SENSOR MAESTROS SFM2 User manual

www.sensormaestros.com

1 | P a g e

User Manual V1.0.3

Sensor Fusion Module User Manual

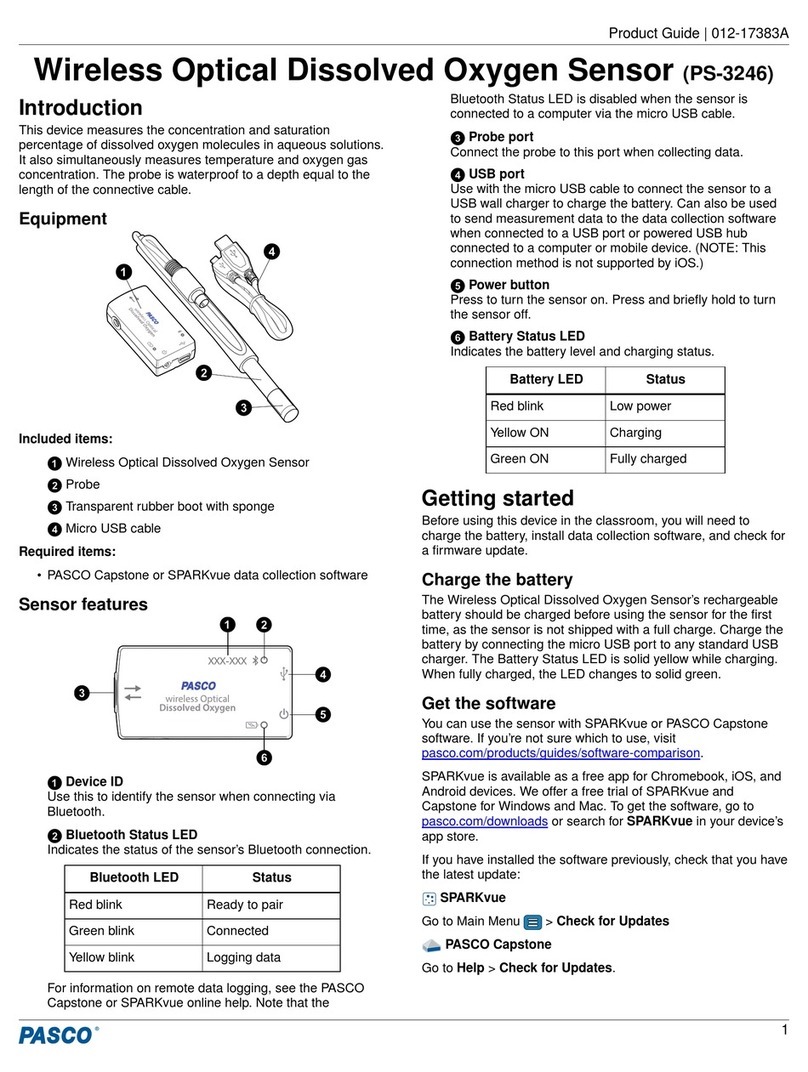

The SFM2 is the smallest form-factor and lowest

power wireless 9 DOF Sensor Fusion Module with

optional Pressure, Temperature and Humidty sensors.

The SFM2 offers both a Bluetooth Low Energy and a

USB/COM port interface. The SFM2 provides an

extremely flexible BLE and USB interfaces and allows

complete customization of sensor output streams and

sensor configurations. The SFM2 can easily be worn

using the Velcro strap ran through slot in the bottom

of the enclosure.

Shown with Black Enclosure. For other color options please inquire

Product Highlights

➢40.9 x 28 x 14.3mm (1.61” x 1.10 x 0.563”) Form Factor

➢Wearable: Enclosure has slot for Velcro strap.

➢USB and BLE Interfaces: Connect up to 5 SFM2’s running 208Hz Fusion ODR and Quaternion data with newer

iOS and Android Devices. High ODR Rates possible depending on mobile device performance.

➢Field Updatable using ‘Over the Air’ update

➢9 DOF: 3-Axis Gyro, Accel, Mag

❖with Pressure, Temp, and Humidity Sensors

➢Up to 833Hz Sensor Fusion Operation. Multiple Streams can be enabled at same time.

❖Tared & Un-Tared Quaternion Output

❖Fusion Compass Heading and Tilt Output

❖Fusion Linear Acceleration Output

❖Fusion Euler Angle Output

➢Sensor Fusion Output via BLE or USB Interface

❖833, 417, 208, 104, 52, 26Hz ODR Rate Selections

➢Raw Sensor Output availability for all sensors. Accel/Gyro Max ODR = 1667Hz

➢USB(1Mbps) and BLE Interfaces(DLE and 2Mb PHY capability)

➢iOS and Android apps for sensor and data output configuration.

➢USB/COM command set for sensor and data output configuration.

➢Python API Library to quickly and easily get application up and running

➢TARE function to zero orientation for quaternion output.

➢GLOBAL REFERENCE enable/disable command

➢TIMESTAMP sensor data with 25us resolution with improved accuracy using RTC synchronization

➢Timestamp-timestamp delta accuracy ± 1µs for data logs

➢Multi-Mode Time Synchronization to time synchronized multiple SFM2’s used simultaneously with Average

Standard Deviation between timestamps of multiple SFM2’s typical <10ms

➢Rechargable Battery (130mAh)

❖~73hour battery life with Quaternion output @ 26Hz using BLE interface

❖~47hour battery life with Quaternion output @ 104Hz using BLE interface

❖~30hour battery life with Quaternion output @417Hz using BLE interface

➢Individual Control of each sensor output to be included in Data Stream

❖Sensors and Sensor Fusion can be completely customized including Sensor Filters.

➢Custom OEM/Logo Enclosure available

➢Example Application Software

www.sensormaestros.com

2 | P a g e

User Manual V1.0.3

Table of Contents

PRODUCT HIGHLIGHTS............................................................................................................................................................1

TABLE OF CONTENTS ...............................................................................................................................................................2

CUSTOM DEVELOPMENT AND OEM SOLUTIONS .................................................................................................................5

FUTURE OPTIONS......................................................................................................................................................................5

SFM2 HARDWARE DESCRIPTION...........................................................................................................................................6

ACCEL/GYRO/SENSOR FUSION SPECIFICATIONS................................................................................................................7

MAGNETOMETER SPECIFICATIONS.......................................................................................................................................8

PRESSURE SENSOR SPECIFICATIONS.....................................................................................................................................9

RELATIVE HUMIDITY SENSOR SPECIFICATIONS.................................................................................................................9

TEMPERATURE SENSOR SPECIFICATIONS ...........................................................................................................................9

LED OPERATION DESCRIPTION........................................................................................................................................... 10

BLE OPERATION..................................................................................................................................................................... 10

SFM2 FIRMWARE UPDATE ................................................................................................................................................... 10

SENSOR FUSION...................................................................................................................................................................... 11

14.1 COORDINATE SYSTEMS .................................................................................................................................................................11

14.2 TARE QUATERNION......................................................................................................................................................................12

14.3 HEADTARE .................................................................................................................................................................................12

14.4 GLOBAL REFERENCE .....................................................................................................................................................................12

MANUAL CALIBRATION......................................................................................................................................................... 13

15.1.1 Calibration Steps ............................................................................................................................................................14

15.1.2 Calibration Notes ...........................................................................................................................................................15

TIMESTAMPS........................................................................................................................................................................... 15

16.1 SENSR-LOGR TIMESTAMPS .........................................................................................................................................................16

16.2 USB/COM PORT TIMESTAMPS .....................................................................................................................................................17

SYNCHRONIZE MULTIPLE SFM2’S....................................................................................................................................... 18

BINARY FRAME MODE........................................................................................................................................................... 18

18.1 BINARY FRAME FORMAT...............................................................................................................................................................18

18.2 START BYTE ................................................................................................................................................................................18

18.3 DATA DESCRIPTION ......................................................................................................................................................................18

18.4 TIMESTAMP................................................................................................................................................................................19

18.5 DATA ........................................................................................................................................................................................19

18.6 END BYTE...................................................................................................................................................................................19

EXAMPLES................................................................................................................................................................................ 20

19.1 SFQT+SFLA@104HZ................................................................................................................................................................20

19.2 AD@208HZ +GD@104HZ........................................................................................................................................................20

MOBILE APP ............................................................................................................................................................................ 21

20.1 SCANNER ...................................................................................................................................................................................22

20.2 CHANGE NAME...........................................................................................................................................................................22

20.3 HOME .......................................................................................................................................................................................22

20.3.1 Home: 3D View ..............................................................................................................................................................23

20.3.2 Home: Throughput.........................................................................................................................................................24

20.3.3 Home: Self-Test..............................................................................................................................................................24

www.sensormaestros.com

3 | P a g e

User Manual V1.0.3

20.4 CONFIG .....................................................................................................................................................................................25

20.4.1 Config: Data Rates .........................................................................................................................................................25

20.4.2 Config: Data Streams ..................................................................................................................................................... 26

20.4.3 Config: Reference........................................................................................................................................................... 26

20.4.4 Config: Temperature/Humidity......................................................................................................................................26

20.4.5 Config: Altitude/Pressure............................................................................................................................................... 27

20.4.6 Config: Calibration ......................................................................................................................................................... 27

20.4.7 Config: Accelerometer....................................................................................................................................................28

20.4.8 Config: Gyroscope.......................................................................................................................................................... 28

20.4.9 Config: Magnetometer .................................................................................................................................................. 29

20.4.10 Config: Kalman Filter Parameters ..................................................................................................................................29

20.4.11 Config: Name Change .................................................................................................................................................... 30

20.4.12 Config: Default Settings ................................................................................................................................................. 30

20.5 STATS........................................................................................................................................................................................30

20.5.1 Data Streams ................................................................................................................................................................. 31

20.5.2 BLE Stats ........................................................................................................................................................................32

20.5.3 Serial Port Stats.............................................................................................................................................................. 32

20.5.4 Calibration .....................................................................................................................................................................32

20.5.5 Statistics......................................................................................................................................................................... 33

20.5.6 Connection Params........................................................................................................................................................33

20.6 TIME.........................................................................................................................................................................................34

20.7 LOG..........................................................................................................................................................................................34

20.7.1 Start Logging..................................................................................................................................................................34

20.7.2 View/Explore/Garph Log Files........................................................................................................................................35

20.7.3 Share Log File(store remotely) .......................................................................................................................................36

20.8 MULTI MODE(MULTIPLE SFM2’S) .................................................................................................................................................37

20.8.1 Multi Mode: Config ........................................................................................................................................................37

20.8.2 Multi Mode: Stats .......................................................................................................................................................... 38

20.8.3 Multi Mode: Time Synchronization ................................................................................................................................ 39

SFM2 BLE SERVICES AND CHARACTERISTICS................................................................................................................... 41

21.1 SFM2 BLE CHARACTERISTIC MAP..................................................................................................................................................41

21.2 DATA STREAM CHARACTERISTICS....................................................................................................................................................42

21.2.1 Data Stream 0x0101 ...................................................................................................................................................... 42

21.2.2 Data Stream Settings 0x0102 ........................................................................................................................................42

21.3 SENSOR FUSION SETTINGS 0X0122.................................................................................................................................................44

21.3.1 Data Rate .......................................................................................................................................................................44

21.3.2 Fusion ODR Output Divider ............................................................................................................................................44

21.4 REFERENCE SETTINGS 0X0128.......................................................................................................................................................44

21.5 ACCELEROMETER SETTINGS 0X0201...............................................................................................................................................45

21.5.1 Accelerometer Full Scale ................................................................................................................................................ 45

21.5.2 Accelerometer Filter Configuration................................................................................................................................45

21.5.3 Accelerometer Power Mode ..........................................................................................................................................46

21.5.4 Self-Test Configuration .................................................................................................................................................. 46

21.6 GYROSCOPE SETTINGS 0X0202......................................................................................................................................................46

21.6.1 Gyroscope Full Scale....................................................................................................................................................... 46

21.6.2 Gryoscope LPF1 Configuration .......................................................................................................................................46

21.6.3 Gryoscope HPF Configuration ........................................................................................................................................ 47

21.7 MAGNETOMETER SETTINGS 0X0203 ..............................................................................................................................................47

www.sensormaestros.com

4 | P a g e

User Manual V1.0.3

21.8 SF KALMAN SETTINGS 0X0204......................................................................................................................................................47

21.9 CALIBRATION SETTINGS 0X0207....................................................................................................................................................47

21.9.1 Magnetometer Calibration Auto Storage Mode ............................................................................................................47

21.9.2 Magnetometer Calibration Type....................................................................................................................................48

21.10 ENVIRONMENTAL SENSOR SETTINGS 0X0310...............................................................................................................................48

21.10.1 Pressure Data Rate ........................................................................................................................................................48

21.10.2 Temp/Humidity Sample Mode .......................................................................................................................................48

21.10.3 Altitude Tare 0x0311......................................................................................................................................................49

21.11 STORAGE CHARACTERISTICS ......................................................................................................................................................49

21.11.1 Settings Storage 0x0134 ................................................................................................................................................49

21.11.2 Calibration Storage 0x0135 ...........................................................................................................................................49

21.12 TIME CHARACTERISTICS............................................................................................................................................................49

21.12.1 Time 0x0131................................................................................................................................................................... 49

21.12.2 Time Offset 0x0132........................................................................................................................................................49

21.12.3 Time Trim 0x0142 ..........................................................................................................................................................50

21.12.4 Time Notify Interval 0x0143...........................................................................................................................................50

21.13 OTHER CHARACTERISTICS..........................................................................................................................................................50

21.13.1 Tare 0x0129 ................................................................................................................................................................... 50

21.13.2 Name 0x0133.................................................................................................................................................................50

21.13.3 Stats 0x0137 .................................................................................................................................................................. 50

21.13.4 Connection Parameters 0x0138.....................................................................................................................................51

21.13.5 Calibration 0x0206......................................................................................................................................................... 51

21.13.6 Self-Test 0x0208.............................................................................................................................................................51

21.13.7 SF Kalman Settings 0x0204 ............................................................................................................................................ 52

21.13.8 Calibration Settings 0x0207 ...........................................................................................................................................52

USB COMMANDS..................................................................................................................................................................... 53

22.1 TERMINAL WINDOW SETTINGS ......................................................................................................................................................53

22.2 COMMAND FORMAT:...................................................................................................................................................................53

22.3 SPECIAL CHARACTERS: ..................................................................................................................................................................54

22.4 METAVARIABLES: ........................................................................................................................................................................54

22.5 DATA TYPES:...............................................................................................................................................................................54

22.6 SYSTEM COMMANDS: ..................................................................................................................................................................54

22.7 MOTION SENSOR CONFIGURATION COMMANDS: ..............................................................................................................................55

22.7.1 Accelerometer Commands.............................................................................................................................................55

22.7.2 Gyroscope Commands ...................................................................................................................................................55

22.7.3 Magnetometer Commands............................................................................................................................................ 55

22.8 ENVIRONMENTAL SENSOR CONFIGURATION COMMANDS:...................................................................................................................55

22.9 SENSOR FUSION COMMANDS: .......................................................................................................................................................56

22.10 TIMESTAMP COMMANDS:.........................................................................................................................................................56

22.11 SYSTEM QUERIES: ...................................................................................................................................................................56

22.12 SENSOR QUERIES: ...................................................................................................................................................................57

22.13 SENSOR FUSION QUERIES .........................................................................................................................................................57

22.14 RESPONSES:...........................................................................................................................................................................57

22.15 DATA STREAM FORMAT: ..........................................................................................................................................................58

PYTHON API LIBRARY........................................................................................................................................................... 59

23.1 PYTHON DOCS (HTML DOCUMENTATION).........................................................................................................................................59

23.2 PYTHON SAMPLES........................................................................................................................................................................60

www.sensormaestros.com

5 | P a g e

User Manual V1.0.3

23.3 PYTHON SFM2API’S....................................................................................................................................................................61

23.3.1 sfm2: implementation.................................................................................................................................................... 61

23.3.2 sfm2: interface............................................................................................................................................................... 62

23.3.3 sfm2: Utils ...................................................................................................................................................................... 63

REVISIONS ............................................................................................................................................................................... 63

Custom Development and OEM Solutions

Sensor Maestros can provide customized solutions using the SFM2 as a foundation. Below are

some examples of the common customizable options for the SFM2.

➢Customized Hardware

❖Additional Sensors

•Temperature/Humidity

•Gas: CO2, CO, VOC’s

•PIR

❖Customized Battery options

➢Custom Motion Algorithms

❖Pattern Recognition

❖Machine Learning

❖Vibration Analysis

❖Fitness/Sports Analysis

➢Custom Software Applications

❖iOS

❖Android

❖PC Applications

➢Custom Cloud Applications

➢Custom Enclosure Options

Future Options

➢Compressed Audio Recording Streaming

➢AI / Machine Learning Application Development

➢User Application Flash Memory area to all for User applications to be programmed

directly onto the SFM2

➢SENSR-POD

❖BLE to Cellular Bridge

➢Vibration Analysis

➢Cloud Enablement

www.sensormaestros.com

6 | P a g e

User Manual V1.0.3

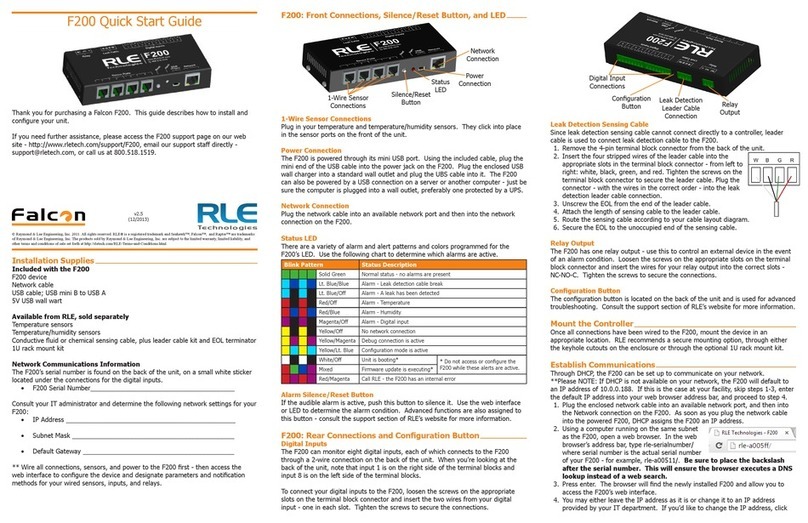

SFM2 Hardware Description

The SFM2 is comprised of a 64MHz Cortex M4F BLE SOC, Motion Sensors, and optional Pressure, Relative Humidity and Temperate

Sensors. A block diagram is shown below with further details below.

Figure 1: SFM2 Block Diagram

➢64MHz Cortex M4F MCU

➢9DOF Sensors

❖LSM6DSO –6 Axis Accelerometer/Gyroscope

❖LIS2DML –3 Axis Magnetometer

➢Optional Environmental Sensors

❖LPS22HH –Pressure Sensor

❖ENS210 –Relative Humidity and Temperature Sensor

➢BLE interface to provide easy means for application developers to make use of the SFM2 for developing custom

applications.

➢Example Software provided for BLE Client side for how to interface to the SFM2

❖Example Python 3D Cube application used to interface to the SFM2 from a USB/CDC Connection.

•Python API Library

❖Native C++ Library(coming soon)

➢USB2.0 Support:

❖SFM2 can be controlled/configured from a COM Terminal program using Serial Commands described in USB

Commands and for higher level Python API’s see Python API Library.

❖Sensor Fusion Data can be sent via USB2.0

❖USB provides Battery charging

➢Highly efficient BLE/Characteristic architecture

❖Every Sensor has its own Sample Rate, Full-Scale Range, Data Enable

❖Every Sensor has a Notification Enable

www.sensormaestros.com

7 | P a g e

User Manual V1.0.3

ACCEL/GYRO/SENSOR FUSION Specifications

Symbol

Parameter

Test conditions

Min.

Typ.(1)

Max.

Unit

FS_ODR

Sensor Fusion Output Data Rate

12.5

833

Hz

LA_FS

Linear acceleration measurement range

±2

g

±4

±8

±16

G_FS

Angular rate measurement range

±125

dps

±250

±500

±1000

±2000

LA_So

Linear acceleration sensitivity(2)

FS = ±2 g

0.061

mg/LSB

FS = ±4 g

0.122

FS = ±8 g

0.244

FS = ±16 g

0.488

G_So

Angular rate sensitivity(2)

FS = ±125 dps

4.375

mdps/LSB

FS = ±250 dps

8.75

FS = ±500 dps

17.50

FS = ±1000 dps

35

FS = ±2000 dps

70

LA_SoDr

Linear acceleration sensitivity change vs. temperature(4)

from -40° to +85°

±0.01

%/°C

G_SoDr

Angular rate sensitivity change vs. temperature(4)

from -40° to +85°

±0.007

%/°C

LA_TyOff

Linear acceleration zero-g level offset accuracy(5)

±20

mg

G_TyOff

Angular rate zero-rate level(5)

±1

dps

LA_OffDr

Linear acceleration zero-g level change vs. temperature(4)

±0.1

mg/ °C

G_OffDr

Angular rate typical zero-rate level change vs. temperature(4)

±0.010

dps/°C

Rn

Rate noise density in high-performance mode(6)

3.8

mdps/√Hz

RnRMS

Gyroscope RMS noise in normal/low-power mode(7)

75

mdps

An

Acceleration noise density in high-performance mode(8)

FS = ±2 g

70

µg/√Hz

FS = ±4 g

75

FS = ±8 g

80

FS = ±16 g

110

www.sensormaestros.com

8 | P a g e

User Manual V1.0.3

Symbol

Parameter

Test conditions

Min.

Typ.(1)

Max.

Unit

RMS

Acceleration RMS noise in normal/low-power mode(9) (10)

FS = ±2 g

1.8

mg(RMS)

FS = ±4 g

2.0

FS = ±8 g

2.4

FS = ±16 g

3.0

LA_ODR

Linear acceleration output data rate

12.5

26

52

104

208

416

833

1666

Hz

G_ODR

Angular rate output data rate

12.5

26

52

104

208

416

833

1666

1. Typical specifications are not guaranteed.

2. Sensitivity values after factory calibration test and trimming.

3. Subject to change.

4. Measurements are performed in a uniform temperature setup and they are based on

characterization data in a limited number of samples. Not measured during final test for production.

5. Values after factory calibration test and trimming.

6. Gyroscope rate noise density in high-performance mode is independent of the ODR and FS setting.

7. Gyroscope RMS noise in normal/low-power mode is independent of the ODR and FS setting.

8. Accelerometer noise density in high-performance mode is independent of the ODR.

9. Accelerometer RMS noise in normal/low-power/ultra-low-power mode is independent of the ODR.

10. Noise RMS related to BW = ODR/2.

Magnetometer Specifications

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

FS

FS

Magnetic dynamic range

±49.152

gauss

So

Sensitivity

-7%

1.5

+7%

mgauss/

LSB

TcyOff

Magnetic Sensor Offset

With offset cancellation

-60

1.5

+60

mgauss

RMS

RMS Noise

High Performance Mode

3

mgauss

(RMS)

www.sensormaestros.com

9 | P a g e

User Manual V1.0.3

Pressure Sensor Specifications

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

P

FS

Pressure Operating Range

260

1260

hPa

Pbits

Pressure bits of data

-7%

24

+7%

mgauss/

LSB

Psens

Pressure Sensitivity

4096

LSB/hPa

PAccRel

Relative Accuracy over pressure

P = 800-1100 hPa

T = 25°C

±0.025

hPa

PAccT

Absolute accuracy over temperature

Pop, T = -20 to 80°C

±0.5

hPa

ODRPres

Pressure output data rate

1

10

25

75

100

200

Hz

Relative Humidity Sensor Specifications

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

P

FS

Pressure Operating Range

260

1260

hPa

Pbits

Pressure bits of data

-7%

24

+7%

mgauss/

LSB

Psens

Pressure Sensitivity

4096

LSB/hPa

PAccRel

Relative Accuracy over pressure

P = 800-1100 hPa

T = 25°C

±0.025

hPa

PAccT

Absolute accuracy over temperature

Pop, T = -20 to 80°C

±0.5

hPa

ODRPres

Pressure output data rate

1

10

25

75

100

200

Hz

Temperature Sensor Specifications

Symbol

Parameter

Test conditions

Min.

Typ.

Max.

Unit

P

FS

Pressure Operating Range

260

1260

hPa

Pbits

Pressure bits of data

-7%

24

+7%

mgauss/

LSB

Psens

Pressure Sensitivity

4096

LSB/hPa

PAccRel

Relative Accuracy over pressure

P = 800-1100 hPa

T = 25°C

±0.025

hPa

PAccT

Absolute accuracy over temperature

Pop, T = -20 to 80°C

±0.5

hPa

ODRPres

Pressure output data rate

1

10

25

75

100

200

Hz

www.sensormaestros.com

10 | P a g e

User Manual V1.0.3

LED Operation Description

COLOR

FUNCTION

NOTES

YELLOW

Connected

Will blink twice every ~2.5 seconds to indicate SFM2

is connected to a BLE Client

YELLOW

Advertising

Will blink once every ~1 second to indicate SFM2 is in

advertising mode

RED

Sensor/Sensors Enabled

Connected: Blink twice every ~2.5 seconds

Unconnected: Blink once every ~1 second

This LED is sequenced with the YELLOW LED if a

Sensor is Active/ON.

BLUE

Active Battery Charging

Solid BLUE Led indicates battery is charging via USB.

Table 1: LED Operation

BLE Operation

The SFM2 provides BLE Peripheral(slave) operation and allows any BLE Client(master) to connect to the SFM2. The SFM2 does not

require Bonding. Description of operation is provided below.

1) BLE ADVERTISING: Upon powering the device the SFM2 Performs BLE Advertising and advertises the Device name “SFM2”.

a. YELLOW BLE LED Blinks at ~1 second interval

b. Advertising Interval = 500ms

c. Currently the device does not allow user adjustment of the Advertising Interval.

NOTE: The Device Advertises as a Connectable BLE Peripheral and does not require any Bonding/Secure Pairing.

2) BLE CONNECTED: Once a BLE Client has connected to the SFM2 the device will transition to what is shown below and

allows the BLE Client to read all the Services, Characteristics, and Descriptors to allow an application to be developed.

a. YELLOW BLE LED Blinks at ~2.5 second interval

b. All BLE Services, Characteristics, Descriptors are available to be read from the Client.

c. The SFM2 Max/Min Connection interval is set for Maximum throughput via a BLE Connection. Not all BLE Clients in

particular Mobile Devices will allow for the minimum 7.5ms Connection interval. Sensor Sample Rates and Sensor

Fusion Output Rates should be configured according to the maximum throughput allowed by the Client BLE device.

3) BLE DISCONNECTED: Upon a BLE Client(master) disconnecting from the SFM2 the device will return to the BLE

ADVERTISING mode.

SFM2 Firmware Update

The SFM2 embedded firmware is not available in source code as open source. Licensing can be made available upon requests.

Developers/users of the SFM2 can make use of the USB Commands and/or the BLE Characteristics to configure and retrieve data

from the SFM2. Sensor Maestros can provide design services for customization of the embedded firmware for specific use cases on

a case by case basis. The SFM2 firmware can be updated via a BLE Connection.

The SENSR-LOGR mobile app will automatically detect if there is a new firmware version available for the SFM2. The SENSR LOGR

App can be found in the Apple App Store and on Google Play by searching for Sensor Maestros.

Android: https://play.google.com/store/apps/details?id=sensormaestros.SensorMaestros

iOS: Go to the ‘App Store’ on your mobile device and search for SENSR-LOGR or Sensor Maestros

If the SENSR-LOGR app detects that there is a newer version of firmware it will automatically prompt you to update to the latest

version of firmware. It is HIGHLY RECOMMENDED to update to the newest version of firmware.

www.sensormaestros.com

11 | P a g e

User Manual V1.0.3

Sensor Fusion

The SFM2 provides for 9DOF Sensor Fusion output that can be enabled by the user. The following Sensor Fusion output

streams are provided by the SFM2 and can be individually enabled/disabled using either the BLE or USB interface.

➢Quaternion

➢Tared Quaternion

➢Compass Heading and Tilt

➢Linear Acceleration

➢Euler Angle

Sensor Fusion output rates (ODR) can be selected by the user from 0(Disabled), 12.5, 26, 52, 104, 208, 417, and 833Hz.

The Sensor Fusion ODR(SFOR) can be set to an ODR rate equal to the highest ODR rate of either the GYRO or ACCEL. For example if

417Hz SFOR ODR rate is desired either the ACCEL or GYRO or both should be configured also to 417Hz. For optimum results it is

recommended to set the ACCEL & GYRO ODR rates to 2X the SFOR ODR rate. Technically the SFOR ODR can be greater than the ODR

rate of either the ACCEL or GYRO but not both. This configuration is NOT recommended though. The Magnetometer does not need

to be ODR rate correlated with the Sensor Fusion ODR rate though for any Sensor Fusion ODR rates 104Hz or greater it is highly

recommended to set the Magnetometer to its max value of 104Hz. The MAG ODR rate does have a requirement that the ODR rate

can’t be greater than both the ACCEL and GYRO. An acceptable configuration is shown below though NOT recommended.

ASR = 12.5Hz GSR = 208Hz MSR = 104Hz

14.1 Coordinate Systems

The SFM2 uses two different Coordinate Systems(CS):

•Local Coordinate System(LCS)

•Global Coordinate System(ENU)

The Global Coordinate System is fixed with the external world and it is ENU standard(East—North-Up, acceleration positive) the

same that is used in the Android coordinate system. It means that Global Coordinate System axes are oriented as follows:

➢X is East

➢Y is North

➢Z is Up

The LCS is a rigidly fixed coordinate system affixed to the SFM2 device and by default is as shown below:

Using the ‘TARE’ function this coordinate system can be re-oriented to any position the SFM2 has been moved to and will be

effectively Zero’d at the position it is in prior to using the ‘TARE’ function.

This means that when the SFM2 rotates(changes its orientation) the LCS rotates with it in the exact same manner. All the SFM2

attitude streams except SFQ provide attitude of current LCS provided in ENU. SFQ provides attitude of default LCS given in ENU. The

sensor measurement vectors(acceleration, angular rate, magnetic) and SFLA(Sensor Fusion Linear Acceleration) are by default given

in LCS but can also be given in ENU by enabling GLOBAL REFERENCE by setting GLOBREF = 1.

www.sensormaestros.com

12 | P a g e

User Manual V1.0.3

14.2 Tare Quaternion

The SFM2 variable SFTARE! provides the ability to change the LCS orientation. Executing SFTARE! creates a new LCS that is the same

as ENU in the moment of executing the command. After taring the SFM2 the LCS orientation is exactly the same as ENU so all angles

are zero. This allows you to change the default LCS to any other you want. This is EXTREMELY USEFUL if the SFM2 has been

mounted or moved the user can use the SFTARE! function to re-orient the LCS to this new orientation. This provides an easy means

for the user to always start from a known orientation starting point regardless of the physical orientation of the SFM2.

Example: Attach the SFM2 to some piece of equipment that is stationary during the attachment. The orientation of the SFM2 with

respect to the equipment doesn’t matter. Orient the equipment in such a way that its X axis point East, Y axis points North and Z

axis points Up(the orientation of equipment is the same as ENU). With the SFM2 in a stable position execute the SFTARE! command

or execute this via the Mobile App. Now the SFM2 outputs are given in the new LCS which is the same as the equipment’s

coordinate system.

14.3 Headtare

Sometimes it is not practical to rotate the equipment to match the ENU axes for taring. Then you can ‘TARE’ in any

orientation(making sure the equipment is not tilted) and then manually correct the SFM2 using the Headtare function

(HEADTARETARE=<angle_in_deg>) according to the current equipment heading angle. The angle is measured between the

West-East axis and the equipment axis is in the counter-clockwise manner(looking from above). Headtare allows for a manual

alignment adjustment to the SFM2 in degrees.

14.4 Global Reference

To understand the Global Reference option, please get familiar with the ‘Coordinate Systems’ first being LCS and ENU.

All sensor measurement vectors(acceleration, angular rate, magnetic) and SFLA(Sensor Fusion Linear Acceleration) are by default

given in LCS.

Tracking Acceleration Example: It is useful for example when you want to measure the acceleration of your car. You fix the SFM2

to your car, tare and adjust the heading using headtare if needed. Then all the accelerations related to car acceleration or breaking

appear on the X axis. When the car accelerates there are positive readings on the X axis, when it is braking there are negative

readings on the X axis. It is no matter how the car is oriented in the external world the X axis is always affixed to forward and

backward motion. No matter whether you are driving South-North or East-West the reading are always on the X axis.

In the presented above car example using measurements given in the LCS is the best solution because it gives you exactly what you

want.

The case is completely different when you want to track the trajectory of a ball.

Tracking Trajectory Example: In this case you would put the SFM2 into the ball and affix it in some manner and throw it. Now you

want to draw the flight trajectory. In the simplest form to get the position(relative to the start point)you have to integrate the

acceleration twice. It would be easy if the ball would not be spinning. When the ball(and SFM2) is spinning its LCS axis are changing

orientation all the time so the acceleration measured on the X axis sometimes refers to North-South movement, sometimes

East-West and sometimes Up and Down. It all depends what is the actual SFM2 orientation in the external world at that moment in

time. Calculating trajectory using measurements given in LCS are not easy and require a bit of math.

The trajectory calculation would be GREATLY SIMPLIFIED if the measurement would be given in some external(global) coordinate

system that is fixed NOT with the SFM2/Ball BUT with the external world. This can be achieved using the ‘Global Reference’ option

by setting GLOBREF=1.

When GLOBREF=1 is set all the measurements are given in the ENU. It means that all the acceleration on the X axis corresponds to

East-West movement, on the Y axis to North-South movement and on the Z axis to Up-Down movement no matter what the ball

orientation is. Calculating the trajectory using measurements given in ENU is MUCH EASIER because you don’t need to take the ball

spin into account.

➢When GLOBREF=1 all vector outputs( raw sensor data and SFLA) are represented in the global reference frame and are not

affected if the SFM2 is ‘tared’.

www.sensormaestros.com

13 | P a g e

User Manual V1.0.3

➢When GLOBREF=0 and the device is ‘tared’ all vector outputs are rotated to match the new orientation. This means that

after taring the SFM2 the Accelerometer output AD should always read approximately x=0, y=0, z=1, until the orientation is

changed.

Manual Calibration

The SFM2 is provided with factory calibration. In general it is not recommended to perform a full re-calibration however there may

be some cases where this may be necessary. Also it should be noted that with ‘Updating enabled’ and ‘Auto storage mode’ enabled

the SFM2 will continuously look for a better calibration than what is currently being used. If a better calibration set of parameters is

found as may be the case if the SFM2 has been mounted to a particular object those new parameters will be used in place of the

prior calibration values.

To determine if the SFM2 already has had a calibration performed go to the Stats->Calibration section. If it is blank as shown below

a manual calibration will need to be performed as there is no calibration values currently stored in the SFM2.

No Calibration Parameters stored in SFM2 Typical Config Values for performing a manual calibration.

www.sensormaestros.com

14 | P a g e

User Manual V1.0.3

15.1.1 Calibration Steps

1) STEP 1: Recommended Manual process is to hold the SFM2 away from any large metal objects as metallic objects will

affect the magnetic calibration process.

2) STEP 2: Hold the SFM2 in open air and rotate/roll the SFM2 around its X axis multiple times trying to keep the rotations

smooth and at a consistent speed.

3) STEP 3: Do this while you are viewing the Stats->Calibration view so you can see the Calibration parameters and Error being

updated in real time.

4) STEP 4: After you see the initial calibration values appear starting with 4 element values continue the same rotation and

you should soon see the Calibration values update to the 7 Element values as shown below…

5) After seeing the Calibration values update to 7 Element values now angle the SFM2 slightly so it is pointing either slightly up

or slightly down. NOTE: The strap can be ignored in the picture below.

6) You will typically see the Calibration values update again to 10 element values after angling the SFM2 while still rotating it

around the X axis. Now angle the SFM2 in the opposite direction you had it in STEP 4: to see if the ‘Mag calibration error’

value improves. We are looking for 10 Element Calibration with ‘Mag Calibration Error’ < 3%.

www.sensormaestros.com

15 | P a g e

User Manual V1.0.3

7) If the 10 element calibration shows a ‘Mag calibration error’ < 3% then you can go to Config-Calibration and select the ‘Save

Calibration’ button. This will store the current calibration values in Non-Volatile memory so that these values will be used

the next time the SFM2 is powered on.

15.1.2 Calibration Notes

1) It can happen that the 4 element values show a Mag Cal error that is less than the 7 element or 10 element. There are

fewer elements taken into account but this is still not as good as a 10 element calibration.

2) If after you perform the Calibration the ‘Mag calibration error’ shows an error > 3% it is recommended to go to

Config->Calibration and click the ‘Clear Storage’ button to ensure any prior Calibration values are cleared from memory.

Power cycle the SFM2 and perform the calibration again.

3) Calibration can be performed with NO Data Streams active. The motion sensors should be configured for ODR rates that

are suitable for the application.

Timestamps

Timestamps are crucial to being able to accurately analyze data. The SFM2 and the SENSR-LOGR app provide methods to allow for

highly accurate, consistent timestamps to be provided in data streams that would be logged whether using the BLE or USB interface.

The default timestamp clocks are defined below.

ClockSource

Tick

Accuracy

Enabled

LSM6DSx

25us

Poor

ALWAYS ON

RTC

30.518us

High

TSDE = 1 & BLE Interface

www.sensormaestros.com

16 | P a g e

User Manual V1.0.3

SENSR-LOGR app by default sets TSDE=1 upon connection to a SFM2. From the USB Interface this can be enabled/disabled

however. If a user desires to develop their own mobile app it is highly recommended to ALWAYS set TSDE=1 to allow for providing

for accurate timestamps.

An example of RTC output in the binary stream is shown below which could apply for BLE or USB connection.

Suppose that AD stream is enabled @208Hz rate and TS data is turned on.

We receive the following binary frames:

Frame idx

Samples

LSM6DSx clock (25us tick)

1

AD

100000

2

AD

100192 ( Sample Delta: 192 ticks * 25us = 4.8ms or 208Hz)

3

AD + TS = 630

100384

4

AD

100576

5

AD

100768

6

AD

100960

7

AD + TS = 1260

101152

8

AD

101344

9

AD

101536

10

AD

101728

11

AD + TS = 1890

101920

The SENSR-LOGR app then uses the TS data to calculate the RTC timestamps corresponding to the remaining AD samples. The

timestamps shown in LOG file from the SENSR-LOGR app are already calculated to an actual time value versus being displayed in

LSM6DSx ‘ticks’.

NOTE: This timestamp synchronization is completely different than synchronizing multiple SFM2’s to each other. Synchronizing

multiple SFM2’s does leverage the highly accurate 32.768kHz clock but there are several additional items that are monitored and

adjusted if necessary to synchronize multiple SFM2’s.

16.1 SENSR-LOGR timestamps

Timestamps shown in Log files from logging Data from a SFM2 or multiple SFM2’s are already converted to an actual time value out

to 7 decimal points. If you are using the SENSR-LOGR app it will automatically adjust individual LSM6DSx timestamps if needed by

utilizing the RTC time that is output in the binary frames which is highly accurate and provides a reference clock to make minor

adjustments in the LSM6DSx timestamp which is output in an Integer value.

Example of a LOG file using the SENSR-LOGR app with SFQT @833Hz which is one of the fastest sampling rates available on the SFM2

for Sensor Fusion outputs. Raw Accelerometer and Gyroscope data can be output as high as 1667Hz.

NOTE: Timestamp Deltas = 1.2268ms and 1.2269ms translating to ~815Hz output rate. The exact output rate can vary slightly but it

will be consistent and the timestamps using the SENSR-LOGR app will be very accurate.

Time [s]

W

X

Y

Z

Delta (µs)

1992.2697675

0.42324

0.07057

-0.04128

0.90232

1992.2709943

0.42172

0.06684

-0.03926

0.90340

1226.800

1992.2722212

0.41955

0.06162

-0.03637

0.90491

1226.900

1992.2734480

0.41857

0.05992

-0.03616

0.90548

1226.800

1992.2746749

0.41550

0.05734

-0.03538

0.90710

1226.900

1992.2759017

0.41486

0.05676

-0.03358

0.90749

1226.800

1992.2771285

0.41432

0.05564

-0.03172

0.90788

1226.800

www.sensormaestros.com

17 | P a g e

User Manual V1.0.3

1992.2783554

0.41513

0.05741

-0.03185

0.90739

1226.900

1992.2795822

0.41694

0.06068

-0.03216

0.90634

1226.800

1992.2808091

0.41911

0.06434

-0.03223

0.90508

1226.900

1992.2820359

0.42085

0.06716

-0.03211

0.90407

1226.800

1992.2832627

0.42198

0.06913

-0.03226

0.90339

1226.800

1992.2844896

0.42384

0.07217

-0.03278

0.90226

1226.900

1992.2857164

0.42410

0.07223

-0.03248

0.90215

1226.800

1992.2869432

0.42549

0.07499

-0.03336

0.90123

1226.800

1992.2881701

0.42568

0.07555

-0.03383

0.90108

1226.900

1992.2893969

0.42532

0.07473

-0.03351

0.90133

1226.800

1992.2906238

0.42448

0.07269

-0.03252

0.90193

1226.900

1992.2918506

0.42362

0.07063

-0.03150

0.90253

1226.800

STD Deviation 20 Deltas(µs)

0.050

16.2 USB/COM Port Timestamps

USB/COM port timestamps are output in a LSM6DSx tick format. An example of the COM port output on a terminal window such as

Putty is shown below. Example of COM Port output for 833Hz TSDE=1 Non-Binary mode.

SFQT:5.3619534E-1,-3.3474213E-1,-3.8904034E-2,-7.73905E-1@393955

SFQT:5.361946E-1,-3.347494E-1,-3.8905397E-2,-7.739021E-1@394003

SFQT:5.3619564E-1,-3.3475372E-1,-3.8908757E-2,-7.738995E-1@394051

SFQT:5.3619516E-1,-3.3475843E-1,-3.890932E-2,-7.738977E-1@394099

SFQT:5.361955E-1,-3.3476514E-1,-3.8911525E-2,-7.7389455E-1@394147

SFQT:5.361958E-1,-3.3476412E-1,-3.8911685E-2,-7.738947E-1@394195

SFQT:5.3619444E-1,-3.3477426E-1,-3.89153E-2,-7.7389115E-1@394243

SFQT:5.361948E-1,-3.347757E-1,-3.891803E-2,-7.7389E-1@394291

SFQT:5.361951E-1,-3.3477685E-1,-3.8917627E-2,-7.738895E-1@394339

SFQT:5.3619426E-1,-3.347772E-1,-3.891741E-2,-7.738899E-1@394387

SFQT:5.361937E-1,-3.3477232E-1,-3.8916305E-2,-7.7389234E-1@394435

SFQT:5.3619385E-1,-3.3476683E-1,-3.8914517E-2,-7.7389467E-1@394483

SFQT:5.361941E-1,-3.34764E-1,-3.8915258E-2,-7.738958E-1@394531

SFQT:5.361934E-1,-3.3475825E-1,-3.8915522E-2,-7.7389866E-1@394579

SFQT:5.361922E-1,-3.3475316E-1,-3.891633E-2,-7.739017E-1@394627

SFQT:5.361896E-1,-3.3475327E-1,-3.8911823E-2,-7.739036E-1@394675

SFQT:5.3618896E-1,-3.347374E-1,-3.8905088E-2,-7.7391136E-1@394723

SFQT:5.361908E-1,-3.3471256E-1,-3.8902704E-2,-7.739209E-1@394771

If the data was to be sorted for the first 5 values preceeding the samples shown above it would look like this…

Note: Timestamp Delta = 48ticks => 48 * 25us = 1.2ms or a 833Hz ODR rate.

Time

W

X

Y

Z

Delta(25µs tick)

393715

5.03E-01

-3.39E-01

-2.55E-02

-7.94E-01

393763

5.03E-01

-3.39E-01

-2.55E-02

-7.94E-01

48

393811

5.03E-01

-3.39E-01

-2.55E-02

-7.94E-01

48

393859

5.03E-01

-3.39E-01

-2.55E-02

-7.94E-01

48

393907

5.03E-01

-3.39E-01

-2.55E-02

-7.94E-01

48

www.sensormaestros.com

18 | P a g e

User Manual V1.0.3

Synchronize Multiple SFM2’s

The SFM2 allows for multiple SFM2’s to be synchronized together to allow multiple SFM2’s to be used with either the BLE or the

USB/COM port interfaces. It is very useful to be able to have multiple SFM2’s operating at the same time simultaneously connected

via the BLE or the USB interfaces to monitor multiple locations of a person or object. The only way this is useful though is if the data

that is logged by each SFM2 is synchronized in time. The SENSR-LOGR app provides an easy means to allow a user to do this using

the ‘Synchronization’ feature in the ‘Time’ view in the SENSR-LOGR app. This is further described in Multi Mode: Time

Synchronization. For USB operation there is an example Python script in the sfm2_python_lib_0_7/examples folder called

‘testing_time_synchronization.py’ that provides an example of this using the USB interface.

Binary Frame Mode

The binary frame mode provides a means for optimizing the throughput of the BLE and USB interfaces by packing sensor data and

optionally RTC timestamp data in binary frames that can be decoded on either the BLE Client/SENSR-LOGR or USB Application side.

For the case of the BLE interface the Binary Frames are sent using the Data Stream 0x0101 Characteristic.

NOTE: The BLE interface ALWAYS operates in Binary Frame mode whereas the USB/COM Port interface can operate either in ASCII

or Binary Frame mode. To enable Binary Frame Mode using the USB/COM port interface the BINMODE=1 command should be used.

18.1 Binary Frame Format

Start by

t

e

0x

FA

Data

description

Timestamp

Da

t

a

End by

t

e

0x

FB

1 byte

2 bytes

4 bytes

Variable length

1 byte

18.2 Start byte

Asingle byte used as a frame delimiter. It’s value is fixed: 0xFA.

18.3 Data description

Indicates what sample types are contained in the frame. The field consists of 16 bits, where

each bit indicates if it’s corresponding sample type is contained in the frame.

Bit

Sample Type

0

AD - Accelerometer

1

GD –Gyroscope

2

MD –Magnetometer

3

SFQ –Sensor Fusion Un-Tared Quaternion

4

SFQT –Sensor Fusion Tared Quaternion

5

SFLA –Sensor Fusion Linear Acceleration

6

SFEA –Sensor Fusion Euler Angles

7

SFCHT –Sensor Fusion Heading

8

SFM –Sensor Fusion Calibrated Magnetometer

9

PD –Pressure

10

ALT –Altitude

11

TD –Temperature

12

HD –Humidity

13

TS –Time Synch

14-15

Reserved for future use

www.sensormaestros.com

19 | P a g e

User Manual V1.0.3

18.4 Timestamp

Contains a single UInt32 value denoting time in 25us resolution. All samples contained in the frame share

the same timestamp.

NOTE: When TSDE=1 the highly accurate RTC time is included in the ‘Data’ frame. This timestamp

is the LSM6DSx time tick.

18.5 Data

Contains measurement sample data.

Sample type

Size

Content

AD - accelerometer

12 bytes

Vector of 3 floats

GD - gyroscope

12 bytes

Vector of 3 floats

MD - magnetometer

12 bytes

Vector of 3 floats

SFQ - Sensor Fusion untared quaternion

16 bytes

Quaternion of 4 floats

SFQT - Sensor Fusion quaternion

16 bytes

Quaternion of 4 floats

SFLA - Sensor Fusion Linear

acceleration

12 bytes

Vector of 3 floats

SFEA- Sensor Fusion EulerAngles

12 bytes

3 floats: Roll, Pitch, Yaw

SFCHT - Sensor Fusion Heading

8 bytes

2 floats: Heading, Tilt

SFM - Sensor Fusion calibrated

magnetometer

12 bytes

Vector of 3 floats

PD –Pressure

4 bytes

Single float value, in hPa

ALT - Altitude

4 bytes

Single float value, in meters

TD –Temperature

4 bytes

Single float value, in Celsius

HD –Humidity

4 bytes

Single float value, in %

TS –Time Synch

4 bytes

Two uint32 values

1) RTC time in RTC ticks(see TIME

command)

2) Configuration index, incremented each

time the RTC is set, either with the TIME

or TOFFSET commands.

NOTE: If a frame contains more than one sample,the samples are packed one after

another in the order as they appear in the table above.

18.6 End byte

Asingle byte used as a frame delimiter. It’s value is fixed: 0xFB.

www.sensormaestros.com

20 | P a g e

User Manual V1.0.3

18.7 Examples

18.7.1 SFQT+SFLA@104Hz

Each data frame contains two samples, one for SFQT, one forSFLA. They always share a common

timestamp.

Field

Start byte

Data

description

Timestamp

Da

t

a

End byte

SFQT

SFLA

Value

0xFA

0x30*

4 bytes

16 bytes

12 bytes

0xFB

*0x30 = 0b0000 0000 0011 0000. With ones at 4th and 5th positions (zero-indexed),

corresponding to SFQT and SFLA.

18.7.2 AD@208Hz + GD@104Hz

There are twice as many AD samples as there are GD. This means thatAD samples are present in

every frame, and GD samples in every other frame.

Frame 1 (AD+GD):

Field

Start byte

Data

description

Timestamp

Da

t

a

End byte

A

D

G

D

Value

0xFA

0x03*

4 bytes

12 bytes

12 bytes

0xFB

*0x03 = 0b0000 0000 0000 0011. With ones at 0th and 1st positions (zero-indexed),

corresponding to AD and GD.

Frame 2 (AD):

Field

Start

byte

Data

description

Timestamp

Da

t

a

End byte

A

D

Value

0xFA

0x01*

4 bytes

12 bytes

0xFB

*0x01 = 0b0000 0000 0000 0001. With a single one at 0th position (zero-indexed),

corresponding to AD.

Frame 1 and 2 come alternately, one after the other.

Other manuals for SFM2

1

Table of contents

Popular Security Sensor manuals by other brands

Inficon

Inficon Pernicka 700H CHLD Translation of the original operating instructions

elobau

elobau 153 Series Translation of the original operating instructions

GE

GE 60-639-95R installation instructions

jablotron

jablotron JA-160PC quick start guide

SHOKO SCIENCE

SHOKO SCIENCE Shodex RI-504 Operation manual

PASCO

PASCO PS-3246 manual