2

The arc rejection algorithm examines the radiant ener-

gy level detected within a specified unit of time (timed

gate). The output of the detector is determined by

three variables:

— sensitivity level

— gate length

— number of consecutive gates required.

Different combinations of these variables allow for

various levels of arc rejection capability. Four arc

rejection levels are selectable for each detector

through a PC running Det-Tronics sortware.

The proper arc rejection setting for a given applica-

tion must be determined through testing. For indoor

applications with known electrostatic energy fields

within 15 feet of the detector, an arc rejection setting

of “very high” or “high” is typical. For outdoor appli-

cations, “medium” or “low” arc rejection settings are

typical.

Sensitivity

Whether the Standard or Arc Rejection mode is

selected, the sensitivity setting must always be pro-

grammed. The selected sensitivity level determines

the fire alarm setpoint. The higher the sensitivity level,

the greater the detection range, but the possibility of

false alarms will be increased. Four sensitivity levels

are selectable through the PC.

The sensitivity setting must be appropriate for the

anticipated fire size at the required distance from the

detector.

Time Delay

Arc rejection mode — If the fire signal meets the

programmed arc rejection requirements, the time

delay begins. A fire output is generated if the fire sig-

nal continues for the duration of the time delay.

Standard mode — A fire output is generated only if

the fire signal exceeds the sensitivity setting for the

entire duration of the programmed time delay.

Automatic or Manual oi

The patented Optical Integrity (oi) system uses an

internally generated UV test signal to determine the

relative condition of the detector and its optical sur-

faces.

If automatic oitesting is selected, the oitest is auto-

matically performed once every minute. The automat-

ic oitest does not generate an alarm output or inter-

fere with normal detector operation.

The manual oitest is initiated using a button on the

point display screen at the PC. The manual oitest

can be used in addition to automatic oito verify cor-

rect system operation.

ALARM LOG

Each detector maintains an alarm log in non-volatile

memory. The time and date are logged for the last 8

alarms.

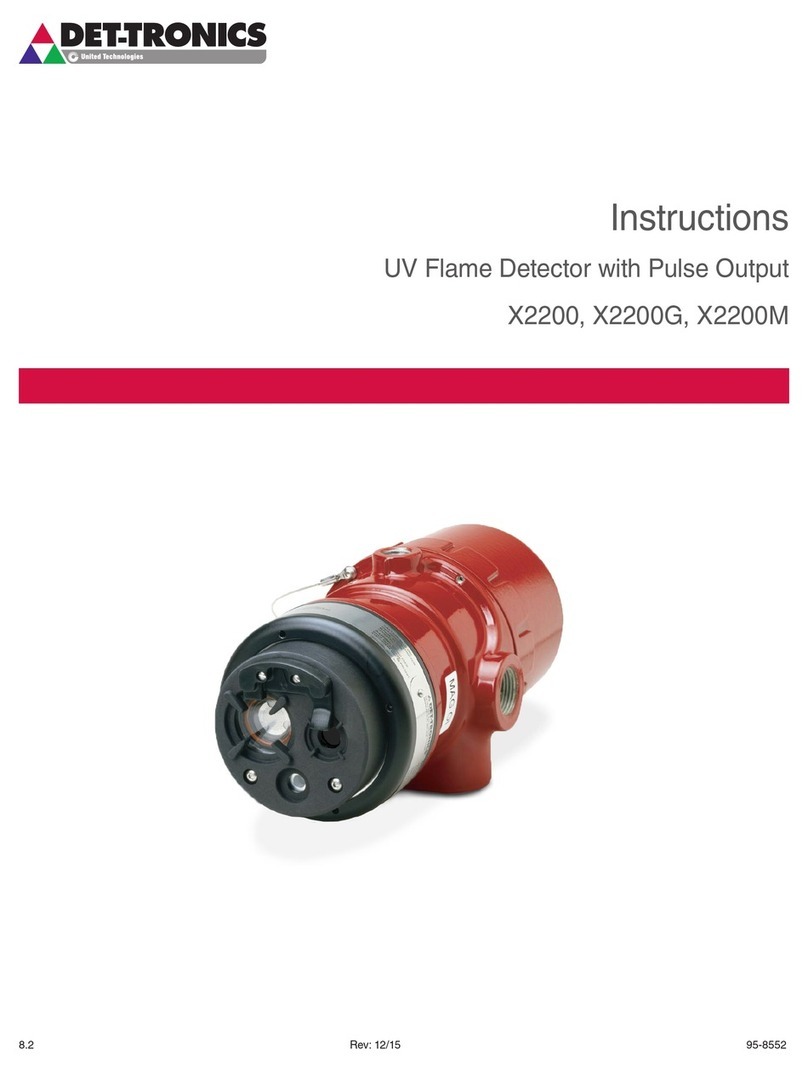

TERMINAL WIRING BOARD

All external wiring is connected to screw terminal con-

nectors on the terminal wiring board located inside

the detector housing (refer to the “Installation” section

for details).

FEATURES

• Programmable for arc rejection or standard signal

processing method.

• Long detection range to gasoline fires.

• Microprocessor based circuitry.

• Selectable automatic or manual oi.

• Adjustable sensitivity and time delay for fire output.

• Selectable latching or non-latching for fire and fault

outputs.

• Easily visible LEDs indicate normal operation, fire

and fault conditions.

• Operates under adverse weather conditions and in

dirty environments.

• Field addressable.

• Fault isolation.

• Pass through communication circuitry on power

loss.

• No calibration required.

• Non-volatile memory for configuration and logging

of alarms.

• Optional swivel mounting bracket for ease of instal-

lation and positioning.

• Screw terminal connectors.

• EMI hardened.

• FMR, CSA, CENELEC and CE Mark Certifications.

• FMR performance verified per ANSI/NFPA 72 and

FM 3260.