Sevcon Dragon8 User manual

Dragon8

Applications

Reference

Manual

Document no:

177/52705

Rev. 1.0

Sevcon Ltd

Kingsway South

Gateshead, NE11 0QA

England

Tel +44 (0)191 497 9000

Fax +44 (0)191 482 4223

Sevcon, Inc.

155 Northboro Road

Southborough, MA 01772

USA

Tel (508) 281 5500

Fax (508) 281 5341

Sevcon SAS

Parc d’Activité du Vert Galant Rue

Saint Simon

St Ouen l’Aumône

95041 Cergy Pontoise Cedex

France

Tel +33 (0)1 34 30 35 00

Fax +33 (0)1 34 21 77 02

Sevcon Japan, East Japan Office

Zip code: 384-2205

720-5 Kasuga, Saku, Nagano, Japan

T +81 267 77 7343

Sevcon Asia Ltd

Room No.202 Dong-Ah Heights

Bldg

449-1 Sang-Dong Wonmi-Gu

Bucheon City Gyeounggi-Do

420-816 Korea

Tel +82 32 215 5070

Sevcon Germany

Hintere Str.32

73266 Bissingen an der Teck

Germany

Tel: +49 (0)170 9980294

www.sevcon.com

ii

Table of Contents

Chapter 1: Introduction 1

About Dragon8 documentation ....................................................................... 2

This version of the manual ...................................................................................................................................2

Copyright...................................................................................................................................................................2

Scope of this manual ...............................................................................................................................................2

Related documents ..................................................................................................................................................2

Drawings and units.................................................................................................................................................2

Warnings, cautions and notes..............................................................................................................................3

Product identification label............................................................................... 4

Technical support ............................................................................................... 4

Product warranty................................................................................................ 4

Chapter 2: About the Dragon8 5

Introduction ......................................................................................................... 5

Standard features and capabilities ................................................................... 7

Intended use of the Dragon8................................................................................................................................7

Available accessories...............................................................................................................................................7

Principles of operation....................................................................................... 7

Functional description ...........................................................................................................................................7

Dragon8 electrical block diagram.......................................................................................................................7

Interfaces ...................................................................................................................................................................8

General operation....................................................................................................................................................9

Safety and protective functions...................................................................... 10

General.................................................................................................................................................................... 10

On-Highway Vehicles ......................................................................................................................................... 10

Chapter 3: Installation 11

Mounting Dragon8 ..........................................................................................11

Location .................................................................................................................................................................. 12

Protection and Chemical Contamination ....................................................................................................... 12

Doc. # 177/52705

Rev. 1.0

iii

Orientation ............................................................................................................................................................. 12

Clearance for LED Access.................................................................................................................................. 12

Mounting Hole Pattern ...................................................................................................................................... 12

Equipment Required............................................................................................................................................ 13

Thermal Grease Application ............................................................................................................................. 13

Dragon8 Cooling requirements.....................................................................14

Dragon8–Air Cooling ........................................................................................................................................ 15

EMC guidelines................................................................................................. 16

General measures ................................................................................................................................................. 16

Measures required for specific signals ............................................................................................................ 16

Additional measures ............................................................................................................................................ 17

Problems to avoid................................................................................................................................................. 17

Typical System..................................................................................................18

Wiring diagram .................................................................................................................................................... 18

Signal wiring ......................................................................................................................................................... 19

Signal wire size ..................................................................................................................................................... 21

CANbus termination............................................................................................................................................ 21

Signal connections................................................................................................................................................ 21

Connecting power cables................................................................................. 22

Battery and motor connections......................................................................................................................... 22

On-board fuse mounting ................................................................................. 24

Chapter 4: Specification 25

Electrical............................................................................................................. 25

Input voltage –control supply.......................................................................................................................... 26

Input voltage –DC Link supply....................................................................................................................... 26

Motor Output protection ................................................................................................................................... 26

Output ratings*..................................................................................................................................................... 27

CAN interface ........................................................................................................................................................ 27

Control inputs and outputs ................................................................................................................................ 27

Isolation .................................................................................................................................................................. 28

Regulatory compliance........................................................................................................................................ 28

Mechanical..........................................................................................................29

Operating environment ...................................................................................................................................... 29

iv

Shock and vibration ............................................................................................................................................. 29

Weight..................................................................................................................................................................... 29

Dimensions............................................................................................................................................................. 30

Chapter 5: System design 31

Auxiliary components...................................................................................... 32

Main Contactor and Precharge circuit ........................................................................................................... 32

Digital Outputs from Dragon8......................................................................................................................... 32

Key switch fuse F2 ............................................................................................................................................... 32

Motor speed sensor (AB encoder) .................................................................................................................... 32

Motor commutation sensor ............................................................................................................................... 33

Initial power up sequence................................................................................38

Checks prior to power up ................................................................................................................................... 38

Checks after power is applied ............................................................................................................................ 38

Discharge sequence after power down.........................................................39

Controller discharge profile............................................................................................................................... 39

Chapter 6: Configuration 41

Introduction .......................................................................................................41

DVT configuration tool...................................................................................42

DVT functionality................................................................................................................................................ 42

Saving, duplicating and restoring a node’s configuration ......................................................................... 42

Data Logging ........................................................................................................................................................ 43

CANopen Configuration..................................................................................43

CANopen protocol ............................................................................................................................................... 43

Object Dictionary ................................................................................................................................................. 43

Network Configuration....................................................................................................................................... 44

H-Protocol..........................................................................................................46

J1939 Compatibility............................................................................................................................................. 46

I-Protocol ...........................................................................................................47

J1939 Compatibility............................................................................................................................................. 47

Configuration process overview ....................................................................49

Access authorization............................................................................................................................................ 49

Doc. # 177/52705

Rev. 1.0

v

How NMT state affects access to parameters............................................................................................... 49

Motor characterisation ....................................................................................50

Supported motor algorithms ............................................................................................................................. 50

Determining Motor Parameters....................................................................................................................... 50

Speed Limit Tuning ............................................................................................................................................. 50

I/O configuration .............................................................................................50

Encoder ................................................................................................................................................................... 51

Digital inputs......................................................................................................................................................... 52

Analog inputs ........................................................................................................................................................ 52

Digital (contactor) outputs ................................................................................................................................ 53

Vehicle performance configuration ...............................................................55

Requirements......................................................................................................................................................... 55

Safety Interlocks ................................................................................................................................................... 55

Driveability Features........................................................................................................................................... 59

Acceleration and braking.................................................................................................................................... 60

Footbrake................................................................................................................................................................ 61

Steering inputs –twin driving motor systems............................................................................................. 62

Driveability profiles ............................................................................................................................................. 64

Smoothing Output Torque ................................................................................................................................ 66

Scenarios ................................................................................................................................................................. 67

Controlled roll-off ................................................................................................................................................ 68

Hill hold .................................................................................................................................................................. 68

Inching .................................................................................................................................................................... 69

Belly Switch ........................................................................................................................................................... 70

Drivability select switches ................................................................................................................................. 70

Economy ................................................................................................................................................................. 70

Seat Regen Braking.............................................................................................................................................. 70

Pump configuration ............................................................................................................................................. 71

Power steer configuration.................................................................................................................................. 72

Vehicle features and functions........................................................................72

Line contactor........................................................................................................................................................ 73

Electro-mechanical brake ................................................................................................................................... 73

Brake Lights........................................................................................................................................................... 74

Horn......................................................................................................................................................................... 74

Vehicle Speed Calculation .................................................................................................................................. 74

vi

Distance Calculation ............................................................................................................................................ 75

Service Indication................................................................................................................................................. 75

Controller heatsink / motor cooling fan ........................................................................................................ 76

Motor over-temperature protection................................................................................................................ 76

Battery protection ................................................................................................................................................ 76

Battery Current Limit ......................................................................................................................................... 77

Displays................................................................................................................................................................... 78

Chapter 7: Monitoring Dragon8 79

Reading status variables..................................................................................80

Motor Data............................................................................................................................................................. 80

Customer Input Data........................................................................................................................................... 80

Device Data............................................................................................................................................................ 80

Identification and version................................................................................................................................... 80

Supply monitoring ............................................................................................................................................... 80

Hours counters...................................................................................................................................................... 81

Logging...............................................................................................................81

FIFO event logs.................................................................................................................................................... 81

Event counters ...................................................................................................................................................... 81

Operational monitoring ...................................................................................................................................... 82

CANopen abort code ........................................................................................83

Faults and warnings......................................................................................... 84

Introduction ........................................................................................................................................................... 84

Fault identification ............................................................................................................................................... 84

Fault list.................................................................................................................................................................. 84

Upgrading the controller software ...............................................................84

Chapter 1:

Introduction

2

About Dragon8 documentation

This version of the manual

This version of the Dragon8 manual replaces all previous versions. Sevcon has made every effort to

ensure this document is complete and accurate at the time of printing. In accordance with our policy of

continuing product improvement, all data in this document is subject to change or correction without

prior notice.

Copyright

This manual is copyrighted 2015 by Sevcon. All rights are reserved. This manual may not be copied in

whole or in part, nor transferred to any other media or language, without the express written permission

of Sevcon.

Scope of this manual

The Application Reference Manual provides important information on configuring motor control

systems using Dragon8 controllers as well as details on sizing and selecting system components, options

and accessories.

The manual also presents important information about the Dragon8 product range.

Related documents

The following documents are available from Sevcon:

•The Object Dictionary providing important information about CANopen communication with

Dragon8.

•The latest Electronic Data Sheet database file is available from Sevcon.

•H-Protocol application note

Drawings and units

Orthographic illustrations in this manual are drawn in Third Angle Projection. SI units are used

throughout this manual.

Introduction

Doc. # 177/52705

Rev. 1.0

3

Warnings, cautions and notes

Special attention must be paid to the information presented in Warnings, Cautions and Notes when they

appear in this manual. Examples of the style and purpose of each are shown below:

A WARNING is an instruction that draws attention to the risk of injury or death and tells you

how to avoid the problem.

A CAUTION is an instruction that draws attention to the risk of damage to the product, process or

surroundings.

A NOTE indicates important information that helps you make better use of your Sevcon product.

4

Product identification label

If you have a customized product your unique identifier will appear at the end of the Type number.

When discussing technical issues with Sevcon always have your product’s Type number, Part number

and Serial number available.

Figure 1 Typical product Identification label

Technical support

For technical queries and application engineering support on this or any other Sevcon product please

contact your nearest Sevcon sales office listed on the inside front cover of this manual. Alternatively you

can submit enquiries and find the details of the nearest support centre through the Sevcon website,

www.sevcon.com.

Product warranty

Please refer to the terms and conditions of sale or contract under which the Dragon8 was purchased for

full details of the applicable warranty.

Chapter 2: About

the Dragon8

6

Introduction

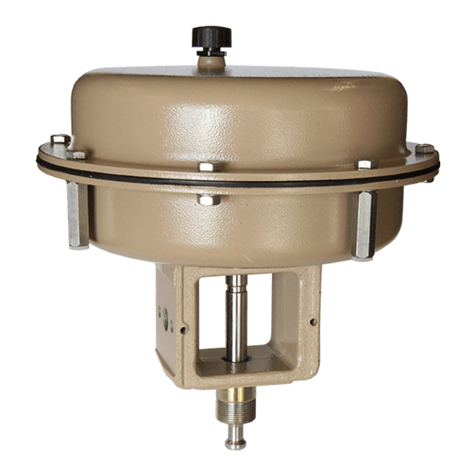

Sevcon Dragon8 controllers are designed to control 3-phase AC induction motors and Permanent

Magnet AC (PMAC) motors in battery and generator powered applications.

The controller adapts its output current to suit the loading conditions and the ambient temperature in

which it is operating (temporarily shutting down if necessary). It will also protect itself if the low voltage

circuits are incorrectly wired.

Signal wiring and power connections have been designed to be as simple and straight forward as

possible. Analog and digital signal inputs and outputs are provided for switches, sensors, contactors,

hydraulic valves and CAN communications. This I/O can be mapped to the CANbus for control by an

external VCU.

Configuration and control of Dragon8 is fully customizable using the latest version of Sevcon’s DVT, a

Windows based configuration software tool.

The state of the controller can be presented via a signal to a dashboard mounted light for example.

Figure 2 Mechanical package

About the Dragon8

Doc. # 177/52705

Rev. 1.0

7

Standard features and capabilities

Intended use of the Dragon8

The Dragon8 motor controller can be used in many applications, such as:

•On-road 4 wheel EV

•Wheel electric motorcycle and scooter

•Off road ATV

•Utility vehicles and burden carriers

•Hybrid vehicle systems

Available accessories

The following accessories are available from Sevcon

•DC-DC converters

•23 way Ampseal connector kit

•Contactors

•Fuses

•DVT - PC based configuration tool

Principles of operation

Functional description

The main function of Dragon8 is to control the power an electric motor (PMAC (SPM and IPM) and

Induction).

Measured phase currents and current demands are used as part of a closed-loop control system to

calculate the necessary voltage demands for each phase of the motor. Voltage demands are then

converted into PWM demands for each phase.

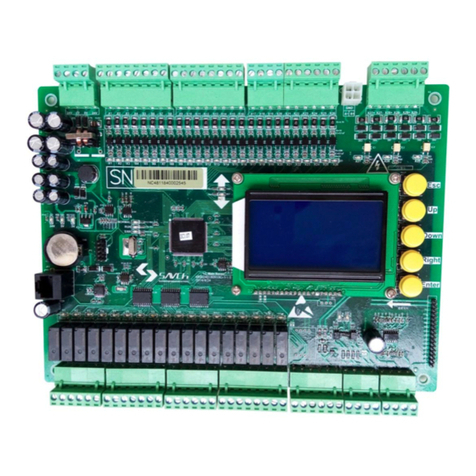

Dragon8 electrical block diagram

The electrical circuit blocks are present in Dragon8 have the following functions:-

•Inverter power stage –this converts the DC battery supply into AC to power the motor. See the

following section for more details.

•Gate drives –the low power gate control signal from the control logic is isolated and buffered by

these circuits. Output short circuits are also detected by these circuits.

•Current and voltage measurement –these circuits provide an isolated voltage and current

measurement for the control logic. Over-current and over-voltage conditions are also detected.

•Control power supplies –these convert a 12V or 24V nominal supply into the voltage required for the

control logic

•Control logic –software runs on microprocessor circuits with input and output circuits for analogue

and digital inputs, the encoder, CANbus and digital outputs.

8

The high voltage power circuits are fully isolated from the logic control and CAN circuits. All of the required

power supplies and control signals for the high voltage system are isolated from the low voltage system.

All the control inputs and outputs such as the analogue inputs, digital inputs and motor encoder are referenced to the

12/24V logic circuit ground. The CANbus is connected to the control circuit ground.

Do not connect the high voltage circuit to the 12/24V logic circuits directly. If you do this the isolation

barrier will be bypassed. This could cause high voltages to be present on circuits which do not have

enough protection against accidental touch.

Power conversion section

The power conversion section of Dragon8 employs a 6-switch MOSFET bridge. Excellent electrical and

thermal efficiency is achieved by:

•Minimization of thermal resistances.

•Use of the latest MOSFET technology

•Internal thermal protection (if temperatures are excessive, switching frequency and output torque

may be reduced).

•Overcurrent protection using device characteristics.

•Internal measurement of output current.

•Overvoltage trip in the event of regenerative braking raising battery voltage to unsafe levels.

Interfaces

In addition to its motor control functions, Dragon8 offers many other functions designed to interface

with electric systems. A variety of digital and analog input sources are supported.

On/off control of contactors is provided by Dragon8. All I/O on the Dragon8 controller is protected

against short-circuit to the control logic positive and negative logic supply.

Dragon8 connectivity and interoperability with other system devices (for example A VCU) using a

CANbus, the CANopen protocol, Sevcon’s H-protocol (providing J1939 compatibility) and Sevcon’s I-

protocol is provided. In addition to in-service operation, the CANopen protocol allows the controller to

be commissioned using the Sevcon DVT tool.

About the Dragon8

Doc. # 177/52705

Rev. 1.0

9

General operation

The Dragon8 controller functions as a motor control and I/O slave, as shown in Figure 3 - Dragon8

Controller –Slave and Figure 4 - Dragon8 Controller - Traction.

Figure 3 - Dragon8 Controller –Slave

Figure 4 - Dragon8 Controller - Traction

The H-protocol allows the VCU to control the state, torque demand, drive/braking torque limits,

forward/reverse speed limits and discharge/recharge current limits to be controlled. Refer to the H-

protocol application note for more information.

I/O control is managed using the I-Protocol. Refer to the I-Protocol application note for more

information.

10

Safety and protective functions

General

Electric vehicles can be dangerous. All testing, fault-finding and adjustment should be carried out

by competent personnel. The vehicle manufacturer's manual should be consulted before any

operation is attempted.

The battery or generator must be disconnected before replacing the controller. After the battery

has been disconnected, wait for the internal capacitors to discharge to less than 60V before

handling the controller or working near exposed terminals.

Hazardous voltages may remain on the controller internally and on exposed power terminals after

the main battery power connections and keyswitch power supplies have been removed if the

controller is connected to a rotating permanent magnet motor.

Controller discharge profile on page 39 for controller discharge times.

Never connect the controller to a battery with vent caps removed or a generator with an open

fuel tank as an arc may occur due to the controller internal capacitance when first connected.

Do not attempt to open the controller as there are no serviceable components. Opening the controller

will invalidate the warranty.

Use cables of the appropriate rating and fuse them according to the applicable national vehicle and

electrical codes.

Where appropriate, use of a suitable line contactor should be considered.

Electric vehicles are subject to national and international standards of construction and operation which

must be observed. It is the responsibility of the vehicle manufacturer to identify the correct standards

and ensure that their vehicle meets these standards. As a major electrical control component the role of

the Dragon8 motor controller should be carefully considered and relevant safety precautions taken. The

Dragon8 has several features which can be configured to help the system integrator to meet vehicle

safety standards. Sevcon accepts no responsibility for incorrect application of their products.

On-Highway Vehicles

General

This applies to all on-highway vehicles, such as cars, motorcycles, buses and trucks

The installer must ensure an appropriate controller configuration is set to ensure that the vehicle

remains in a safe condition, even in the event of a fault.

Chapter 3:

Installation

Installation

12

Mounting Dragon8

Location

The mounting location for the controller should be chosen with care taking into account the following

considerations:-

•Do not mount the controller on the outside of a vehicle where it would be accessible to

unauthorized personnel (for the purposes of UL, the controller enclosure is not considered to be

the ‘ultimate enclosure’ and as such it should be sited within another enclosure).

•Do not mount the controller where it may be susceptible to damage due to minor collisions,

impact from road debris, or chemical contamination (see ‘Protection from chemical

contamination’ below).

•Although the controller has a high degree of ingress protection, the electrical power terminals

are exposed. Avoid mounting the controller in locations where it may be submerged in water,

exposed to jets of water, or exposed to potentially conductive contamination and/or debris.

•Blocking the breather vent (see below) may lead to damage to the controller housing or allow

water ingress

Figure 5 - Breather Vent location

Protection and Chemical Contamination

The covers of Dragon8 controllers are designed for good all-round protection of the electronics.

However the controller should be sited so that it cannot come into contact with significant quantities of

industrial chemicals. The following have shown to be damaging to Dragon8 covers:-

•Most esters (contained in some ‘bio’ hydraulic fluid such as Shell Naturelle HF-E)

•Most industrial alcohols (contained in some contact grease such as Electrolube CG53A)

Electrical terminals on the controller present an electric shock hazard. High currents can also

present a burn hazard. You must ensure that the electrical terminals of the controller are

protected against access by unauthorized personnel.

Orientation

The controller can be mounted in any orientation.

Clearance for LED Access

If you want an operator of your vehicle to be able to view the onboard LED, it is advisable to consider

the line of sight to the LED at this time.

Mounting Hole Pattern

Table of contents

Other Sevcon Controllers manuals

Popular Controllers manuals by other brands

BLAUBERG Ventilatoren

BLAUBERG Ventilatoren SGS E1 Operation manual

Mitsubishi Electric

Mitsubishi Electric Central Controller G-50A Technical manual

Signal

Signal SDS Series Operator's manual

HomeMatic

HomeMatic HM-LC-Dim1T-FM Installation and operating manual

WIKA

WIKA A2G-100 operating instructions

Nico Technology

Nico Technology 3010L user manual

Motion

Motion AXIS STUIFMEEL Thomson PC-Series installation manual

ProMinent

ProMinent Aegis-II Assembly and operating instructions

Lehigh

Lehigh E-Flex 1.2.3 H2861 installation guide

Extron electronics

Extron electronics RAC 104 user guide

AUMA

AUMA SQ 05.2-SQ 14.2 manual

Carrier

Carrier RTU Open v3 Installation and startup guide