Part Number: 1460105

REV: A

When installing, make sure power is off when connecting the sensor, field, and relay wiring to the

appropriate terminal blocks. DO NOT turn the power back on until the 3100 is secured to the housing using

all four hex head screws.

•What are the characteristics of the gas that is to be detected? Is it lighter or heavier than air? If it is

lighter than air the sensor should be placed above the potential gas leak. Place the sensor close to the

floor for gases that are heavier than air. Note that air currents can cause a gas that is heavier than air to

rise. In addition, if the temperature of the gas is hotter than ambient air or mixed with gases that are

lighter than air, it could also rise.

•How rapidly will the gas diffuse into the ambient air? Select a location for the sensor that is close to the

anticipated source of a gas leak.

•Wind or ventilation characteristics of the immediate area must also be considered. Movement of air may

cause gas to accumulate more heavily in one area than in another. The detector should be placed in the

areas where the most concentrated accumulation of gas is anticipated. For outdoor applications with

strong wind conditions, it may require the sensors to be mounted closer together and on the downwind

side, to the anticipated area of a gas leak. Also take into consideration for indoor applications, the fact

that many ventilation systems do not operate continuously.

•The sensor should be accessible for maintenance.

•Excessive heat or vibration can cause premature failure of any electronic device and should be avoided

if possible.

•Follow all national and local installation codes and practices.

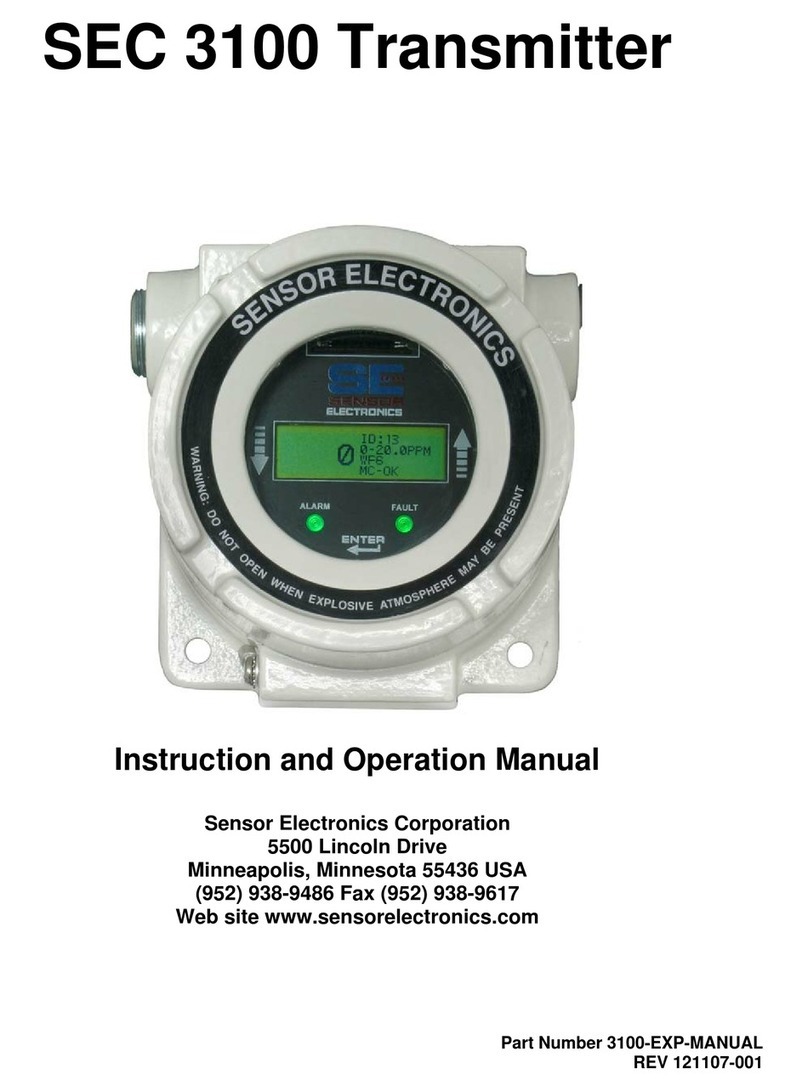

The SEC 3100 has three (3) ¾” NPT threaded connectors for mounting and wiring the sensor and

transmitter into a permanent installation.

Field wiring connections are made on the backside of the SEC 3100 printed circuit board (PCB). For wiring

details refer to Figure 2 in the back of the manual. ¾ NPT threads must pass L1 thread/plug gauge.

Mounting:

Mount the SEC3100 to rigid wall (wood based or stronger) or bulkhead structures using 1” or longer

fasteners with a minimum 3/16” diameter. Mounting to drywall (wallboard, plasterboard, etc.) or similar

material is not recommended.

Wiring:

Wire insulation for relay contacts should have a minimum breakdown voltage of twice that of the working

voltage of the signal. E.g. 110v lines should have a minimum insulation breakdown voltage of 220v, 240v

signals should have a minimum insulation breakdown voltage of 480v.

Wire insulation should be temperature rated for greater than or equal to 70°C.

There are 2 earth screws on the SEC 3100. One is on the outside of the enclosure and the other is

located on the inside of the enclosure. Both are marked with earth ground symbols and green

screws. Installation of this wire should include the use of a locking feature (i.e. locking washer).

Power wire sizing:

0 to 500 feet, recommended wire gauge size 16 AWG

501 to 1000 feet, recommended wire gauge size 14 AWG

Shielded cable is recommended. Wiring should be installed in medal conduit with no other cabling in the

same conduit. Use copper conductors only on all terminal blocks.

Colder applications may require an optional LCD heater for the SEC 3100 to make sure the LCD can be

always visible. This is a closed loop heater that will turn on when the temperature drops below