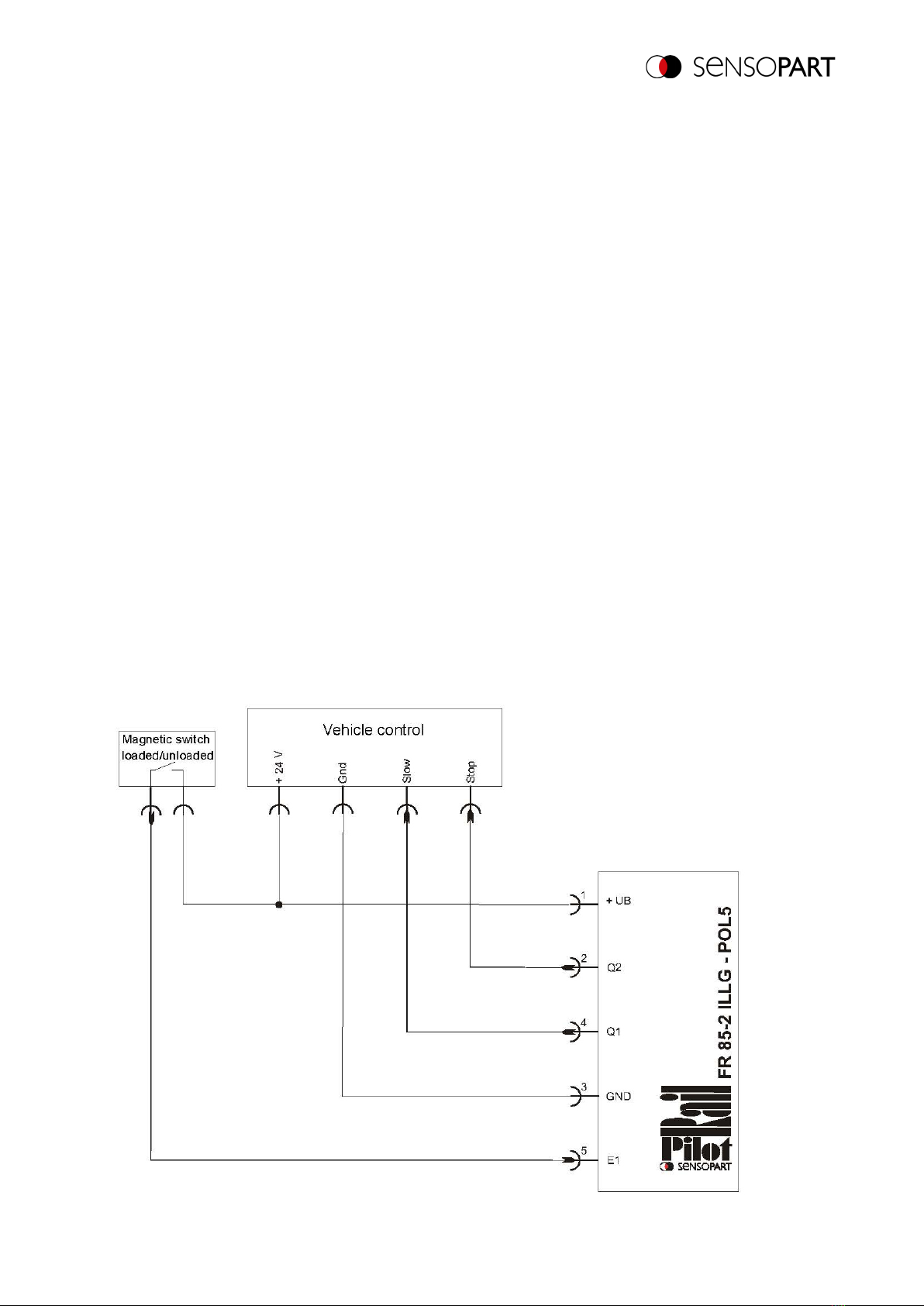

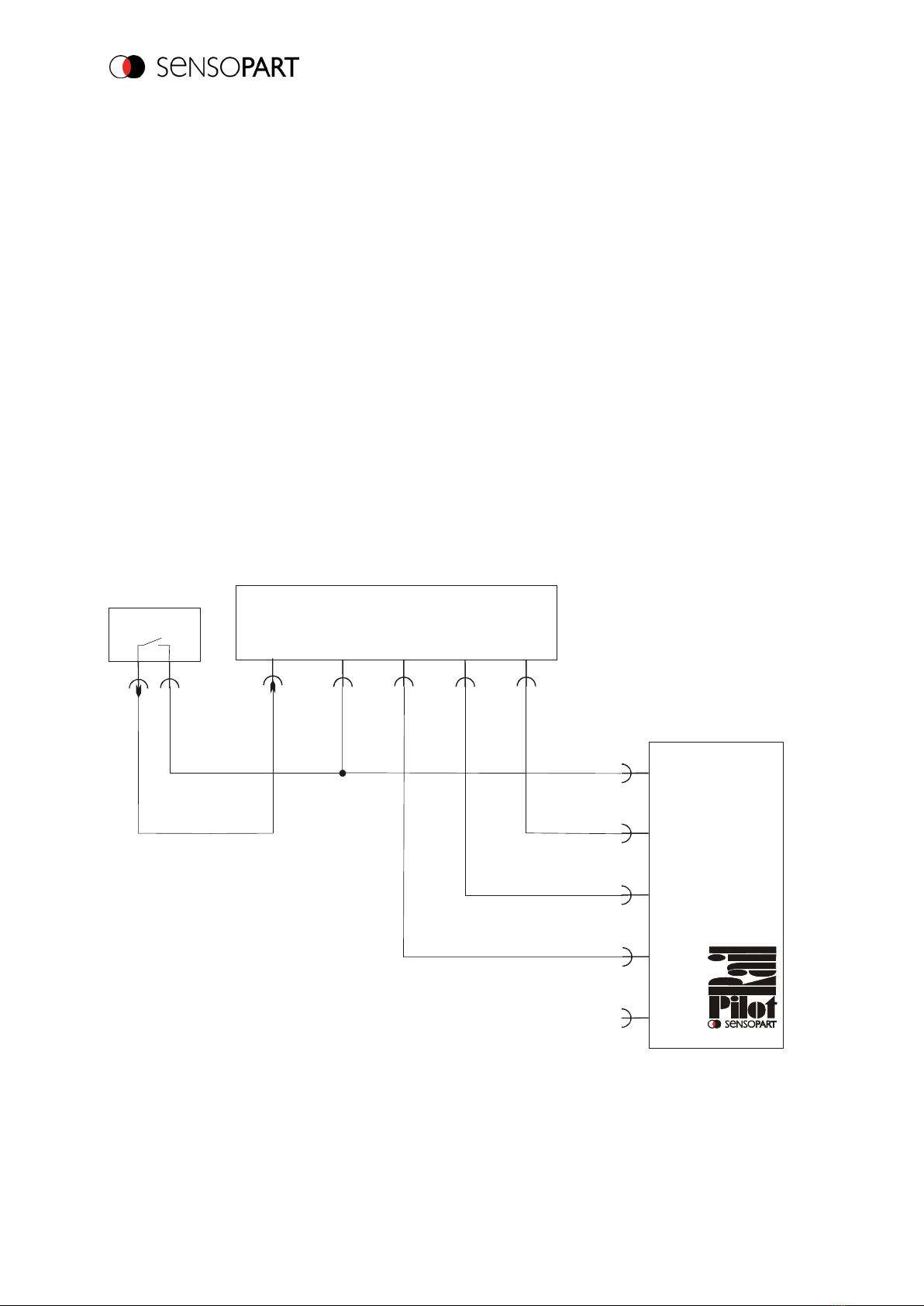

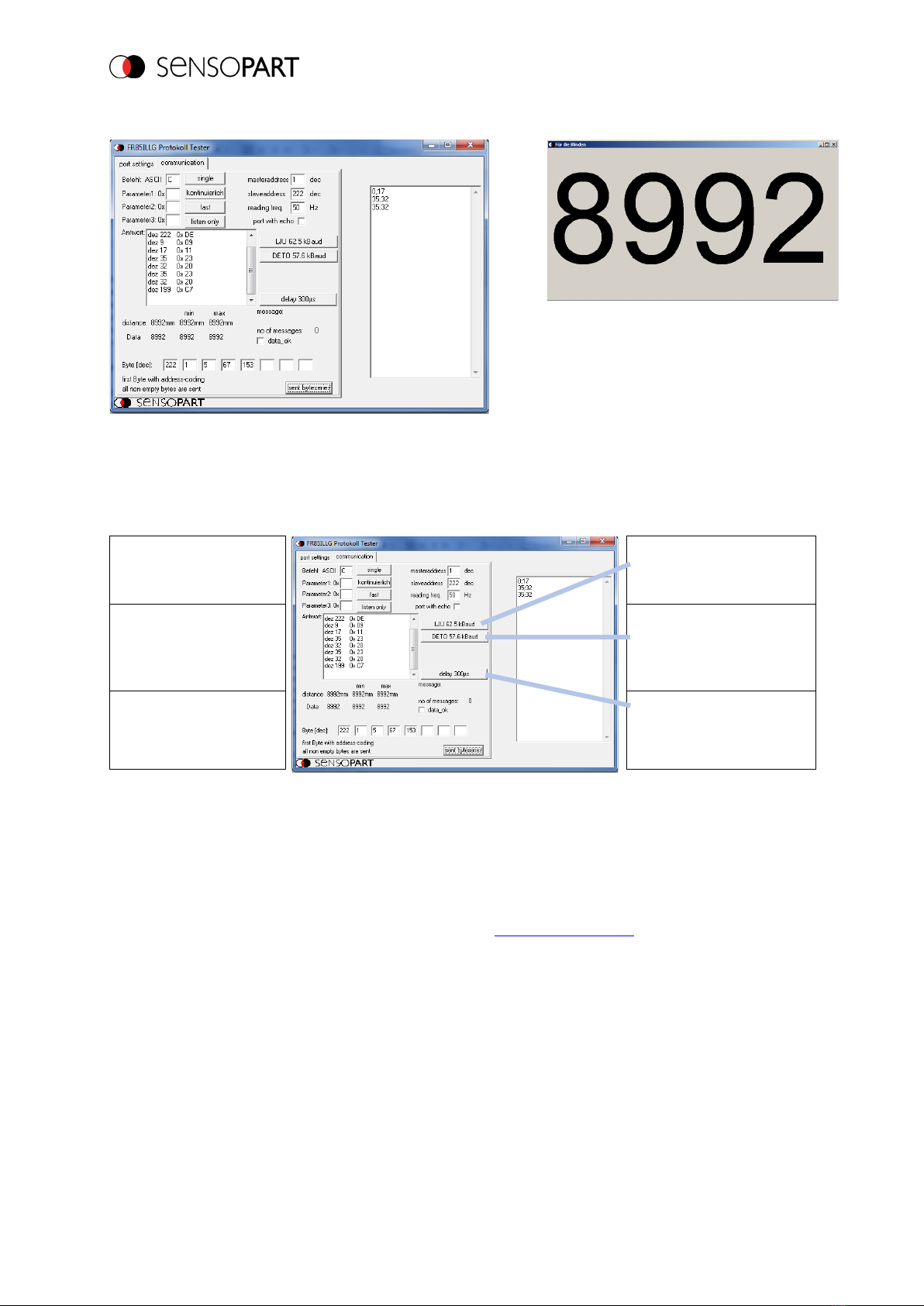

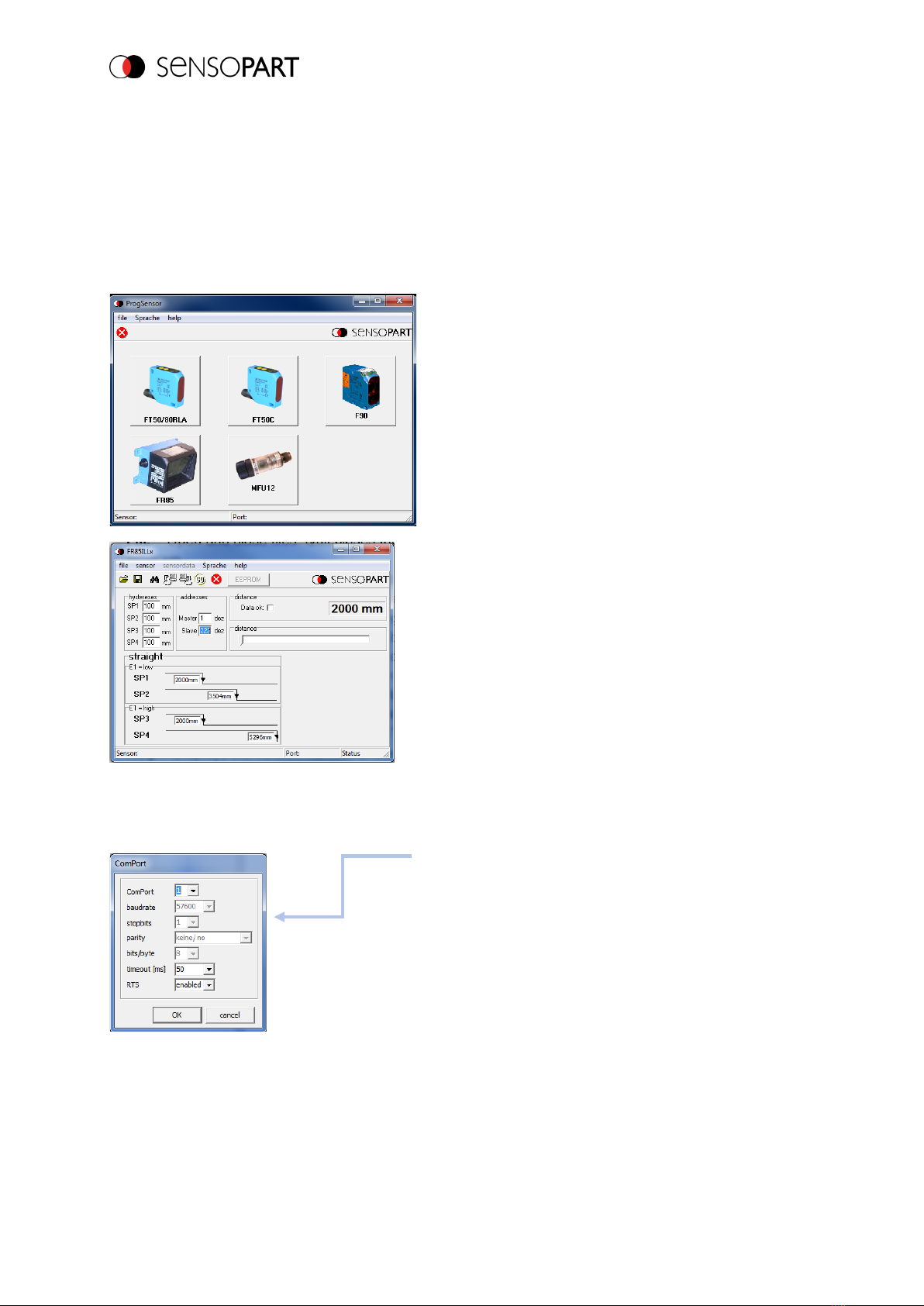

Sensopart RailPilot FR 85-2 ILLG-POL5 User manual

This manual suits for next models

4

Table of contents

Popular Security Sensor manuals by other brands

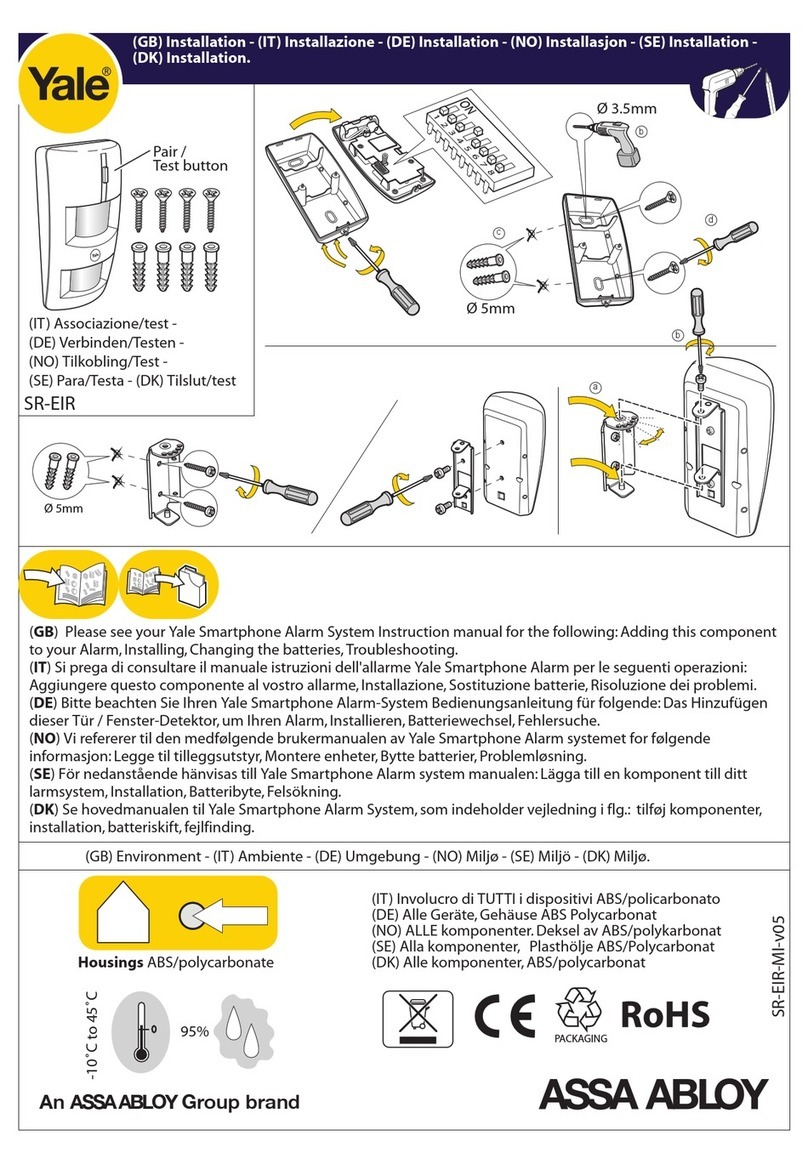

Assa Abloy

Assa Abloy Yale SR-A100-0EIR Installation

PCB Piezotronics

PCB Piezotronics ICP W138A05/-0019 Installation and operating manual

Bosch

Bosch DS939 installation instructions

Niko

Niko 351-0314 Series manual

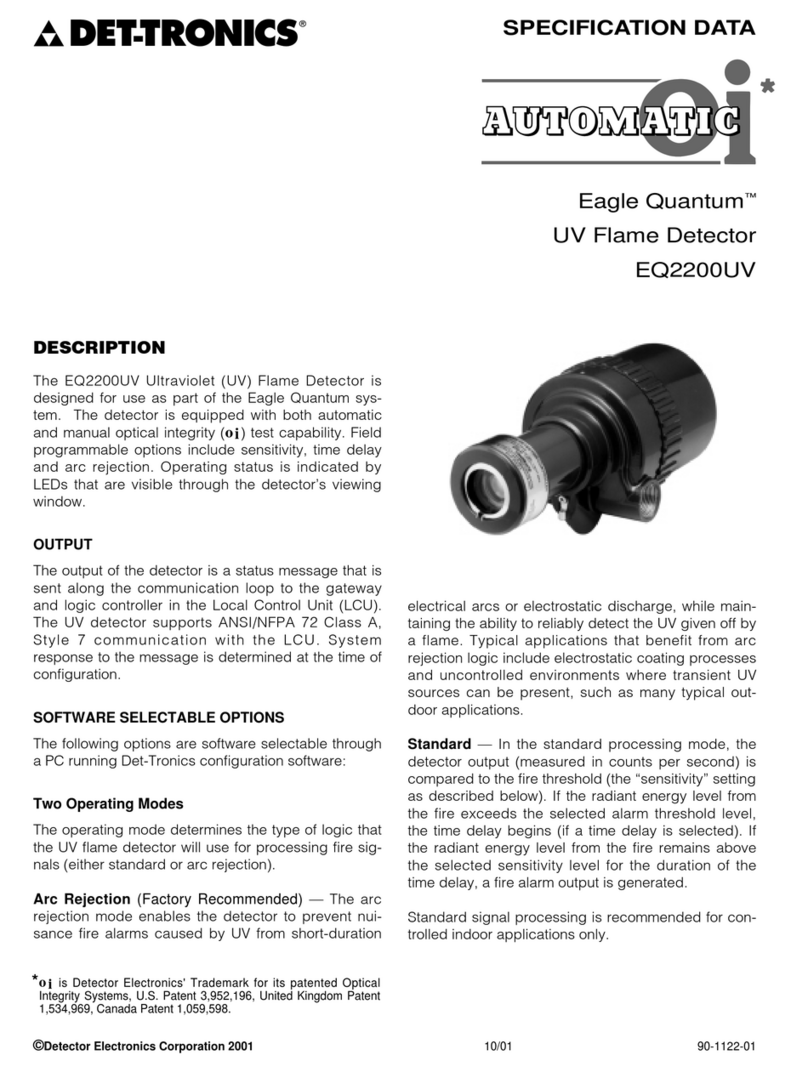

Det-Tronics

Det-Tronics Automatic Eagle Quantum EQ2200UV manual

PCB Piezotronics

PCB Piezotronics 118B11 Installation and operating manual

ABB

ABB Stanilite Series installation manual

Orno

Orno OR-AK-1210 Operating and installation instruction

B.E.G.

B.E.G. LUXOMAT PD9-M-1C+HVAC Installation and operating instruction

LEGRAND

LEGRAND Plexo 695 01 manual

Elkron

Elkron IR600VC Installation, programming and functions manual

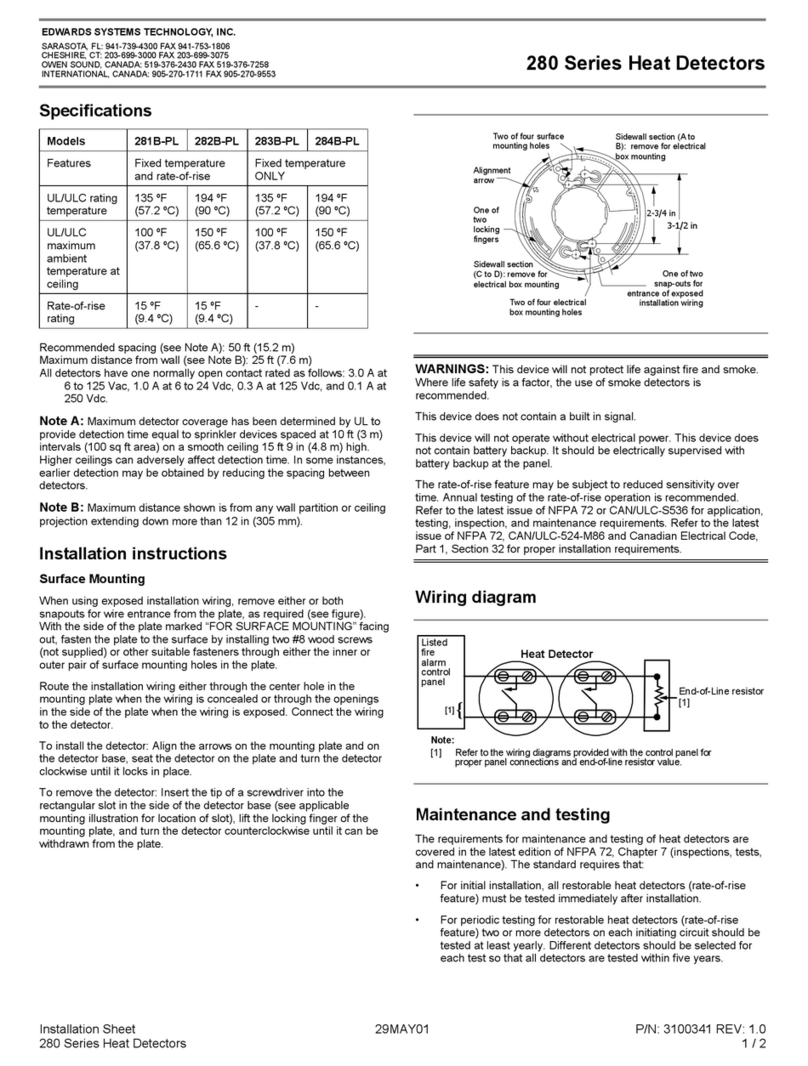

EDWARDS SYSTEMS TECHNOLOGY

EDWARDS SYSTEMS TECHNOLOGY 280 Series Installation sheet