Seres OL OPAL Manual

This document is theproperty of Seres OL and cannot be reproduced without authorization

1 Stream

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 1/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot be reproduced without authorization

1 UPDATE AND APPROVAL SHEET

Rev

Raison for updating

Issued by:

Approved by:

Date

A

Creation of the document

R&D SERES

Environnement

Quality Department

20/07/12

B

Way and Zero modifications

R&D SERES

Environnement

Quality Department

03/04/13

C

JBUS add

R&D SERES

Environnement

Quality Department

11/04/13

D

self-priming pump

R&D SERES

Environnement

Quality Department

03/10/13

E

Alarm Blocking fault add (10*)

R&D SERES

Environnement

Quality Department

02/12/13

F

Update spares part

DALIA R&D

SERES

Environnement

GOZZI Quality

Department

29/11/16

G

Update SERES OL + ISO certificate

DALIA R&D

SERES OL

DALIA QHSE

SERES OL

19/02/20

H

Update List spares part

DALIA R&D

SERES OL

Quality Department

31/07/20

I

Update ISO, contact and Hydrocyclone

removed

DALIA R&D

SERES OL

Quality Department

23/10/20

J

Update document

DALIA R&D

SERES OL

Quality Department

12/11/20

K

Update ISO

LENOBLE

SERES OL

Quality Department

10/03/21

L

Drawing 1103NOT02-BASE updated

BOUTRELLE

SERES OL

Industrialization

26/03/21

M

Update CE/UKCA Declaration

LENOBLE

SERES OL

Quality Department

19/08/21

N

Update spares part list

LENOBLE

SERES OL

Quality Department

13/10/21

O

Update document

LENOBLE

SERES OL

Quality Department

19/01/22

P

Addition of back-flush and temperature

without cooler

LENOBLE

SERES OL

Quality Department

28/03/22

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 2/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot be reproduced without authorization

2 Summary

1UPDATE AND APPROVAL SHEET _______________________________________________________________ 1

2SUMMARY ____________________________________________________________________________________ 2

3WARRANTY CONDITIONS _____________________________________________________________________ 4

3.1 REMINDER OF THE MAIN WARRANTIES CONDITIONS APPLICABLE TO THE DETECTOR __________________________ 4

3.2 SECURITY INSTRUCTIONS_______________________________________________________________________ 4

3.2.1 Safety Regulations _________________________________________________________________________ 4

3.2.2 Detector’s characteristics ___________________________________________________________________ 4

3.2.3 Environmental conditions ___________________________________________________________________ 5

3.3. INTERNATIONAL SYMBOLS RECOGNIZED BY SERES OL __________________________________________________ 5

3.4. AFTER SALE SERVICE CONTACT ___________________________________________________________________ 5

3.5. INFORMATION ON THE COMPANY __________________________________________________________________ 6

3.6. THE BOOK ____________________________________________________________________________________ 6

3.7. ACCESS CODES ________________________________________________________________________________ 6

3.7.1. Description ______________________________________________________________________________ 6

3.7.2. Your access codes_________________________________________________________________________ 7

4UNPACKING BOOK ____________________________________________________________________________ 8

4.1 PRECAUTION ________________________________________________________________________________ 8

5MEASURING METHOD________________________________________________________________________ 10

5.1 OPERATING PRINCIPLE ________________________________________________________________________ 10

5.2 APPLICATION _______________________________________________________________________________ 11

5.3 MEASUREMENT CYCLE________________________________________________________________________ 11

5.4 FEATURES OF THE MEASURING METHOD___________________________________________________________ 11

6TECHNICAL SPECIFICATIONS ________________________________________________________________ 12

6.1 THE ENVIRONMENT __________________________________________________________________________ 12

6.2 FEATURES _________________________________________________________________________________ 12

6.2.1 Standard dimensions ______________________________________________________________________ 12

6.2.2 Electric features__________________________________________________________________________ 12

6.2.3 Sample input_____________________________________________________________________________ 12

6.2.4 Sample output sortie_______________________________________________________________________ 12

6.2.5 Electrical connections _____________________________________________________________________ 12

6.2.6 Recordings ______________________________________________________________________________ 12

6.2.7 Cleaning of the vessel _____________________________________________________________________ 12

7PRESENTATION OF THE EQUIPMENT _________________________________________________________ 13

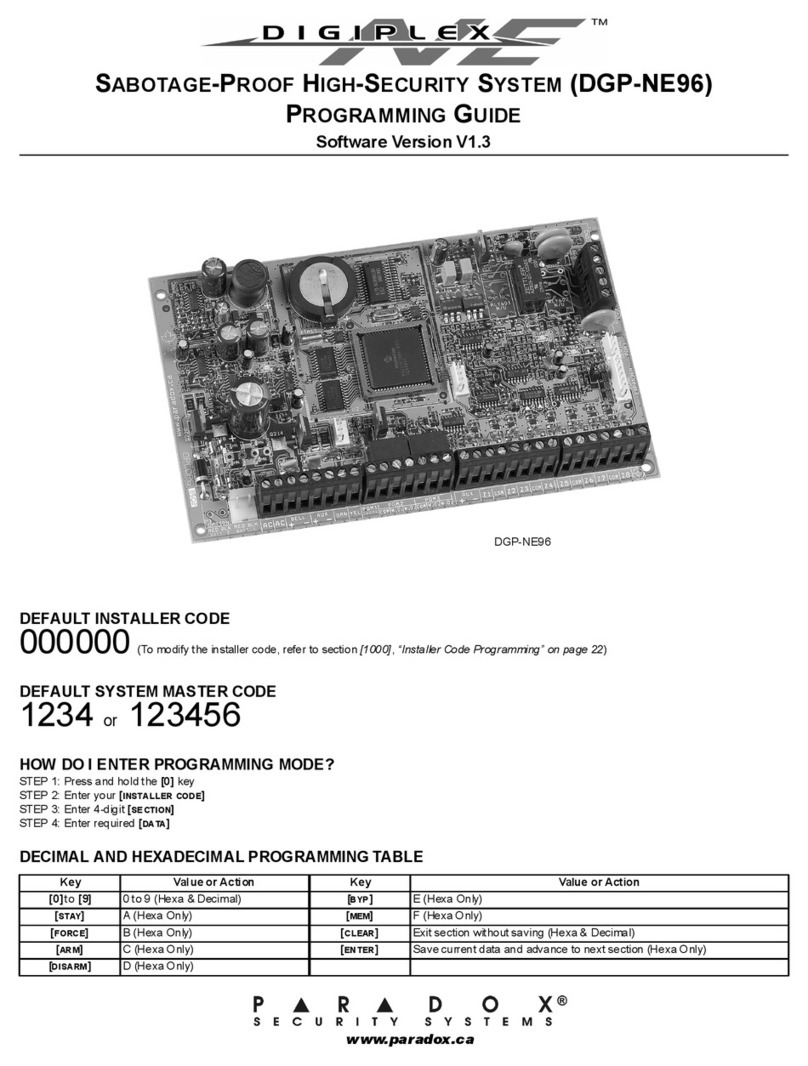

7.1 DESCRIPTION OF THE DETECTOR ________________________________________________________________ 13

7.2 DESCRIPTION OF SUBSETS _____________________________________________________________________ 15

7.2.1 The Vessel_______________________________________________________________________________ 15

7.2.2 Touchscreen _____________________________________________________________________________ 16

7.2.3 Measuring board _________________________________________________________________________ 17

7.2.4 The Engine/TM 61 pump group (Calpeda) _____________________________________________________ 22

7.2.5 The flowmeter____________________________________________________________________________ 26

8INSTALLATION MANUAL _____________________________________________________________________ 29

8.1 LOCATION _________________________________________________________________________________ 29

8.2 INSTALLATION DRAWINGS (DIMENSIONAL DRAWINGS,PRINCIPLE DIAGRAMS) _____________________________ 30

8.3 FIXATION __________________________________________________________________________________ 41

8.4 ELECTRICAL CONNECTIONS ____________________________________________________________________ 41

8.4.1 Wiring Diagram __________________________________________________________________________ 42

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 3/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot be reproduced without authorization

8.4.2 Communication __________________________________________________________________________ 43

8.5 HYDRAULIC CONNECTIONS ____________________________________________________________________ 44

8.5.1 Sample to analyse_________________________________________________________________________ 44

8.5.2 Clean water for the zero measurement ________________________________________________________ 44

8.5.3 Compressed air (Option) ___________________________________________________________________ 44

8.5.4 Cooling water (option)_____________________________________________________________________ 44

9THE OPERATION MANUAL ___________________________________________________________________ 46

9.1 PRE-START_________________________________________________________________________________ 46

9.2 COMMISSIONING ____________________________________________________________________________ 46

9.3 LIST OF MENUS______________________________________________________________________________ 48

9.3.1 User settings_____________________________________________________________________________ 50

9.3.2 Back-ups________________________________________________________________________________ 57

9.3.3 Recordings ______________________________________________________________________________ 60

9.3.4 Information______________________________________________________________________________ 61

9.4 ALARMS___________________________________________________________________________________ 62

9.4.1 Viewing the alarms________________________________________________________________________ 62

9.4.2 Exceeded threshold alarm __________________________________________________________________ 63

9.4.3 General failure (or detector fault)____________________________________________________________ 63

9.4.4 Management of a blocking failure____________________________________________________________ 66

9.4.5 Management of Y-filter back-flush (if selected)__________________________________________________ 66

10 THE MAINTENANCE MANUAL ________________________________________________________________ 69

10.1 CONTROLS_________________________________________________________________________________ 69

10.1.1 Zero setting ___________________________________________________________________________ 70

10.1.2 Optical test –Control of Operation ________________________________________________________ 73

10.1.3 Equipment testing ______________________________________________________________________ 74

10.1.4 Range summary ________________________________________________________________________ 77

10.1.5 Software update ________________________________________________________________________ 77

10.2 DISASSEMBLING THE ELEMENTS_________________________________________________________________ 79

10.2.1 Touchscreen___________________________________________________________________________ 79

10.2.2 The measuring board (or main board) ______________________________________________________ 79

10.2.3 The measuring vessel____________________________________________________________________ 81

11 THE TROUBLESHOOTING MANUAL___________________________________________________________ 85

11.1 TROUBLESHOOTING __________________________________________________________________________ 85

12 SPARE PARTS ________________________________________________________________________________ 87

13 ANNEXES ____________________________________________________________________________________ 88

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 4/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot be reproduced without authorization

3 Warranty conditions

3.1 Reminder of the main warranties conditions applicable to the detector

Our general terms of warranty are applied to this detector and integrated in our general terms of sale.

Normal operation conditions. Only follow-up of the rules supplied by Seres OL guarantees the analyzer’s

good operation. In case of non observance of the rules of directive formulation by user, Seres OL reserves

the right to refuse the one-year manufacturer warranty for the supplied apparatus.

3.2 Security instructions

3.2.1 Safety Regulations

To avoid injury to persons caused by electricity, please respect all the safety regulations of this book.

The equipment should to be used exclusively with a ground plug.

If the equipment is used in a way not specified by the manufacturer, the protection provided with the

equipment can be affected.

Any spare part has to be replaced exclusively by a qualified person using only the parts specified by

the manufacturer. It is always recommended that all power supplies are switched off before

dismounting or replacement of any component.

For any intervention on the hydraulic part of the detector, wear adapted protections (protective

clothing, gloves, glasses).

Please, do not use this equipment if there is flammable liquids or vapours, this could represent a risk for

security.

3.2.2 Detector’s characteristics

110 or 240V AC (On request)

50 or 60hz

All wirings have be in accordance with local standards and realised by a skilled and authorized

electricians.

All wirings and connections (electrical, hydraulic …) should be done according to local regulations of the

country in force and only by qualified authorized and skilled personal. The equipment warranty won’t be

guaranteed by the manufacturer in case of non observance of the standards and regulations reported in

points 8 and hereafter in this book.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 5/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

3.2.3 Environmental conditions

Relative humidity

10% to 80%

Temperature

5 to 45 C

Pollution level

2

Installation category

II

Maximum altitude

2000m.

Please, do not use this equipment if there is flammable liquids or vapours, this could represent a risk for

security.

3.3. International symbols recognized by Seres OL

IEC 60417, No. 5016

Electrical fuse

IEC 60417, No. 5017

Ground

IEC 60417, No. 5021

Equipotentiality

IEC 60417, No. 5032

Alternative current

IEC 60417, No. 5041

Be careful, hot surface

ISO 3864, No. B.3.1

Be careful, see documents

ISO 3864, No. B.3.6

Be careful, electric shock risks

3.4. After Sale Service Contact

After Sale Service / Spare parts : Tel : 04.42.97.37.91, psav@seres-ol.com

NB: To avoid errors, when ordering spare parts or service attendance please specify the serial number of

the analyser if possible.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 6/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

3.5. Information on the company

SERES OL

219 Avenue de Provence

13730 SAINT VICTORET

FRANCE

Tel: +33 (0)4 42.97.37.37

Web: www.seres-ol.com

SIRET : 85323753500028

NAF 2651B

TVA Intracommunautaire FR84853237535

3.6. The book

The information contained in this book may be subject of any changes without notice beforehand and don’t represent

any engagement on behalf of Seres OL. Seres OL reserves the right to make changes in the construction, design,

specifications, and / or in the procedures that cannot be reflected in the book.

This book is supplied under the condition that the provided information will not be used to the detriment of Seres OL.

3.7. Access codes

3.7.1. Description

Some menus have a limited access. There are two access levels:

User access. Possible Actions: Consulting the main window data.

User with authorization access (or User W). Possible Actions: Consulting the measure in process, Stop of

the measure in process, access to the settings menu (Zero, Setting 4-20mA output ...).

Once the access code is entered, if there is no action within 5 minutes, the code will be asked again automatically. If

the code is unknown, press Cancel and the main page will appear automatically.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 7/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

3.7.2. Your access codes

Some menus have a limited access. There are two access levels:

User access

oPossible actions: Consulting the main window datas.

User access with authorization (or User W).

oPossible Actions: Consulting the measure in process, Stop of the measure in process, access to the

settings menu (Zero, Setting 4-20mA output ...).

oUser with authorization access CODE: 0712

Once the access code is entered, if there is no action within 5 minutes, the code will be asked again automatically. If

the code is unknown, press Cancel and the main page will appear automatically.

THE PAGE IS TO BE CUT AND KEPT IMPERATIVELY

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 8/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

4 Unpacking book

4.1 Precaution

Position the box corectly (Up/Down)

Unpack carefully the detector

Check the analyzer for damage

oIf the device seems to be damaged, don’t plug it and get into touch with the After Sale Service

Department immediately (contact in Chapter Warranty).

Attach the rubber mounts for the pump that are in the plastic bag hanging on it

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 9/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

SECTION 1

EQUIPMENT RECORDS

5. MEASURING METHOD

6. TECHNICAL SPECIFICATIONS

7. PRESENTATION OF THE EQUIPMENT

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 10/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

5 Measuring method

5.1 Operating principle

The water that undergoes analysis flows through a measurement vessel made out of a glass cylinder.

On either side of the vessel there are:

•an infrared transmitter.

•a trimming cell that corrects possible deviations.

• a measuring cell that measures absorption and serves as a reference (180°).

•a measuring cell that receives, by reflection on hydrocarbon particles, a portion of the energy emitted by the

infrared transmitter (150°).

•A measuring cell that receives, by reflection on iron oxide-type particles, a portion of the energy emitted by

the infrared transmitter (90°).

The quantity of energy thus emitted is proportional to the number of particles and is converted into hydrocarbon

ppm. An alarm with an adjustable threshold warns the user if concentration levels are exceeded.

To prevent deposits from forming on the inside of the measuring vessel, a scraper controlled by an electrical actuator

regularly cleans the inside of the vessel.

Figure 1 : Layout of the various elements used in the measuring vessel.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 11/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

5.2 Application

OPAL is a new generation detector: online, live feed, measurement of IR light scattering, reaction agent-free, for the

control of hydrocarbon particles suspended in water.

All types of water:

• condensate return water, heat exchangers

• industrial water,

• industrial and urban waste water

Range of domains:

• Onshore: refineries, oil drilling, petrochemical, energy and other industries,

• Offshore: oil rigs, ships,

5.3 Measurement cycle

Measurements are taken continuously. The maximum recommended working temperature is 40°C.

5.4 Features of the measuring method

Characteristic values stemming from the method are given as an end-of-scale percentage.

Wavelength

850nm

Measurement range

0 –10 –30 –50 –120 –250 –500

ppm

Repeatability

±2-3% FS

Accuracy

±2-3% FS

Interfering factors

Turbidity (contact Seres)

Bubbles

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 12/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

6 Technical specifications

6.1 The environment

Installation instructions:

Ambient temperature should be between 5°C and 45°C, maximum

6.2 Features

6.2.1 Standard dimensions

Chassis: l*h*d: 1055*800*250 mm

Volume: 0.21m3

Weight: chassis 30kg (45kg with the cooling unit)

Protection: IP65

If additional options are present, refer to the dimensional drawing.

6.2.2 Electric features

Power consumption: Typical: 150 VA - Maximum 700 VA (with pump)

Input supply: 110 or 240 V, 50 ou 60 Hz

6.2.3 Sample input

Flow: The normal flow is of 200l/h (sample or zero water). The minimum tolerated flow rate is 100l/h knowing that

we recommend 200l/h. Below 60l/h there will be an alarm to protect the pump.

Pressure: 3 bars maximum

Temperature: min: 5°C max: 50°C

6.2.4 Sample output sortie

Unobstructed exit, open.

6.2.5 Electrical connections

Input/output signals:

Standard output signals: 4-20 mA (0mA if alarms) or 0-20mA and floating contacts

Input signals:

oStandby/Option/Accidental Leak

6.2.6 Recordings

Via USB port.

6.2.7 Cleaning of the vessel

Automatic and programmable.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 13/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

7 Presentation of the equipment

7.1 Description of the detector

In order to simplify the installation process, the entire equipment is placed on a metal frame (D) (see photo and

dimensional drawing below), on which the following items are assembled:

the detector (A), which includes a plastic box that holds the electronic components and the electrical

connection strips, with the measuring vessel mounted on the right side of the box,

a pump (C) ensuring the emulsion and distribution of the sample that undergoes analysis.

a flowmeter (B) that measures the flow of the sample,

a flow setting valve (G) for the clean water/sample,

a 3-way valve (E) for the distribution of clean water/sample

a filter sieve (F),

Optionally, the device may also include:

a cooling unit (I) with cold water circulation maintaining the sample at a temperature of less than 50°C

before it enters the pump,

a hot water safety feature (temperature sensor and solenoid valve (SV)) that cuts off the pump if the sample

temperature rises too much (in excess of 50°C),

a back-flush of the Y filter.

Figure 2: OPAL on assembly (without options).

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 14/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

Figure 3: General Dimensional Drawing (with options).

A

B

C

D

E

F

I

G

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 15/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

7.2 Description of subsets

7.2.1 The Vessel

The vessel is made of DELRIN and of PVC. It includes 3 parts:

The top unit: contains the sample output and the electrical actuator.

The core unit: contains the transmitter, the four sensors and the transmitter, as well as the desiccant capsule. It

also serves as a support of the vessel on the box.

The bottom unit: contains the sample input.

Figure 4: Installed measuring vessel.

Figure 5: See-through display of the measuring vessel.

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 16/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

7.2.2 Touchscreen

The "screen" or "display" board serves as a user interface.

It displays the measurement, the alarms, and allows access to certain settings.

7.2.2.1 Aspect and dimensions

The screen is mounted on the box's door.

Figure 6: Front view of the OPAL box door. Figure 7: Rear view of the door.

7.2.2.2 Power supply

The screen is powered by OPAL measuring board via the grey ribbon cable. The supply voltage is of 3.3V.

The ribbon cable is coded, and the USB-end of the cable provides the coding.

Figure 8: Details of the display board's connections.

Ribbon cable for power

supply and

communications

Keyboard ribbon cable

(option)

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 17/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

7.2.3 Measuring board

The electronic board includes the Measurement function and the Input/output management function.

It also controls the emulsion pump.

7.2.3.1 Power supply

This board is directly connected to the mains. The Start/Stop switch on the board is used to start the device.

It is fitted with 2 time-delay 5A fuses (5x20mm). The AC/DC-type power supply allows the conversion into

24VDC.

Features:

Input voltage range

85V AC to 264V AC

Frequency

50/60hz

Output voltage

24 V / 1.25A / 30W

Overload protection

105%.

Over voltage protection

120% of output nominal voltage

Resistance to over voltage

I/P-O/P: 3KVAC, 1minute

7.2.3.2 Functions

It performs an optical measurement using the synchronous rectification method.

Figure 9: Measuring board - seen from above.

Informational description of the sensors and actuators of the measuring board.

Electrical outlet

(230/110 –50/60Hz)

5A fuses

ON/OFF switch

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 18/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

The configuration and use of the different elements depend on the measuring method.

Measurement:

1 projector

4 optical receptors (Hydrocarbon, Absorption, Compensation... measurements)

1 pump control

1 electric actuator control

1 temperature measuring unit (PT100)

1 Flow measuring unit

2 busbars I2C (Option)

1 USB port for measurement retrieval

Inputs/outputs:

1 4-20 mA-type analogue output. This output is identified with the term 4/20mA.

11 TOR outputs, identified with the terms RELAYS and OUTPUTS VOLTAGE, and distributed in

the following manner:

o7 relay outputs (floating contacts 24V at 1A max) for information about the measurement's

status (alarms, thresholds…).

o4 TOR 24V 500mA outputs for direct cabling of a solenoid valve, a buzzer...

3 TOR inputs identified with the term INPUTS.

1 RS232 output.

1 optional communication output (RS232-RS485).

The input and outputs may be configured for ATEX mode (ATmosphères EXplosibles - explosive atmospheres).

OPAL :

OPERATION & MAINTENANCE BOOK

Page : 19/90

Manual N°: 10796

This document is theproperty of Seres OL and cannot bereproduced without authorization

7.2.3.3 Functions of outputs and inputs

7.2.3.3.1 Functions of outputs

(1) possible configurations: 4-20mA, 0-20mA, (2) TOR floating contact output. Type NO or NF, (3) Solenoid valve power output.

C.S. = Floating contact (can be configured as NO /NF)

N.U. = Not used

Direction

Type

Qty per

board

board

(Address: 1 –N=0)

Name

Function

Output

Analogue

1

4-20mA (1) (1)

4/20mA Measurement

Digital (all or nothing) (0-24V)

Relay

RELAY 1(2)

C.S. Reserved threshold 1

Relay

RELAY 2(2)

C.S. Reserved threshold 2

Relay

RELAY 3(2)

2 possibilities depending of

the configuration:

a) C.S. Reserved hot water

SV status

b) 24VDC Hot water SV

command

Relay

RELAY 4(2)

C.S. Reserved valid

measurement

Relay

RELAY 5(2)

C.S. Reserved general alarm

Relay

RELAY 6(2)

C.S. Option

Relay

RELAY 7(2)

C.S. Flow Fail

Voltage

OUTPUT

VOLTAGE 1(3)

C.S. Reserved hot water SV

command

Voltage

OUTPUT

VOLTAGE 2(3)

C.S. Reserved way SV

command

Voltage

OUTPUT

VOLTAGE 3(3)

C.S. Reserved zero water

SV command

Voltage

OUTPUT

VOLTAGE 4(3)

C.S. Reserved buzzer

command

Table of contents

Popular Security System manuals by other brands

Samsung

Samsung SSC-21WEB user guide

Ness Security Products

Ness Security Products SecurityGuardII owner's manual

ESP

ESP HDview Remote Viewing Guide

AVS Electronics

AVS Electronics VECTOR Plus installation manual

KALEAS

KALEAS KlimaDetector operating instructions

Honeywell

Honeywell ADEMCO LYNXR Series Installation and setup guide