Sensitron GAS-PRO User manual

GASPRO

SENSITRON

A Halma Company

GAS-PRO

Manual

M07995

SENSITRON S.R.L. - All rights reserved - www. sensitron.it

Multi-gas monitor

Manual

M07995 - Issue 14 July 2020

Sensitron S.r.l., Viale della Repubblica 48, Cornaredo (MI)

TEL. +390293548155 FAX. +390293548089

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 2/47

P. 5 Prologue

P. 5 Gas-Pro Overview

P. 5 Safety Information

P. 8 Unpacking

P. 8 1. Set-up

P. 8 1.1 Prior to use

P. 8 1.2 Gas-Pro orientation

P. 8 1.3 Charging

P. 9 1.4 Fitting a flow plate

P. 10 1.5 Quick view

P. 11 2. Operation

P. 11 2.1 General

P. 11 2.2 Turn on

P. 11 2.3 Pump test

P. 14 2.4 Detecting gas

P. 15 2.4.1 Diusion monitoring

P. 15 2.4.2 Pumped mode

P. 15 2.4.3 Manual sampling

P. 16 2.4.3.1 Using the Hand Aspirator

P. 17 2.5 Alarms

P. 17 2.5.1 Low battery alarm

P. 17 2.5.2 Instantaneous alarm

P. 17 2.5.3 Time weighted average alarm (TWA)

P. 18 2.5.3.1 TWA Resume function

P. 18 2.5.4 Accepting and clearing alarms

P. 19 2.5.5 Sensor types

P. 19 2.5.5.1 Oxygen sensors

P. 19 2.5.5.2 Electro-chemical sensors

P. 20 2.5.5.3 Infra red sensors

P. 20 2.5.5.4 Pellistor sensors

P. 20 2.5.5.5 Pellistor saver mode

P. 20 2.5.5.6 PID

P. 20 2.6 Gas-Pro functions

P. 21 2.6.1 Accessing the user menus

P. 21 2.6.2 Home screen

P. 21 2.6.3 Manual zero

P. 22 2.6.4 Time weighted average

P. 22 2.6.5 Pre-entry check (PEC)

P. 22 2.6.5.1 Starting a Pre-entry check

P. 23 2.6.5.2 Carrying out a Pre-entry check

P. 24 2.6.6 Peak review

P. 25 2.6.7 Pellistor Correction Factor

P. 25 2.6.8 Settings

P. 25 2.6.8.1 User setting

P. 25 2.6.8.2 Pump setting

P. 25 2.6.8.3 Sounder volume

P. 26 2.7 Shut down

P. 26 2.8 Additional Features

P. 26 2.8.1 +ve Safety™

P. 26 2.8.1.1 +ve Safety™ indicator meanings

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 3/47

P. 26 2.8.2 Data and event logging

P. 27 2.8.3 Bump/Pump functionality

P. 27 2.9 Tank Check Mode

P. 27 2.9.1 Dual-Range Operation

P. 29 2.9.2 Dierences with Home Screen

P. 29 2.9.2.1 Instantaneous Alarms

P. 29 2.9.2.2 TWA

P. 29 2.9.2.3 Pre-Entry Check (PEC)

P. 29 2.9.2.4 Confidence Tone

P. 29 2.9.2.5 Display Backlight

P. 29 3. Gas testing and calibration

P. 30 3.1 Introduction

P. 30 3.2 Bump Test Functionality

P. 31 3.2.1 Speedy bump

P. 31 3.2.1.1 Procedure

P. 31 3.2.2 Smart bump

P. 32 3.2.2.1 Procedure

P. 32 3.2.3 Calibration after bump fail

P. 32 3.2.3.1 Procedure

P. 33 3.2.4 New sensor calibration/service

P. 33 3.3 Gas test screen flow

P. 34 4. Icon overview

P. 35 5. Service and maintenance

P. 35 6. PC interface and Portables Pro

P. 35 6.1 General

P. 35 6.2 PC interface cable

P. 36 7. Accessories

P. 36 8. Specification

P. 38 9. Troubleshooting

P. 39 9.1 Pump test failure

P. 39 9.2 Fault screens

P. 39 9.2.1 Fault Descriptions

P. 40 9.2.2 Fault codes

P. 41 10. Appendices

P. 42 10.1 Sensors

P. 42 10.1.1 Toxic

P. 42 10.1.2 Flammable Pellistor Sensors

P. 42 10.1.3 Flammable IR Sensors

P. 42 10.1.4 Oxygen

P. 43 10.1.5 IR

P. 43 10.1.6 PID

P. 43 10.2 Sensor Limitations

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 4/47

P. 44 10.3 Charging and run times

P. 44 10.4 Contacts

P. 45 Warranty

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 5/47

Prologue

Safety Information

GASPRO OVERVIEW

Thank you for purchasing the new Gas-Pro. At Crowcon we recognise the need

for reliable and robust personal monitors which are sized to be worn and simple

to use.

Gas-Pro is a portable monitor capable of detecting up to 5 gases in a compact

and wearable design featuring an optional internal pump. Focused on users and

fleet managers alike, Gas-Pro oers application focused solutions giving greater

operating time and reduced set up time.

Gas-Pro is classified for use in hazardous areas and gives loud and bright audi-

ble and visual alarm indications as well as a vibrate alert. The top mount display

is backlit for ease of use, and the simple single button solution makes using and

training quick and easy.

- Gas-Pro is a hazardous area certified gas detector and as

such must be operated and maintained in strict accord-

ance with the instructions, warnings and label information

included in the manual. Gas-Pro must be operated within

the limitations stated.

- Read and understand all instructions in the operation sec-

tion of the manual prior to use.

- Before use ensure that the equipment is in good condition,

the enclosure is intact has not been damaged in any way.

- If there is any damage to the equipment do not use, contact

your local oce or agent for repair/replacement.

- Do not disassemble or substitute components as this may

impair intrinsic safety and invalidate safety certification.

- Only genuine replacement parts must be used; substitute

components may invalidate certification and warranty of

the Gas-Pro and accessories, reference “Service and Main-

tenance” section of the manual for details.

- No live maintenance is permissible.

- Observe all warnings and instructions marked on the unit

and within the manual.

- Observe site health and safety procedures for gases being

monitored and evacuation procedures.

- Understand the screen display and alarm warnings prior

to use.

- If this product is not working properly, read the trouble-

shooting guide and/or contact your local oce or agent, for

details reference the ‘Contacts’ section of the manual.

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 6/47

- Ensure maintenance, service and calibration is carried out

in accordance with the procedures in the manual and only

by trained personnel.

- Gas-Pro must not be charged or have communication to

the device, at ambient temperatures outside of the temper-

ature range 0°C to 40°C.

- Only connect to Gas-Pro in a safe area for charging or

communications.

- Charging cable assemblies, whilst nominally providing a

voltage of 6.5V, must not exceed a voltage of 9.1V as this

may impair intrinsic safety and invalidate safety certification

(Um=9.1V).

- Communication cable assemblies, whilst nominally oper-

ating at a voltage of 3.0V TTL, must not exceed a voltage of

9.1V as this may impair intrinsic safety and invalidate safety

certification (Um=9.1V).

- The devices are intended for use in normal atmospheric

conditions of temperature –20 °C to +55 °C; pressure 80

kPa (0,8 bar) to 110 kPa (1,1 bar); and air with normal oxygen

content, typically 21 % v/v (volume/volume).

- Gas-Pro may be used in Zones 1 and 2, for Group llA, llB

and llC gases and vapours and for Temperature Classes T1,

T2, T3 and T4. (See Certification labels below).

Certification labels

The certification marking is as follows:

- Gas-Pro is certified for use in ambient temperatures in the

range -20°C to +55°C (-4 to 131°F).

- Applicable Standards

Refer to equipment marking for confirmation of applicable

certification before use.

UL CERTIFICATION LABEL ATEX/IECEX CERTIFICATION LABEL MED CERTIFICATION LABEL

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 7/47

IECEx

IEC 60079-0: 2013, 6th Edition

Explosive atmospheres – Part 0:

Equipment – General requirements

IEC 60079-1:2014 7th Edition

Explosive atmospheres – Part 1:

Equipment protection by flameproof enclosures “d”

IEC 60079-11: 2012, 6th Edition

Explosive atmospheres – Part 11:

Equipment protection by intrinsic safety “i”

Ex db ia IIC T4 Gb Tamb -20°C to +55°C

IECEx ULD 11.0004X

ATEX

EN 60079-0: 2012 + A11: 2013

Explosive atmospheres – Part 0:

Equipment – General requirements

EN 60079-1:2014

Explosive atmospheres – Part 1:

Equipment protection by flameproof enclosures “d”

EN 60079-11: 2012

Explosive atmospheres – Part 11:

Equipment protection by intrinsic safety “i”

II 2 G Ex db ia IIC T4 Gb Tamb -20°C to +55°C

DEMKO 11 ATEX 1031772X

UL

Gas detector use in hazardous locations Class 1 Division 1, Groups A, B, C and D

only as to intrinsic safety.

UL 913 Applicable Edition of the UL standard

UL60079-0 Applicable Edition of the UL standard

UL60079-11 Applicable Edition of the UL standard

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 8/47

Remove the Gas-Pro from the packaging. The standard accessories are under

the supporting trays. The following items will be included as standard:

Box contents

- Gas-Pro

- Quick Start Guide

- Calibration report

The following items are optional:

Optional items

- Charger cradle

- Charger lead (see Power & Communication Cables

Technical Data)

- Flow plate (standard for pumped units)

If you have ordered a charger and/or cradle this will also be

included in the box. Further accessories are available but

will not be contained in the box (see Section 7).

Gas-Pro in the off state can be left on charge indefinitely

Should the unit be deep discharged, the charging indica-

tion will not be shown until the unit has been charging for 1

hour and the operator button has been pressed.

When on and charging a warning will advise the user to turn

the Gas-Pro off after 12 hours or remove from charge.

Store the battery in a full state and recharge at least once

every 3 months.

. PRIOR TO USE

Before use, the Gas-Pro should always be checked for any signs of physical

damage.

Gas-Pro uses a Lithium Ion (Li-ion) battery pack and should arrive with sucient

charge to be used straight out the box. However, if this is the first time of use, you

may need to charge the battery to attain the full operating time (see Charging).

For battery run times, see the table on section 10.3.

The actual operating time will depend on the types of sen-

sor installed.

. GASPRO ORIENTATION

Unpacking

1. Set-up

1. D-ring 4. Sounder 7. Sensor apertures 10. Charging cable

2. Alarm bars 5. Operator button 8. Dual colour LCD display 11. Certification label

3. +ve Safety™ indicator 6. Pump inlet/outlet* 9. Alligator clip

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 9/47

. CHARGING

Charging should only take place in non-hazardous (safe) areas. To charge, sim-

ply plug the cable into the charging socket on the Gas-Pro and turn on the

mains supply (see Figure 2 below). If a charging cradle or vehicle cradle is being

used, ensure the Gas-Pro fits firmly on to the power connector.

The charger must be able to supply 6.5V@ 450mA with an

output voltage that does not exceed 9.1V (Um).

When o, to show the Gas-Pro is charging, both LEDs within the alarm bars will

flash red and will change to green once fully charged. This state will contin-

ue until the trickle charge is complete. Charging will then terminate showing no

indication. The screen will also show the battery icon filling in the middle of the

screen when the Gas-Pro is o, and in the bottom left-hand corner when it is on.

The battery icon contains a maximum of six segments to indicate the battery’s

state of charge. For example, with three segments shown and a fourth flash-

ing, the battery is 50% charged , and when all six are shown, the battery is fully

charged (see Figure 3 below).

1

2

3

4

578

10

11

9

6

* Blanked for non-pumped unit.

Figure 2:

Charger connection

Figure 3:

Charging indications

Figure 1:

Gas-Pro

1

1 2

2

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 10/47

. FITTING A FLOW PLATE

A flow plate can be used for a number of applications including pumped opera-

tion (remote sampling), manual gas test/calibration or for manual sampling. If the

pumped flow plate is attached before turning the Gas-Pro on and the Gas-Pro

includes a pump, a pump test will commence as part of the start up process (see

Pump test).

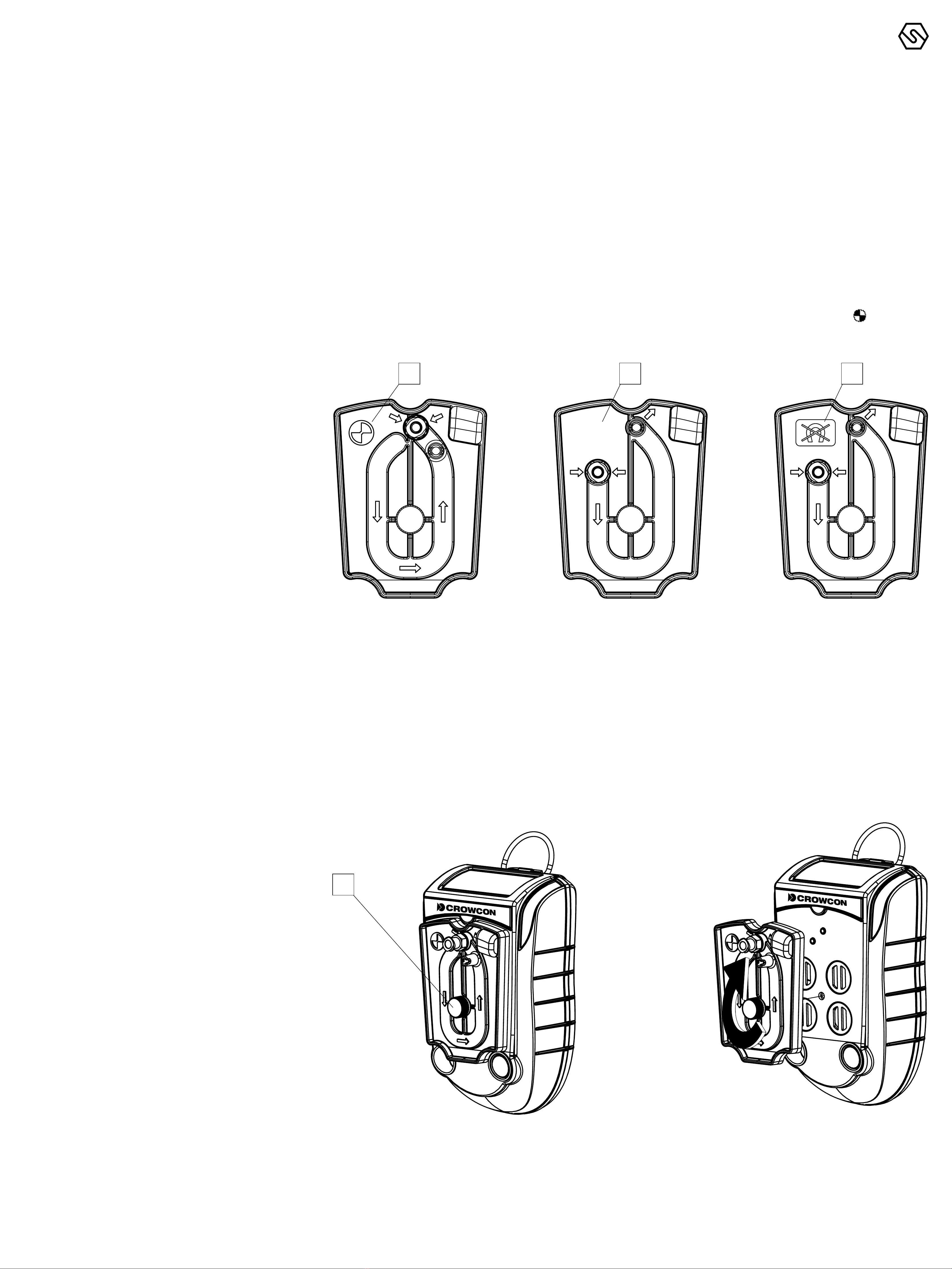

There are 3 types of flow plate: one for a Gas-Pro with internal pump, one for a

Gas-Pro with no pump and a non-magnetic version for PC calibration or for ma-

nual sampling. Although there is no dierence to the attachment procedure, they

are not interchangeable (see Figure 4). The pumped flow plate has the symbol

in the top left corner to aid recognition.

Pumped flow plate

Non pumped flow plate

PC Cal/Test Flow Plate

Check the flow plate’s gasket is free from dirt and has not been damaged prior

to fitting. To fit a flow plate, locate it over the Gas-Pro sensors as shown in Figure

5 and tighten the securing screw .

The flow plate includes a quick connect fitting for attaching sample tubes and

probes.

1 2 3

Figure 4:

Pumped and non pumped flow plates

Figure 5:

Fitting a flow plate

1

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 11/47

. QUICK VIEW

Even when the detector is o, users can display details about the configuration

of the Gas-Pro by momentarily pressing the operator button for one audible blip.

The LED to the left of the display will flash red once and the Quick view screen

shown in Figure 6 below will be displayed for 10 seconds.

Gas type and unit detected

Battery status

Quickview icon

ID or serial number

The +ve Safety™ LED status is also shown (see Figure 1).

. GENERALITÀ

Before turning the Gas-Pro on, ensure it is in ‘clean air’

(i.e. outside, in normal air, away from any plant process or

suspected gas location). This will allow the Gas-Pro to be

zeroed using clean air as the base point. If the Gas-Pro is

zeroed in contaminated air a false gas reading can result,

or the zero could fail.

. TURN ON

In ‘clean air’, turn on the Gas-Pro by holding down the operator button for 3 audi-

ble blips. The Gas-Pro will warm up, going through a series of automatic proces-

ses as follows:

Firstly a test screen pattern will be generated. Watch this to ensure there are no

missing pixels on your display screen.

Whilst the Gas-Pro is warming up, two screens will be displayed.

2

4

3

1

Figure 6:

Quick view display

Figure 7:

Initial screens at turn on

2. Operation

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 12/47

After a successful test cycle the LCD screen will remain green, the sounder and

LEDs will indicate the Gas-Pro is healthy.

A Gas-Pro fitted with a pump is configured as standard to

start the pump automatically when switched on, provided

that a flow plate is fitted. Such a Gas-Pro tests the pump

automatically at this point (for more details on this, see

Pump test).

If the battery level is low, an alarm will sound, and the bat-

tery icon on the screen will be partial.

If a second ‘splash’ screen has been configured via Por-

tables Pro it will be shown next in the turn on sequence.

If the Gas-Pro is configured for regular Gas Testing (Bump Test), the date of the

last Gas Test will also be shown (for more information on Gas Testing, see Gas

testing and calibration).

The next screen indicates when the Gas-Pro was last calibrated. It also indicates

when the next calibration is due with a warning symbol next to the number of

days left, if this is fewer than 30 days. If the calibration due date has expired, the

number of days figure is not displayed and the warning symbol flashes.

If the calibration due lockout feature has been enabled the lockout icon will

be displayed and the Gas-Pro will not proceed past this point.

Figure 8:

Gas test due screen

Figure 9:

Calibration due screen

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 13/47

The next screen (Figure 10) will display the current detector settings (for more in-

formation on these settings, see Gas-Pro functions).

The Autozero Confirm screen will be displayed next.

An Autozero should not be performed unless the Gas-Pro is in clean air. Press

the operator button to enter the Autozero mode, otherwise the countdown will

progress and will not perform a zero.

If the operator button is not pressed the countdown will complete and this fun-

ction will be skipped.

When the autozero has finished or been skipped, the next screen is the home

screen (Figure 12) and displays the gas levels.

The next screen on the Gas-Pro TK edition of Gas-Pro is the Tank Check scre-

en. See the Tank Check Mode section (see Section 2.9) for more information.

Figure 12 shown below is for 5 gases in clean air.

Figure 10:

Current settings screen

Figure 11:

Autozero confirm screen

Figure 12:

Home screen

21

3

4

5

6

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 14/47

Gas type

Unit

Level

Home Screen icon

Battery level

Pump present (rotating when on)

In ‘clean air’, CO2 and Oxygen levels are typically 0.04% and 20.9% respectively.

In zero mode, these gases will actually run an ‘oset’ zero.

The Gas-Pro is now ready for use.

EN60079-29 part 1 has been harmonised under the ATEX

directive (2014/34/EU). Therefore to comply with the ATEX

directive, portable apparatus sensing flammable gases

should have a functional check with flammable gas before

each day of use (see Gas testing and calibration). Other

testing regimes may be employed depending on local cir-

cumstances.

. PUMP TEST

In the default configuration, a pumped Gas-Pro with a flow plate attached (see

Fitting a flow plate) will run a pump test during the start up process. A pump test

will also be run whenever a flow plate is attached during normal operation.

If the Gas-Pro is configured for Bump functionality, the

Bump/Pump prompt will be displayed if a flow plate is at-

tached and a gas bump test is due or the Gas-Pro is placed

in a Q-Test module during normal use (see Bump/Pump

functionality).

Prior to fitting, the flow plate’s gasket should be checked for

any damage.

The pump test ensures accurate sealing as well as monitoring pump perfor-

mance. The user will need to cover the pump inlet À (see Figure 13 below) when

prompted to do so by the symbol on the screen.

When the test has finished, the pump will either pass or fail .

If the pump test takes place during start-up and the Gas-Pro passes, the pump

will remain on and the start-up process will continue as normal. If the test is

1

Figure 13:

Pump inlet

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 15/47

passed during normal use, the Gas-Pro will remain in the pumped mode until the

flow plate is removed.

On failing the pump test the fail screen will persist with an audible alert until the

button is pressed and the test repeats OR the flow plate is removed and the

Gas-Pro returns to non-pumped operation. For further detail on failing a pump

test see Pump test failure.

. DETECTING GAS

When sampling an area that may contain water, use the ball float probe to re-

duce the potential for water travelling up the sample line.

.. DIFFUSION MONITORING

If you wish to monitor gases in ambient air for dangerous levels, the Gas-Pro

can be worn by either clipping the strong alligator clip to clothing/overalls in the

breathing zone or through the use of a chest harness.

In the default, non-alarm state, Gas-Pro’s sounder will emit a beep every 10

secs, its confidence LEDs will flash green, the +ve Safety™ indicator will

show the current status, and the LCD display will indicate it is running by flash-

ing the icon.

In the alarm state, Gas-Pro will vibrate, its sounder will emit a rapid tone, the

alarm LEDs will flash red and blue, the +ve Safety™ indicator will be o in

alarm, the LCD display will also be red and highlight the gas in alarm.

.. PUMPED MODE

Safety Information: the following instructions should be observed when using

the instrument in Pumped or Manual Sampling mode.

1

2

4

3

Figure 14:

Gas-Pro indicators

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 16/47

It is strongly recommended before proceeding that a func-

tion check is performed using the pump and sample tube

with the gas/vapour to be detected.

To reduce the risk of adsorption of the gas/vapour in the

sample tube, ensure the temperature of the sampling tube

is above the flash-point temperature of the target vapour.

Ensure the monitor is correctly calibrated for the target

gas/vapour.

Only use the sample tube supplied by Crowcon. It is strong-

ly recommended that ‘reactive gas tubing’ (part no: AC0301)

is used for sampling gases/vapours that are likely to be

adsorbed (examples: toluene, chlorine, ammonia, hydrogen

sulphide, ozone, hydrogen chloride NOx etc).

Keep the sample tube length as short as possible.

Allow sufficient time for the gas/vapour to reach the sensor,

allow at least 3 seconds per metre plus the normal T90 re-

sponse time of the sensor (typically 30-40 seconds). Exam-

ple times are provided in the table below.

Pumped operation requires the use of the pumped flow plate which automat-

ically activates the pump (see Bump/Pump functionality). Gas-Pro can either

be worn or used with hoses and probes to sample from spaces prior to entry.

The pump capacity in the Gas-Pro is 0.5l/m and will draw a sample of gas from

30m within 80 seconds. Please note the expected losses for some gases below.

Please allow at least 3 seconds per meter of hose used.

If Gas-Pro is operated in pumped mode in combination

with an exhaust pipe, a set of bellows should be used inline

(e.g. flow plate, 2cm maximum tube, bellows, 3000cm max-

imum tube).

Gas-Pro also has a specific pre-entry mode (see Section

2.6.5).

.. MANUAL SAMPLING

If the internal pump option has not been chosen the hand aspirator may be used

for pre-entry checks and remote sampling. This is not however recommended

Tube Type Standard (AC0201/03/05/10/20/30)

Tube length 5 metres 10 metres 30 metres

Measurement Gas Name Loss Time Loss Time Loss Time

CO (250ppm) Carbon Monoxide 0ppm 9 s 0ppm 20 s 1ppm 79 s

H2S (25ppm) Hydrogen Sulphide 0ppm 10 s 1ppm 20 s 6ppm 78 s

CH4(2.5% VOL) Methane 0% VOL 10 s 0% VOL 20 s 0% VOL 78 s

CO2(5% VOL) Carbon Dioxide 0% VOL 9 s 0% VOL 20 s 0% VOL 79 s

O2(18% VOL) Oxygen 0% VOL 9 s 0% VOL 20 s 0% VOL 79 s

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 17/47

for sample hoses longer than 5 meters due to the amount of time (and therefore

squeezes) it would take to get a repeatable sample to the sensors. A water trap

and filter should be used.

... USING THE HAND ASPIRATOR

The hose end of the hand aspirator should be attached to the exhaust of the

non-pumped flow plate, a sensors covered warming will be shown and the

user should accept this. The bulb should then be depressed whilst holding a fin-

ger over the inlet to ensure that a tight seal has been achieved. The detector will

at this point likely go into alarm (this is due to the pressure effect on the oxygen

sensor) and the bulb of the aspirator should not return to the rounded shape. If

this does not happen – reposition the flow plate and repeat the test. Once the

test is passed allow the O2 sensor to stabilise to 20.9% and then attach the re-

quired sample hose length to the inlet on the flow plate and commence sam-

pling. Depress the aspirator bulb every other second in order to get a constant

sample flow to the sensors. Every depression of the aspirator bulb should pull

the sample approximately 25cm up the tube. Therefore to sample from a 5 meter

hose – at least 20 aspirations will be required, however a minimum of 1 minute is

recommended to ensure a stable sample is read.

If the Gas-Pro being used is fitted with a carbon monoxide sensor (CO) a 5%

increase in reading is expected during this process due to the extra pressure

placed on the sensor (ie if the sample being tested is 30ppm – the expected re-

sult onscreen will show 32ppm.

If Gas-Pro is being used regularly for sampling, Crowcon strongly recommend

the use of the internal pumped option to reduce time and potential for error.

Do not use the pumped flow plate for manual sampling.

. ALARMS

The Gas-Pro has the following types of alarm:

- Low battery

- Instantaneous

- Time weighted average (TWA)

.. LOW BATTERY ALARM

When the Gas-Pro warns of a low battery, the sounder will emit an audible dou-

ble blip every 5 seconds and, if configured to do so, the +ve Safety™ LED will

change state. This means the battery has at least 20 minutes of battery life re-

maining. After 20 minutes the Gas-Pro will enter full alarm state and the battery

icon will flash empty.

Users should finish their current activity and move to a safe

area as the instrument will power off without further warn-

ing unless charged.

.. INSTANTANEOUS ALARM

The Gas-Pro will go into alarm immediately if the level of any of the gases it is

configured to detect become outside acceptable limits. A minimum and maxi-

mum acceptable level is set for oxygen, for most other gases the Gas-Pro will go

into alarm state 1 or 2 according to which level has been exceeded.

In the alarm state, the ‘bell’ alarm symbol on the LCD screen will show a or

to indicate which level of alarm has been triggered. In alarm, the sounder will

emit a tone and the Gas-Pro will vibrate. The LEDs will flash red and blue, and

the background of the LCD will change colour from green to red and the gas in

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 18/47

alarm display will invert periodically. Symbols on the LCD will show the level and

nature of the alarm.

.. TIME WEIGHTED AVERAGE ALARM TWA

When activated, the Gas-Pro begins a new record for each toxic gas being moni-

tored where it stores information about gas levels detected. If the average levels

detected over a period of time exceeds predetermined levels, the Gas-Pro will

go into alarm.

In the alarm state, the TWA symbol on the LCD screen will indicate a 15 min-

ute or 8 hour limit . The sounder will emit a tone and the Gas-Pro will vibrate.

The LEDs will flash red and blue, and the background of the LCD display will

change colour from green to red.

The LCD display will indicate the alarm has been triggered by exposure over

time rather than instantaneously. Levels are set for a short period of 15 minutes

and a longer one of 8 hours.

TWA alarms cannot be cleared. (The 8 hour TWA can be re-

viewed in the user menu – see Section 2.6.4). The TWA can

only be cleared by turning the Gas-Pro off (see Shut down).

Refer to Health and Safety guidelines on TWA alarms.

If TWA is monitored with the +ve safety™ configuration, the

TWA +ve safety alert is only cleared by downloading the da-

talog via Portables Pro.

... TWA RESUME FUNCTION* SOFTWARE VERSIONS V AND HIGHER

TWA Resume allows TWA, STEL and peak readings to be retained after Gas-Pro

has been switched o for a period of time, for example while an operator trav-

els to a new location. This prevents recent toxic exposure history from being lost

and the associated risk of the operator exceeding safe exposure levels.

If Gas-Pro is switched o for less than 15 minutes and the TWA Resume function

is selected (see below), Gas-Pro will retain the STEL, TWA and peak gas values

when powered back on.

If Gas-Pro is switched o for more than 15 minutes but less than 8hrs, and the

TWA Resume function is selected (see below), Gas-Pro will retain the TWA and

peak gas values when powered back on but the STEL values will be cleared.

If Gas-Pro is switched o for more than 8hrs the TWA Resume function will not

be available in the start-up sequence and Gas-Pro will clear the TWA, STEL and

peak gas values when powered back on.

The TWA Resume function can be activated during the start-up sequence. Upon

start up, following the test screen, if Gas-Pro is switched on within 8 hours of be-

ing switched o, the screen shown right will be displayed for 10 seconds allowing

the user to ‘resume’ if required.

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 19/47

Simply click the operator button.

If Gas-Pro is now being used by a new operator and the TWA Resume function is

not required do not click the operator button and allow countdown to expire. This

will reset the STEL, TWA and peak values back to zero.

* Patent pending – UK Patent Application Number 1501699.1

.. ACCEPTING AND CLEARING ALARMS

While in alarm, the Gas-Pro will continue to record levels of

all the gases being monitored.

.. SENSOR TYPES

The Gas-Pro can be fitted with the following sensor types:

- Oxygen

- Electro-chemical

- Infra red (IR)

- Pellistor

- Photoionization Detector (PID)

... OXYGEN SENSORS

These sensors are in the form of an electro-galvanic fuel cell which is an electri-

cal device used to measure the concentration of oxygen gas in the ambient air.

Set as default with both higher and lower alarm levels.

Figure 15

Setting Alarm 1 Alarm 2

Non-latched Alarms will not be latched returning

to non-alarm state without user

acceptance

Alarm can be turned o only when

gas has returned to acceptable levels

Latch Accept Allows the user to silence alerts but

remains in alarm. Once gas has

returned to acceptable levels the user

needs to accept the state.

Alarm can be turned o only when

gas has returned to acceptable levels

Latched Alarm can be turned o only when

gas has returned to acceptable levels

Alarm can be turned o only when

gas has returned to acceptable levels

SENSITRON

A Halma Company

M07995

GAS-PRO

Manual (EN)

P. 20/47

... ELECTROCHEMICAL SENSORS

Electrochemical gas sensors measure the volume of a target gas by oxidising or

reducing the target gas at an electrode and measuring the resulting current.

... INFRA RED SENSORS

Gas is pumped or diuses into the sample chamber, and gas concentration

is measured electro-optically by its absorption of a specific wavelength in

the infrared (IR).

... PELLISTOR SENSORS

Pellistor sensors (or catalytic beads) are specifically designed to sense explosive

gases. The detecting element consists of small “pellets” of catalyst loaded ce-

ramic whose resistance changes in the presence of gas.

... PELLISTOR SAVER MODE

While in saver mode and the subsequent stabilise time, the gas level displayed

on the LCD screen will indicate over range. If the alarm is so severe as to cause a

sensor over-range the Gas-Pro should have a gas test to ensure no lasting dam-

age has occurred.

Pellistor sensors can suer degradation if powered while exposed to flammable

gas concentrations of greater than 100% LEL, and also if exposed to high levels

of H2S or silicones.

To reduce the degradation the instrument the Gas-Pro employs a Pellistor

saver mode.

When the gas exceeds the saver threshold (user configurable: default 90% –

95%) then the detector will turn o the sensor for a minimum period of 3 minutes

20 seconds.

After this time the sensor can be re-activated by a single click of the operator

button.

After a stabilisation time, if the gas level still exceeds the threshold then the sen-

sor will be turned o and the cycle starts again.

EN60079-29 part 1 has been harmonised under the ATEX

directive (2014/34/EU). Therefore to comply with the ATEX

directive, portable apparatus sensing flammable gases

should have a functional check with gas before each day of

use (see Gas testing and calibration). Other testing regimes

may be employed depending on local circumstances.

... PID

PID sensors are configured and calibrated to Isobutylene when manufactured.

The PID sensor can be configured to detect Volatile Organic Compounds (VOC)

other than Isobutylene by changing the correction factor in the PID sensor type

options

Details of how to change the VOC correction factor can be found in Portables

Pro user manual

Gas-Pro fitted with a PID sensor may require periodic cleaning and calibration of

the sensor to ensure correct performance in normal use.

The sensor may need maintenance if any of the following occur:

Other Sensitron Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

BIOPAC Systems

BIOPAC Systems opSens TSD 180 How to Clean

GW Instek

GW Instek PEL-5000G Series user manual

Kestrel

Kestrel 4400 Instructional manual

Troxler

Troxler Enhanced RoadReader Plus 3451 Manual of Operation and Instruction

Buhler

Buhler GAS 222.20 Denox Installation and operation instructions

Huvitz

Huvitz CR-9000 Operation manual