SET Lynx-CustomFit LYNX2-MPO User manual

North Carolina (USA)

Sumitomo Electric Light wave Corp.

78 Alexander Drive, P.O. Box 13445, RTP, NC 27709

TE +1-919-541-8100

http://www.sumitomoelectric.com/

Yokohama (Japan)

Sumitomo Electric In ustries, Lt .

(Lightwave Network Pro ucts Division)

1, Taya-cho, Sakae-ku, Yokohama 244-8588, Japan

TE +81-45- 853-7223, http://global-sei.com/fttx/

Lon on (UK)

Sumitomo Electric Europe Lt .

220 Centennial Avenue, Elstree, Herts. WD6 3S , UK

TE +44 (0)20-8953-8118

http://www.sumielectric.com/

Splicer Fiber Splicing Program Heater Program

T-66M12-

MPO

SMF SM12c: ynx MPO SM ynx MPO

MMF MM12c: ynx MPO MM

Fusion Splicer

T-66M12-MPO

Fiber Cleaver

FC-6M

Jacket Remover

JR-6

Fiber Holder

FHM-12

SMF : G.652, G.657

MMF : MM50(OM2), MM50(OM3), MM50(OM4), MM62.5(OM1)

The ynx-CustomFit® Splice-On Connector is designed and

manufactured to assure personal safety. Improper operation

can result in bodily injury and serious damage to this product.

Please read and observe all warnings instructions given in this

operation manual.

Wear safety glasses to protect your eyes when

handling optical fiber.

Never look into the end of a microscope or optical

cable connected to an optical output device that is

operating. aser radiation is invisible, and direct

exposure can severely injure the human eye.

Alcohol is flammable, causes irritation and is harmful

if swallowed or inhaled. Keep alcohol away from

heat, sparks, skin, and avoid contact with eyes.

In the case of the work at the high place, please be

careful not to drop an assembling tool.

ynx

ynx-

-CustomFit

CustomFit®

®Splice

Splice-

-On

On Connector

Connector Ver. 2

Ver. 2

-

-LYNX2

LYNX2-

-MPO

MPO for

for Ribbon

Ribbon Cor

Cor -

-

Installation

Installation Manual

Manual

!

!

!

1. Improper assembly will result in a loss of performance.

Please read instructions given in this operation manual

and the operation manual of the fusion splicer.

2. Never touch the fiber of the stub. It has been inspected

in the factory.

3. The product is sensitive to dirt or dust. Do not take out

any parts from the package until it is to be used.

4. The characteristic will be influenced by the fiber

cleaved surface condition. Please use a cleaver which

has a good cleaving characteristic.

5. Do not remove the dust cap until the connector has

been completely assembled in order not to cause an

high insertion loss due to them.

For your safety operation

!

Precautions

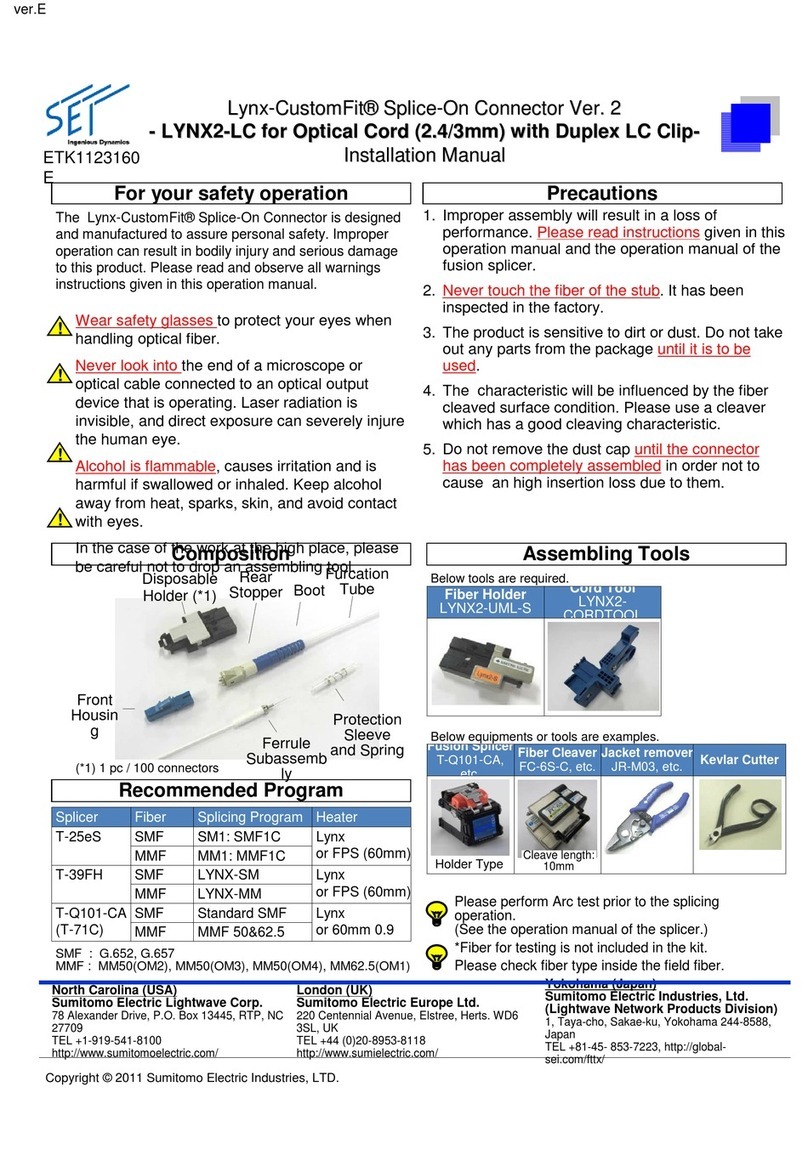

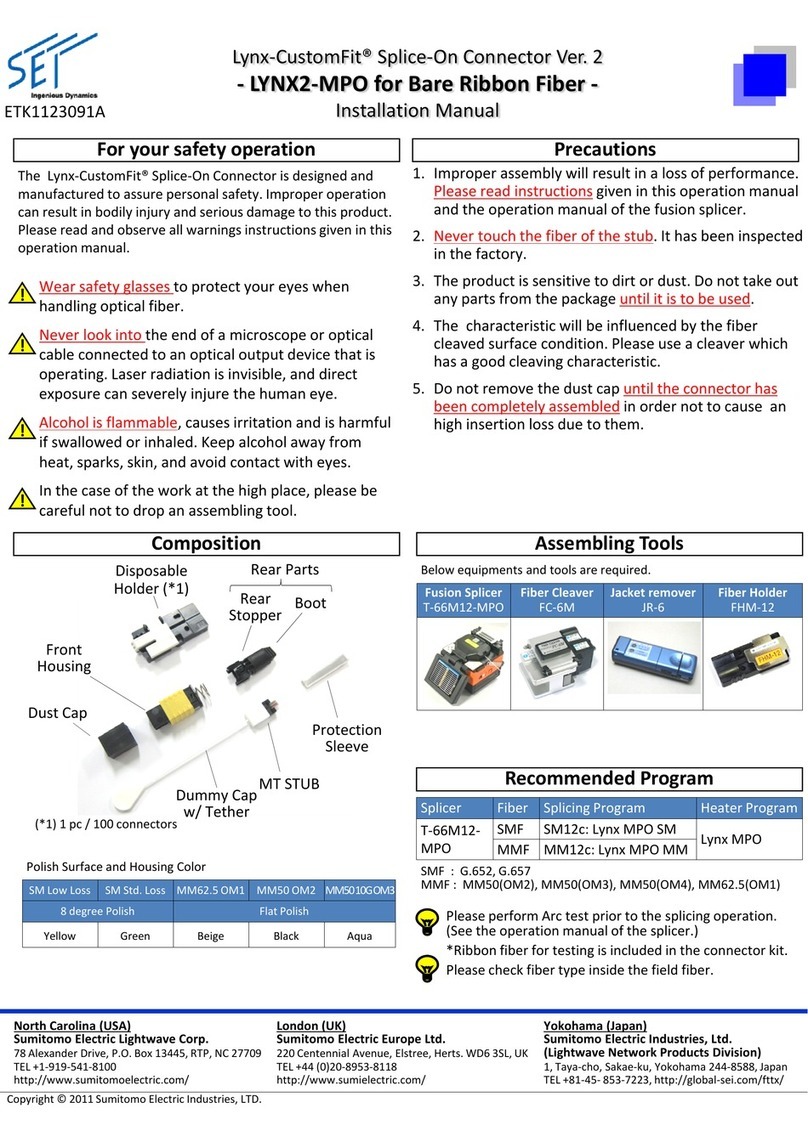

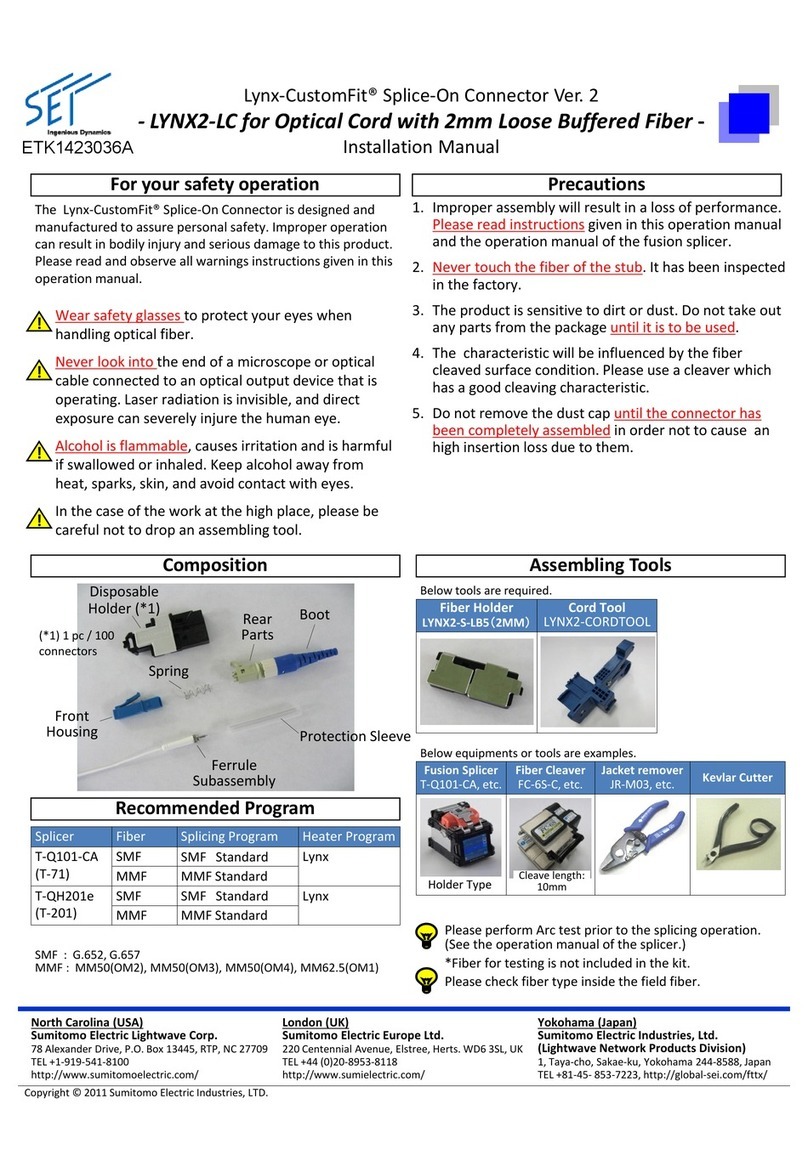

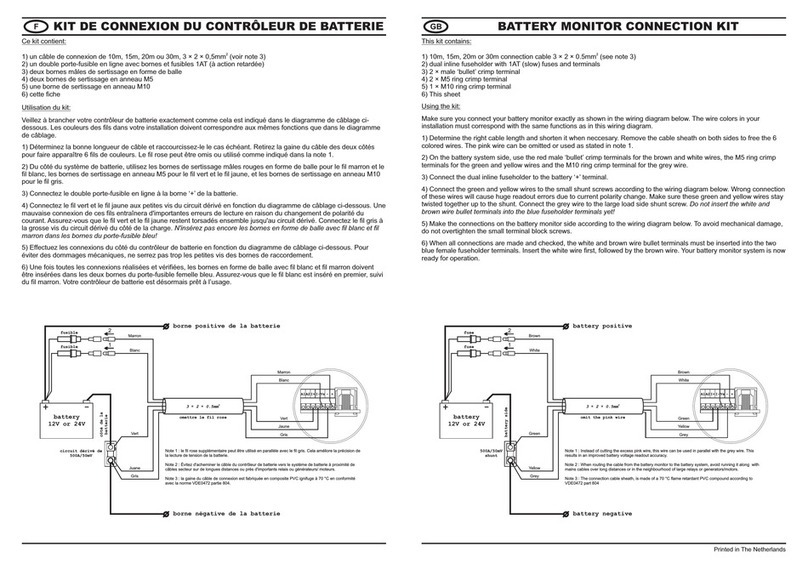

Composition

Disposable

Holder (*1)

Dust Cap

Front

Housing

Rear

Stopper

MT STUB

Boot

Protection

Sleeve

(*1) 1 pc / 100 connectors

Assembling Tools

Recommen e Program

Please perform Arc test prior to the splicing operation.

(See the operation manual of the splicer.)

*Ribbon fiber for testing is included in the connector kit.

Please check fiber type inside the field fiber.

ETK1123235A

Below equipments and tools are required.

Dummy Cap

w/ Tether

SM ow oss SM Std. oss MM62.5 OM1 MM50 OM2 MM50 10G

OM3

8 degree Polish Flat Polish

Yellow Green Beige Black Aqua

Polish Surface and Housing Color

Furcation

Tube

Copyright © 2011 Sumitomo Electric Industries, TD.

Rear Parts

Cord Tool

YNX2-CORDTOO -2&3

Kevlar Cutter

YNX2

YNX2-

-MPO for

MPO for Ribbon

Ribbon Cord

Cord

Assembly

Assembly Proce ure

Proce ure ETK1123235A

Copyright © 2011 Sumitomo Electric Industries, TD.

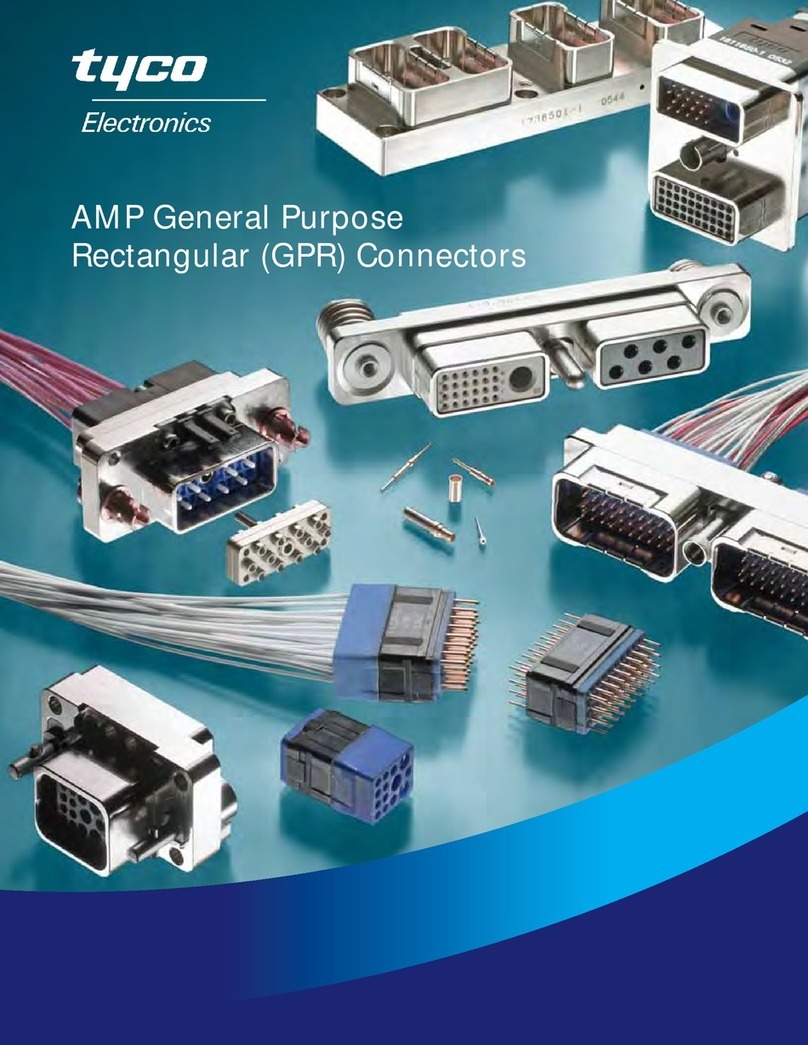

(6) Set ribbon fiber on FHM-12 hol er.

(7) Remove Coating (JR-6)

1. Place

3. Sli e

Clean rubber clamp

an bla e regularly

(9) Cleave the fiber (FC-6M)

No gap

(10) Set fiber hol er on the splicer

(left si e).

2. Close

Place fiber on

V-groove gently

(A) Set Fusion Con ition

Push “power key” for more

than 1 sec, then “splice” scene

(B) Perform Arc Test

Arc Test “ON”.

Then perform the arc test

according to the instruction.

*Fiber for testing is included

in the kit.

Please check fiber type

inside the field fiber.

Select

“Condition Change”

Select

Fiber Type

See the operation manual of T-66M12-MPO.

Spring

(Remove from

Front Parts) Protection

Sleeve CH1 Fiber(

((

(Blue)

))

)

Front Si e

Stainless Steel

Bottom Si e

Make sure the

orientation of Sleeve

CH1 Fiber

Front Si e

25~

~~

~30mm

(8) Fiber Cleaning.

Moistene

with alcohol

Push . Select

Sleeve Type Push .

(1) Sli e Rear Parts onto

the cor .

(2) Mark at 130mm from the

en of the cor .

130mm

(4) Fol the slit outer sheath an

Kevlar backwar . Hol them by a

men ing tape.

(5) Sli e Rear Parts, Spring an Protection

Sleeve onto the ribbon cor .

UP

Grasp here

Do not touch bare fiber

(11) Pick up MT STUB an set the stub on the plastic

hol er.

(12) Set stub hol er on the splicer (right si e).

Place fiber on

V-groove gently

If the position of the fiber

is wrong, set the fiber or

stub again.

(13) Fusion Splice.

Button to

start splicing

Push to

close

UP shoul be

upper si e

Sleeve an Spring

shoul be out of

the cover.

Protection

Sleeve

Spring

(14) Sli e the sleeve to the hol er. (16) Pick up the splice fiber.

No twisting

(17) Sli e Protection Sleeve to MT STUB.

No twisting

Left si e first

(15) Open the cover of the hol er.

Then right si e

Lightly maintaining tension

to prevent ben ing

Lightly maintaining tension

to prevent ben ing

Ribbon Cor

(3) Make slit by LYNX2-CORDTOOL-2&3.

Set the Ribbon cor on “3mm” groove perpen icularly.

YNX2

YNX2-

-MPO for

MPO for Ribbon

Ribbon Cord

Cord

Assembly

Assembly Proce ure

Proce ure ETK1123235A

Copyright © 2011 Sumitomo Electric Industries, TD.

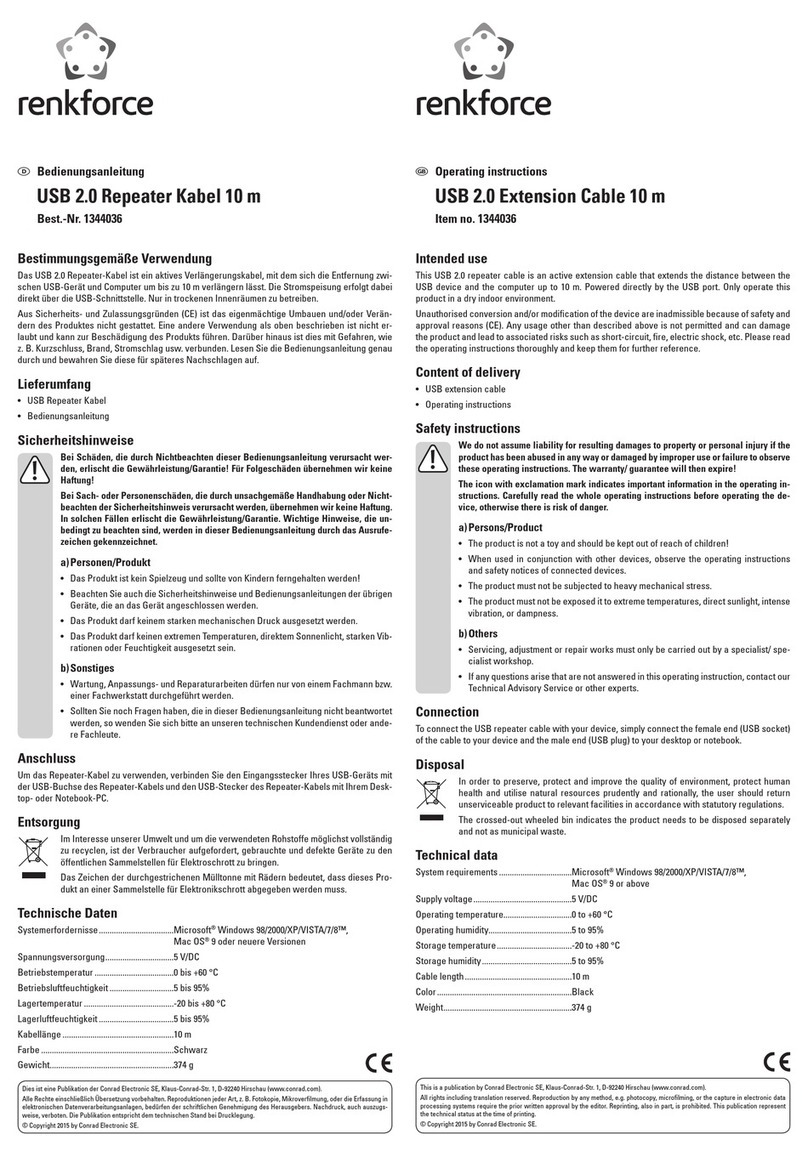

(18) Set Sleeve into the heater.

No twisting

(19) Confirm the position before heating.

No gap

Button to

start heating

(20) Heat Protection Sleeve.

Lynx heater program runs

a fan to cool the sleeve

after heating

Win ow

(23) Put Front Housing.

Lightly maintaining

tension on fiber

Right si e first Then left si e

Ri ge

Align Win ow an Ri ge

Front Parts

Rotate counter-clockwise.

(21) Disassemble Rear Parts.

Rear

Stopper

Kevlar Stopper

an Boot

MT STUB Dummy CAP

(22) Sli e Rear Parts an remove Dummy Cap.

Rear Stopper

(24) Sli e Kevlar Stopper. Trim the slit outer sheath.

Get the parts/components closer

to each other an straighten the

fibers covere with the Kevlar in

the Sheath

Rotate Kevlar Stopper

with hol ing Kevlar on

Housing

Kevlar

Stopper

(25) Secure Kevlar by screwing of Kevlar Stopper & Cut an excess of Kevlar

Boot

(26) Put Boot.

Cut Kevlar here

Complete

Cap

Cut Sheath here

Do not bend(Fiber Kevlar Sheath)

Furcation Tube

Make sure that the

Outer Sheath with

Kevlar are not twiste .

Please cut the Sheath into

chevron shape an set it on this

position

Other SET Cables And Connectors manuals