Sensitron MULTISCAN++PK-16 Guide

MT4299E Rev.1 15/10/2019 Pagina 1 di 55

Gas Detection System for

Car Parks

with Control Panel

MULTISCAN++PK-16

INSTALLATION AND USE

MANUAL

SENSITRON S.r.l. Viale della Repubblica, 48

20010 CORNAREDO MI - Italy

Ph: + 39 02 93548155 Fax: + 39 02 93548089

Technical Manual MULTISCAN++PK

MT4299E Rev.1 15/10/2019 Pagina 2 di 55

Warning

THIS MANUAL MUST BE CAREFULLY READ BY ALL PERSONS WHO HAVE OR

WILL HAVE THE RESPONSIBILITY FOR INSTALLING, USING OR SERVICING THIS

PRODUCT.

Like any equipment, this product will perform as designed only if installed, used and

serviced in accordance with the manufacturer’s instructions. OTHERWISE, IT COULD

FAIL TO PERFORM AS DESIGNED AND PERSONS WHO RELY ON THIS PRODUCT

FOR THEIR SAFETY COULD SUFFER SEVERE PERSONAL INJURY OR DEATH.

The warranties made by Sensitron s.r.l. with respect to this product are voided if the

product is not installed, used and serviced in accordance with the instructions in this

user guide. Please protect yourself and others by following them.

We recommend our customers to write or call regarding this equipment prior to use or

for any additional information relative to use or repair.

Technical Manual MULTISCAN++PK

MT4299E Rev.1 15/10/2019 Pagina 3 di 55

THIS TECHNICAL MANUAL DESCRIBES THE PRODUCT

IN ITS COMPONENTS, THE INSTALLATION AND THE

OPERATION OF THE SYSTEM. THE CONFIGURATION

SOFTWARE IS NOT INCLUDED, SO PLEASE REFER TO

THE PROPER MANUAL.

Technical Manual MULTISCAN++PK

MT4299E Rev.1 15/10/2019 Pagina 4 di 55

INDEX

1) INTRODUCTION................................................................................................................................... 5

1.1) SYSTEM BLOCK DIAGRAM WITH MULTISCAN++16-PK CONTROL PANEL................................................ 5

2) SMART P GAS DETECTORS.............................................................................................................. 6

2.1) TECHNICAL SPECIFICATIONS.............................................................................................................. 7

2.2) DETECTOR INSTALLATION ................................................................................................................. 8

2.3) CIRCUIT LAYOUT............................................................................................................................... 9

2.4) ELECTRIC WIRING........................................................................................................................... 10

2.5) DETECTOR POWER ON................................................................................................................... 11

2.6) TESTING AND USE .......................................................................................................................... 11

2.7) HANDHELD CALIBRATION KEYPAD ST.S/CKD PK............................................................................. 11

3) MULTISCAN++16-PK CONTROL PANEL......................................................................................... 16

3.1) UNIT FEATURES.............................................................................................................................. 16

3.2) SYSTEM CONFIGURATION................................................................................................................ 17

3.3) TECHNICAL SPECIFICATIONS............................................................................................................ 17

3.4) INSTALLATION................................................................................................................................. 17

3.4.1) DIAGRAM AND PART IDENTIFICATION......................................................................................... 19

3.4.2) MAIN BOARD LAYOUT............................................................................................................... 20

3.4.3) POWER SUPPLY CONNECTIONS ................................................................................................ 21

3.4.4) DIP SWITCH SETTING FOR THE RS485 BUSS,PC COMMUNICATION AND CONTROL PANEL LANGUAGE

21

3.5) FIELD DEVICE CONNECTION............................................................................................................. 22

3.5.1) DETECTORS CONNECTION ....................................................................................................... 23

3.6) STG/IN8-PK REMOTE INPUT MODULE ............................................................................................. 28

3.7) STG/OUT16-S REMOTE OUTPUT MODULE ...................................................................................... 29

3.7.1) STG/8REL RELAY EXPANSION BOARD ..................................................................................... 30

3.7.2) STG/IN8-PK AND STG/OUT16-S MODULE ADDRESSING ......................................................... 30

3.7.3) DETECTOR IDENTIFICATION...................................................................................................... 32

3.8) PROGRAMMING BY PC.................................................................................................................... 32

3.1) TCP/IP OPTIONAL MODULE............................................................................................................. 33

4) SYSTEM POWER UP AND OPERATION.......................................................................................... 33

4.1) POWER ON.................................................................................................................................... 34

4.2) SYSTEM STATES AND OPERATION.................................................................................................... 35

4.2.1) SYSTEM STATES...................................................................................................................... 35

4.3) USER LEVELS................................................................................................................................. 39

4.3.1) OPERATOR LEVEL.............................................................................................................. 39

4.3.2) MAINTENANCE LEVEL.......................................................................................................... 40

4.3.3) ENGINEER LEVEL ................................................................................................................. 41

4.4) MENU DETAILS........................................................................................................................... 41

4.5) MENU........................................................................................................................................... 41

4.5.1) ACTIVE EVENTS.................................................................................................................. 41

4.5.2) EVENT LOG.......................................................................................................................... 44

4.5.3) PRINT................................................................................................................................... 46

4.5.4) SYSTEM INFO...................................................................................................................... 47

4.6) 2-LOGOUT................................................................................................................................... 47

4.7) 4-LOGIN....................................................................................................................................... 47

4.8) 3-SYSTEM ................................................................................................................................... 48

4.8.1) ZONES.................................................................................................................................... 49

4.8.2) MODULES ............................................................................................................................... 50

4.8.3) RELAY OUTPUTS ..................................................................................................................... 50

4.8.4) DETECTORS (CHANNELS)........................................................................................................ 53

MT4299E Rev.1 15/10/2019 Pagina 5 di 55

1) INTRODUCTION

The SPS MULTISCAN++PK gas detection system for car parks is made up of the

MULTISCAN++16-PK control panel and SMART-P detectors, specifically designed to meet

EN50545-1 European standards. Other detectors can be connects (i.e.: Sensitron Smart3 NC)

with 4-20 mA output via 8-input ST.G/IN 8 PK module.

Detectors can be addressable (Smart P) and thus directly connectible in buss, or 4-20 mA

analogue type, connectible via 8-input remote STG/IN8-PK modules.

The unit allows for three alarm thresholds to be set for each detector. The alarm threshold

activation mode changes according to the type of gas detection profile and connected detector:

There are two alarm threshold modes: Average thresholds and Real-time (Fixed) thresholds.

For the LEL Profile (for explosive gas detectors), only real-time thresholds can be set.

For the Toxic Park Profile, both real-time and average thresholds can be set.

For the Toxic Park EN50545-1 Profile, only average thresholds can be set.

System architecture also includes 6 on-board relays and the possibility to expand outputs up to

32 using remote STG/OUT16-S modules and 8-relay boards.

The unit is inserted in a plastic box complete with 27 Vdc 4 A power supply.

1.1) System block diagram with Multiscan++16-PK control panel

BUS 1

BUS 2

(1)

(4)

(3)

(2)

(5)

(6)

(4)

(1) RILEVATORI GAS ANALOGICI 4-20 mA/ 4-20 mAANALOG GAS DETECTORS

(2) MODULO 8 INGRESSI ANALOGICI ST.G/IN8-S / ANALOG 8INPUT MODULE

ST.G/IN8-S

(3) CAVO 2 FILI TWISTATI PER Rs485 +2 FILI PER ALIMENTAZIONE (12-24Vdc) /

2 TWISTED WIRES FOR THE Rs485 BUS +2 WIRES FOR THE POWER SUPPLY (12-24 Vdc)

(4) RILEVATORI GAS CON USCITASERIALE Rs485 / GAS DETECTORS WITH Rs485 OUTPUTS

(5) MODULO 16USCITE O/C ST.G/OUT16 / 16O/C OUTPUTS MODULE ST.G/OUT16

(6) MODULO 8 RELE’ ST.G/8REL / 8 RELE’ ST.G/8REL MODULE

16 O/C

MULTISCAN++PK 16 CONTROL PANEL

E’ possibile realizzare il sistema con

1 BUS aperti oppure 1 BUS chiuso

Itispossible to make the systemwith

2 open BUS or 1 closed BUS

MT4299E Rev.1 15/10/2019 Pagina 6 di 55

2) SMART P GAS DETECTORS

SMART P gas detectors come in the following versions based on the type of gas to be

detected:

CO, range 0-300 ppm, 3 pin industrial cell

NO2, range 0-30 ppm, 3 pin industrial cell

Detectors with dual sensor were manufactured to optimise installation costs, coupled with the

CO-NO2 and CO-PETROL VAPOUR sensor in a single case.

SMART P use high performance sensor cells and test all functions including a self test for

CO cell reliability.

SMART P detectors are set for 4-wire connections: 2 for power and 2 for data communications

via RS485 serial to the MULTISCAN++PK unit.

SMART P provide fast and safe installation as well as easy maintenance and field calibration

via the STS/CKD-PK calibration keypad.

Detectors run on 12-24 Vdc power and sold in IP55 metallic cases.

SMART P-1

Designed to fulfil the new European Standard

for gas detection in car parks, the SMART P-1

gas detectors provide a serial RS485.

The SMART P-1 employ electrochemical cells

for the detection of CO or NO2.

To meet with the standard in full, these

detectors are to be connected to

MULTISCAN++PARK gas control panels.

SMART P-1 detectors for Carbon Monoxide and NO2

CODE

DESCRIPTION

CAT.

€

S2398CO

CO detector for car parks RS485 serial outputs. Range 0-300

ppm.

B

240,00

S2399ND

NO2 detector for car parks, RS485 serial outputs. Range 0-30

ppm.

B

320,00

SMART P-2

Designed to fulfil the new European Standard

for gas detection in car parks, the SMART P-2

gas detectors offer the simultaneous detection

of CO and NO2 or Petrol vapours integrated in

the same detector.

The SMART P-2 provide a serial RS485.

To meet with the standard in full, these

detectors are to be connected to

MULTISCAN++PARK gas control panels.

MT4299E Rev.1 15/10/2019 Pagina 7 di 55

SMART P-2 detector for Carbon Monoxide and Nitrogen Dioxide/Petrol

Vapours

CODE

DESCRIPTION

CAT.

€

S2400CO-ND

CARBON MONOXIDE & NITROGEN DIOXIDE detector for car

parks, RS485 serial output. Range 0-300 ppm CO and 0-30

ppm NO2.

B

400,00

S2400CO-VB

CARBON MONOXIDE & PETROL VAPOURS detector for car

parks, RS485 serial output. Range 0-300 ppm CO and 0-

100%LEL Petrol Vapours.

B

420,00

CALIBRATION TOOLS for SMART P

CODE

DESCRIPTION

CAT.

€

STS/CKD-PK

Handheld calibration keypad to be connected to the detector to

adjust the Zero, Span and 4-20mA values.

A

200,00

2.1) Technical specifications

Typical use

To be used with MULTISCAN++PK

256/128/64/32 type units to monitor toxic gas in

car parks and garages

Detectable gas

Carbon Monoxide 0-300 ppm.

Nitric dioxide 0 - 30 ppm

Petrol Vapours 0-100% LEL

Sensor used

Electrochemical cell for CO and NO2. Catalytic

for Petrol Vapour.

Power

12-24 Vdc (-20% +15%)

Proportional output

RS485 serial

Absorption at

12-24Vdc

CO max 70mA

NO2 max 70mA

CO+NO2 max 80mA

CO+PETROL VAPOUR max 110 mA

Repeatability

5% FS

Storage temp.

-25 / + 60 °C

Working temperature

-20 / + 60 °C

Relative humidity

20-90 % non condensed RH/40°C

IP protection level

IP55

Weight

600 gr.

Dimensions

L. 100, H. 180, D. 65 mm

Estimated sensor life

4 years for CO and PETROL VAPOUR sensors

3 years for NO2 sensor

MT4299E Rev.1 15/10/2019 Pagina 8 di 55

2.2) Detector installation

At the mounting and installation phase be sure all safety precautions have been

considered.

Always consider how important it is the correct positioning of gas detectors to get the

optimum response. Be careful never to install gas detectors close to air intakes or fans

causing strong air currents.

Be sure the detectors are attached to a firm base to prevent vibration that can damage

them, producing unreliable results.

Although the electronics comply with the electromagnetic compatibility rules, it is

advised to keep the detectors at a distance from any radio frequency senders (such as

radio links or similar).

Please be also sure that detectors are placed in a convenient location for future

maintenance and calibration requirements.

We recommend you mount the Smart P detector at nose level (about 150 cm off the ground)

since this is the position suited to detect CO and NO2. The Petrol Vapour detector should, on

the other hand, be installed about 30 cm off the ground. the CO+PETROL VAPOUR detector

comes with an extension kit to mount the Petrol Vapour sensor 30 cm off the ground.

Also remember that correct detector positioning is essential to ensure prompt and accurate

detection.

The gas detector is always to be mounted with the sensing element placed downward.

For no reasons at all the enclosure can be drilled.

Wall mount the detectors by employing the existing holes

150mm

front back

MT4299E Rev.1 15/10/2019 Pagina 9 di 55

2.3) Circuit layout

1

2

3

4

+

-

A

B

Connections terminal block

Morsettiera collegamento

Scheda elettronica rilevatore

Detector electronic board

Sensor Head 2 connection (E.C. Electr. Cell or Cat sensor)

Testa sensore 2 (E.C. Cella Elettrochimica o sensore catalitico)

Jp10 Rs485 End of Line 120 Ohm resistor

Closed: resistor Open: no resistor

Jp10 resistenza fine linea Rs485 (120 Ohm)

Closed: resistenza ins. Open: no resistenza

Sensor Head1 connection (E.C. Electr. Cell)

Testa sensore 1 (E.C. Cella Elettrochimica)

Jp8 selezione baudrate Rs485 comm

APERTO

:9600 Bps / : 115000 Bps

Jp8 Rs485baud rate selection

OPEN

:9600 Bps /

CLOSED : 115000 Bps

Jp7 connection of hand held

calibration keypad

Jp7 collegamento

tastiera calibrazione

Dl2 Led Green: detector activity.

Repeat the various detector status

Led Verde Dl1: attività dispositivo.

Ripete i diversi stati del rilevatore

Dl3 Led Red: Rs485 monitor

Lit in communication

Led Rosso Dl3: monitor

Rs485. Accesso in comunicazione

Dl2 LedRed: Rs485 Watch dog

monitor. Serious problem Led ON

Led Rosso Dl2: monitor Watch dog

Led ON guasto dispositivo

CHIUSO

MT4299E Rev.1 15/10/2019 Pagina 10 di 55

2.4) Electric wiring

The connection of the detectors to RS485 bus lines should be performed by using a 4-wire

cable, 1 pair for the RS485 bus and 1 for the power supply.

Wiring between the detectors and the control panel should be made by using connection cable

EIA RS485: 2 core wires with section 0.22 / 0.35 mm2 and shield (twisted pair). Nominal

capacity between the wires <50pF/m, nominal impedance 120 ohm.

These features can be found in BELDEN cable 9842 or similar (data transmission cable in EIA

RS485).

Using this wiring, the total length of the line should not exceed m 1000.

Detectors and output modules are to be wired in daisy chain mode. We recommend avoiding

star or tree mode connection as interference immunity would be reduced.

Make sure that a 120 Ohm end line resistor is placed at the beginning and at the end (on the

last detector or output module) of the bus line.

For the detectors' power supply connection we recommend to use a 2-wire cable with suitable

section according to the distance and number of detectors.

Once the installation has been completed, verify that each detector reaches at least 12 Vdc.

Each Smart P detector connected on the unit line must have a univocal address. Use the

specific STS/CKD PK keypad to set the detector address. See the specific paragraph below in

the manual.

+

-

A

B

S2

S1

1

6

A

B

+

-

Detector

+

-

A

B

S2

S1

1

6

A

B

+

-

Detector

+

-

A

B

S2

S1

1

6

A

B

+

-

Detector

Al rilevatore successivo (*)

to the next detector (*)

Dalla centrale

From the control panel

note: if the detector (or the module)

is the last of the line: close

the 120 ohm resistor jumper

nota: se il rilevatore (o il modulo uscite)

è l’ultimo sulla linea: chiudere

il jumper della resistenza da 120 ohm

+-

A B

ST.G/OUT16 module

MT4299E Rev.1 15/10/2019 Pagina 11 di 55

2.5) Detector power ON

When the detector is powered on, the green LED DL1 on the motherboard starts blinking at

slow intermittence.

After nearly two minutes, the red LED flash rate is equivalent to the detector working status (see

table below).

Once the warm-up phase is over, the detector can work correctly, although the optimal

performances will be achieved after two hours.

2.6) Testing and Use

Detectors are factory calibrated for the specific gas required by the customers. Future

adjustment of the preset calibration can be carried out by employing the calibration keypad.

Testing should be carried out by using a gas mixture in the appropriate range, along with our

calibration kit.

The green DL1 LED on the electronic board flashes to indicate detector status as illustrated in

the table below.

LED DL1 (green) shows the detector's operative status (mS= milliseconds)

Warm-Up

Flashing 750 mS ON; 250 mS OFF

Fault low

Lit fixed

Allarm 1

Flashing 250 mS ON; 1750 mS OFF

Allarm 2

Flashing 250 mS ON; 250 mS OFF; 250 mS ON; 1250 mS OFF

Allarm 3

Flashing 250 mS ON; 250 mS OFF; 250 mS ON; 250 mS OFF

250 mS ON; 750 mS OFF

Fault high

Flashing 250 mS ON; 250 mS OFF

Normal status

Flashing 1 sec. ON; 1 sec. OFF

2.7) Handheld calibration keypad ST.S/CKD PK

Smart P gas detectors offer a field adjustment for the Zero, Span (response to gas) and the

serial address (for the RS485 bus).

By operating with the handheld calibration keypad, pressing ENTER, ESC, Arrow UP and Arrow

DOWN, the Zero, Span and serial Address shall be accomplished.

The keypad can be connected when the detector is powered ON and operating. Before opening

the detector enclosure, be sure all safety precautions have been considered.

Insert the female connector of the keypad at the edge of the flat cable into the male connector

on the Smart P main board.

Once connected, the keypad will display the gas concentration being measured.

MT4299E Rev.1 15/10/2019 Pagina 12 di 55

Adjustments are required whenever either Fault or unjustified Alarms due to environmental

conditions occur (Zero adjustment) or detectors need modifying their response to gas (Span

adjustment).

Span adjustment requires a calibrated gas cylinder, either filled with the same gas the detector

has been calibrated for or a reference gas advised by the manufacturer

For the Zero adjustment, gas detectors are to be in fresh air (without any gas or interfering

compounds) and powered on since 8 hours at least.

Once the routine is over a test with gas is to be made to verify the right working condition.

KEYPAD

MT4299E Rev.1 15/10/2019 Pagina 13 di 55

Calibration keypad menu

0,0

ZERO SPAN VER ADR

ENT

ENT ENT ENT ENT

ESC

0,0 0,0 0,12 001

rES

ENT

WAIT

ZERO

When the detector SMART P is turned On for the first time, or when a new kit sensor is

mounted into the instrument, the AUTO ZERO calibration is recommended. This action

has to be done under the following two conditions:

Gas detectors are to be in fresh air (without any gas or interfering compounds) and

powered on since 8 hours at least. Where there is no such certainty of being in clean air

(without gas), calibration Auto zero is necessary to use a special mixture of synthetic air

(79% nitrogen and 20.9% oxygen).

Once the routine is over a test with gas is to be made to verify the right working

condition.

Perform the task of Auto Zero Smart P detector simply by pressing ENT from Auto Zero

menu and follow the steps in the block diagram.

SPAN

The Span allows the instrument calibration and is to be executed if when tested in gas occurred

that the instrument is not properly calibrated. To run the Span is essential the use of a mixture

(cylinder) gas sample with the Target Gases (gas that the tool should detect) or with a reference

gas to which the sensor is sensitive.

To apply the mixture of gases sample at Smart P, Sensitron makes available a dedicated

calibration kit. The calibration KIT, supplied with a carrying case, comprises the necessary

instrumentation to verify in situ the response of Sensitron's gas detectors The calibration cap

can be fitted on all of Sensitron sensing heads by employing, when necessary, the endowed

adaptors.

MT4299E Rev.1 15/10/2019 Pagina 14 di 55

Both gaskets and screw threads inside the cap allow an optimum tightness between the sensing

head and the cap. The analysis chamber inside the calibration cap has been designed and

realized to obtain a test method identical to that adopted in our laboratory for the initial factory

calibration.

The valve complete with flow meter is to be mounted on the gas can to allow a gas outlet at a

controlled velocity to obtain accurate data to verify the sensing element status.

rES Reset

Reset of Fault status

VER Version

Detector firmware version

ADR Address

Address of detector for communicating to RS485 bus. Ex. 004

MT4299E Rev.1 15/10/2019 Pagina 15 di 55

0,0

ENT

SPAN

ENT

VER

ENT

ADR

ZERO

ENT

ZGL

000,0

0,0

DONE

SGL

200,0

FACT

YES

ZGL Concentrazione gas

per lo Zero: lasciare a “000,0”

per VB, CO, NO ed No2

ZGL Zero Gas Level: let to

“000,0” for VB, CO, NO

and No2

ENT

ENT

ENT

Indicazione del valore attuale

letto dal rilevatore. Per azzerare

lo strumento confermare con ENT

Real time value indication. To

make the Zero adjustment,

confirm by ENT

Taratura di Zero eseguita

Zero adjustement done

SGL: Concentrazione gas

per la taratura della sensibilità.

Inserire il valore della concentrazione

gas della bombola usata

(es. 200 ppm CO)

SGL Span Gas Level: Gas Level

for the detector sensivity adjustement.

Enter the gas concentration of the

gas bottle used

FACT: fattore relativo nel caso

venga usato un gas di riferimento per

la taratura della sensibilità.Altrimenti

selezionare YES

FACT: Coefficent Factor, to be used

in case a difference reference gas

is used, for the sensivity adjustement.

Otherwise select and confirm YES.

0,0

195,0

A questo punto far fluire allo strumento

il gas di taratura, l’indicazione aumenterà

fino a fermarsi al valore massimo

(in circa 30 secondi).

Premere ENT per confermare.

L’indicazione visualizzata sarà ora

quella della concentrazione del gas di

taratura.

200,0

DONE

0.0.12 004

rES

ENT

WAIT

MT4299E Rev.1 15/10/2019 Pagina 16 di 55

3) MULTISCAN++16-PK CONTROL PANEL

This part of the manual details the procedures required to install the MULTISCAN++16-

PK gas detection unit.

3.1) Unit features

The MULTISCAN++16-PK is a gas detection control unit designed to meet the widest range of

flexibility required by the market.

The control panel is based on a powerful microprocessor which provides a wide range of self-

diagnostic procedures to detect and locate possible faults.

Extremely flexible and reliable, it can manage up to 24 gas detectors simultaneously. These can

be either of addressable type (16 x Smart P), directly connected on buses, or 4-20mA

analogical types connected via 8-input STG/IN8-PK remote modules.

System architecture also includes 6 on-board relays and the possibility to expand outputs up to

32 using remote STG/OUT16-S modules and 8-relay boards.

Summary table of the devices that can be connected to the various MULTISCAN++16-PK unit

versions.

Panel type

Number of

serial bus

Detectors

max

number

Outputs

max

number

ST.G/IN8-S

Max number

ST.G/OUT16

Max number

Notes

MULTISCAN++16-PK

2 open or 1

closed

16+8(*)

32+6(*)

2

2

(*) 4-20mA channels enclosed in the panel

Other features:

•Event log can be displayed on the screen or downloaded to a PC.

•RS232 serial port for PC connection for programming and control via specific software.

•Parallel port for printer connection.

MT4299E Rev.1 15/10/2019 Pagina 17 di 55

3.2) System configuration

BUS 1

BUS 2

(1)

(4)

(3)

(2)

(5)

(6)

(4)

(1) RILEVATORI GAS ANALOGICI 4-20mA/ 4-20 mAANALOG GAS DETECTORS

(2) MODULO 8 INGRESSI ANALOGICI ST.G/IN8-S / ANALOG 8INPUT MODULE

ST.G/IN8-S

(3) CAVO 2 FILI TWISTATI PER Rs485 +2 FILI PER ALIMENTAZIONE (12-24Vdc) /

2 TWISTED WIRES FOR THE Rs485 BUS +2 WIRES FOR THE POWER SUPPLY (12-24Vdc)

(4) RILEVATORI GAS CON USCITASERIALE Rs485 / GAS DETECTORS WITH Rs485 OUTPUTS

(5) MODULO 16USCITE O/C ST.G/OUT16 / 16O/C OUTPUTS MODULE ST.G/OUT16

(6) MODULO 8 RELE’ ST.G/8REL / 8 RELE’ ST.G/8REL MODULE

16 O/C

MULTISCAN++PK 16 CONTROL PANEL

E’ possibile realizzare il sistema con

1 BUS aperti oppure 1 BUS chiuso

Itispossible to make the systemwith

2 open BUS or 1 closed BUS

3.3) Technical specifications

Technical specifications

Housing:

Plasticbox IP65 dim. L.470, H.426, D.148 mm.

Inputs:

Max. 16 detectors with RS485 communications connected on the bus (SMART P) or 4-20

mA via STG/IN8 PK modules

Outputs:

6 relays on the unit + 32 Open Collector outputs on STG/OUT16-S modules (optional

STG/8REL relay board)

Relay Contact rating

8 A at 250 Vac

Optional ST.G/8REL relay

contact rating

16A at 250Vac

Serial ports:

2 x RS485)

1 x RS232 (PC connection)

Network connection

Optional TCP/IP module

Power:

100-120 Vac or 200-240 Vac selectable on the power supply via switch

Absorption:

Max 10 VA

Warm-up time:

Settable from 2 to 10 min. (default 3 min.)

Display:

Liquid crystal display (LCD)

Optic indications:

Double row of 9 leds

Working temp.

0/-55°C

Storage temp.

-20 ÷ +60 C°

Working RH:

15-85% (non condensed)

Storage RH

5-85% (non condensed)

3.4) Installation

After opening the transparent unit door, also open the front panel by rotating the black lock to

UNLOCK.

Remove the 4 screws at the 4 corners of the box and remove the front part of the unit box.

Holes can now be drilled in the bottom part of the box for wire passage.

MT4299E Rev.1 15/10/2019 Pagina 18 di 55

We recommend you use an IP65 wire clamp at wire entrance to maintain the same protection

level as the unit.

Secure the back of the unit to the wall using the holes (D) or by the enclosed brakets.

Dimensions (mm): A 470, B 426, C 380, D 312, E 128, F 148, G 14, H 125, I 75, L 50, M 48, N

98, O 41

Connect the tri-polar mains wire to the power supply terminal board (minimum 1.5mm2per pole)

and secure it with the specific wire clamp.

Power the unit and, next, connect the red and black tipped faston wires to the 2 x 12 V 7 Ah

max lead buffer battery power supply.

Vac

Power Supply

+-

BATTERIES

MT4299E Rev.1 15/10/2019 Pagina 19 di 55

3.4.1) Diagram and part identification

Box version

1

2

3

4

5

6

78

1- Power Supply (27 Vdc 4A)

2- 2 x 12V 7Ah batteries (not included)

3- RS232 serial port (PC connection)

4- RS485 serial boards

5- Relay outputs (8)

6- 8 detectors 4-20 mA inputs

7- Bus RS485 bus connections

8- Panel main board

MT4299E Rev.1 15/10/2019 Pagina 20 di 55

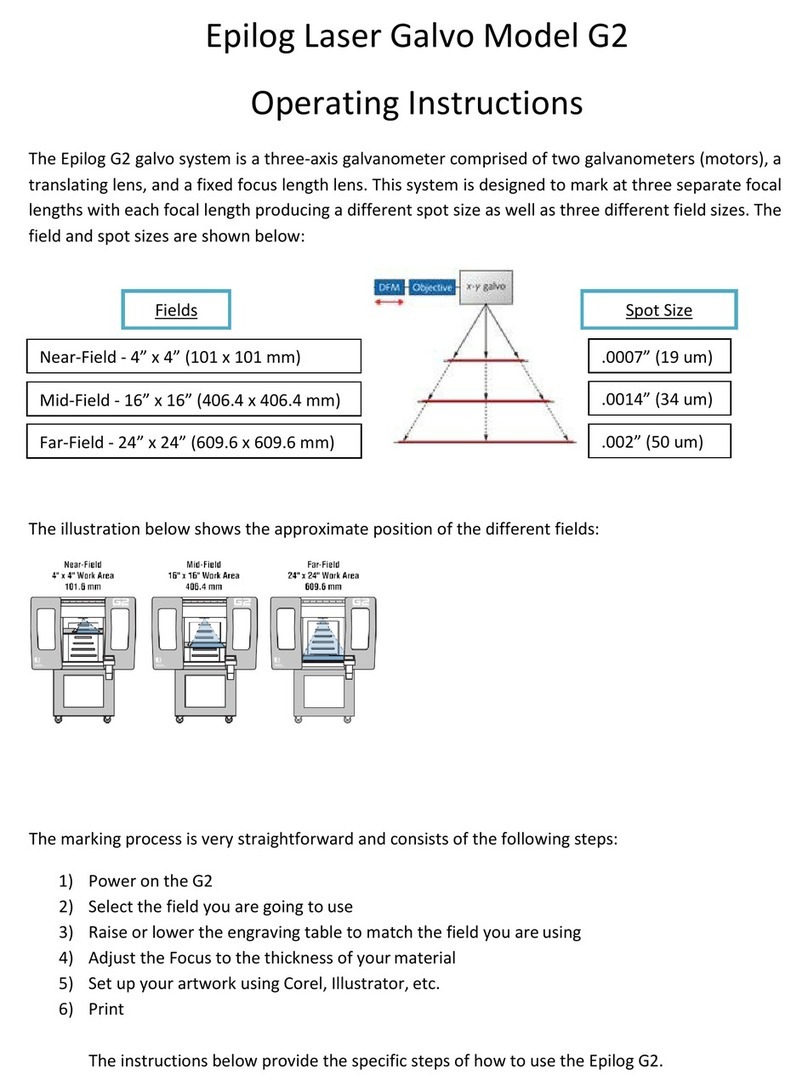

3.4.2) Main board layout

+

+-

-

ingressi analogici 4-20mA

4-20mAanalog inputs

digital input

(not used)

Usciterelè/ relayoutputs

123456

D3 switches: Control panel la nguage

Lang uage

En glish

Italian

Sp anish

Po rtog uese

Sw4 Sw3 Sw2 Sw1

ON OFF OFF OFF

OFF

OFF

OFF OFF

ON ON ON

ON ON ON

ON

ON

ON

ON

OFF ON

ON OFF ON

ON OFF OFF

OFF

ON

German

French

Slovenian

Dip switchsettaggio (vedi tabella)

Setting switches (seetable) Rs232

for PC

Rs485

line 1

Rs485

line 1

Rs485

line 2

NC

C

NO

NC

C

NO

NC

C

NO

Table of contents

Other Sensitron Measuring Instrument manuals