SENSY 5910 User manual

MA-5910_EN Page 1 on 9 Rev: 26/04/2021

LOAD CELL 5910

INSTALLATION MANUAL

1. GENERAL INFORMATION .................................................................................................................................................................2

1.1. Leveling .......................................................................................................................................................................................2

1.2. Shocks.........................................................................................................................................................................................2

1.3. Electrical soldering ......................................................................................................................................................................2

1.4. Lightning......................................................................................................................................................................................3

1.5. Outer mechanical influences .......................................................................................................................................................3

1.6. Setting of the counter force .........................................................................................................................................................3

2. CABLING.............................................................................................................................................................................................4

2.1. Cable ...........................................................................................................................................................................................4

2.2. Wiring ..........................................................................................................................................................................................4

2.3. Parallel connection ......................................................................................................................................................................5

2.4. Calibration ...................................................................................................................................................................................5

2.5. Measurement errors....................................................................................................................................................................5

2.6. Insulation test ..............................................................................................................................................................................6

2.7. Output impedance :.....................................................................................................................................................................6

2.8. Input impedance..........................................................................................................................................................................7

3. MOUNTING .........................................................................................................................................................................................7

3.1. Mounting with 3 load cells ...........................................................................................................................................................8

3.2. Mounting with more than 3 load cells..........................................................................................................................................8

4. EU DECLARATION OF CONFORMITY..............................................................................................................................................9

MA-5910_EN Page 2 on 9 Rev: 26/04/2021

Rev.

Date

Reason

1

26/04/2021

Insertion of an EU Declaration Of Conformity

1. GENERAL INFORMATION

1.1. Leveling

This operation guarantees a good

distribution of the loads, as well as the

verticality of the effort.

It is advised to ensure that a good

leveling of the cells and the support

elements is carried out.

Use thickness chocks if necessary.

1.2. Shocks

An important shock may damage the cell when this shock

corresponds to 1,5 to 3 times to the nominal load; it is in this case

preferable to install a shock absorber between the load and the

cell. (Ex: piling of rubber and metal plates)

1.3. Electrical soldering

When arc welding must be done on the structure, we advise to

install stranded ground wire, in order that the derived current does

not pass through the cell, damaging it.

It is also advised to disconnect the cells from the measurement

instrument.

MA-5910_EN Page 3 on 9 Rev: 26/04/2021

1.4. Lightning

If there is a risk of lightning, it is advised to isolate

the cell the best possible, and to derive the former

by stranded wire.

To do that, place a rubber sheet under the sole and

polyamide waterproof washers under the fixing

screws.

1.5. Outer mechanical influences

In order to avoid measurement

errors, the load to be weighed

should not be subject to parasitic

contributions: connecting pipes,

cables and stops or draw-bolts. If

there are any, they must be

installed with the greatest

flexibility.

Also ladders, bridges for access

should be suitably articulated, etc.

(Clamping).

1.6. Setting of the counter force

This setting must be done when the cell is UNLOADED.

With the hand, bring nut A at 1mm of the structure, then screw B

against A.

Finally, using a wrench, block nut A upon nut B, so that no effort is

exerted on the load cell.

Direct earthing of the structure through the electrical ground strap

MA-5910_EN Page 4 on 9 Rev: 26/04/2021

2. CABLING

2.1. Cable

The cells are delivered with a 4-wire screened cable. The screen

(shielded wire) cannot in any case be in contact with the ground, e.g;

in metallic junction boxes, it is necessary to isolate the screen with a

sheath (thermal).

The screen can only be connected to standardized earth.

It is advised to install a thermo-retractable sheath (retracted 4x) at the

end of the cable (retracted 4x) with inside, a waterproof paste, to

avoid any leak.

If there is any possible danger of damage along its wiring, it is

necessary to use an additional cable protection, passing the cable

through a pipe (steel, preferably).

2.2. Wiring

The cell wiring should be far away from power lines

(motors, transformers), and placed in separate pipes.

Soldered connections must be applied in the junction

box, (preferably screwed connections).

It is advised to place a bag of SILICA-GEL to keep dry

inside the junction box.

SENSY can provide, upon request, a PVC junction

box with a PG9 packing-gland – which could receive 4

or 6 parallel cells.

REF.: Junction Box

JBOX-4R (4 inputs - 1 output)

JBOX-6R (6 inputs - 1 output)

A) Display (ex. dv680)

B) Junction box

C) Cell

R) Adjustment resistance

1) Signal (out) -(white)

2) Excitation -(yellow)

3) Excitation + (brown)

4) Signal (out) + (green

5) Ref. (sense) + (pink)

6) Ref. (sense) + (grey)

MA-5910_EN Page 5 on 9 Rev: 26/04/2021

2.3. Parallel connection

The cells must be installed in parallel, with the stranded mass wire joined to itself. The sense must be joined to

the cell supply before the points of parallel wiring and the stabilizing resistances.

2.4. Calibration

It must be done after the sensor has been turned on for a while (10-15 minutes) to obtain a uniform

temperature of the installation.

The cells do not usually need to be adjusted with each other.

However, when greater precision is needed, it is sometimes necessary to stabilise the cells individually with

the resistances in the junction box. Those resistances are of several ohms (±10) and are installed in the

supply circuit. A parallel adjustable resistance is mounted with a fixed resistance.

The most sensitive cell will have its input resistance increased and the least sensitive will have its lowest input

resistance. You will see that it is preferable to work on both supply cables: schematic mounting is given for

your information and allows a variation of 0 to 20 ohms in series on the input impedance (2x10 ohms).

Note: A well known weight of more than 20% of the nominal load of the system can be expected. The

calibration error is always much higher than the error made on the evaluation of the load.

2.5. Measurement errors

When the calibration is difficult and measurement errors are observed, it is necessary to check the installation.

Mechanically, the cells must be free in the direction of the load and well positioned. Electrically, the

connections must be secure, the junction boxes exempt from humidity and the cables intact. If there is no fault

to be seen, it is necessary to verify the internal circuit.

SENSY can help to diagnose based on the associated diagnosis sheet provided in the appendix and filled in

beforehand.

MA-5910_EN Page 6 on 9 Rev: 26/04/2021

2.6. Insulation test

The measuring of the insulating resistance is done with a

multimeter. The standardized testing voltage is 10 V. It is

applied to a conductor.

It can be determined by disconnecting the measuring

instrument and applying voltage between one of the conductors

and the metallic mounting structure - or individually, cell by cell,

to locate the leakage with precision.

The insulation must not, in any case, be lower than 2 GΩ for a

10 V voltage. This insulation default will generate measurement

errors if the insulation resistance is lower than several hundred

MΩ.

Insulation default can also be generated by environmental

conditions (temperature, humidity).

2.7. Output impedance :

The Wheatstone bridge is made up of 350 Ωgauges.

At the output signal (OUT+: green,OUT-: white), the resistance

is 700 Ω± 5 Ω.

This impedance must be in accordance with the individual cell

data sheet, which can easily be determined with a multimeter. If

a wider varying resistance is read, it means that there is a

break-off or a short circuit current; a resistance variation of

several ohms would instead be a consequence of a severe over

voltage problem.

MA-5910_EN Page 7 on 9 Rev: 26/04/2021

2.8. Input impedance

Input signal (IN+: brown, IN-: yellow): its resistance is

usually of ± 700 Ω± 5 Ω, its impedance must be in

accordance with the individual cell data sheet.

If a different resistance is read, it means that there is a

break-off or a short circuit current. It is at the input that

one finds drift compensation, slope and sensitivity

adjusted resistance.

3. MOUNTING

The EASY MOUNT integrates the fixing plates, the support elements, as well as the anti-reversing and the

anti-rotation (shifting) in one direction.

This kit with knee joint absorbs forces up to 20 kN in the X-direction and lets enough movement space in the

Z-direction for the dilatations.

Rm Sensitivity drift compensation

(compensation de dérive de sensibilité)

Rms Sensitivity drift adjustement

(ajustement de dérive de sensibilité)

Rs Sensitivity calibration

(réglage de sensibilité)

Rzb Zéro calibration

(réglage de zéro)

Rzc Zéro drift compensation

(compensation de dérive du zéro)

MA-5910_EN Page 8 on 9 Rev: 26/04/2021

M5910

I5910

I5910

I5910

3.1. Mounting with 3 load cells

This mounting offers the best load repartition properties

and movement space for the element to weigh.

3.2. Mounting with more than 3 load cells

When using more than 3 load cells, each element must be

placed at the same level, to obtain an optimal distribution of

the loads. The output signals of each cell with the element to

weight, empty, must be identical (case of a symmetrical

element).

In order not to clamp the movements (dilatation) of the

element to weigh, a maximum of three I5910 used together

must be respected. For the other cells, use the mounting kit

M5910. In cases for which the dimension variations are

slight, the use of a mounting system with four I5910 is

authorized – which offers the best characteristics as far as

the resistance against parasitic efforts are concerned.

Remark: the characteristics of the cells are guaranteed

between –10°C and 45°C without thermal gradient at the

level of the cell and quick temperature variation, use of

protecting screen and an isolated element to form a barrier

between the warmth source and the cell (sun, wind, thermal

striking, conduction).

MA-5910_EN Page 9 on 9 Rev: 26/04/2021

4. EU DECLARATION OF CONFORMITY

Manufactured by:

SENSY SA

Z.I. Jumet – Allée Centrale

B – 6040 JUMET

Phone: +32 71 25.82.00

Fax: +32 71 37.09.11

Website: http://www.sensy.com

CONCERNED ITEMS: 5910, see calibration certificate related to model and serial number.

SENSY S.A. certify that the items described here above have been duly designed, manufactured and tested for use in accordance

with the essential requirements defined in the European Directives listed here under.

2014/30/EU

Electro-Magnetic Compatibility Directive

2011/65/EU

amended by

directive

2017/2102 / EU

Restriction of the use of certain hazardous substances in the electrical and electronic equipment

(RoHS)

2014/35/EU

Safety / low voltage directive

Conception and compliance of this equipment is made according to all of part of the following standards:

EN 61326 (2006)

If designed, manufactured and tested safety ref. D-DP SIL3 READY (option):

see specific and separate certificate according to ISO 13849-1 and/or EN 62061

If designed, manufactured and tested for use in potentially explosive atmospheres (option):

see specific and separate certificate.

Jumet,

April 26th, 2021

Augustin DUBOIS

Product Development Division

Table of contents

Popular Accessories manuals by other brands

Endress+Hauser

Endress+Hauser Oxymax W COS51D operating instructions

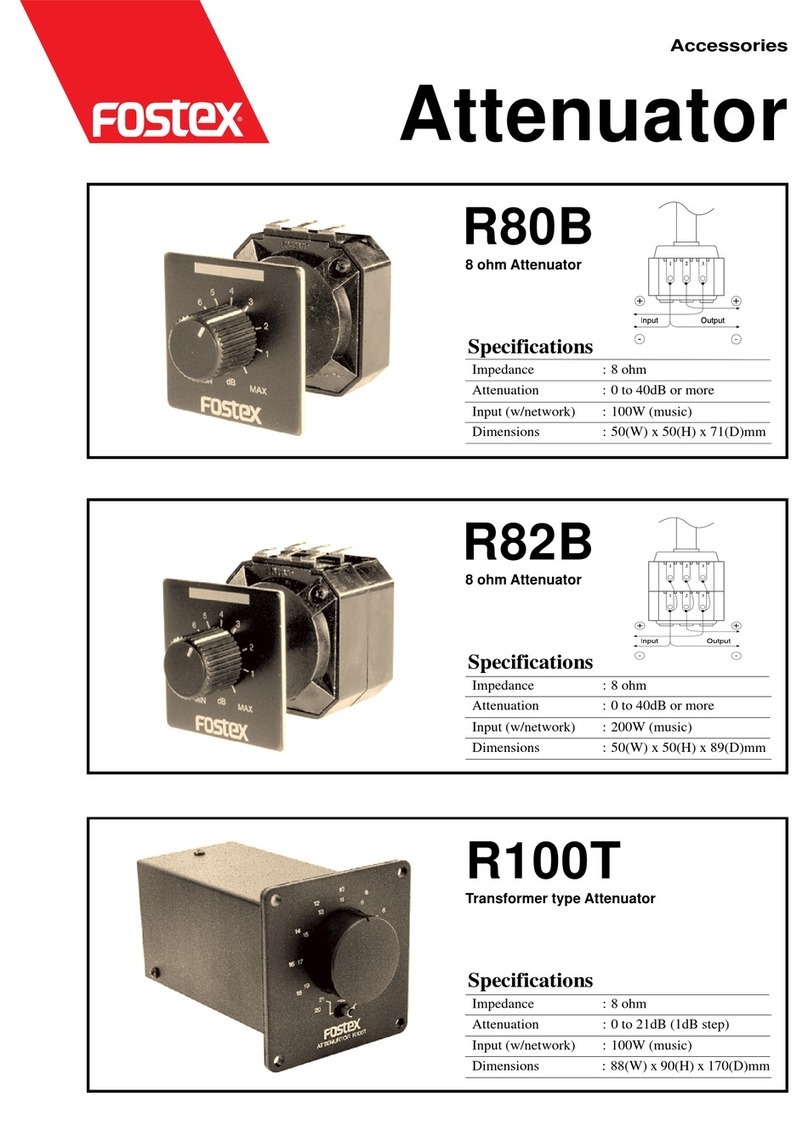

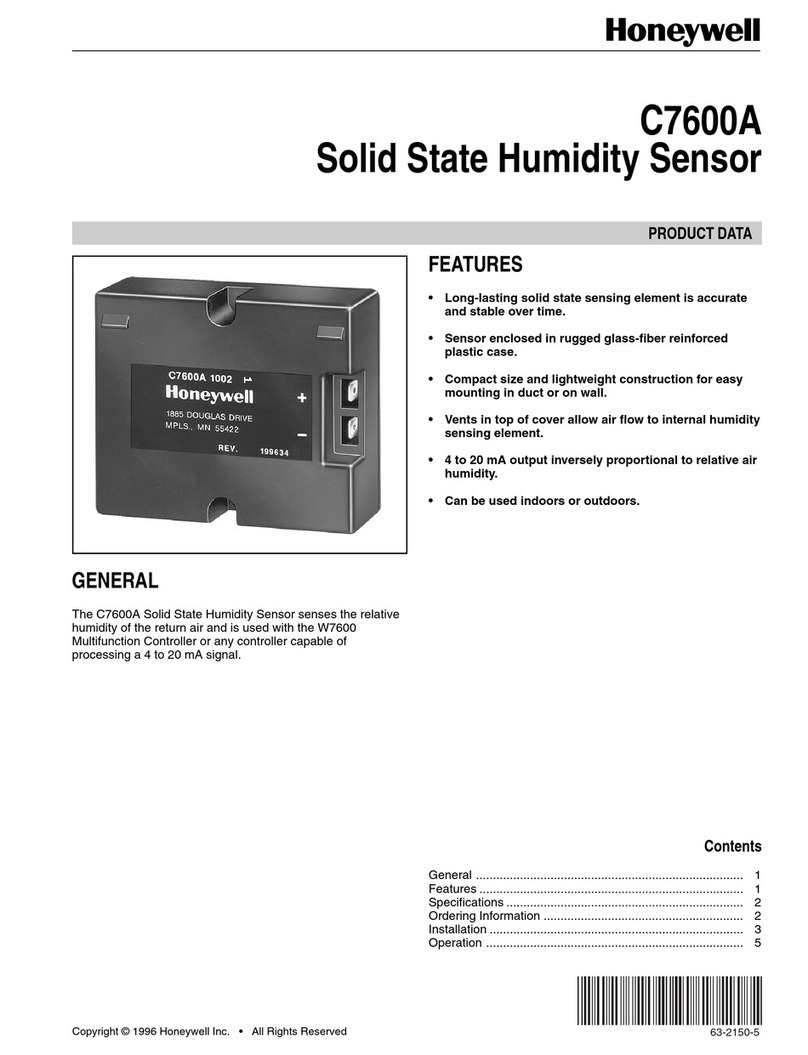

Honeywell

Honeywell C7600A Product data

Arrowhead Alarm Products

Arrowhead Alarm Products Elite Control TRX PIR installation instructions

Eaton

Eaton E67 Series Instruction leaflet

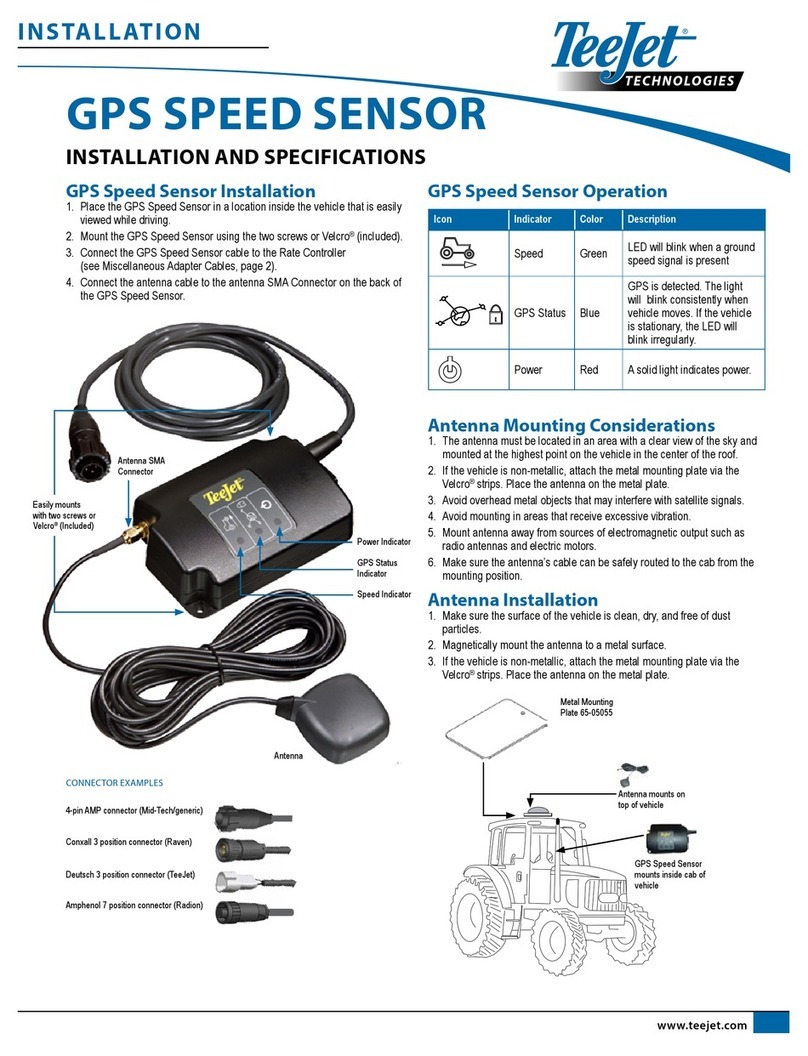

TeeJet

TeeJet gps speed sensor Installation

texet

texet PowerPack TPB-2113 user guide