Sepura HBC User manual

Installation Guide

Sepura Mobile

Transceivers

sepura

WARNING

Do NOT operate your Sepura mobile radio in an explosive atmosphere.

Obey “Turn OFF Two-Way Radios” signs where posted.

Do NOT touch the antenna when the radio is turned on.

Standard & Colour Console options

Accessories

Accessories

Console options and accessories

Up to

two consoles can be connected. The two consoles can be a mix of SCC with an HBC or HBC2, or alternatively connect

an SCC3 with an HBC3. You cannot mix an SCC

, HBC and HBC2 with an SCC3 or HBC3.

Handset

Fist microphone

Remote Microphone

& Switches

Remote Microphone &

Switches

Handset

Accessory Connector view

Vehicle battery (via fuse provided)

Ignition switch (via fuse provided)

Loudspeaker

Programmable I/O

Vehicle harness:

Remote Console Cable

GPS

Ant.

Transceiver

Handset Based Console option

Vehicle harness:

Remote Console Cable

Handset

Based

Console

Vehicle battery (via fuse provided)

Ignition switch (via fuse provided)

Loudspeaker

Programmable I/O

Antenna

Antenna

Transceiver

Standard Console

123

65

4

7 8 9

0

-abc def

mnojklghi

pqrs tuv wxyz

,;

*#

PTT

Soft Key 5

PTT

Soft Key

(HB

C2/HBC3

only)

Transceiver

Remote mic.

& switches

(see page 4 for details)

GPS

Ant.

Interface

& Handsfree

Box

Bracket

Rear Accessory Connectors

Dedicated

Data

Connector

Handset /

Fist mic.

Handset /

Fist mic.

Transceiver

Split bung

Cable tie

Remote Mic. & switches

(see page 4 for mic. termination)

AAI1

AAI2

DDC

TRANSCEIVER

Handset /

Fist mic.

Rear Accessory Connectors

Handset /

Fist mic.

Transceiver

Split bung

Cable tie

Remote Mic. & switches

(see page 4 for mic. termination)

Front Accessory Connector (VAC):

Handset / Speaker Mic. / USB Data Cable

Colour Console

Jack socket (Rev3 & later)

[R

eserved – do not

connect audio devices

]

2

Important Information

The transceiver is designed for nominal 12 V negative earth systems.

The equipment is to be installed in accordance with the requirements of local

radio communications authorities and/or Health and Safety regulations.

12 V supply leads, antenna cables and speaker wiring is to be routed as far away as

possible from gas or fuel lines, and any in-vehicle electrical wiring. This reduces the risk to

safety in the event of a leak.

The transceiver should be positioned so that it does not obstruct, or become at risk of

damage from, any occupant or carried items. All cabling should be hidden and not left

loose.

Unpacking

Unpack the container(s) and ensure all items specified on any delivery note are present.

The manufacturer, or their authorised agents, must be notified within ten days of

receipt of equipment if any damage or shortages are found

(customer.su[email protected]).

No consoles or accessories are shipped in the box with the transceiver except the

Power Cable Assembly and the Transceiver Mounting Kit. Due to the many

combinations available the accessory pack must be specified at time of ordering.

Operator Access and Safety

The console must be fitted in such a position that the operators have easy access to the

controls and the microphones when wearing a seat belt. The controls must also be within

the driver's normal field of vision.

Fitting positions above the driver's or passenger's head, or in other positions where the unit

would present a hazard in an accident, must be avoided.

The microphone/handset hook mount must be fitted such that the microphone/handset is

easily accessible and the cable cannot interfere with the vehicle control, or with the driver's

feet.

Preferably, the loudspeaker should be installed such that the grille is facing the operator,

but out of sight of the remote hands-free microphone (if fitted).

Installation

This installation guide provides basic installation information and is not intended to be

definitive, as different types of vehicles will require different installation configurations.

The installer must ensure that fixing screws of an appropriate length are used (some

installations may require different screws). The information given here is general and for

guidance only.

The installation should comply with FCS 1362 CODE OF PRACTICE for the installation of

mobile radio and related ancillary equipment in land based vehicles - see

http://www.fcs.org.uk.

Installation Precautions

Motor vehicle manufacturers make use of electronic vehicle control systems, e.g.,

ignition, anti-skid devices etc. The following information is supplied to ensure that

there is no radio frequency interference effect upon the vehicle's electronic systems.

To prevent interference with any other electronic systems in the vehicle, the antenna

should be mounted as far away as possible from these units and their associated

cables. Refer to the vehicle manufacturer's handbook to locate these items.

Consult the manufacturer's handbook to establish whether it is practical to

disconnect the vehicle battery without affecting devices, such as central locking

mechanisms, engine management computers, security-coded in-car entertainment

units etc.

WARNING

1. Disconnect the vehicle’s battery before commencing installation (be aware

of effect on public broadcast radio security code, alarm systems and some

engine management systems).

2. Do not smoke, or use naked flames, when working near the vehicle’s fuel

system.

3. Ensure that fuel lines, hydraulic lines and existing cables are not damaged

during installation.

4. Ensure that the installation does not impede the normal operation of the

vehicle, including the operation of any safety device, e.g., airbags and

seatbelt tensioners.

5. Speed control, fuel injection, anti-lock braking, navigation, air bag and other

electronic systems are relatively immune to RF interference. However, if

difficulty is experienced or faulty operation suspected, consult the vehicle’s

dealer.

6. This equipment is suitable for 12 V negative earth vehicles only. Use on

other supply systems will result in damage to the equipment.

7. No part of the equipment should be mounted such that injury to the

occupants is likely during an accident.

8. Prolonged operation of the transceiver with the vehicle engine switched off,

could drain the vehicle’s battery.

9. In order to reduce the risk of RF burns the antenna must always remain

connected whilst the equipment is switched on. Under no circumstances

should the antenna connection be connected or disconnected whilst the

equipment is switched on.

Specialised Vehicles

The installation on certain specialised vehicles, such as fuel tankers and fire-fighting

vehicles may be subject to additional safety regulations which must be closely observed.

Prior to commencing an installation on such a vehicle, make sure that any relevant safety

regulations are fully understood.

Petrol and Diesel Powered Vehicles

Ensure that there are no petrol/diesel leaks before commencing an installation involving the

use of electric tools as these can produce sparks. Ensure that no damage to the fuel tank

or fuel lines occurs when drilling holes.

Gas Powered Vehicles

Before installation starts ensure that there are no gas leaks before commencing an

installation involving the use of electric tools as these can produce sparks. DO NOT USE A

NAKED FLAME. Butane and propane are heavier than air, so if there is a leak the gas may

lay on the floor of the boot. The gas is detectable by its characteristic smell. The point of

escaping gas may show signs of frosting. The vehicle owner should arrange for the leak to

be repaired before the installation is commenced.

Ensure that no damage to the gas tank or gas lines occurs when drilling holes. Supply

cables should be run, if possible, on the opposite side of the vehicle to the gas fuel pipe.

Vehicles Fitted with Electronic Devices

In theory, any vehicle electronic systems could be affected by the presence of an RF field of

sufficient intensity, which when detected may cause the device to malfunction. The source

of RF may be a mobile transceiver installed in the vehicle itself or one operating in another

vehicle in close proximity. If interaction did occur, loss of control could result for the

duration of the transmission.

In the interests of safety, the user must be asked to test the vehicle when the installation is

complete.

Installation Guidelines and Recommendations

Temperature Considerations

Reliable transmit operation will be achieved if the transceiver is mounted such that the

finned heat sink receives a free flow of air, i.e., if it is mounted in the normal vertical

orientation with no restriction to the flow of convected air. For any other orientation, varying

degrees of degradation may result.

Fitting the transceiver or console on top of the dash is not recommended. Exposure to

direct sunlight may cause the temperature to rise to over 100 °C. Prolonged exposure to

these temperatures may damage the equipment and invalidate the warranty.

Do not mount the transceiver close to a heat source, e.g., in front of a heater vent.

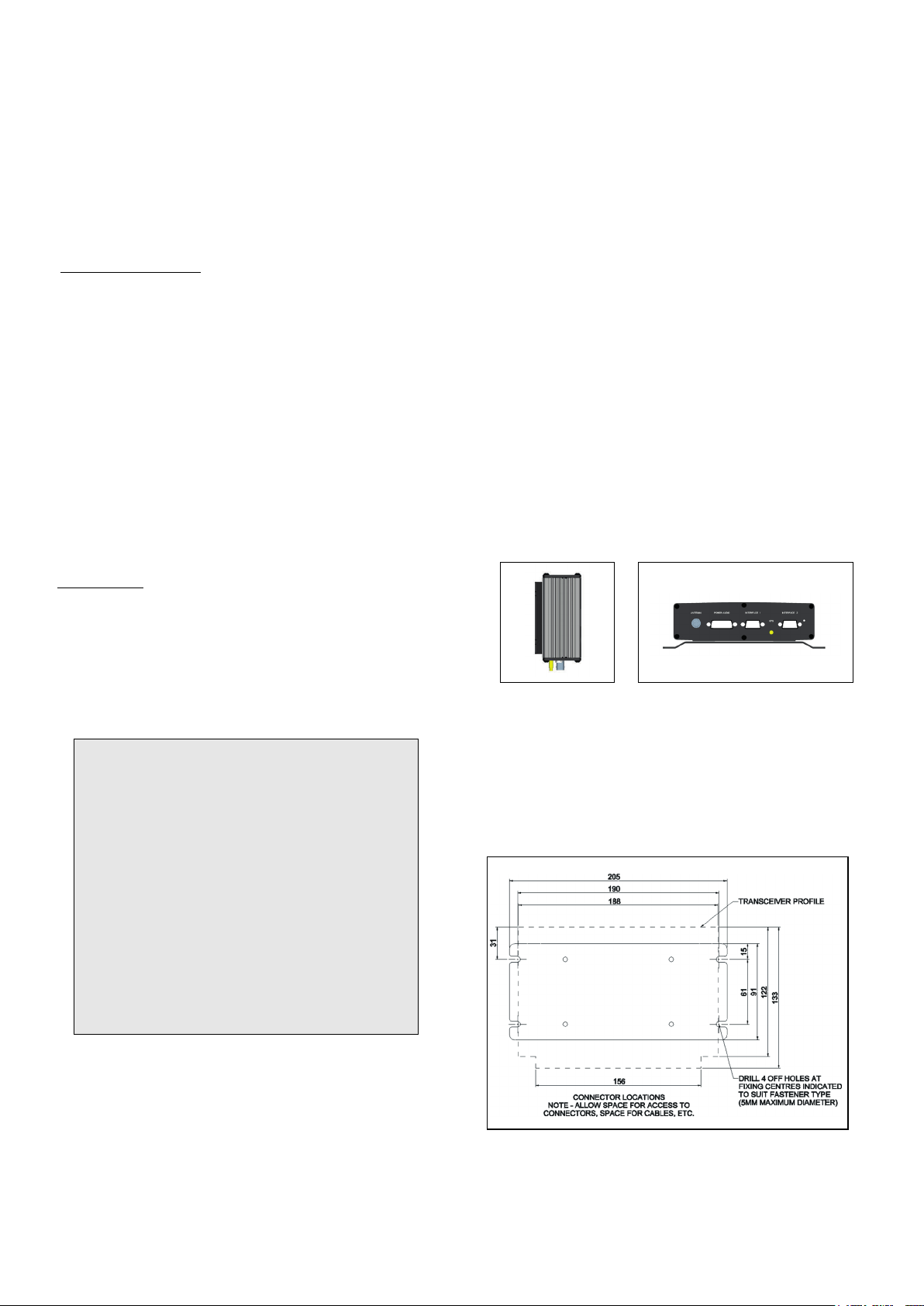

Installing the Transceiver

Orientation Considerations

It is recommended that the transceiver is mounted within 15 ° of the vertical with the

connectors at the bottom; this reduces the effects of vibration and likelihood of

dust/moisture ingress. Ensure the heat sink fins are in free air as much as possible. The

heat sink may become hot after long periods of transmission; therefore, make sure that

accidental contact with the heat sink is not possible. Ensure sufficient space is provided

above the installation to allow fitment and removal of transceiver (see diagrams below).

Preferred Orientation

Alternative Horizontal Orientation

Location Considerations

The transceiver must be fitted within the interior of the vehicle (excluding the engine

compartment) and protected from the external environment and vehicle cleaning

operations. When fitted, no part of the transceiver may be allowed to obstruct the operation

of the vehicle or impair the safety of any occupant.

Locate the transceiver away from cables carrying very high currents, e.g., the starter motor

cable or the electric traction motor, and its cables, of electric vehicles.

Transceiver Mounting Bracket Installation

The transceiver mounting bracket must be screwed to the desired surface using at least

four screws. The bracket may be used as a template.

Fixing Hole Positions for Transceiver Mounting Bracket (all dimensions in mm)

Transceiver profile includes small clearance allowance; additional allowances should be

made for cables depending on installation configuration.

Cables

Both the remote console and loudspeaker extension cables are colour coded blue at the

transceiver end to aid installation before the transceiver is available.

Ensure that the remote console cable and the loudspeaker cable are routed so that

they are kept well clear of the antenna cable and of any other electronic devices such

3

as electromagnetic systems or AM/FM radios. One end of the remote console cable is

plugged into the 16-way header on the rear of the Standard Console (or Interface &

Handsfree Box of Handset Based Console) and the strain relief/environmental grommet

located in place within the moulding. The other end plugs into either of the “D-type”

Interface sockets on the rear of the transceiver.

If the transceiver is running V9, or earlier, software, do not connect or disconnect the

console(s) while the transceiver is powered. V10, and later, software supports “hot

swapping”.

If a connector is unused, fit the dust cover provided.

Power/Audio Connector Wiring Colour Code

Wire Colour

Description

Wire Colour

Description

Red

Positive connection +12 V

Orange

Programmable input 1

Black

Negative connection GND

Yellow

Programmable input 2

Blue

Ignition Sense

Light green

Programmable input 3

Grey

Loudspeaker

Pink

Programmable output

Unused cables may be cut to 2 cm and insulated (e.g. with heat shrink sleeving).

WARNING

The transceiver will be damaged if either of the loudspeaker conductors (grey twin

conductor cable) is connected to ground. If the loudspeaker output is to be

connected to other audio systems, an audio isolation transformer must be used.

DC Supply Connection

The power cable plugs into the rear of the transceiver utilising a 15 way D-type connection.

The cable also provides an ancillary connection point for function such as loudspeaker and

other special I/O functions.

1 With the transceiver end of the power connector resting in its intended final position,

route the wires to the vehicle battery; threading the cable through the bulkheads if

required (include the blue wire where ignition switching is not required, see 4 below).

2 The positive power line must include a fuse as close as possible to the power

source. The negative power line must be connected close to the battery-to-vehicle-

body connexion (not directly to the battery) and must not include a fuse.

3 It is recommended that the power cable runs are kept as short as possible.

4 The blue wire provides an ignition sensing input. If ignition switching is required, trim

the wire to length so that it can be wired, via a fuse, to the ignition switch, using the

splicing connector provided. Otherwise this wire must be connected, via a fuse, to

the permanent positive supply.A fuse must always be fitted close to where the wire

is connected.

5 Check the installation and fit the blade fuses. Fuse rating:- Positive supply 10 A,

Ignition sense 1 A (Automotive 19 mm blade type - Littelfuse ATO®).

Antenna Installation

For best all round performance of the product, the antenna should be fitted on the centre of

the vehicle roof. Alternative positions, such as wing mounting, will give degraded

performance. The coaxial feeder should be secured along its length to eliminate the

possibility of damage by sharp edges or moving parts.

Antenna Installation – GPS (optional)

If a GPS receiver is fitted at time of manufacture, a GPS antenna socket will be fitted.

Please note that the SRG3900 transceiver tracks GLONASS and GPS satellites

simultaneously. See customer support bulletin CUS-14-2045.

The antenna unit connects to a SMC connector on the rear of the transceiver and should,

ideally, be mounted on the highest point of the vehicle (i.e., roof) with an uninterrupted view

of the sky, and as far from the TETRA antenna as possible. For mounting, follow

manufacturer’s installation instructions. It is recommended to fit the GPS antenna

connector before connecting the Remote Control Cable.

An active antenna is recommended, the supply of which is on the centre pin, 5 V nominal,

40 mA maximum. This supply feed is short circuit protected.

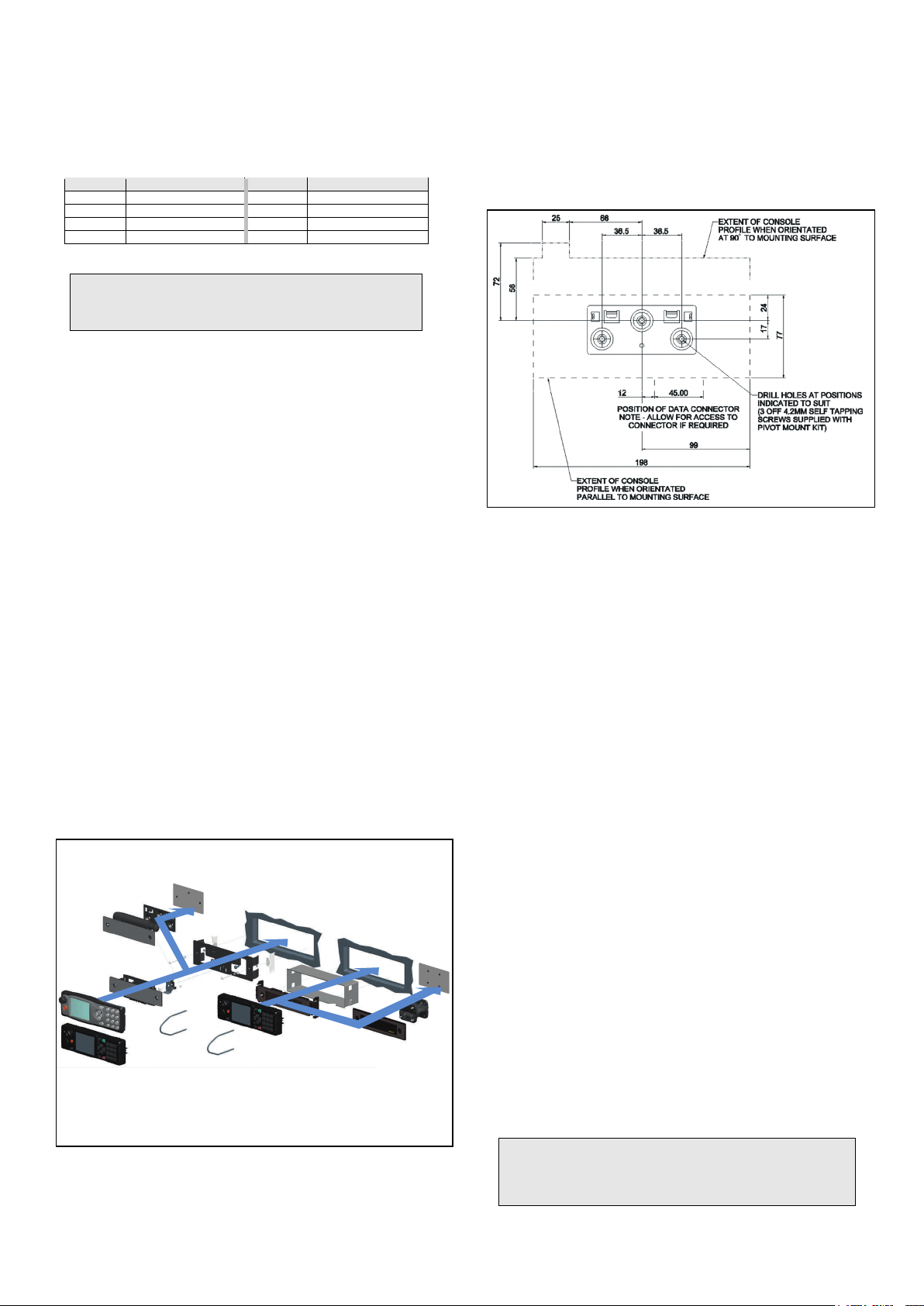

Standard & Colour Console Installation

Mounting Options

Mounting the Standard or Colour Console on the Dash

The console is mounted into the desired position utilising the Console Pivot Mount Kit.

This consists of two main parts:

The dash mount bracket onto which the support bracket is attached.

An adjustable support bracket onto which the console is fixed.

The dash mount bracket should be fixed to a suitable surface, using the three screws

provided. Ensure orientation is correct for the viewing situation (i.e., tilt up or tilt down) and

access is considered to the RS232 data connector, if required.

Ensure that the microphone(s) are connected and cables laid in the cable exits on the rear

of the console (see illustration on P4). Fit the bungs provided into any unused cable exits.

Fix the support bracket to the rear of console using screws provided (tightening torque =

0.8 Nm). Avoid trapping wires with the bracket during assembly.

The support bracket then slots into the mounting bracket and is held by a single, fixed

sprung screw.

The viewing angle of the console can be adjusted by loosening the release knob until the tilt

mechanism is free enough to move, a ratchet action provides incremental positioning. The

knob should then be re-tightened fixing the console in place.

Fixing Hole Positions for Console Pivot Mounting Kit (all dimensions mm)

The console profile includes small clearance allowance; additional allowances should be

made for cables depending on installation configuration.

Mounting the Standard Console using a DIN Slot

See mounting options diagram. Fit DIN Fascia kit onto DIN slot using screws provided.

Fit a self-locking nut to the end of each of the two screws that secure the DIN fascia kit, so

that if the fascia is subsequently removed, the two grip plates are prevented from fully

detaching from the securing screws.

Either the rear panel kit or the pivot mount kit may be fitted with the DIN fascia (the dash

mount bracket supplied with the pivot mount kit is then not required).

Cable Routing

Ensure that cables are connected and laid in the cable channels on the rear of the

console (See illustration on P4). Fit the bungs provided into any unused channels.

Fit either the Rear Panel Kit or the Pivot Mount Kit to the Console and then fit this

assembly to the DIN Fascia Kit. Fix either the support bracket, or the console rear

panel, to the rear of the console using the screws provided. Avoid trapping wires

during assembly.

Mounting the Colour Console using a DIN Slot

See mounting options diagram. Fit the DIN cage into the slot. Fit bungs provided into all

console cable channels. Feed cables through the DIN cage and DIN mount kit. Using the

screws provided: secure the DIN adapter to the console, fit the bungs provided into any

unused channels in the DIN adapter, fit the cable access cover using the screws provided

and push the assembly into the DIN cage. Avoid trapping wires during assembly.

Standard Handset or Fist Mic. accessories can be fitted to the rear of the colour

console, just like the standard console. New VAC based Speaker RSM or Speaker

Handsets should be connected to the Colour Console’s front accessory connector.

Mounting the Colour Console using a DIN Slot to achieve IP55 sealing

To mount the Colour Console so that it is sealed against front water ingress to IP55 when

mounted in DIN slot, follow the instructions in the separate document Mounting the Colour

Console into a DIN Slot to achieve IP55 sealing (SPR-DOC-03974-01).

Handset Based Console Installation

The handset based console is supplied with a magnetic mounting bracket and interface

box. The bracket can be mounted separately or on the box using the screws provided.

Note: the interface box is not sealed – avoid positions with risk of water or dust entry.

Connect the transceiver to the 16-way header in the interface box with a remote console

cable.. Ensure that the strain relief bung is seated at the cable entry in the box front with

flat face down. Refer also to “Cables” section at the top of this page.

(Refer to “Remote Microphone and Switches Installation” on P4 if this option is supplied.)

Press the inner wires of the Remote Console Cable into the clips on the PCB. Screw the

box halves together securely, taking care not to trap any wires.

Plug the handset based console into the interface box through the retaining clip and fold the

clip back over the plug body.

Place the handset in the mounting bracket with the display facing the user.

Additional mounting kits available separately:

300-00629 Car Cradle Fixing Kit: a knuckle joint which provides vertical tilt adjustment.

4-Hole AMPS Mounting Kit 1: additional brackets providing versatile mounting options.

IMPORTANT

The handset based console bracket and colour console AMPS adaptor kit are

compatible with AMPS standard mounting kits. If these are to be used, the installer

should check that the chosen kit is sufficiently rugged to suit the user’s operating

environment.

Dash mounted standard or colour console with

fixed re

ar panel kit or pivot mount kit

1. Pivot mount kit support bracket

4. DIN fascia kit

7. DIN cage

2. Dash mount bracket

5. DIN release tool

8. AMPS adaptor kit

3. Rear panel kit (fixed)

6. DIN mount kit

9. AMPS bracket (example)

DIN mounted

colour console

3

6

8

7

1

2

4

9

5

DIN mounted standard console with

fixed rear panel kit or pivot mount kit

AMPS mounted

colour console

4

Sepura plc

9000 Cambridge Research Park, Beach Drive, Waterbeach

Cambridge, CB25 9TL, United Kingdom

www.sepura.com

© SPR-DOC-00117

Issue 17

Configuring HBC2/HBC3 for Handset Mode or Fist Mic Mode

You can set the HBC2/HBC3 to Handset Mode or Fist Mic Mode by powering on whilst

pressing and holding the PTT and Navi-keys as described here. The mode persists even if

the power supply is disconnected.

To power on the HBC2 press the Mode key. To power on the HBC3 press and hold the

Cancel/Home key only until the green LED comes on then release the Cancel/Home key.

•for Handset Mode press and hold the PTT and the – Navi-key whilst powering up.

After the LED flashes green twice (Handset Mode), release the PTT and the – Navi-

key.

•for Fist Mic. Mode press and hold the PTT and the + Navi-key whilst powering up.

After the LED flashes blue twice (Fist Mic Mode), release the PTT and the + Navi-key.

Remote Microphone and Switches Installation (optional)

It is recommended that the microphone is located away from any wind noise in a position

suitable for the operator(s), e.g., near internal rear view mirror.

The switch unit should also be located centrally for the operator(s) to access. A self-

adhesive hook and loop pad is provided for mounting the remote PTT on a flat surface, e.g.,

dashboard.

Only one hands free microphone can be used in an installation, which can be connected to

either audio accessory interface.

Termination to console connector

The remote microphone is supplied un-terminated for ease of installation. Terminate to the

console as shown below after the switch unit and microphone are positioned.

If you are installing an Interface and Handsfree Box revision 2.0 or later with HBC (not

HBC2/HBC3), disconnect the Remote PTT Red Wire from the Remote PTT connector.

If you intend to upgrade to HBC2/HBC3 later, the red wire should be carefully removed from

the connector and taped out of the way, so that it can be reconnected as part of the

HBC2/HBC3 installation process.

Cable entry - Standard & Colour Console

Dress the cables via the guide channel as shown on page 1 (the two console types have

slightly different cable channels). Fit the split bung and the cable tie (supplied) around the

cables. Press the bung into the recess in the channel. Tighten the cable tie behind the

bung to secure the cables and allow slack at the 10-way plug termination.

Note: when used in conjunction with a handset or fist-microphone accessory the hands free

kit must be plugged into the Audio Accessory Interface 1 connector (back left) to allow all

cables to be routed correctly (as shown on page 1).

Cable entry - Handset Based Console

Dress the cables via the small guide channels at the bottom end of the cradle box (the

microphone channel is slightly smaller). The cables are gripped when the lid is secured.

Note: when used in conjunction with HBC2/HBC3 the Soft Key of the Remote Microphone

and Switches accessory is only operational with Interface and Handsfree Box revision 2.0

or later. To enable it with Interface and Handsfree Box revision 1.0, an additional shorting

link must be added between pins 4 and 6.

Fist Microphone/Handset (optional)

The Fist microphone and/or Handset should be located centrally for the operator(s) to

access, using the screws provided. Ensure that the cables are placed in the rear of the

Standard or Colour console so that the grommets seal correctly. Colour Console specific

accessories attach to the Front Accessory Connector (VAC). These should be used when

mounting in a DIN slot. Note: if replacing a rear connecting handset with a front connecting

handset, also replace the magnetic hook rest with the one supplied.

Multiple Fist Microphones and/or Handsets may be connected in an installation, which may

be connected to either audio accessory interface.

Loudspeaker

The loudspeaker should be positioned so that it faces the operator, but is out of the line of

sight of the Remote Microphone.

Programmable I/O

The transceiver supports 4 programmable digital I/O lines: 3 inputs and 1 output.

The following functions may be allocated on the input lines:

•External Alarm Input

•External Input Triggered Status Messages

The following functions may be allocated on the output line:

•External Alert Output

•Status Message Triggered External Outputs

For details of how to programme the functions refer to the Radio Manager documentation.

For details of the signals and their characteristics, see the following table:

Wire

Colour

Description Performance

Orange Programmable

input 1

V

IH

min = 2.0 V

VIL max = 0.8 V

Protected against accidental application of vehicle

supply voltage, 15.6 V maximum.

Assertion time: >100 ms

Wire

Colour

Description Performance

Yellow Programmable

input 2

V

IH

min = 2.0 V

VIL max = 0.8 V

Protected against accidental application of vehicle

supply voltage, 15.6 V maximum.

Assertion time: >100 ms

Green Programmable

input 3

V

IH

min = 2.0 V

VIL max = 0.8 V

Protected against accidental application of vehicle

supply voltage, 15.6 V maximum.

Assertion time: >100 ms

Pink Programmable

output

Open drain, active low.

500 mA max. sink current

15.8 V max. external voltage. Internally protected

against inductive loads, and with a re-settable fuse.

VOL max = 200 mV @ 0.5 A

WARNING

To control devices from the programmable output which require more than 0.5 A,

use a suitable automotive relay to ensure correct operation. Connect the relay coil

between the output wire and the vehicle positive supply. The device must be

protected by an appropriate fuse in its positive supply. Check with the local

regulatory authority where the output is used to drive external alert devices such as

horns or sirens.

Installation with a Mobile Data Terminal (MDT)

This guide does not include specific details about installing with a MDT. For Standard

Console, connect via the 15-way D-type connector on the lower face using a Data Lead.

For Colour Console, connect via rear 8-way Dedicated Data Connector (DDC) using a DDC

PEI Tail and Data Lead or via Front Accessory Connector (VAC) using USB Data Cable.

Alternatively, connect via spare a 15-way interface on the transceiver using a Data Lead. If

a spare 15-way interface is not available, connect a Console Interface Box (300-00221)

between the transceiver and console using remote console cables not exceeding 10 m in

total length. Connect the MDT to the spare 15-way connector on the interface box.

Customising/Programming the Mobile Radio

To customise or re-program the internal software in the mobile radio you will need the

following items:

Radio Manager

Mobile Radio Power/Audio lead

Mobile Radio Data lead or USB Data Cable (option for colour console)

Connect the power lead to the power connector on the rear of the transceiver. The red and

black wires in the power lead should be connected to a suitable power supply set to 12 V

nominal with a rating of 5 A. Connect the blue ignition wire in the power lead to the positive

terminal on the power supply. All other wires may be left unconnected.

Standard Console Connection

Connect the Data Lead to either of the 15-way D-type Interfaces on the transceiver or to the

Data Connector on a console. Connect the other end of the data lead to a COM port on a

PC loaded with the Programmer.

Colour Console Connection

Connect to the PC com port via the Dedicated Data Cable (DDC) from the rear of the

console or to a USB port using the USB Data Cable from the Front Accessory Connector

(VAC).

RF Compatibility Checks

The following checks must always be carried out if the vehicle is equipped with electronic

anti-skid, electronic ignition or engine management systems.

The transmitter should be operated only for the time required to make an observation.

The transmitter should be operated on a TETRA System, or these checks will have to be

carried out in DMO.

An assistant will be required for the following checks.

1 With the vehicle stationary and the engine running at fast idle, operate the

transmitter. Check that the brake lights do not illuminate and that the engine

continues to run normally, i.e., with no surging or cutting out.

2 Operate the brake pedal, key the transmitter and check that the brake lights do not

extinguish.

3 Put the vehicle into motion at a speed of 15 – 25 km/h (10 – 15 mph), key the

transmitter and operate the brake pedal simultaneously. Check that the braking

action is normal and that the engine does not surge or cut out.

WARNING

In the event of an apparent malfunction in the braking or any other systems during

RF compatibility checks, the transceiver installation should be rendered inoperative

and the vehicle manufacturer should be contacted before any further use is made of

the transceiver installation.

Unqualified persons should not attempt to modify these units in any way.

NOTICE

Sepura mobile transceivers have a small rechargeable internal back-up battery.

This battery powers the internal Real Time Clock in the event that the main power to

the product is removed. The battery may have discharged during the manufacturing

process or if the product has been in storage for some time. Once the product is

connected to its main supply, the back-up battery will charge regardless of whether

the product is turned on or not. The charge period for a full charge may be up to 48

hours.

Mobile Radio Series Vehicle Accessories

For details of the accessories available visit the Sepura website (www.sepura.com) or

contact your support partner.

Switch Unit

Remote

Microphone

Crimp-entry view of

10-way console plug

1

3

2

6

4

5

8

7

Identification

link

Microphone

termination

10

9

1

This manual suits for next models

2

Other Sepura Transceiver manuals