SENSIRION STS32-DIS User manual

www.sensirion.com / D1 Version 3 –December 2022 1/24

STS32/33-DIS

3th Generation, High-Reliability, Certified

Digital Temperature Sensor

Features

•Accuracy ±0.4 °C

•VDD = 2.15 V … 5.5 V

•Low drift, <0.01 °C per year

•Sensor-specific calibration certificate acc. to

ISO 17025:2017, 3-point temp. calibration

•Operating range: −40…125 °C

•True NIST-traceability, unique serial number

•JEDEC JESD47 qualification

•I2C FM, CRC checksum, multip. I2C addr.

•Tiny 8-pin DFN package with ALERT pin

General Description

The STS32/33-DIS are Sensirion’s new low-drift digital calibrated and ISO17025 certified

temperature sensors. Both rely on the industry proven CMOSens® technology, enabling

increased computational power, reliability and improved accuracy specifications compared to

its predecessors. Itsfunctionality includes enhanced signal processing, two distinctive and user

selectable I2C addresses and communication speeds of up to 1 MHz. The DFN package has

a footprint of 2.5 x 2.5 mm2while keeping a height of 0.9 mm. Every STS32 or STS33 is

identified by its unique serial number and is supplied with an ISO17025-accredited calibration

certificate. The calibration certificate comprises three temperatures, −30 °C, 5 °C, and 70 °C.

In terms of communication, electrical specifications, and footprint, the SHT33-DIS is fully identical

with the STS3x-DIS.

Device Overview

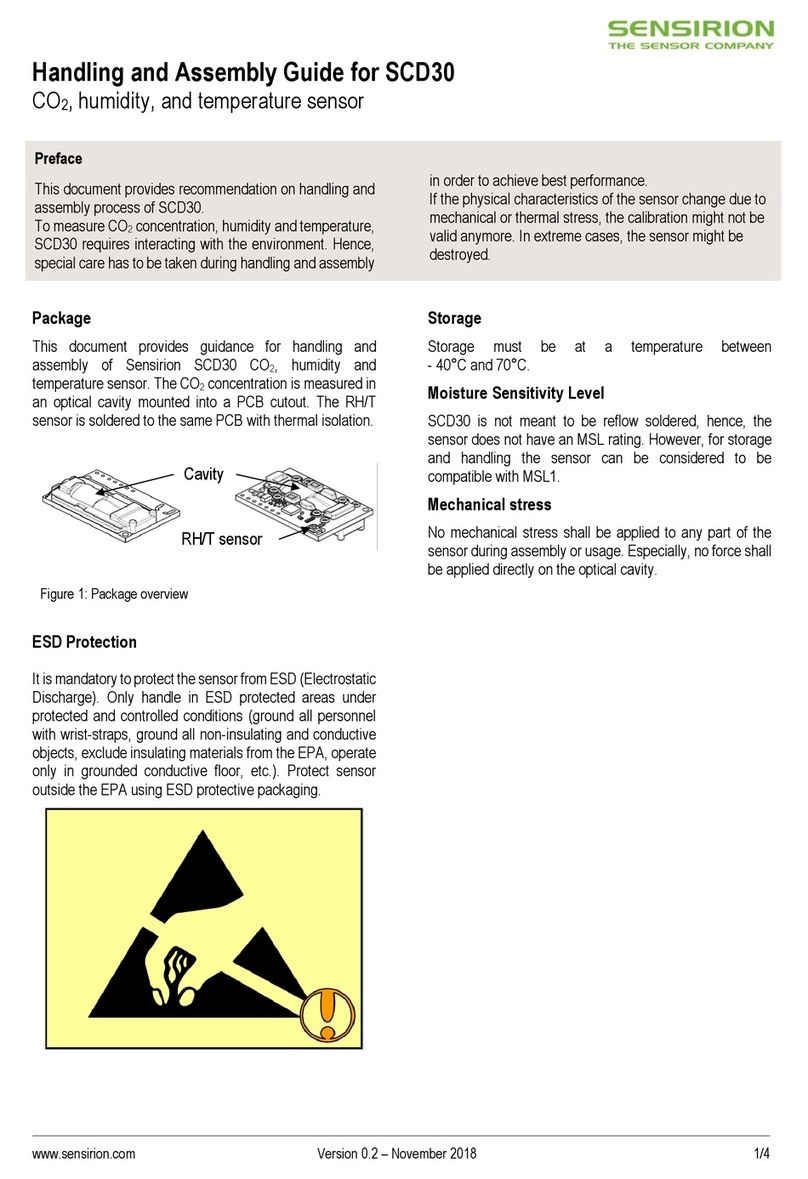

Functional Block Diagram

Products

Details

STS32-DIS

ISO17025 3-point calibration certificate

accuracy profile 1

STS33-DIS

ISO17025 3-point calibration certificate

accuracy profile 2

Full product list on page 22

SCAN ME to give feedback and help us to

improve this document. —Thank you!

www.sensirion.com / D1 Version 3 –December 2022 2/24

Contents

Features........................................................................................................................................................................1

General Description...................................................................................................................................................1

Device Overview.........................................................................................................................................................1

Functional Block Diagram........................................................................................................................................1

Contents........................................................................................................................................................................2

1 Sensor Performance..............................................................................................................................................4

1.1 Temperature.....................................................................................................................................................4

1.2 ISO17025 certification with 3-point calibration data.............................................................................5

2 Electrical Specifications........................................................................................................................................6

2.1 Electrical Characteristics..............................................................................................................................6

2.2 Timings...............................................................................................................................................................7

2.3 Absolute Maximum Ratings.........................................................................................................................7

3 Pin Assignment........................................................................................................................................................8

3.1 Power Pins (VDD, VSS) ...............................................................................................................................8

3.2 Serial Clock and Serial Data (SCL, SDA)...............................................................................................8

3.3 Die Pad (center pad)......................................................................................................................................9

3.4 ADDR Pin..........................................................................................................................................................9

3.5 ALERT Pin........................................................................................................................................................9

3.6 nRESET Pin .....................................................................................................................................................9

4 Operation and Communication.........................................................................................................................10

4.1 Power-Up and Communication Start......................................................................................................10

4.2 Starting a Measurement.............................................................................................................................10

4.3 Measurement Commands for Single Shot Data Acquisition...........................................................10

4.4 Readout of Measurement Results for Single Shot Method.............................................................11

4.5 Measurement Commands for Periodic Data Acquisition Mode......................................................11

4.6 Readout of Measurement Results for Periodic Mode........................................................................12

4.7 Break command/ Stop Periodic Data Acquisition Mode...................................................................13

4.8 Reset.................................................................................................................................................................13

4.9 Heater...............................................................................................................................................................14

4.10 Status Register............................................................................................................................................15

4.11 Serial Number..............................................................................................................................................15

4.12 Checksum Calculation..............................................................................................................................17

4.13 Conversion Signal Output........................................................................................................................17

4.14 Communication Timing.............................................................................................................................18

5 Packaging................................................................................................................................................................19

5.1 Traceabilty.......................................................................................................................................................19

5.2 Package Outline............................................................................................................................................19

5.3 Land Pattern...................................................................................................................................................20

6 Shipping Package.................................................................................................................................................21

www.sensirion.com / D1 Version 3 –December 2022 3/24

7 Quality and Material Contents...........................................................................................................................21

8 Product Nomenclature.........................................................................................................................................22

9 Ordering Information............................................................................................................................................22

10 Bibliography..........................................................................................................................................................22

11 Revision History..................................................................................................................................................23

www.sensirion.com / D1 Version 3 –December 2022 4/24

1 Sensor Performance

Every STS33/32 is individually tested and calibrated and is identifiable by its unique serial number

(see section 4.11 for details on the serial number). For the calibration, Sensirion uses transfer

standards, which are subject to a scheduled calibration procedure. The calibration of the reference,

used for the calibration of the transfer standards, is NIST traceable through an ISO/IEC 17025

accredited laboratory.

1.1 Temperature

Parameter

Conditions

Value

Units

STS32 Accuracy

max. 0°C to 65°C

0.4

°C

max.

See Figure 1

-

STS33 T Accuracy

max. −30°C to 70°C

0.48

°C

max.

See Figure 1

-

Repeatability1

high

0.04

°C

medium

0.08

°C

low

0.15

°C

Resolution

-

0.01

°C

Specified range

-

–40 to +125

°C

Response time2

63%

>2

s

Long-term drift

typ.

<0.01

°C/y

Table 1. General temperature sensor specifications.

Figure 1. Maximal Temperature accuracy of the STS32 (left) and STS33 (right), respectively. The green lines

represent the calibration points for ISO-17025 certification.

1

The stated repeatability is 3 times the standard deviation (3σ) of multiple consecutive measurements at the stated repeatability and at constant ambient conditions.

It is a measure for the noise on the physical sensor output.

2

Temperature response time depends on heat conductivity of sensor substrate and design-in of sensor in application. [2]

±0.0

±0.5

±1.0

±1.5

-40 -20 0 20 40 60 80 100 120

Temperature (°C)

STS32

maximal tolerance

DT (°C)

±0.0

±0.5

±1.0

±1.5

-40 -20 0 20 40 60 80 100 120

Temperature (°C)

STS33

maximal tolerance

DT (°C)

www.sensirion.com / D1 Version 3 –December 2022 5/24

1.2 ISO17025 certification with 3-point calibration data

All STS32 and STS33 can be uniquely identified by their serial number (read out command see

paragraph 4.11). For each sensor an individual 3-point calibration is performed, accredited to

ISO/IEC 17025:2017. The accreditation is performed and granted by the Swiss Accreditation

Service (SAS), a public institution of the Swiss Government. The accreditation is documented on

the SAS website under the name SCS 0158 and can be downloaded from this link

3

. The three

calibration temperatures are T = −30 °C, T = 5 °C, and T = 70 °C. Measurement uncertainties and

decision rules according to the SAS are given in Table 2.

Metrological traceability of the calibration is in accordance to ch. 6.5 of ISO/IEC 17025:2017,

encompassing but not limited to NIST traceability or traceability to other national metrology

institutes, according to the CIPM Mutual Recognition Arrangement (CIPM MRA).

Reel-wise calibration certificates and data for each STS32/33 can be downloaded through a web-

client and through an API from libellus.sensirion.com, which allows for efficient processing by

automated systems. For detailed documentation, kindly refer to the Libellus documentation.

Temperature

Expanded measurement uncertainty (k=2)*

Decision rule

−30 °C

0.40 °C

Shared risk (JCGM 106:2010, 8.2)

5 °C

0.20 °C

Shared risk (JCGM 106:2010, 8.2)

70 °C

0.20 °C

Shared risk (JCGM 106:2010, 8.2)

Table 2. Measurement uncertainty and decision rule for the accredited calibration according to Swiss

Accreditation Service (SAS). *Measurement uncertainties represent a confidence level of 95% using a

coverage factor of k = 2.

3

https://www.sas.admin.ch/sas/en/home/akkreditiertestellen/akkrstellensuchesas.exturl.html/aHR0cHM6Ly9zYXNkYi5jbGllbnRzLmxpaXAuY2gvc2VhcmNoLm/h0bWw=.html?csrfmiddlewa

retoken=2Ie2f1aOTUge9YQ3nuaL0ILEYS980ZMdH60doLdY8Nh1sHC3wpw3YvLLVBezmDRn&lang=en&search_term=0158&accreditation_type=2&submit=Start+search

www.sensirion.com / D1 Version 3 –December 2022 6/24

2 Electrical Specifications

2.1 Electrical Characteristics

Parameter

Symbol

Condition

Min.

Typ.

Max.

Units

Comments

Supply

voltage

VDD

2.15

3.3

5.5

V

Power-

up/down level

VPOR

1.8

2.1

2.15

V

Slew rate

change of the

supply voltage

VDD,slew

-

-

20

V/ms

Voltage changes

on the VDD line

between VDD,min

and VDD,max should

be slower than the

maximum slew

rate; faster slew

rates may lead to

reset;

Supply current

IDD

idle state

(single shot

mode)

T = 25 °C

-

0.2

2.0

µA

Current when

sensor is not

performing a

measurement

during single shot

mode

idle state

(single shot

mode)

T = 125 °C

-

-

6.0

idle state

(periodic data

acquisition

mode)

-

45

-

µA

Current when

sensor is not

performing a

measurement

during periodic data

acquisition mode

Measuring

-

600

1500

µA

Current

consumption while

sensor is

measuring

Average

-

1.7

-

µA

Current

consumption

(operation with one

measurement per

second at lowest

repeatability, single

shot mode)

Alert Output

driving

strength

IOH

1.5x

VDD

mA

See also section

3.5

Heater power

PHeater

Heater running

3.6

-

33

mW

Depending on the

supply voltage

Table 3. Electrical specifications, typical values are valid for T = 25 °C, min. & max. values for

T = −40 °C …125 °C.

www.sensirion.com / D1 Version 3 –December 2022 7/24

2.2 Timings

Parameter

Symbol

Conditions

Min.

Typ.

Max.

Units

Comments

Power-up time

tPU

After hard reset,

VDD ≥ VPOR

-

0.5

1.5

ms

Time between VDD

reaching VPOR and sensor

entering idle state

Soft reset time

tSR

After soft reset

-

-

1

ms

Time between ACK of soft

reset command and

sensor entering idle state.

Measurement

duration

tMEAS,l

Low repeatability

-

2.5

4.5

ms

The three repeatability

modes differ with respect

to measurement duration,

noise level and energy

consumption

tMEAS,m

Med. repeatability

-

4.5

6.5

ms

tMEAS,h

High repeatability

-

12.5

15.5

ms

Duration of reset

pulse

tRESETN

1

-

-

µs

See section 4.8

Table 4. System timing specifications (valid from −40 °C to 125 °C and VDD,min … VDD, max ).

2.3 Absolute Maximum Ratings

Stress levels beyond those listed in Table 5 may cause permanent damage or affect the reliability

of the device. These are stress ratings only and functional operation of the device at these

conditions is not guaranteed. Ratings are only tested each at a time.

Parameter

Rating

Supply voltage VDD

−0.3 V to 6 V

Max. voltage on any pin

VSS −0.3 V … VDD +0.3 V

Input current on any pin

±100 mA

Operating temperature range

−40 °C … 125 °C

Storage temperature range4

−40 °C …150 °C

ESD HBM5

4 kV

ESD CDM6

750 V

Table 5. Absolute maximum ratings. Values may be only applied for short time periods.

4

The recommended storage temperature range is 10-50 °C. Please consult the document “SHTxx Handling Instructions” [4] for more information.

5

According to ANSI/ESDA/JEDEC JS-001-2014; AEC-Q100-002.

6

According to ANSI/ESD S5.3.1-2009; AEC-Q100-011.

www.sensirion.com / D1 Version 3 –December 2022 8/24

3 Pin Assignment

The STS32/33-DIS come in a tiny 8-pin DFN package –see Table 6.

Pin

Name

Comments

1

SDA

Serial data; input / output

2

ADDR

Address pin; input; connect to either logic high or low, do not leave

floating

3

ALERT

Indicates alarm condition; output; must be left floating if unused

4

SCL

Serial clock; input / output

5

VDD

Supply voltage; input

6

nRESET

Reset pin active low; input; if not used it is recommended to be left

floating; can be connected to VDD with a series resistor of R ≥2 kΩ.

7

R

No electrical function; to be connected to VSS

8

VSS

Ground

Table 6. STS32/33-DIS pin assignment (transparent top view). Dashed lines are only visible if viewed from

below. The die pad is internally connected to VSS.

3.1 Power Pins (VDD, VSS)

The electrical specifications of the STS32/33-DIS are shown Table 3. The power supply pins must

be decoupled with a 100 nF capacitor that shall be placed as close to the sensor as possible –see

Figure 2 for a typical application circuit.

3.2 Serial Clock and Serial Data (SCL, SDA)

SCL is used to synchronize the communication between microcontroller and the sensor. The clock

frequency can be freely chosen between 0 to 1000 kHz. Commands with clock stretching according

to I2C Standard

7

are supported. The SDA pin is used to transfer data to and from the sensor.

Communication with frequencies up to 400 kHz must meet the I2C Fast Mode7standard.

Communication frequencies up to 1 MHz are supported following the specifications given in Table

20. Both SCL and SDA lines are open-drain I/Os with diodes to VDD and VSS. They should be

connected to external pull-up resistors (please refer to Figure 2). A device on the I2C bus must

only drive a line to ground. The external pull-up resistors (e.g. Rp = 10 kΩ) are required to pull the

signal high. For dimensioning resistor sizes please takebus capacity andcommunicationfrequency

into account (see for example Section 7.1 of NXPs I2C Manual for more details [1]). It should be

noted that pull-up resistors may be included in I/O circuits of microcontrollers. It is recommended

to wire the sensor according to the application circuit as shown in Figure 2.

1

2

3

45

8

7

6

www.sensirion.com / D1 Version 3 –December 2022 9/24

Figure 2. Typical application circuit. Please note that the positioning of the pins does not reflect the position

on the real sensor. This is shown in Table 6.

3.3 Die Pad (center pad)

The die pad or center pad is visible from below and located in the center of the package. It is

electrically connected to VSS. Hence electrical considerations do not impose constraints on the

wiring of the die pad. However, due to mechanical reasons it is recommended to solder the center

pad to the PCB. For more information on design-in, please refer to the document “SHTxx_STSxx

Design Guide” [2].

3.4 ADDR Pin

Through the appropriate wiring of the ADDR pin the I2C address can be selected (see Table 7 for

the respective addresses). The ADDR pin can either be connected to logic high or logic low. The

address of the sensor can be changed dynamically during operation by switching the level on the

ADDR pin. The only constraint is that the level has to stay constant starting from the I2C start

condition until the communication is finished. This allows to connect more than two STS32/33-DIS

onto the same bus. The dynamical switching requires individual ADDR lines to the sensors. Please

note that the I2C address is represented through the 7 MSBs of the I2C read or write header. The

LSB switches between read or write header. The wiring for the default address is shown Table 7

and Figure 2. The ADDR pin must not be left floating. Please note that only the 7 MSBs of the I2C

Read/Write header constitute the I2C Address.

STS32/33-DIS

I2C Address in Hex. representation

Condition

I2C address A

0x4A (default)

ADDR (pin 2) connected to logic low

I2C address B

0x4B

ADDR (pin 2) connected to logic high

Table 7. I2C Device addresses

3.5 ALERT Pin

The alert pin may be used to connect to the interrupt pin of a microcontroller. The output of the pin

depends on the value of the temperature reading relative to programmable limits. Its function is

explained in a separate application note. If not used, this pin must be left floating. The pin switches

high when alert conditions are met. The maximum driving loads are listed in Table 3. Be aware

that self-heating might occur, depending on the amount of current that flows. Self-heating can be

prevented if the Alert Pin is only used to switch a transistor.

3.6 nRESET Pin

The nReset pin may be used to generate a reset of the sensor. A minimum pulse duration of 1 µs

is required to reliably trigger a reset of the sensor. Its function is explained in more detail in section

4. If not used it is recommended to leave the pin floating or to connect it to VDD with a series

VDD

RR

PP

100nF

ADDR(2)

ALERT(3)

die

pad R(7)

SDA(1)

SCL(4)

VDD(5)

VSS(8)

nRESET(6)

www.sensirion.com / D1 Version 3 –December 2022 10/24

resistor of R≥2 kΩ. However, the nRESET pin is internally connectedto VDD with a pull up resistor

of R = 50 kΩ (typ.).

4 Operation and Communication

The STS32/33-DIS supports I2C fast mode (and frequencies up to 1000 kHz). Clock stretching can

be enabled and disabled through the appropriate user command. For detailed information on the

I2C protocol, refer to NXP I2C-bus specification [1]. After sending a command to the sensor a

minimal waiting time of 1 ms is needed before another command can be received by the sensor.

All STS32/33-DIS commands and data are mapped to a 16-bit address space. Additionally, data

and commands are protected with a CRC checksum. This increases communication reliability. The

16 bits commands to the sensor already include a 3 bit CRC checksum. Data sent from and

received by the sensor is always succeeded by an 8 bit CRC. In write direction it is mandatory to

transmit the checksum, since the STS32/33-DIS only accepts data if it is followed by the correct

checksum. In read direction it is left to the master to read and process the checksum.

4.1 Power-Up and Communication Start

The sensor starts powering-up after reaching the power-up threshold voltage VPOR specified in

Table 3. After reaching this threshold voltage the sensor needs the time tPU to enter idle state. Once

the idle state is entered it is ready to receive commands from the master (microcontroller). Each

transmission sequence begins with a START condition (S) and ends with a STOP condition (P) as

described in the I2C-bus specification. Whenever the sensor is powered up, but not performing a

measurement or communicating, it automatically enters idle state for energy saving. This idle state

cannot be controlled by the user.

4.2 Starting a Measurement

A measurement communication sequence consists of a START condition, the I2C write header (7-

bit I2C device address plus 0 as the write bit) and a 16-bit measurement command. The proper

reception of each byte is indicated by the sensor. It pulls the SDA pin low (ACK bit) after the falling

edge of the 8th SCL clock to indicate the reception. A complete measurement cycle is depicted in

Table 8. With the acknowledgement of the measurement command, the STS32/33-DIS starts

measuring the temperature.

4.3 Measurement Commands for Single Shot Data Acquisition

In this mode one issued measurement command triggers the acquisition of a 16 bit temperature

value. During transmission that value is always followed by a CRC checksum, see section 4.4. In

single shot mode different measurement commands can be selected. The 16 bit commands are

shown in Table 8. They differ with respect to repeatability (low, medium and high) and clock

stretching (enabled or disabled). The repeatability setting influences the measurement duration

and thus the overall energy consumption of the sensor. This is explained in section 2.2.

www.sensirion.com / D1 Version 3 –December 2022 11/24

Condition

Hex. code

Repeatability

Clock stretching

MSB

LSB

High

enabled

0x2C

06

Medium

0D

Low

10

High

disabled

0x24

00

Medium

0B

Low

16

e.g. 0x2C06: high repeatability measurement with clock stretching enabled

Table 8. Measurement commands in single shot mode. The first “SCL free” block indicates a minimal waiting

time of 1 ms (clear blocks are controlled by the microcontroller, grey blocks by the sensor).

4.4 Readout of Measurement Results for Single Shot Method

After the sensor has completed the measurement, the master can read the measurement result by

sending a START condition followed by an I2C read header. The sensor will acknowledge the

reception of the read header and send two bytes of data (temperature) followed by a one-byte CRC

checksum. Each byte must be acknowledged by the microcontroller with an ACK condition for the

sensor to continue sending data. If the sensor does not receive an ACK from the master after any

byte of data, it will not continue sending data. After having received the checksum for the

temperature value a NACK and stop condition should be sent (see Table 8). The I2C master can

abort the read transfer with a NACK condition after any data byte if it is not interested in the CRC.

No Clock Stretching

When a command without clock stretching has been issued, the sensor responds to a read header

with a not acknowledge (NACK), if no data is present.

Clock Stretching

When a command with clock stretching has been issued, the sensor responds to a read header

with an ACK and subsequently pulls down the SCL line. The SCL line is pulled down until the

measurement is complete. As soon as the measurement is complete, the sensor releases the SCL

line and sends the measurement results.

4.5 Measurement Commands for Periodic Data Acquisition Mode

In this mode one issued measurement command yields a stream of 16 bit temperature values. In

periodic mode different measurement commands can be selected. The corresponding 16 bit

commands are shown in Table 9. They differ with respect to repeatability (low, medium and high)

and data acquisition frequency (0.5, 1, 2, 4 & 10 measurements per second, mps). Clock stretching

cannot be selected in this mode.

SCL free

SCL free

I2C Address

Temperature MSB

16-bit command

I2C write header

I2C read header

I2C Address

I2C Address

I2C read header

measurement

completed

measurement

ongoing

measurement

ongoing

measurement

ongoing

SCL pulled low

Temperature LSB

16-bit temperature value Checksum

S

S

W P

CRC

P

R

R

clock stretching

disabled

clock stretching

enabled

ACK

ACK

ACK

Command LSBCommand MSB

S

NACK

ACK

ACK

ACK NACK

P

ACK

www.sensirion.com / D1 Version 3 –December 2022 12/24

The data acquisition frequency and the repeatability setting influence the measurement duration

and the current consumption of the sensor. This is explained in 2.2 of this datasheet. If a

measurement command is issued, while the sensor is busy with a measurement (measurement

durations see Table 4), it is recommended to issue a break command first (see section 4.7). Upon

reception of the break command the sensor will abort the ongoing measurement and enter the

single shot mode.

Condition

Hex. code

Repeatability

mps

MSB

LSB

High

0.5

0x20

32

Medium

24

Low

2F

High

1

0x21

30

Medium

26

Low

2D

High

2

0x22

36

Medium

20

Low

2B

High

4

0x23

34

Medium

22

Low

29

High

10

0x27

37

Medium

21

Low

2A

e.g. 0x2130: one high repeatability measurement per second (mps)

Table 9. Measurement commands for periodic data acquisition mode (clear blocks are controlled by the

microcontroller, grey blocks by the sensor). N.B.: At the highest mps setting self-heating of the sensor might

occur.

4.6 Readout of Measurement Results for Periodic Mode

Transmission of the measurement data can be initiated through the fetch data command shown in

Table 10. If no measurement data is present the I2C read header is responded with a NACK (Bit

9 in Table 9. Measurement commands for periodic data acquisition mode (clear blocks are

controlled by the microcontroller, grey blocks by the sensor). N.B.: At the highest mps setting self-

heating of the sensor might occur.) and the communication stops. After the read-out command

fetch data has been issued, the data memory is cleared, i.e. no measurement data is present.

www.sensirion.com / D1 Version 3 –December 2022 13/24

Command

Hex code

Fetch Data

0x E0 00

Table 10.Fetch Data command (clear blocks are controlled by the microcontroller, grey blocks by the sensor)

4.7 Break command/ Stop Periodic Data Acquisition Mode

The periodic data acquisition mode can be stopped using the break command shown in Table 11.

It is recommended to stop the periodic data acquisition prior to sending another command (except

Fetch Data command) using the break command. Upon reception of the break command the

sensor will abort the ongoing measurement and enter the single shot mode. This takes 1 ms.

Command

Hex Code

Break

0x3093

Table 11.Break command (clear blocks are controlled by the microcontroller, grey blocks by the sensor).

4.8 Reset

A system reset of the STS32/33-DIS can be generated externally by issuing a command (soft reset)

or by sending a pulse to the dedicated reset pin (nReset pin). Additionally, a system reset is

generated internally during power-up. During the reset procedure the sensor will not process

commands. In order to achieve a full reset of the sensor without removing the power supply, it is

recommended to use the nRESET pin of the STS32/33-DIS.

Interface Reset

If communication with thedevice is lost, the following signal sequence will reset the serial interface:

While leaving SDA high, toggle SCL nine or more times. This must be followed by a Transmission

Start sequence preceding the next command. This sequence resets the interface only. The status

register preserves its content.

Soft Reset / Re-Initialization

The STS32/33-DIS provides a soft reset mechanism that forces the system into a well-defined state

without removing the power supply. When the system is in idle state the soft reset command can

be sent to the STS32/33-DIS. This triggers the sensor to reset its system controller and reloads

calibration data from the memory. In order to start the soft reset procedure the command as shown

in Table 12 should be sent. It is worth noting that the sensor reloads calibration data prior to every

measurement by default.

I2C Address

Temperature MSB

16-bit command

I2C write header

I2C read header

I2C Address

Temperature LSB

16-bit temperature value Checksum

S W P

CRC

R

ACK

ACK

ACK

Command LSBCommand MSB

S

ACK

ACK

ACK

P

NACK

www.sensirion.com / D1 Version 3 –December 2022 14/24

Command

Hex Code

Soft Reset

0x30A2

Table 12. Soft reset command (clear blocks are controlled by the microcontroller, grey blocks by the sensor)

Reset through General Call

Additionally, a reset of the sensor can also be generated using the “general call” mode according

to I2C-bus specification. This generates a reset which is functionally identical to using the nReset

pin. It is importantto understand that a reset generated inthis way is notdevice specific. All devices

on the same I2C bus that support the general call mode will perform a reset. Additionally, this

command only works when the sensor can process I2C commands. The appropriate command

consists of two bytes and is shown in Table 13.

Command

Code

Address byte

0x00

Second byte

0x06

Reset command using the

general call address

0x0006

Table 13.Reset through the general call address (clear blocks are controlled by the microcontroller, grey

blocks by the sensor).

Reset through the nReset Pin

Pulling the nReset pin low (see Table 6) generates a reset similar to a hard reset. The nReset pin

is internally connected to VDD through a pull-up resistor and hence active low. The nReset pin has

to be pulled low for a minimum of 1 µs to generate a reset of the sensor.

Hard Reset

A hard reset is achieved by switching the supply voltage to the VDD Pin off and then on again. In

order to prevent powering the sensor over the ESD diodes, the voltage to pins 1 (SDA), 4 (SCL)

and 2 (ADDR) also needs to be removed.

4.9 Heater

The STS32/33 is equipped with an internal heater, which is meant for plausibility checking only.

The temperature increase achieved by the heater depends on various parameters and lies in the

range of a few degrees centigrade. It can be switched on and off by command, see table below.

The status is listed in the status register. After a reset the heater is disabled (default condition).

www.sensirion.com / D1 Version 3 –December 2022 15/24

Command

Hex Code

MSB

LSB

Heater Enable

0x30

6D

Heater Disabled

66

Table 14.Heater command (clear blocks are controlled by the microcontroller, grey blocks by the sensor)

4.10 Status Register

The status register contains information on the operational status of the heater, the alert mode and

on the execution status of the last command and the last write sequence. The command to read

out the status register is shown in Table 15 whereas a description of the content can be found in

Table 18.

Command

Hex code

Read Out of status register

0xF32D

Table 15.Command to read out the status register (clear blocks are controlled by the microcontroller, grey

blocks by the sensor)

Clear Status Register

All flags (Bit 15, 10, 4) in the status register can be cleared (set to zero) by sending the command

shown in Table 16.Command to clear the status register (clear blocks are controlled by the

microcontroller, grey blocks by the sensor).

Command

Hex Code

Clear status register

0x 30 41

Table 16.Command to clear the status register (clear blocks are controlled by the microcontroller, grey

blocks by the sensor)

4.11 Serial Number

The Serial number allows for an unambiguous identification of each individual device, it is stored

in the one-time programmable (OTP) memory of the chip. Table 17 shows the command structure

to read the serial number. After issuing the measurement command and sending the ACK bit the

sensor needs the time tIDLE = 1 ms to respond to the I2C read header with an ACK bit. Hence it is

recommended to wait tIDLE = 1 ms before issuing the read header. The Get Serial Number

command returns two words, every word is followed by a CRC Checksum. Together the 2 words

(SNB_3 to SNB_0 in Table 17, SNB_0 is the LSB,whereas SNB_3 is the MSB) constitute a unique

serial number with a length of 32 bit. This serial number can be used to individually identify each

sensor.

www.sensirion.com / D1 Version 3 –December 2022 16/24

Command

Hex Code

Get Serial Number

0x 37 80

0x 36 82

Table 17. Command to read out the Serial Number (clear blocks are controlled by the microcontroller, grey

blocks by the sensor)

Bit

Field description

Default value

15

Alert pending status

'0': no pending alerts

'1': at least one pending alert

‘1’

14

Reserved

‘0’

13

Heater status

‘0’ : Heater OFF

‘1’ : Heater ON

‘0’

12:11

Reserved

‘00’

10

T tracking alert

‘0’ : no alert

‘1’ . alert

‘0’

9:5

Reserved

‘xxxxx’

4

System reset detected

'0': no reset detected since last ‘clear status register’

command

'1': reset detected (hard reset, soft reset command or

supply fail)

‘1’

3:2

Reserved

‘00’

1

Command status

'0': last command executed successfully

'1': last command not processed. It was either

invalid, failed the integrated command checksum

‘0’

0

Write data checksum status

'0': checksum of last write transfer was correct

'1': checksum of last write transfer failed

‘0’

Table 18. Description of the status register.

ACK

ACK

ACKACK

tIDLE

936

SNB_3 SNB_2 CRC

ACK

ACK

ACK

Serial Number Word 1 Checksum

37 63

SNB_1 SNB_0 CRC

ACK

ACK

ACK

Serial Number Word 2 Checksum

P

SNB_3

I2C Address Command MSB Command LSB

16-bit command16-bit command

I2C write header

I2C read header

I2C Address

S W

SR

1 2 3 4 56 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27

1 2 3456 7 8

ACKACK

9

www.sensirion.com / D1 Version 3 –December 2022 17/24

4.12 Checksum Calculation

The 8-bit CRC checksum transmitted after each data word is generated by a CRC algorithm. Its

properties are displayed in Table 19. The CRC covers the contents of the two previously

transmitted data bytes. To calculatethe checksum only these two previously transmitted data bytes

are used.

Property

Value

Name

CRC-8

Width

8 bit

Protected data

read and/or write data

Polynomial

0x31 (x8+ x5+ x4+ 1)

Initialization

0xFF

Reflect input

False

Reflect output

False

Final XOR

0x00

Examples

CRC (0xBEEF) = 0x92

Table 19.I2C CRC properties

4.13 Conversion Signal Output

Measurement data is always transferred as 16-bit values (unsigned integer). These values are

already linearized and compensated for supply voltage effects. Converting those raw values into a

physical scale can be achieved using the following formulas.

Temperature conversion formula (result in °C & °F):

( 1 )

( 2 )

STdenotes the raw sensor output for temperature. The formulas work only correctly when STis

used in decimal representation

www.sensirion.com / D1 Version 3 –December 2022 18/24

4.14 Communication Timing

Parameter

Symbol

Conditions

Min.

Typ

Max.

Units

Comments

SCL clock frequency

fSCL

0

-

1000

kHz

Hold time (repeated)

START condition

tHD;STA

After this period,

the first

clock pulse is

generated

0.24

-

-

µs

LOW period of the SCL

clock

tLOW

0.53

-

-

µs

HIGH period of the SCL

clock

tHIGH

0.26

-

-

µs

SDA hold time

tHD;DAT

0

-

250

ns

Transmitting data

0

-

-

ns

Receiving data

SDA set-up time

tSU;DAT

100

-

-

ns

SCL/SDA rise time

tR

-

-

300

ns

SCL/SDA fall time

tF

-

-

300

ns

SDA valid time

tVD;DAT

-

-

0.9

µs

Set-up time for a

repeated START

condition

tSU;STA

0.26

-

-

µs

Set-up time for STOP

condition

tSU;STO

0.26

-

-

µs

Capacitive load on bus

line

CB

-

-

400

pF

Low level input voltage

VIL

0

-

0.3xVDD

V

High level input voltage

VIH

0.7xVDD

-

1xVDD

V

Low level output voltage

VOL

3 mA sink current

-

-

0.4

V

Table 20.Timing specifications for I2C communication, valid for T= −40°C … 125°C and VDD,min … VDD, max.

The nomenclature above is according to the I2C specification (UM10204, Rev. 6, April 4, 2014). [1]

Figure 3. Timing diagram for digital input/output pads. SDA directions are seen from the sensor. Bold SDA

lines are controlled by the sensor, plain SDA lines are controlled by the micro-controller. Note that SDA valid

read time is triggered by falling edge of preceding toggle.

SCL

70%

30%

tLOW

1/fSCL

tHIGH

tR

tF

SDA

70%

30%

tSU;DAT

tHD;DAT

DATA IN

tR

SDA

70%

30%

DATA OUT

tVD;DAT

tF

www.sensirion.com / D1 Version 3 –December 2022 19/24

5 Packaging

STS32/33-DIS sensors are provided in a dual flat no leads (DFN) package. The sensor chip is

made of silicon and is mounted to a lead frame. The latter is made of Cu plated with Ni/Pd/Au. Chip

and lead frame are overmolded by an epoxy-based mold compound leaving the central die pad

and I/O pins exposed for mechanical and electrical connection. Please note that the side walls of

the sensor are diced and therefore these diced lead frame surfaces are not covered with the

respective plating. The package follows JEDEC publication 95, design registration 4.20, small scale

plastic quad and dual inline, square and rectangular, No-LEAD packages (with optional thermal

enhancements) small scale (QFN/SON), Issue D.01, September 2009. STS32/33-DIS has a

Moisture Sensitivity Level (MSL) of 1, according to IPC/JEDEC J-STD-020. At the same time, it is

recommended to further process the sensors within one year after date of delivery.

5.1 Traceabilty

All STS32/33-DIS sensors are laser marked for easy identification and traceability. The marking on

the sensor top side consists of a pin-1 indicator and two lines of text. The top line carries the product

name. The bottom line consists of 6 letters. The first two digits XY (=DI) describe the output mode.

The third letter (A) represents the manufacturing year (4 = 2014, 5 = 2015, etc). The last three

digits (BCD) represent an alphanumeric tracking code. That code can be decoded by Sensirion

only and allows for tracking on batch level through production, calibration, and testing –and will be

provided upon justified request. If viewed from below pin 1 is indicated by triangular shaped cut in

the otherwise rectangular die pad. The dimensions of the triangular cut are shown in Figure 5.

Dimensional drawing of STS32/33-DIS sensor package through the labels T1 & T2.

Figure 4. Top view of the STS32/33-DIS illustrating the laser marking.

5.2 Package Outline

Figure 5. Dimensional drawing of STS32/33-DIS sensor package

STS32

XYABCD

www.sensirion.com / D1 Version 3 –December 2022 20/24

Parameter

Symbol

Min

Nom.

Max

Units

Comments

Package height

A

0.8

0.9

1

mm

Leadframe height

A3

-

0.2

-

mm

Pad width

b

0.2

0.25

0.3

mm

Package width

D

2.4

2.5

2.6

mm

Center pad length

D2

1

1.1

1.2

mm

Package length

E

2.4

2.5

2.6

mm

Center pad width

E2

1.7

1.8

1.9

mm

Pad pitch

e

-

0.5

-

mm

Pad length

L

0.25

0.35

0.45

mm

Center pad marking

T1xT2

-

0.3x45°

-

mm

indicates the position of pin 1

Table 21.Package outline.

5.3 Land Pattern

The land pattern (Figure 6) is understood to be the open metal areas on the PCB, onto which the

DFN pads are soldered. The solder mask is understood to be the insulatinglayer on top of the PCB

covering the copper traces. It is recommended to design the solder pads as a Non-Solder Mask

Defined (NSMD) type. For NSMD pads, the solder mask opening should provide a 60 μm to 75 μm

design clearance between any copper pad and solder mask. As the pad pitch is only 0.5 mm we

recommend to have one solder mask opening for all four I/O pads on one side. For solder paste

printing it is recommended to use a laser-cut, stainless steel stencil with electro-polished

trapezoidal walls and with 0.1 or 0.125 mm stencil thickness. The length of the stencil apertures for

the I/O pads should be the same as the PCB pads. However, the position of the stencil apertures

should have an offset of 0.1 mm away from the center of the package. The die pad aperture should

cover about 70% –90% of the die pad area –thus it should have a size of about 0.9 mm x 1.6 mm.

For information on the soldering process and further recommendation on the assembly process

please consult the Application Note SHTxx_STSxx_Assembly_of_SMD_Packages [3], which can

be found on the Sensirion webpage.

Figure 6. Recommended metal land pattern (left) and stencil apertures (right) for the STS32/33-DIS. The

dashed lines represent the outer dimension of the DFN package. The PCB pads (left) and stencil apertures

(right) are indicated through the shaded areas.

Recommended Land Pattern Recommended Stencil Aperture

1.7

0.25

0.551

0.5 0.5 0.5

2.35

0.2 0.9

1.6

0.5 0.5 0.5

0.25

0.55

2.55

0.3

This manual suits for next models

1

Table of contents

Other SENSIRION Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

Powtier Controls

Powtier Controls ACC-6-00 instruction manual

Philio

Philio PAT14 quick start guide

TERMOFOL

TERMOFOL TF-WIFI Mark II installation manual

Tech Controllers

Tech Controllers EU-T-3.1 user manual

RKC INSTRUMENT

RKC INSTRUMENT V-TIO-G instruction manual

Viessmann

Viessmann VITOTROL 100 operating instructions