Lynx‐CustomFit® Splice‐On Connector Ver.2

‐LYNX2‐MPO for Bare Ribbon Fiber ‐

Installation Manual

Foryoursafetyoperation Precautions

ETK1123091A

TheLynx‐CustomFit® Splice‐On Connectoris designedand

manufacturedtoassurepersonalsafety.Improperoperation

canresultinbodilyinjuryandseriousdamagetothisproduct.

Pleasereadandobserveallwarningsinstructionsgiveninthis

operationmanual.

Wearsafetyglassestoprotectyoureyeswhen

!

1. Improperassemblywillresultinalossofperformance.

Pleasereadinstructions giveninthisoperationmanual

and the operation manual of the fusion splicer.

2. Never touch the fiber of the stub. It has been inspected

in the factory.

3. Theproductissensitivetodirtordust.Donottakeout

an

ngop

ca

er.

Neverlookintotheendofamicroscopeoroptical

cableconnectedtoanopticaloutputdevicethatis

operating.Laserradiationisinvisible,anddirect

exposurecanseverelyinjurethehumaneye.

Alcoholisflammable,causesirritationandisharmful

!

.

4. Thecharacteristicwillbeinfluencedbythefiber

cleavedsurfacecondition.Pleaseuseacleaverwhich

hasagoodcleavingcharacteristic.

5. Donotremovethedustcapuntiltheconnectorhas

beencompletelyassembled inordernottocausean

highinsertionlossduetothem.

ifswallowedorinhaled.Keepalcoholawayfrom

heat,sparks,skin,andavoidcontactwitheyes.

Inthecaseoftheworkatthehighplace,pleasebe

carefulnottodropanassemblingtool.

!

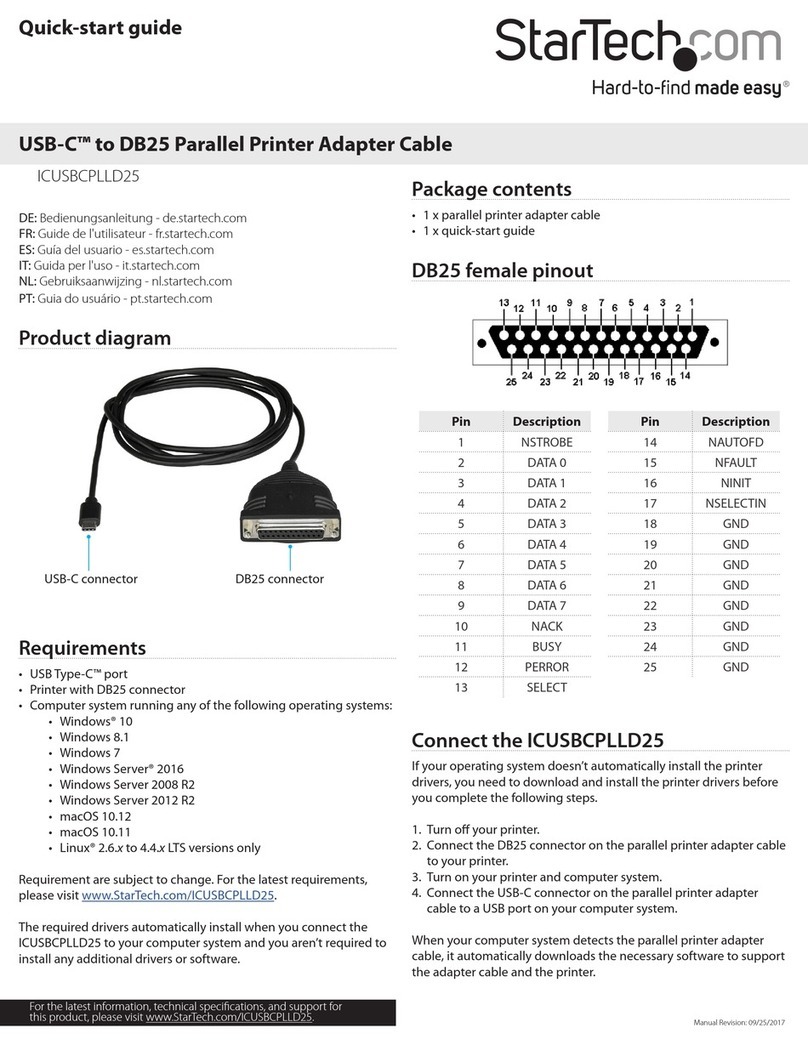

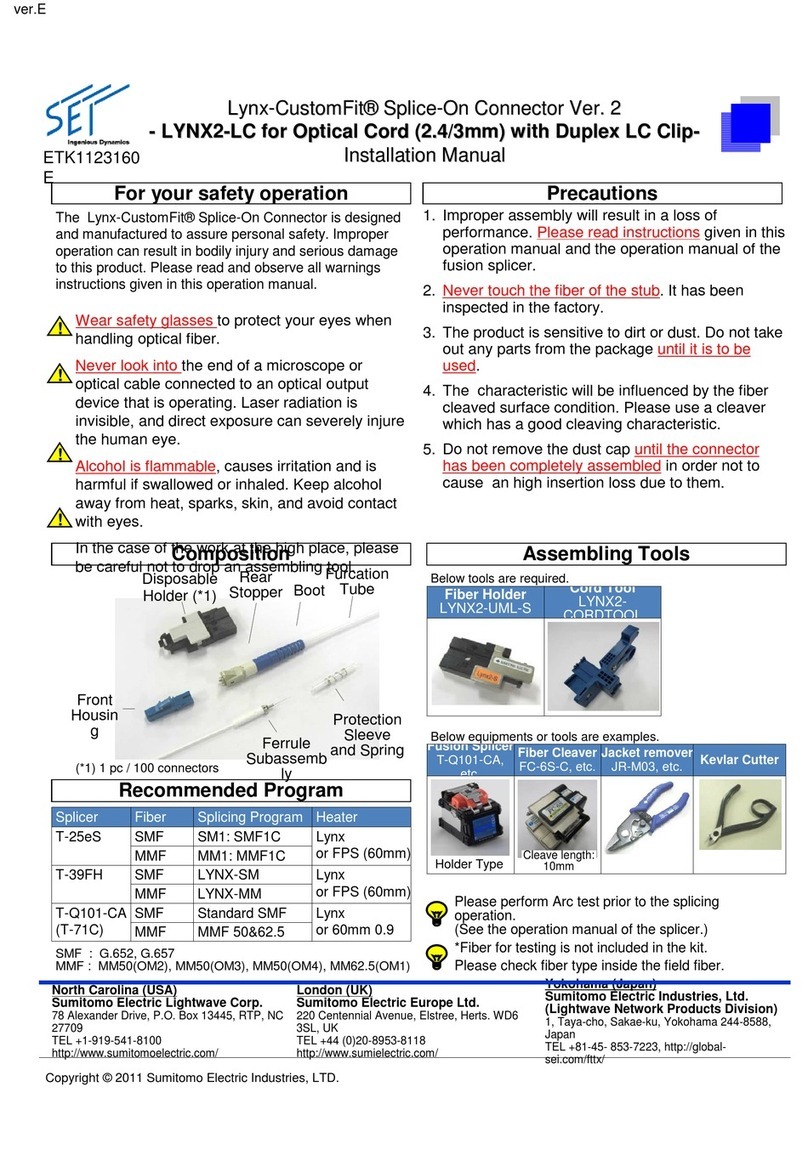

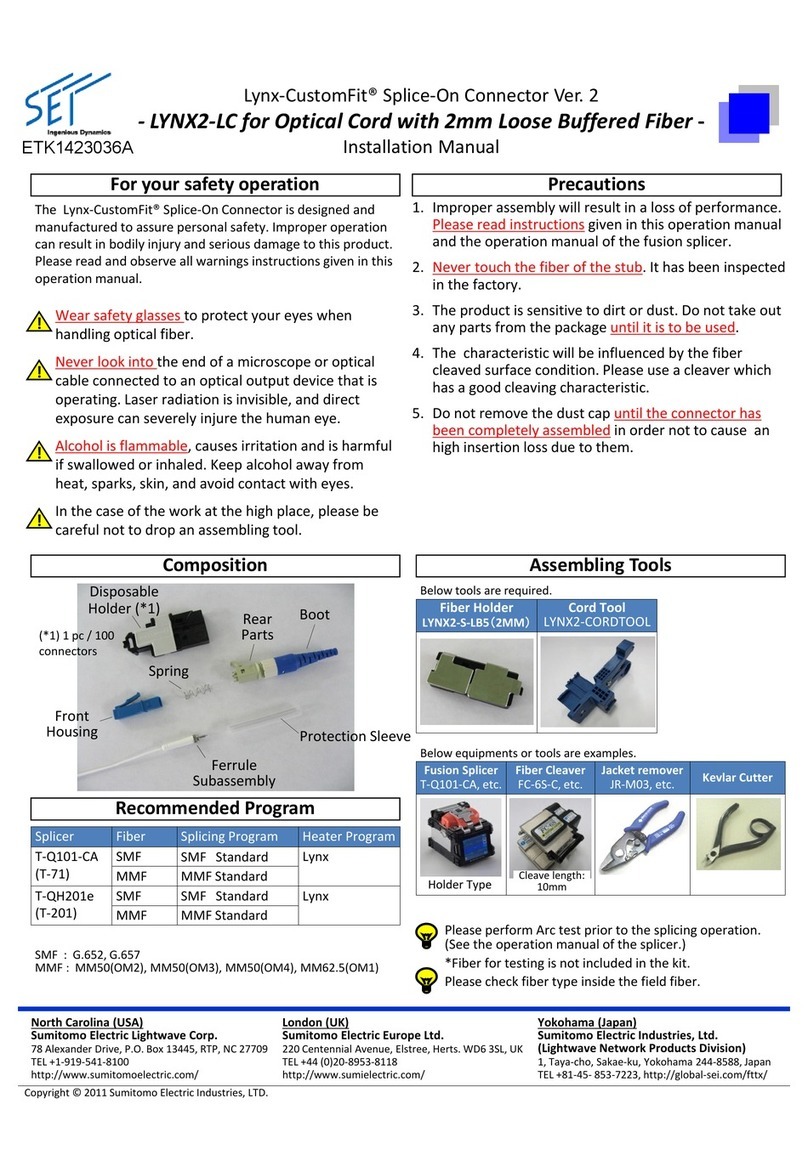

Composition

Assembling Tools

FusionSplicer

T‐66M12‐MPO

FiberCleaver

FC‐6M

Jacketremover

JR‐6

Fiber Holder

FHM‐12

Holder(*1)

Front

Housing

Rear

Stopper Boot

.

DustCap

MT STUB

Protection

Sleeve

(*1) 1 pc / 100 connectors

Recommended Program

Splicer Fiber SplicingProgram HeaterProgram

T‐66M12‐SMF SM12c: Lynx MPO SM

Dummy Cap

w/ Tether

SMF:G.652,G.657

MMF:MM50(OM2),MM50(OM3),MM50(OM4),MM62.5(OM1)

MPO

MMF MM12c: Lynx MPO MM

PleaseperformArctestpriortothesplicingoperation.

(Seethe operation manual of the splicer.)

*Ribbon fiberfortestingisincludedintheconnector kit.

Please check fiber type inside the field fiber.

SM Low Loss SM Std. Loss MM62.5 OM1 MM50 OM2 MM5010GOM3

8 degree Polish Flat Polish

Yellow Green Beige Black Aqua

PolishSurfaceandHousingColor

Copyright©2011SumitomoElectricIndustries,LTD.

North Carolina (USA)

SumitomoElectricLightwaveCorp.

78 Alexander Drive, P.O. Box 13445, RTP, NC 27709

TEL+1‐919‐541‐8100

http://www.sumitomoelectric.com/

Yokohama (Japan)

SumitomoElectricIndustries,Ltd.

(LightwaveNetworkProductsDivision)

1, Taya‐cho, Sakae‐ku, Yokohama 244‐8588, Japan

TEL+81‐45‐853‐7223, http://global‐sei.com/fttx/

London (UK)

SumitomoElectricEuropeLtd.

220 Centennial Avenue, Elstree, Herts. WD6 3SL, UK

TEL+44 (0)20‐8953‐8118

http://www.sumielectric.com/