT.

1.6. Do not operate genset starting system if it has received a sharp blow, been dropped, been inverted, or

otherwise damaged in any way; shut off power at the branch circuit protectors and have the unit serviced

or replaced by qualified personnel.

1.7. To reduce risk of electric shock, disconnect the branch circuit feeding the genset starting system before

attempting any maintenance or cleaning. Turning off controls will not reduce this risk.

1.8. WARNING –RISK OF FIRE, EXPLOSION OR BURNS

1.8.1. WORKING IN THE VICINITY OF A NICKEL-ZINC BATTERY IS DANGEROUS. STORAGE BATTERIES

GENERATE EXPLOSIVE GASES DURING NORMAL BATTERY OPERATION. FOR THIS REASON, IT IS OF

UTMOST IMPORTANCE THAT YOU READ THIS MANUAL AND FOLLOW THE INSTRUCTIONS EACH

TIME YOU USE THE GENSET STARTING SYSTEM.

1.8.2. Do not disassemble battery, heat above 75°C, incinerate, puncture or impact.

Mise en garde : Risque d’incendie, d'explosion ou de brûlures. Ne pas démonter, chauffer à plus de

75°C (ou °F) ou incinérer.

1.8.3. To reduce the risk of battery explosion, follow these instructions and those published by the battery

manufacturer and the manufacturer of any equipment you intend to use in the vicinity of a battery.

Review cautionary markings on these products and on the engine.

Pour réduire le risque d’explosion, lire ces instructions et celles qui figurent sur la batterie.

1.8.4. Ensure battery spill control procedures exist in accordance with building, fire and installation codes.

1.9. PERSONAL PRECAUTIONS

1.9.1. Someone should be within range of your voice or close enough to come to your aid when you work

near a storage battery.

1.9.2. Have plenty of fresh water and soap nearby in case battery electrolyte contacts skin, clothing, or

eyes.

1.9.3. Wear complete eye protection and clothing protection. Avoid touching eyes while working near a

storage battery.

1.9.4. If battery electrolyte contacts skin or clothing, wash immediately with soap and water. If electrolyte

enters eye, immediately flood the eye with running cold water for at least 10 minutes and get

medical attention immediately.

1.9.5. NEVER smoke or allow a spark or flame in vicinity of battery or engine.

Ne jamais fumer près de la batterie ou du moteur et éviter toute étincelle ou flamme nue à proximité

SENS SuperTorque™8Z Technical Manual

5

de ces derniers.

1.9.6. Be extra cautious to reduce risk of dropping a metal tool onto the battery. It might spark or short

circuit the battery or another electrical part that may cause explosion. Using insulated tools reduces

this risk but will not eliminate it.

1.9.7. Remove personal metal items such as rings, bracelets, necklaces, and watches when working with a

storage battery. A storage battery can produce a short circuit current high enough to weld a ring or

the like to metal, causing a severe burn.

1.9.8. NEVER charge a frozen battery.

Ne jamais charger une batterie gelée.

1.9.9. The charging circuit contains a DC output fuse for internal fault protection, but this will not protect

the DC wiring from fault currents available from the battery. Consult national and local ordinances

to determine if additional battery fault protection is necessary in your installation.

1.10. Preparing Battery For Charge

1.10.1. Ensure area around battery is well ventilated and in accordance with local fire and installation codes

while battery is being charged.

1.10.2. Ensure battery terminals are clean and properly tightened. Be careful to keep corrosion from

coming in contact with eyes.

1.10.3. Do not operate genset starting system with damaged cables. Defective cables must be replaced

before operation.

1.10.4. Verify that all cables are properly secured and connected.

1.11. Installation Location

1.11.1. Operating temperature: -10°C to 55°C

1.11.2. Do not tip, keep genset starting system level.

1.11.3. Do not set anything on top of genset starting system.

1.12. Warranty and Service

1.12.1. Do not open genset starting system, not field serviceable.

1.12.2. Always operate within -10°C to 55°C. Do not operate outside of 0°C to 50°C for more than 10% of

operating life.

SENS SuperTorque™8Z Technical Manual

6

2MODEL NUMBER BREAKOUT

8Z

-

24

-

B

-

15

-

B

-

1

-

1

-

00

A

-

B

-

C

-

D

-

E

-

F

-

G

-

H

Parameter

Code

Value

A

Product Family

8Z

SuperTorque 8Z

B

DC Output Voltage

12

12 VDC

24

24 VDC

C

Battery Capacity

B

80 Ah

D

Charging Current

15

15 Amps

E

Interface and

Communication

A

Base model; includes status LEDs, two Form C

relays, SENSbus, USB-C

B

Base model + LCD + keypad control + J1939 + RS-

485 Modbus

C

Base model + LCD + keypad control + RS-485 and

TCP/IP Modbus

F

Mounting

1

Standard, not for rigid mounting

2

With rigid mounting brackets

G

Terminals

1

Threaded inserts for ring lug connection (M8)

2

SAE battery terminal posts

H

Configuration

00

Standard Configuration

SENS SuperTorque™8Z Technical Manual

7

3PERFORMANCE SPECIFICATIONS

SuperTorqueTM 8Z is a genset starting system including a high-performance NiZn battery, charging system,

controls, communications, and user-interface in one package, specially targeted for long-life and high reliability.

2 Standard Form C contact alarms are factory set and field reconfigurable, with indication via communication

port, optional front panel LCD and assignable alarm relays. Keypad control and data communications including

serial and Ethernet Modbus optional. Specifications are detailed in the table below, see following sections for

installation and operation instructions.

AC Input

VAC, Hz

90-265 VAC single-phase, 47-63 Hz

24V: full charging current available above 170VAC input, 80% rated

charging current 100-170VAC

Protection

Supplementary overcurrent protection fuse, transient protected to EN

61000-4-5 level 4

Power factor &

efficiency

PF >.95 typical; efficiency to 93%; meets CEC Title 20 Efficiency

Regulations; standby AC draw < 3W

DC Charging

Output

Volts

12V or 24V nominal with less than 30mV ripple

Recharge rate

80-160Ah battery capacity, 15A charge current

Charging modes

NiZn-specific, multi-stage, non-adjustable

Current limit

Factory set at 100% of rating

Charging

characteristic

Constant voltage, current limited; patented Dynamic Boost control

Line & load regulation

±0.5%

Battery temp.

compensation

Standard

Engine Starting

Performance

Typical cranking

current

2,700 amps at breakaway while maintaining battery terminal voltage

above 12.0 volts (24V model). Rolling current is typically ~30% of

breakaway (locked rotor) current.

Typical engine

displacement per 8Z

unit

70 liter per one 24-volt 8Z battery system. Actual performance depends

on number of starters and installation

Typical crank cycles

Depends on number of starters and their configuration. More than four

cranks of 15 seconds typical.

Sequential discharges

Delayed recharge may occur after multiple sequential discharges. See

recharge section for details.

Redundancy

Combine 8Z units in parallel for increased starting performance and

redundancy. Integrates seamlessly with Best Battery Selectors for isolated

redundancy.

Status Display

LEDs

Two multi-color front panel status LEDs

Metering & status

display

Optional, requires LCD. Battery voltage accurate to +1%; charger current

to +1%; 20-character display of status & alarms.

Quiescent draw

Max quiescent draw with AC disconnected and unit not in “Sleep” mode:

Model

12/24V

Base model

164mA/82mA

Base model + LCD + keypad +

Modbus RS-485

193mA/101mA

Base model + LCD + keypad +

Modbus RS-485 and TCP/IP

237mA/123mA

SENS SuperTorque™8Z Technical Manual

8

Alarms

Alarms

Factory set, field reconfigurable. Alarm functions announced on the J-

1939 and Modbus ports and on the optional LCD. Any one of 20+ alarms

or any combination of alarms is assignable to either Form C contact.

Alarms: Form C

contacts

Two Form C contacts, each rated 30V, 2A resistive, assignable

Networking

J-1939

communications

Optional CAN 2.0 extended ID on RJ-45 port

Modbus

communications

Optional Modbus RS-485 or TCP/IP on RJ-45 port

SENSbus

Proprietary bus for connection of paralleled units and SENS accessories

USB

USB-C connectivity via SENS Setup Utility

Environmental

Operating

temperature

-10°C to +55°C; storage from -20°C to +60°C

Humidity

5% to 95%, non-condensing

Altitude

Full specification 0 to 13,000 ft (0 to 4000 m)

Ingress protection

NEMA2/IP22, NEMA3R/IP34 with optional field cover (p/n 209665-22), UL

“Rainproof”

Vibration & shock

resistance

Vib: Swept Sine (EN60068-2-6): 4G, 18-500 Hz, 3 axes. Random: 20-500Hz,

.01G2/Hz. Shock: EN 60068-2-27 (15G)

Electrical transient

ANSI/IEEE C62.41 & EN 61000-4-12 on power terminals

Abuse

Protection

Overvoltage

shutdown

Selective; shutdown only operates if the overvoltage condition is caused

by the internal charger itself

Overtemperature

protection

Gradual output power reduction if heatsink temperature becomes

excessive; recovery is automatic.

Regulatory

Compliance

North America

Internal batteries and charger are C-UL Listed/Recognized for US &

Canada

NFPA-70

FCC Part 15, Class B

Seismic: Rigid & non-isolated floor mount; max SDS of 2.5G, z/h = 0, Ip =

1.5. IBC 2000-2021, Calif. BC 2007-2021

American Bureau of Shipping: Type Approved

European Union (CE),

United Kingdom

(UKCA)

EMC: 2014/30/EU, UK 2016 (EN 61000-6-2 & EN 61000-6-4)

LVD/Safety: 2014/35/EU, UK 2016 (EN 60335-1 & EN 60335-2-29)

RoHS: 2015/863, UK 2012 (EN 63000)

Battery Directive: 2006/66/EC

Construction

Housing/configuration

Rainproof aluminum enclosure with non-conductive top

AC connections

AC Input Connection: IEC 320 C13

AC Pass-through Connection: IEC 320 C14, 750W maximum

AC Input Locking 8ft cord with NEMA 5-15R plug provided.

Optional UL Listed field-terminable IEC 320 C13 connector for hard wiring.

DC connections

Standard: M8 threaded inserts for positive and negative.

Optional: SAE battery terminal posts.

Alarms & comms

connections

J-1939 and Modbus TCP/IP: RJ-45; Modbus RS-485 and Form C alarms: 28-

16AWG terminal blocks

SENS SuperTorque™8Z Technical Manual

9

4SYSTEM OVERVIEW

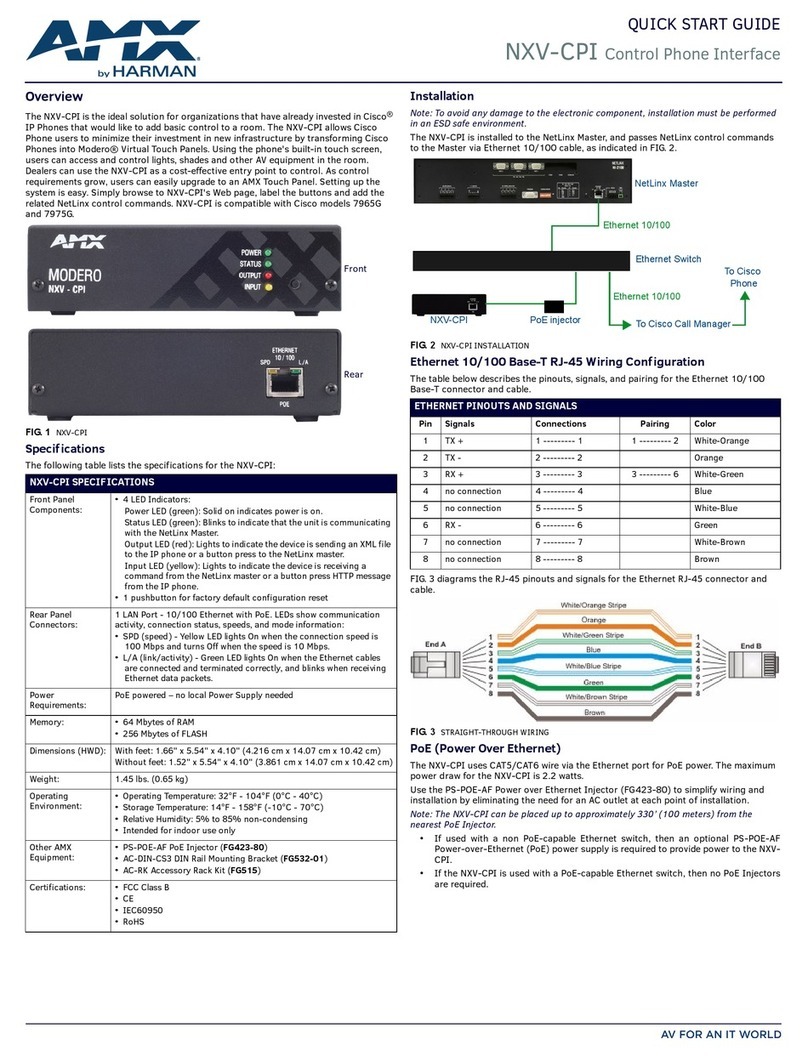

4.1. Physical Overview

SENS SuperTorque™8Z Technical Manual

10

4.2. Functional Overview

4.2.1. Configuration

Each SuperTorque 8Z comes factory configured from the factory and requires no output

adjustments. Configuration details are given on the configuration label. These values are assigned

according to the profile configuration selected during the customer order. Adjustments to

communications settings and other configurable settings can be made using the front panel

keypad (optional) or the SENS Setup Utility software. Connect a computer with the SENS Setup

Utility to the unit via USB-C.

Example Configuration Label

4.2.2. Standard Items

4.2.2.1. 2 Form C alarm relay contacts

4.2.2.2. USB-C

4.2.2.3. SENSbus communications

4.2.3. Factory Optional Items

4.2.3.1. Front panel LCD

4.2.3.2. Keypad control

4.2.3.3. Modbus (TCP/IP and RS-485) communications

SENS SuperTorque™8Z Technical Manual

11

5MOUNTING INSTRUCTIONS

INSTALLATION OF THE UNIT MUST COMPLY WITH LOCAL ELECTRICAL CODES AND OTHER APPLICABLE

INSTALLATION CODES AND BE MADE ACCORDING TO THE INSTALLATION INSTRUCTIONS AND ALL APPLICABLE

SAFETY REGULATIONS.

Printed circuit boards contain static sensitive components. Damage can occur even when static levels are too low

to produce a noticeable discharge shock. To avoid static discharge damage, handle the unit by the chassis only.

5.1. Mounting

See diagrams at back of manual for dimensions and mounting information.

5.1.1. Unit rated IP44, NEMA 3R.

5.1.2. Operate unit at -10°C to +55°C (14°F to +131°F). Do not operate outside of 0°C to 50°C (32°F to

122°F) for more than 10% of operating life.

5.1.3. Mounting surface must safely support the weight of the unit and the fixed wiring. Unit weighs

89.0 lb (40.4 kg). Lift the unit using a lifting device or two or more people.

5.1.4. Place on battery shelf or in battery box. Optional rigid floor mounting brackets available; install

using 3/8-inch fasteners (provided by installer).

5.1.5. Mount with battery terminals facing up. Do not permanently tip unit.

5.1.6. Allow sufficient room for routing the fixed wiring to the unit. AC, alarm and communications field

connections may enter the unit side using 1/2-inch conduit knockouts. See diagrams at back of

manual for further information.

SENS SuperTorque™8Z Technical Manual

12

6SETUP AND WIRING

IMPORTANT! Charge for 8 hours minimum prior to placing into service. Do not leave AC disconnected. To avoid

battery damage, do not drain battery below 10.5VDC (12V nominal systems) or 21.0VDC (24V nominal systems).

Storage - recharge every 6 months or when open circuit battery voltage drops below 13.5VDC (12V nominal

systems) or 27.0VDC (24V nominal systems).

The unit is configured at the factory and requires no adjustments before operating. Refer to the label on the field

wiring end of the unit for alarm relay assignments. Communications settings are configured using the front panel

keypad (optional) or the SENS Setup Utility.

6.1. Wire Ratings

All wiring must comply with applicable codes and local ordinances. All power conductors should be rated

for use at 90°C or higher and 600V or higher. Alarm relay conductors and communications data cable

should be rated for use at 75°C or higher. The field wiring area is accessed by removing the field wiring

access cover (optional). Use conduit entry holes to route wires as needed.

CAUTION:

VOLTAGE ALWAYS PRESENT ON BATTERY TERMINALS!

6.2. Grounding Instructions

Unit must be grounded via grounded AC input connection to reduce risk of electric shock. The unit must

be connected to a grounded, metal, permanent wiring system, or an equipment-grounding conductor

(earthing conductor) must be run with the circuit conductors.

6.3. Sleep and Wake Up Buttons

To prevent battery discharge when AC power is not connected, press “SLEEP” button to turn off display

and communications (unit shipped from factory in SLEEP mode). Press “WAKE UP” button to turn display

and communications on when AC power is not connected. The internal battery is always connected to

the DC output terminals and will always be available to start an engine when the display and

communications are powered off.

WARNING:

PRESSING “WAKE UP” BUTTON WITHOUT AC CONNECTED WILL CAUSE

BATTERY DISCHARGE, CONNECT AC POWER AS SOON AS POSSIBLE!

Field wiring access

cover (optional)

1/2-inch conduit

knockouts

SENS SuperTorque™8Z Technical Manual

13

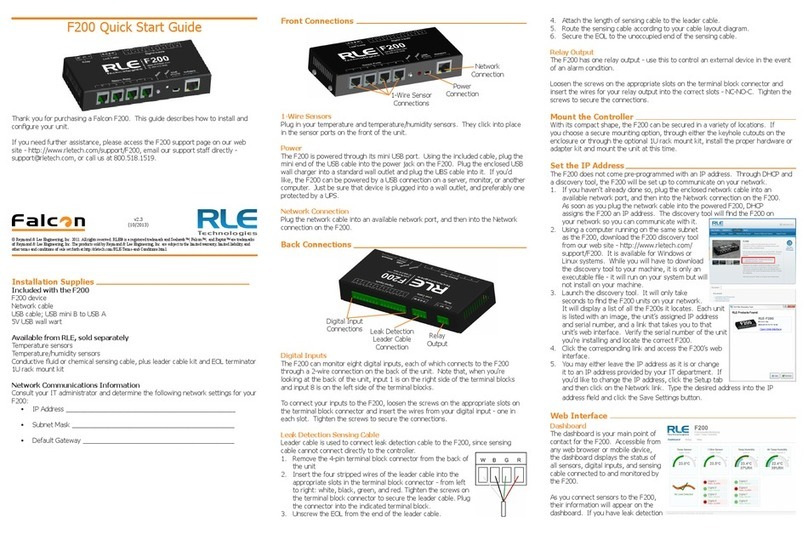

6.4. DC Connection

Connect DC output conductors to the DC output terminals on the unit using ring lugs and M8 fasteners.

Always observe proper polarity of the DC output leads. Tighten connections to 60lb-in using a 13mm

socket wrench. Do not rely on threads for electrical connection; ensure connection to terminal surface.

Route DC wiring at least ¼ inch (6 mm) away from AC and alarm wiring. Optional –connect DC output

conductors to SAE battery terminal posts on models including posts instead of standard terminals.

See engine manufacturer recommendation for DC output conductor gauge and length between the 8Z

unit and the engine starter / DC bus.

WARNING:

BATTERY TERMINALS MUST BE COVERED

TO PROTECT AGAINST ELECTRICAL SHOCK!

SENS SuperTorque™8Z Technical Manual

14

6.5. AC Connection

AC input voltage rated 100-240VAC, 50/60Hz. Connect an IEC 320 C13 locking power cord to the AC input

connector on the unit. Optional - wire AC input to locking screw terminal adapter provided with field

termination kit (18-14AWG, tighten to 3.5lb-in). Route AC wiring at least ¼ inch (6 mm) away from DC

and alarm wiring.

6.6. AC Pass-through

The AC pass-through IEC 320 C14 connection provides/passes-through the input voltage connected at

the AC input connection. Rated 750W maximum. Use for load sharing units or connecting SENS-approved

external devices.

6.7. Alarm Connections

See label on the field wiring end of the unit for original factory alarm relay assignments. Alarm relay

assignments are custom configurable using the SENS Setup Utility. Alarm circuits are rated 2A at 30V AC

or DC. Connect alarm wiring to the respective terminals on the pluggable terminal block on the unit. To

make wiring easier, the terminal block unplugs from its header. Pull terminal block straight out from

header to remove. Connect wires to terminal block by tightening screws at each position. After wires are

connected, plug terminal block securely back into header. Wire from FAIL or OK to COM depending on

whether the alarm should be present on an open or closed circuit. Connect alarm terminals only to low

voltage, limited energy (“Class 2”) circuits. The terminals accept 28-16 AWG (0.08-1.5 mm2) conductors.

Tighten connections to 2.0 Lb-In (0.22 Nm) using a small slotted driver. Route alarm wiring at least ¼ inch

(6 mm) away from DC and AC wiring.

SENS SuperTorque™8Z Technical Manual

15

Position 1

Alarm Relay Connections

Wire from COM to OK for alarm present on open circuit or from COM to FAIL for present on closed circuit.

RELAY 1

Non-latching Coil

RELAY 2

Non-latching Coil

Relay Contacts

AC Fail

Charger Fail

Common

COM (Pos 1)

COM (Pos 4)

Open on alarm

OK (Pos 2)

OK (Pos 5)

Close on alarm

Defaults to FAIL with

no AC and DC power

(normally closed)

FAIL (Pos 3)

FAIL (Pos 6)

6.8. RS-485 Connection

Every unit includes RS-485 connections via a 4-pin pluggable terminal block. This interface is intended for

monitoring and communicating with the unit using Modbus. Connect wiring to the respective terminals

on the pluggable terminal block on the unit. To make wiring easier, the terminal block unplugs from its

header. Pull terminal block straight out from header to remove. Connect wires to terminal block by

tightening screws at each position. After wires are connected, plug terminal block securely back into

header. Wire connector position 1 for Modbus +D1 (A), position 2 for Modbus –D0 (B), position 3 for

COM and position 4 for Shield. The terminals accept 28-16 AWG (0.08-1.5 mm2) conductors. Tighten

connections to 2.0 Lb-In (0.22 Nm) using a small slotted driver. Route alarm wiring at least ¼ inch (6 mm)

away from DC wiring, AC wiring and low voltage wiring. See section 12 for further information on

Modbus operation and registers.

2 RELAYS,

3 POSITIONS PER

RELAY:

COM, OK, FAIL

PULL TO REMOVE

FROM HEADER

SENS SuperTorque™8Z Technical Manual

16

Position 1

6.8.1. Termination

For proper operation, a 120-ohm terminator is required at the ends of the RS-485 bus. If multiple

devices are on the bus, only the devices on the ends of the network bus need termination

resistors. Termination may be provided as part of the network cabling or 120-ohm termination

plugs for the RJ-45 communications connector on the unit are available to order separately (SENS

p/n 803707). SENS units are slave devices. Pull-up and pull-down resistors are optional per

Modbus specifications. Below figure shows an example of how to terminate the network.

LT = Line Termination 120-ohm resistor

4 POSITIONS:

Pos 1: +D1 (A)

Pos 2: –D0 (B)

Pos 3: COM

Pos 4: Shield

PULL TO REMOVE

FROM HEADER

SENS SuperTorque™8Z Technical Manual

17

PINOUT:

Pin 1: J1939 Data High

Pin 2: J1939 Data Low

Pin 8: Common (referenced to battery

negative)

Pin 1

6.9. Ethernet or SAE J1939

The unit is equipped with an RJ45 port for Ethernet Modbus TCP/IP or J1939 communications, depending

on model. See label below connector for indication of Ethernet or J1939 configuration.

6.9.1. Ethernet—Optional

Connect Cat5 or better ethernet cable. This provides a 10/100 ethernet connection. Ethernet

communication includes ethernet connectivity to the unit for monitoring via Modbus TCP/IP.

6.9.1.1. Configure TCP/IP Address

Configure TCP/IP settings using the SENS Setup Utility or the keypad. To adjust settings using

the keypad, ensure the access level is set to allow adjustments. Set the IP address as desired.

It may take up to 10 seconds for the network setting changes to apply. A TCP/IP address of

0.0.0.0 implies DHCP (Dynamic) addressing. Adjust the Gateway and Subnet Mask values as

required. The displayed Hardware Address is the MAC address corresponding to the Ethernet

interface. This value is not adjustable. See section 12 for further information on Modbus

TCP/IP operation and registers.

6.9.2. SAE J1939 (CANbus)—Optional

The J1939 interface provides a highly reliable, low-cost method of delivering to the genset

controller all information that NFPA 110 requires a charging system to deliver. To be operational,

the genset controller must support the unit J1939 connection. See section 11 for further

information on J1939 operation and registers.

J1939 communications are disabled by default and until the BCH address is configured (see

section 6.9.2.1). Connect J1939 communications using a twisted pair cable. Wire connector pin 1

for J1939 Data High, pin 2 for J1939 Data Low and pin 3 for Common. Communications are non-

isolated and referenced to negative battery terminal. An adapter from RJ45 to an 8-position

terminal block may be connected to the RJ45 connector and is available to order separately (SENS

p/n 208026).

SENS SuperTorque™8Z Technical Manual

18

Pin 1

RJ45 to Terminal Block Adapter —Ordered Separately

6.9.2.1. J1939 Address (BCH)

Configure the J1939 address using the SENS Setup Utility or optional front panel keypad

(J9139 communications are disabled until this address is configured). J1939 supports two

units per network cable. Set to address 1 for main unit or address 2 for auxiliary unit. The

unit is set to address 1 by default.

6.9.2.2. Termination

For proper J1939 operation, a 120-ohm terminator is required at the ends of the J1939 bus.

If multiple devices are on the bus, only the devices on the ends of the network bus need

termination resistors. The unit is not equipped with terminators. Termination may be

provided as part of the network cabling or 120-ohm termination plugs for the RJ45

communications connector on the unit are available to order separately (SENS p/n 803707).

Use a splitter as needed in the RJ45 port on the unit to connect both the network cable and

terminator. Below figure shows an example of how to terminate the network.

6.10. SENSbus Connection

The unit is equipped with two SENSbus RJ45 ports. This connection is used to interconnect SENS specific

devices.

WARNING:

DO NOT PLUG ETHERNET INTO THIS CONNECTION

SENS SuperTorque™8Z Technical Manual

19

6.10.1. Parallel/Load Share Connection—Optional

Multiple 8Z units may be connected in parallel to provide redundancy and increased capacity.

Connect a network cable from one unit to another using the SENSbus RJ45 port on each unit to

automatically initiate load sharing. For proper load share operation, a 120-ohm terminator is

required at both ends of the SENSbus connection. Connect DC outputs from each unit in parallel

to engine starter or DC bus. Connect AC input jumper from one unit to another using AC input

and AC pass-through connectors. Paralleling kits are available to order separately (SENS p/n

209665-20 for end-to-end mounting, p/n 209665-21 for side-by-side mounting).

6.10.2. Remote Alarm/Communications Panel Accessory Connection—Optional

The optional remote alarm/communications panel accessory provides the ability to adjust and

communicate with multiple units using one external device. The remote panel accessory may be

configured with different alarm relay assignments than the alarm relays native to the unit.

Connect a straight-thru splitter to the RJ45 SENSbus port on the remote panel. Place a 120-ohm

terminator in one of the positions on the remote panel splitter to ensure a terminator is located

at both ends of the communications bus. Connect the remote panel to the 8Z unit using a

network cable from the SENSbus RJ45 port on the unit to the remote panel splitter. Ensure a

terminator remains in another SENSbus RJ45 port on the 8Z unit.

6.11. USB Connection

The unit is equipped with a USB-C connector for monitoring and configuration via the SENS Setup

Utility.

6.12. Verify Connections

6.12.1. Verify that all connections are secure and in the proper locations. Tighten all unused screws on

terminal blocks to secure them against vibration.

6.12.2. Ensure all wires are routed in a way that the field cover or other objects will not pinch or damage

them.

SENS SuperTorque™8Z Technical Manual

20

7START-UP PROCEDURE

7.1. Connect DC Output

Connect DC wires from 8Z unit to engine starter / DC bus (see section 6.4). The unit is configured at the

factory and requires no adjustments before operating.

7.2. Apply AC Power

Connect AC power to 8Z unit to start charging internal battery (see section 6.5). Charge for 8 hours

minimum prior to placing into service.

Depending on the battery state of charge, the unit may go into current limit upon initial AC connection.

In this case, the output voltage will be reduced as the internal charger operates in constant current

mode. As the battery is charged, the charging current demand will taper to a value below the current

limit setpoint and the internal charger will revert to constant voltage output. Operation will continue in

boost mode for a variable time ranging from a few minutes to several hours depending on state of

charge of the batteries.

WARNING:

DO NOT LEAVE AC DISCONNECTED.

TO AVOID BATTERY DAMAGE, DO NOT DRAIN BATTERY BELOW

10.5VDC (12V NOMINAL SYSTEMS) OR 21.0VDC (24V NOMINAL SYSTEMS).

7.3. Connect Alarms and Communications

Connect alarm and communications wiring (see section 6.7). Refer to the label on the field wiring end of

the unit for alarm relay assignments. Review and adjust alarm relay assignments and communications

settings using the front panel keypad (optional) or the SENS Setup Utility. See section 9.6 for additional

details on keypad navigation.

Table of contents

Popular Controllers manuals by other brands

Kantech

Kantech Door Controller Innovative and Powerful... installation manual

SMC Networks

SMC Networks LECP7-XB54 Series Operation manual

Rosslare

Rosslare AYC-Q54B Installation and programming manual

Frymaster

Frymaster 3000 Training manual

BENDIX

BENDIX EC-13 TRAILER ANTILOCK CONTROL manual

WURM

WURM AHC-XP quick start guide

Belimo

Belimo LRB24-SR-T Wiring diagrams

Technifor

Technifor XF510Cr Operating and maintenance manual

Omron

Omron SYSMAC CS1W-EIP21 Operation manual

YASKAWA

YASKAWA OYMC V1000 Programming manual

CentraLine

CentraLine MERLIN NX Series Installation & commissioning instructions

Pego

Pego PLUS 100 THR Use and maintenance manual