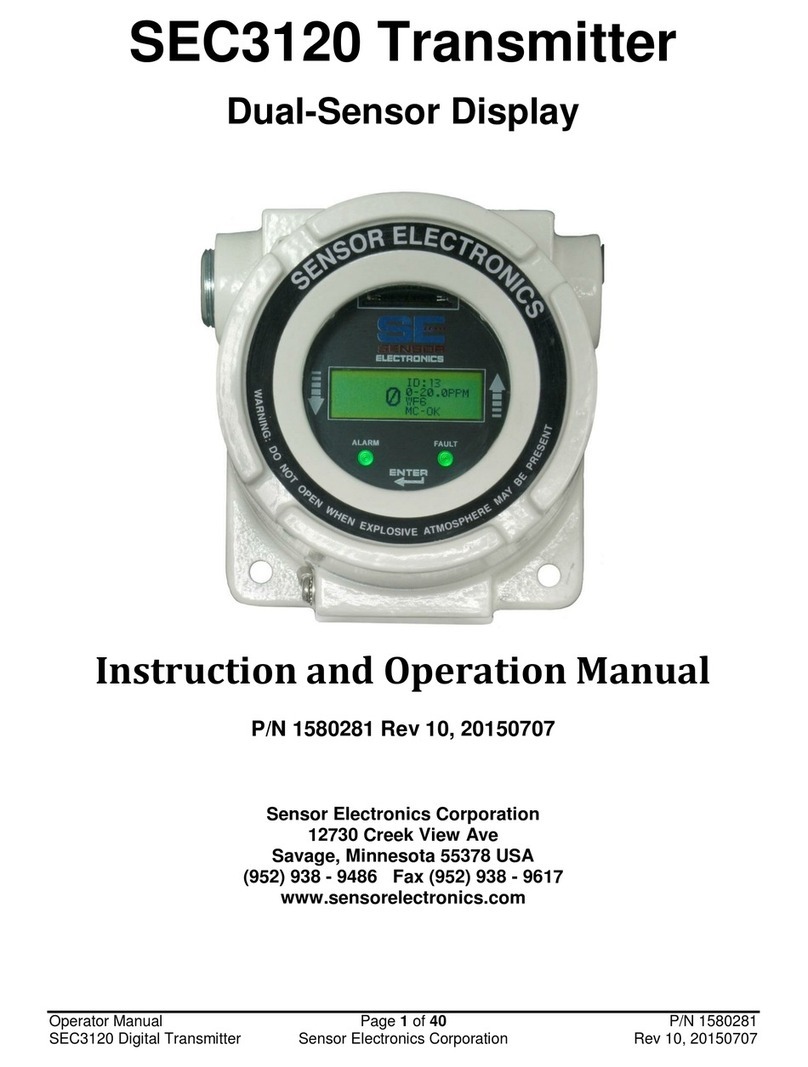

Sensor Electronics SEC 3100 Manual

SEC 3100 Transmitter

Instruction and Operation Manual

Sensor Electronics Corporation

5500 Lincoln Drive

Minneapolis, Minnesota 55436 USA

(952) 938-9486 Fax (952) 938-9617

Web site www.sensorelectronics.com

Part Number 3100-EXP-MANUAL

REV 121107-001

Sensor Electronics Corporation

Sensor Electronics Corporation (SEC) designs and manufactures innovative fixed system gas detection

quality and service are uncompromising. our products with a two-year warranty on all

Gas Detect

Individually designed maintenance pack ic customer needs. Service begins with

Sensor Electronics Corporation (SEC) warrants anufactured by SEC to be free from defects in

cluding rough handling, mechanical damage, alteration or repair. This

Year 2000 Compliance

All Sensor Electronics products have b d by Sensor Electronics to accurately

equipment, for combustible gases, oxygen, carbon dioxide and toxic gases.

Commitment

Our We back each of

materials and workmanship. We offer technical support, user training and on-site service and maintenance

of equipment to meet the needs of our customers.

ion Service

ages are available for specif

verification of the system installation that includes an initial system check and calibration. We then offer

customer training programs (on-site and at factory) to insure that technical personnel fully understand

operation and maintenance procedures. When on-the-spot assistance is required, service representatives

are available to handle any questions or problems immediately.

Warranty

products m

workmanship and materials for a period of two (2) years from date of shipment from the factory. Any parts

returned freight pre-paid to the factory and found defective within the warranty would be repaired or

replaced, at SEC's option. SEC will return repaired or replaced equipment pre-paid lowest cost freight. This

warranty does not apply to items, which by their nature are subject to deterioration or consumption in normal

service. Such items may include:

Fuses and Batteries. y abuse in

Warranty is voided b

warranty covers the full extent of SEC liability and SEC is not responsible for removal, replacement costs,

local repair costs, transportation costs or contingent expenses incurred without prior written approval.

Sensor Electronics Corporation's obligation under this warranty shall be limited to repair or replacement of

any product that has been returned to Sensor Electronics Corporation for warranty consideration. This

warranty is expressly in lieu of any and all other warranties expressed or implied, and all other obligations or

liabilities on the part of Sensor Electronics Corporation including but not limited to, the fitness for a particular

purpose. In no event shall Sensor Electronics Corporation be liable for direct, incidental, or consequential

loss or damage of any kind connected with the use of it's products or failure to function or operate properly.

een tested and are certifie

process date/time and date/time related data from, into and between the 20th and 21st centuries. Sensor

Electronics products neither contain nor create any logical or mathematical inconsistency, will not

malfunction, and will not cease to function when processing date/time data.

Please contact Sensor Electronics for further information.

Table of Contents

I. SPECIFICATIONS

II. GENERAL DESCRIPTION

III. OPERATION

Installation and Startup

Fault Codes

IV. MAGNETIC SWITCH OPERATION

V. FIGURES

Figure 1 – Overall Layout

Figure 2 – SEC 3100 Wiring

Figure 3 – SEC Sensor Separation Kit

I. SPECIFICATIONS

Model:

SEC 3100 Transmitter

For use with:

SEC Millenium and SEC Signature series infrared sensors and SEC 3000 Toxic and Oxygen gas sensors.

Part Number: SEC 3100100

Output (analog):

4-20 mA (Source type), max. 1000 Ohm load at 24 VDC supply voltage

Output (digital):

RS485 LAN (isolated)

Output (relays):

Three (3) Alarm, Low, Mid High. One (1) Fault

Rated for 8 Amps 30 VDC or 220VAC

Display:

LCD (backlit)

Construction:

Epoxy coated aluminum

Class 1, Division 1, Groups B, C and D

Operating Temperature Rating:

-40°to +158°F at 0 to 99% RH (non-condensing)

(-20°to +70°C)

Operating Voltage:

24 VDC

Operating range: 18 to 30 VDC measured at the detector head

Max. Current Draw: (at 24 VDC with sensor)

Average: 250 mA

Peak: 500 mA

Installation Category: Cat. I, Pollution Degree 2

II GENERAL DESCRIPTION

CONVENTIONS

The following conventions are used in this manual.

Warning Statement

!

VDC (DC Voltage)

SEC 3100

The SEC 3100 transmitter is designed to be used with the SEC Millenium, SEC Signature infrared gas

sensors or SEC 3000 toxic gas detectors. The SEC 3100 is a microprocessor based intelligent transmitter

continuously monitoring information from the gas sensor. The LCD of the SEC 3100 displays the gas

concentration and sensor status. The SEC 3100 has one (1) “Alarm” LED and one (1) “Status” LED. The

SEC 3100 also has three (3) magnetic switches located around the circumference of the unit. This manual

will describe the operation and use of the SEC 3100 transmitter.

Features

•Explosion Proof

•Back lighted LCD Display

•Low Cost

•Plug and play toxic, oxygen and combustible gas sensors

•Self-check system

•4-20 mA ouput

•RS-485 Interface (Isolated)

•Optional alarm and fault relays

•Non-intrusive programming

•Non-intrusive calibration

•Removable, non-volatile, time stamped data logging

•Optional IS barrier

•Digital communication link to SEC 3000 and SEC Millenium Gas Detectors

•Multi port housing for easy installation

III. OPERATION

Installation and Startup

Warning: The user shall be made aware that if the equipment is used in a manner not specified by the

manufacturer, the protection provided by the equipment may be impaired.

!

The first step in the installation process is to establish a mounting location for the SEC 3100 transmitter and

gas sensor. Select a location that is typical of the atmosphere to be monitored or close to the anticipated

source of a dangerous gas.

It is very important that the SEC 3100 and gas sensor be properly located enabling it to provide maximum

protection. The most effective number and placement of sensors vary depending on the conditions of the

application. When determining where to locate gas sensors the following factors should be considered.

•What are the characteristics of the gas that is to be detected? Is it lighter or heavier than air? If it is

lighter than air the sensor should be placed above the potential gas leak. Place the sensor close to the

floor for gases that are heavier than air. Note that air currents can cause a gas that is heavier than air to

rise. In addition, if the temperature of the gas is hotter than ambient air or mixed with gases that are

lighter than air, it could also rise.

•How rapidly will the gas diffuse into the ambient air? Select a location for the sensor that is close to the

anticipated source of a gas leak.

•Wind or ventilation characteristics of the immediate area must also be considered. Movement of air may

cause gas to accumulate more heavily in one area than in another. The detector should be placed in the

areas where the most concentrated accumulation of gas is anticipated. For outdoor applications with

strong wind conditions, it may require the sensors to be mounted closer together and on the down wind

side, to the anticipated area of a gas leak. Also take into consideration for indoor applications, the fact

that many ventilation systems do not operate continuously.

•The sensor should be accessible for maintenance.

•Excessive heat or vibration can cause premature failure of any electronic device and should be avoided

if possible.

•Follow all national and local installation codes and practices.

The SEC 3100 has three (3) ¾” NPT threaded connectors for mounting and wiring the sensor and

transmitter into a permanent installation.

Field wiring connections are made on the backside of the SEC 3100 printed circuit board (PCB). For wiring

details refer to Figure 2 in the back of the manual.

Power wire sizing:

0 to 500 feet, recommended wire gauge size 16 AWG

501 to 1000 feet, recommended wire gauge size 14 AWG

Shielded cable is recommended. Wiring should be installed in medal conduit with no other cabling in the

same conduit.

Warm-up

When power is applied to the SEC 3100, it enters a one (1) minute warm-up mode. The output current will

be 0.8 mA during the warm up time period. At the end of the warm-up period with no faults present, the

SEC 3100 automatically enters the normal operating mode (4.0 mA with no gas present). If a fault is

present after warm-up, the detector current output and LCD will indicate a fault. The Fault LED will also

indicate the fault.

Normal

In the normal operating mode, the 4 to 20 mA signal levels correspond to the detected gas concentration.

The transmitter continuously checks for and displays system faults or initiation of calibration and

automatically changes to the appropriate mode.

The 4 to 20 mA output of the SEC 3100 sensor is a non-isolated current source.

Current Output and Corresponding Status

Current Output Status

0-20 mA Normal measuring mode

0.0 mA Unit Fault

0.2 mA Reference channel fault

0.4 mA Analytical channel fault

0.8 mA Unit warm up

1.0 mA Optics fault

1.2 mA Zero drift fault

1.6 mA Calibration fault

2.0 mA Unit spanning

2.2 mA Unit zeroing

4.0 mA Zero gas level (0% of full scale)

5.6 mA (10% of full scale)

8.0 mA (25% of full scale)

12 mA (50% of full scale)

16 mA (75% of full scale)

20 mA Full scale (100% of full scale)

20.1- 23 mA Over-range (> 100% of full scale)

Once the fault is cleared the SEC 3100 will atomatically resume normal operation.

Flash

Rate Output Current Unit Status

Label Possible Problem

1 4-20ma Unit Running Unit is measuring gas and adjusting 4-20ma output accordingly.

2 2.2ma Unit Zero Calibrating Unit going through its zero calibration procedure.

3 2.0ma Unit Spanning Unit going through its spanning procedure.

5 0.8ma Unit Warm-up Only for one minute after unit power-up

6 0.0ma Power-up Fault Hard Fault (refer to gas sensor manual)

7 1.6ma Calibration Fault 1. Attempt Unit Span with no gas

2. Attempt Unit Zero with gas

8 NA NA Currently Not Used

9 0.0ma Unit Fault Hard Fault (refer to gas sensor manual)

10 1.0ma Optics Fault Clean sensor’s windows

11 1.2ma Zero Drift Fault Hard Fault (refer to gas sensor manual)

12 0.0ma Configuration Fault Hard Fault (refer to gas sensor manual)

16 0.2ma Reference Channel Fault Hard Fault (refer to gas sensor manual)

17 0.4ma Active Channel Fault Hard Fault or Unit Zero with gas

IV. MAGNETIC SWITCH OPERATION

The SEC 3100 has three (3) magnetic switch pickups on the Display PCB. The picture below shows the

location of the magnetic switches labeled UP, DOWN and ENTER. Placing a magnet in close proximity to

one of the switches will cause the following operations to occur.

Switch Operation

ENTER Enter Menu Mode, Selects a menu to Enter

UP Moves up through Menu selections

DOWN Moves down through Menu selections

For further details on gas sensor calibration refer to the appropriate SEC sensor instruction manual.

The LCD contrast potentiometer, (POT1) is located under the protective faceplate shown above on the front

side (LCD side) of PCB to the left of the LCD.

Gas Sensor Port (1 x¾h)

SEC 3000

SEC Millenium

Magnetic Switch (3)

Field Wiring Port (2 x¾h)

¾Power

¾4-20 mA

¾RS485 (MODBUS)

¾Alarm Relays

Fault LED

Green OK

Memory Data Card

Slot

Red Fault

LCD Display:

Real Time Status

Gas Type

Gas Concentration

Fault Identification

Range

ID Number

Memory Card Status

Interactive Menus

Calibration

Relay Programming

ID & Zone Number

Mounting holes (2)

Alarm LED

Green OK

Yellow Low Alarm

Orange Mid Alarm

Red High Alarm

V. MENU OPERATION

Inital Power Up Sequence of the SEC 3100

SYSTEM BOOT PROCESS

--- WAIT FOR SYNC –-

SYSTEM BOOT PROCESS

-WAIT FOR SENSOR -

INITIALIZING

ID: xx

WARM SN: xxxxx

UP TYP: x.x

VER: x.x

ID: xx

WARM 0-20.0PPM

UP WF6

ENT TO ABORT

ID: 1

0-20.0 PPM

WF6

MC - REMOVED

0

In normal operating mode. Actual gas concentration will be displayed to the left of ID #, Range, Gas

Type, MC (Memory Card) status.

Selecting Enter when the SEC 3100 in in normal operating mode will advance to the following display:

Selecting Enter will allow the operator to safely remove the Memory Card.

Down Arrow Arrow Down

* EJECT MEMORY CARD

INFO

MAIN MENU

EJECT MEMORY CARD

* INFO

MAIN MENU

Entering the INFO menu will display the following screen

Selecting Enter at UNIT INFO displays the following:

SN is the SEC 3100 serial number. VER is the SEC 3100 software version number. Selecting Enter again

will return the display to the main info menu.

The following are the other INFO sub displays and descriptions. To return back to the main INFO menu

from the sub menus, select Enter.

Sensor Status Menu

TYP: Sensor type (0.0 is a SEC 3000, 32.0 is SEC

Millenium)

SN: Sensor serial number.

VER: Version of sensor software.

CAL: Calibration date of sensor.

Sensor Status Menu

RBR COUNT : SEC information

ICE COUNT : SEC information

. BATTERY : Displays status of SEC 3100 battery

Select Exit to go back to

* UNIT INFO

SENSOR INFO

STATS

EXIT

3100 UNIT INFO:

SN- XXXXXXXXXXXXXXX

VER- X X.XXX.XXX

SENSOR INFO:

TYP: XXX

SN: XXXXX VER: XX.X

CAL: XX

–

XX - XXXX

* UNIT INFO

SENSOR INFO

STATS

EXIT

SYSTEM STATS:

RBR COUNT : XXX

ICE COUNT : XXX

BATTERY : XXX

UNIT INFO

SENSOR INFO

STATS

* EXIT

EJECT MEMORY CARD

* INFO

MAIN MENU

Main Menu and Sub Menus

Enter Calibration Menu

EJECT MEMORY CARD

INFO

* MAIN MENU

* CALIBRATION

ALARM

RELAY

Used to calibrate

the gas sensor.

DownArrow

Alarm Menu

Usedtoset

CALIBRATION

* ALARM

RELAY

alarm level set

points and

parameters.

Down Arrow

Relay Menu

Forsetting

alarmrelay

On&Offdelay&

Energizedstates.

CALIBRATION

ALARM

* RELAY

Down Arrow

Network Menu

Used to set

Zone #, ID # and

Select Online

* NETWORK

HIDE NO

DownArrow

Hide Menu

Hideisusedto

blankthe

NETWORK

* HIDE NO

display up to

low alarm setting

DownArrow

Self Test Menu

Generatesa

signalonthe

display, RS485

& 4-20 mA

* SELF TEST

DATE TIME

Down Menu Date Time Menu

Sets the date

and time in the

real time clock.

SELF TEST

* DATE TIME

DownArrow

Exit back to

normal

operation.

* EXIT

Calibration Menu

Enter

* CALIBRATION

ALARM

RELAY

Using the Up and Down arrows allows the operator to move the cursor (*) to select a function.

To Zero the sensor apply clean air (N2 for an oxygen sensor) and select enter. The following will be

displayed.

Then the following will be displayed.

Once complete the following will be displayed. The sensor has been successfully zeroed.

Arrow down to CAL. VAL to verify the span gas calibration value matches the value of the span gas

calibration on hand. If not, select Enter and the following screen will appear.

ZERO

SPAN

* CAL. VAL 5 *

EXIT

* ZERO 0

SPAN

CAL. VAL

EXIT

CALIBRATION PROCESS

------- WAIT ----------

CALIBRATION PROCESS

------- DONE ----------

* ZERO 0

SPAN

CAL. VAL

EXIT

Using the Up and Down arrows will allow the operator to change the calibration gas value of the sensor to

match the calibration gas used to span the sensor. Once the correct value is displayed select Enter and the

sensor will be uploaded with the new calibration gas value.

To Span the sensor with calibration gas use the Up and Down arrows to select the following display.

Apply span gas to the sensor for the appropriate amount of time in order for the sensor to stabilize. The gas

reading is displayed to the right of ZERO. Once stable select Enter. This will go the display:

If calibration span gas is still present the display will read:

Apply clean air to the sensor to reduce this reading.

The display will advance to the following:

ZERO 3

* SPAN

CAL. VAL

EXIT

CALIBRATION PROCESS

------- DONE ----------

GAS LEVEL : 5

CALIB. GAS PRESENT

---- WAIT ----

* ZERO 0

SPAN

CAL. VAL

EXIT

This completes the calibration and the device can be put back into the normal operating mode.

Arrow Down to

ZERO

SPAN

CAL. VAL

* EXIT

Enter

* EXIT

Enter again and the SEC 3100 returns to normal operation.

Alarm Menu

Enter

CALIBRATION

* ALARM

RELAY

Enter

Select the Alarm Relay (LOW, MID, HI) using the down arrow. Once the cursor is on the alarm relay you

wish to configure, hold the magnet over Enter. The example LOW will be used. The same operations can

be used to set the MID or HI relays.

* LOW

MID

HI

EXIT

* ALARM LOW 4

LATCH

ACTIVE

EXIT

Selecting Enter will display the following screen allowing the alarm set point to be

programmed. Using the Up and Down arrows will change the set point. Once the correct set point is

displayed select Enter and the new value will be accepted.

* ALARM LOW 2 *

LATCH

ACTIVE

EXIT

CONFIGURING PROCESS

------ WAIT -------

* ALARM LOW 2

LATCH

ACTIVE

EXIT

Arrow Down

ALARM LOW

* LATCH NO

ACTIVE

EXIT

Selecting Enter will allow the operator to change the operation of the relay operation from Non-Latching

(NO) to Latching (YES).

Arrow Down

Selecting Enter will allow the operator to change the operation of the relay operation from Active HI to Active

LOW. HI activates the relay on a rising alarm level. LOW actives the relay when the alarm threshold falls

below the alarm set point. Once the correct operation is selected, use the Down arrow to advance to the

next menu item.

Arrow Down

Selecting Exit will advance to the next menu.

This menu will allow the operator to select another relay to program. Or select Exit and the next display will

be:

ALARM LOW

LATCH

* ACTIVE HI

EXIT

* LOW

ALARM LOW

LATCH

ACTIVE

* EXIT

MID

HI

EXIT

* EXIT

Selecting Enter on this display will put the SEC 3100 back into normal operation.

Relay Menu

CALIBRATION

ALARM

* RELAY

Selecting Enter will advance to the following menu.

* LOW

MID

HI

Arrow down to the next screen will be

* FAULT

EXIT

Select the Alarm Relay (LOW, MID, HI, FAULT) that is to be configured using the down arrow. Once the

cursor is on the correct alarm relay, hold the magnet over Enter. The example LOW will be used. The

same operations can be used to set the MID, HI, or FAULT relays.

* LOW

MID

HI

Select Enter

Select Enter

Using the Up and Down arrows the operator can change the ON delay time for the relay to actuate after the

alarm threshold has been exceeded. The time is measured in seconds (0-255). Once the correct time is

displayed select Enter to accept the new value. Then Exit the menu and proceed on to the next selection.

In this example the Low alarm relay will actuate 30 seconds after the Low set point is exceeded.

* ON DLY LOW 0

OFF DLY

ENERGIZED

EXIT

* ON DLY LOW 0 *

OFF DLY

ENERGIZED

EXIT

* ON DLY LOW 30

OFF DLY

ENERGIZED

EXIT

Select Enter

ON DLY LOW

* OFF DLY 0

ENERGIZED

EXIT

Select Enter

ON DLY LOW

* OFF DLY 0 *

EXIT

Using the Up and Down arrows the operator can change the OFF delay time for the relay to turn OFF after

the reading has decreased below the alarm point threshold. The time is measured in seconds (0-255).

Once the correct time is displayed select Enter to accept the new value. Then Exit the menu and proceed

on to the next selection.

In this example the Low alarm relay will stay energized for 60 seconds after the alarm has cleared.

ON DLY LOW

* OFF DLY 60

ENERGIZED

EXIT

Arrow Down

ON DLY LOW

OFF DLY

* ENERGIZED NO

EXIT

Selecting Enter will allow the operator to change the operation of the relay coil from normally de-energized

(ENERGIZED NO) to normally energized (ENERGIZED YES). Once the correct operation is selected, use

the Down arrow to advance to the EXIT menu. Select Enter to go back to the Relay Menu

* LOW

MID

HI

This menu will allow the operator to select another relay to program. Or select Exit and the next display will

be:

* FAULT

EXIT

Arrow Down to Exit

FAULT

* EXIT

Enter

* EXIT

Selecting Enter will return the SEC 3100 into normal operation.

Network Menu

* NETWORK

HIDE

Select Enter

* ZONE 0

ID

ONLINE

EXIT

Select Enter to change the Zone number of the SEC 3100.

* ZONE 0 *

ID

ONLINE

EXIT

Use the Up and Down Arrows change the Zone number (0-255). Once the correct Zone number is

displayed select Enter.

Arrow Down to ID. To change the ID number select Enter. Use the Up and Down Arrows to change the ID

number (0-255). Once the correct ID number is displayed select Enter.

Arrow Down to Online.

ZONE

* ID 1 *

ONLINE

EXIT

ZONE

ID

* ONLINE YES

EXIT

Using Enter the operator can toggle between Online YES and Online NO. Online YES turns on the MODUS

RS485 communication. Online NO turns the MODBUS RS485 communication off.

Arrow Down to Exit

ZONE

ID

ONLINE

* EXIT

Enter

* EXIT

Hide Menu

NETWORK

* HIDE NO

Using Enter the operator can toggle between Hide YES and Hide NO.

The Hide function allows the operator to not display the gas reading until the Low Alarm threshold is

exceeded. All outputs will function as normal when the Hide mode selected to YES.

Self Test Menu

* SELF TEST

DATE TIME

Selecting Enter for the Self Test will make the sensor generate a 4-20 mA input into the SEC 3100 from 4

mA to 20 mA (0-fullscale). In the self test mode the SEC 3100 outputs are fully functional. The SEC 3100

will display the rising gas level, the 4-20 mA output will increase to 20 mA, the relays will actuate and the

RS485 information will be transmitted to the control system. The following screen will be displayed

: 1ID

0

W

S

10.4 -20.0 PPM

F6

ELF TESTD

Once the unit reaches full scale the SEC 3100 automatically returns to normal.

Time Date Menu

SELF TEST

* DATE TIME

Entering this menu will allow the operator to set the time and date of the SEC 3100 real time clock.

Selecting Enter will locate a cursor (*) above the number allowing the operator to use the Up Down arrows

to increase or decrease the numbers. Once the correct number is displayed, select Enter with the magnet

and the cursor will advance to the next number.

Date is MM/DD/YYYY. Time is HH/MM/SS. Below is an example.

Enter from above display.

Arrow Up one number.

Enter

Continue with the sequence until the correct date appears. Then select Enter and the following will be

displayed.

At this point the operator can advance to setting the correct time using the Down Arrow.

Time numbers are changed using the procedure as the Date numbers. Once the correct Time is

programmed, select Enter and arrow down to Exit.

* DATE 1 / 30 / 2006

TIME

EXIT

*

* DATE 1 / 30 / 2006

TIME

EXIT

*

* DATE 2 / 30 / 2006

TIME

EXIT

*

* DATE 2 / 30 / 2006

TIME

EXIT

* DATE 2 / 15 / 2006

TIME

EXIT

DATE

* TIME 14 : 33 : 04

EXIT

DATE

TIME

* EXIT

Other manuals for SEC 3100

1

Table of contents

Other Sensor Electronics Transmitter manuals

Popular Transmitter manuals by other brands

Dwyer Instruments

Dwyer Instruments 626 Series Installation and operating instructions

Remote Control Systems

Remote Control Systems EVO-DUPLEX-Tx manual

Audiovox

Audiovox Pursuit Series manual

Thermo Scientific

Thermo Scientific ALPHA COND 500 - REV 4 manual

JUMO

JUMO 4AP-30 operating instructions

DKS

DKS microPLUS user guide