K3NX K3NX

6

Operation

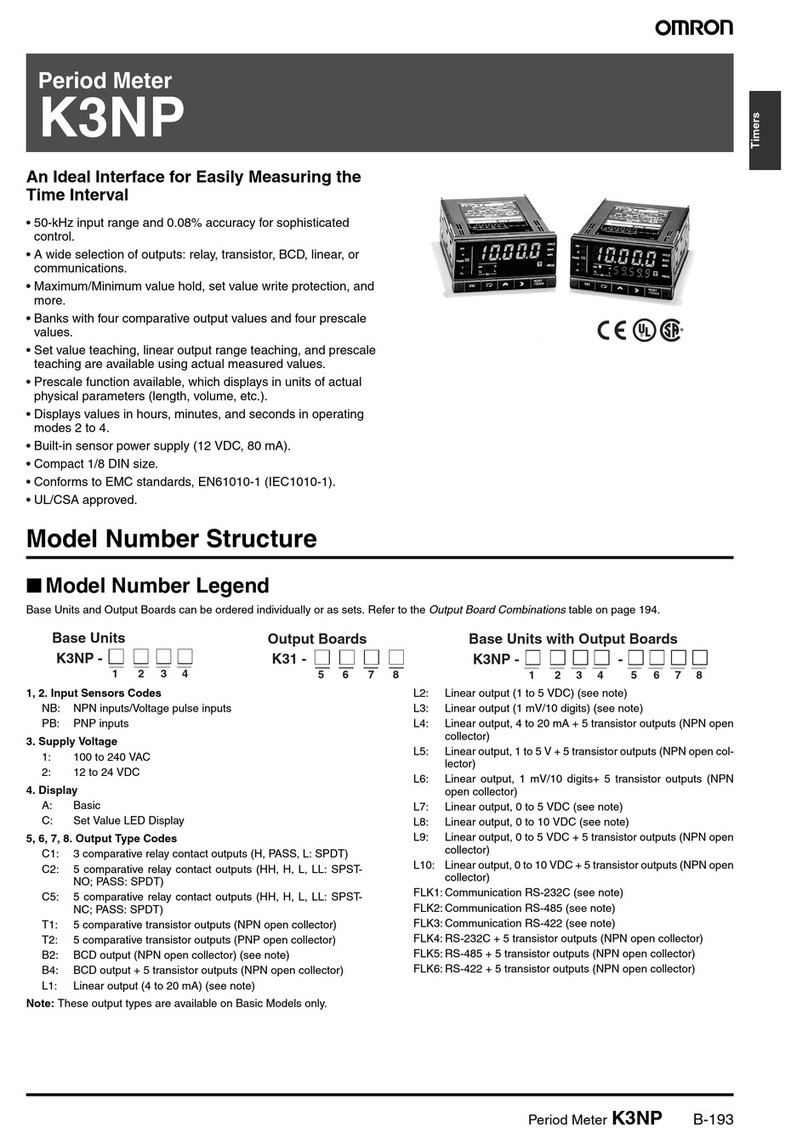

3SETTING PROCEDURES

The K3NX has four modes: RUN mode for normal operations, Setting mode for initial parameter input, Protect mode for lock-out configu-

ration, and Maintenance mode for initializing set values and user calibration. The parameters that are accessible on any individual K3NX

will vary depending on the Output Board installed. Refer to the

K3NX Operation Manual

for details.

RUN Mode: Remains in this mode under normal operation.

The process value or the max./min. value can be monitored.

Usingthefrontpanelkeys,thecomparativesetvaluecanbechangedandforced-zeroresetormax./min.valuesreset

can be performed.

Setting Mode: Used for making initial settings.

Includes four menus (Set value (,ç,â-), scaling (,äæ%â), setup (,â-.)), option (()-)) and the output test.

Protect Mode: Used for locking the front key operation or parameter changes.

Maintenance Mode: Used for initializing set values and user calibration of the inputs.

The user calibration is valid for selected input ranges.

Power ON

RUN mode

Setting mode

Maintenance mode

Protect mode

1s

1s

+

+

ESC ESC

ESC

ESC

When power is ON

,ç,â- - Program set values

,ç÷!! Enter set value HH

,ç÷ ! Enter set value H

,ç÷ % Enter set value L

,ç÷%% Enter set value LL

,äæ%â - Display scaling

"')÷ô Enter signal level for scaling point #2

ã,)÷ô Enter display reading for scaling point #2

"')÷õ Enter signal level for scaling point #1

ã,)÷õ Enter display reading for scaling point #1

ãâäø) Select decimal point

,â-.) - Program input range/Serial communications

"'ø- Specifying input range

á+â Select the supply frequency to eliminate inductive

noise

.ø'( Enter the unit no. for the host

å), Select the baud rate

%â' Select the word bit length

,å"- Select the stop bits

)+-1 Select the parity bits

()- - Supplementary settings related to display or control

æ. Set for averaging process value

,-"&â Set startup compensation time

!1, Enter hysteresis value

äø(.- Select the output pattern

%,â-÷! Enter the upper limit (H) of linear output range

%,â-÷% Enter the lower limit (L) of linear output range

+ø% Select the remote/local programming

-â,- - Generating simulated input for testing the output function

)+(- - Program lock-out configuration

æ%% Enable all key protection

,ç,â- Enable set value change prohibition

ëâ+( Enable prohibition of forced-zero reset using the

front panel keys

&&÷+,- Enableprohibitionofmax./min.valueresetusingthe

front panel keys

,âä+ Specify the menus to be protected against setting in

the setting mode.