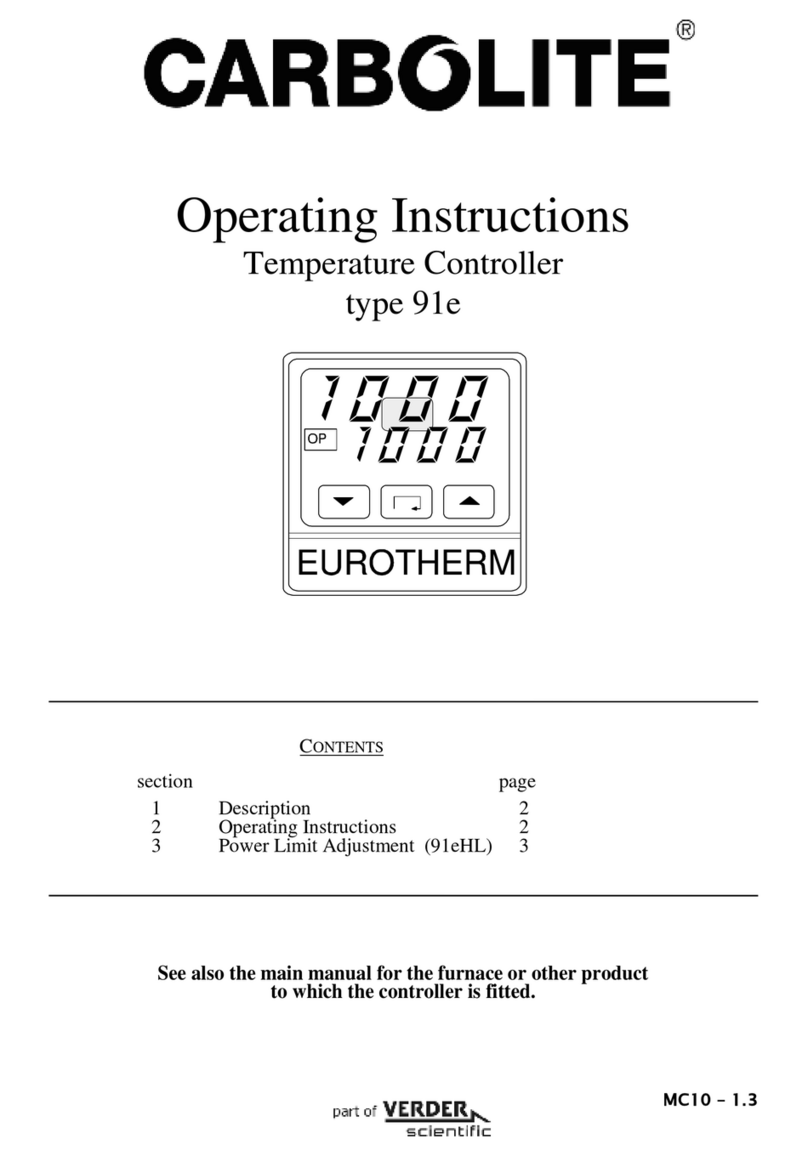

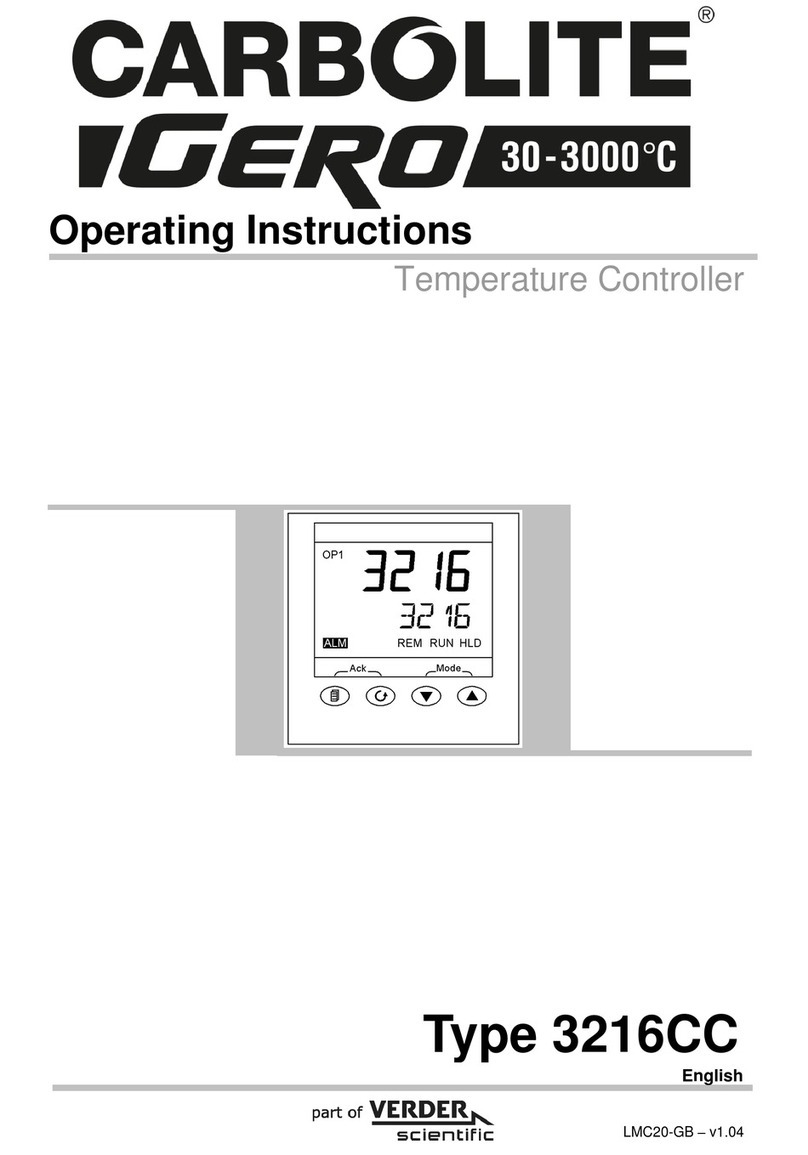

Carbolite Type 301 User manual

Other Carbolite Temperature Controllers manuals

Popular Temperature Controllers manuals by other brands

P.W. KEY

P.W. KEY rt-208gt operating manual

BH Thermal

BH Thermal BriskONE owner's manual

West Control Solutions

West Control Solutions KS 45 Operation Notes

MCS

MCS RITC-15B Operator's manual

SMC Networks

SMC Networks Thermo-con INR-244-639 Operation manual

eltherm

eltherm Ex-TC It Series operating instructions

Omron

Omron C200H-TV Series Operation manual

industrie technik

industrie technik CA1 instructions

KRAL

KRAL EET 32 operating instructions

dixell

dixell XR420C Installing and operating instructions

Opt Lasers

Opt Lasers TEC-8A-24V-PID-HC operating manual

Vaillant

Vaillant VR 92/3 Operating and installation instructions