Sevcon MillipaK 4QPM User manual

Document History

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 2 13/08/03

Document History

Author Reviewer

Initials Date Initials Date Version Reason for Modification

PB 06/03/01 - - 0.01 Original.

DL /

CEH 14/09/01 1.01 Document updated for V1.01 software

PG 19/11/01 - - 1.50.00 Document updated for V1.50.00 software

PG 07/03/02 1.50.01 Document updated for V1.50.01 software

PMR 20/03/02 1.50.01 Document updated to reference PCpaK

PS 24/05/02 1.50.03 Modified overtemp cutback characteristics

SRO Delay personality

CEH 19/02/03 1.50.03

(A)

Added page numbers and tidied up

document.

Contents

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 3 13/08/03

CONTENTS

INTRODUCTION .........................................................................................................................................................5

SAFETY .........................................................................................................................................................................6

INSTALLATION...........................................................................................................................................................7

MOUNTING ..................................................................................................................................................................7

MILLIPAK 4QPM POWER WIRING ..............................................................................................................................8

MILLIPAK LIGHT WIRING EXAMPLE............................................................................................................................9

CALIBRATOR ............................................................................................................................................................11

TRACTION DRIVE HOURS COUNTER ..........................................................................................................................12

CALIBRATOR SECURITY LEVELS................................................................................................................................13

NAVIGATION..............................................................................................................................................................14

ADJUSTMENTS ...........................................................................................................................................................15

STATUS AND TEST INFORMATION ..............................................................................................................................16

CONFIGURATION ....................................................................................................................................................17

SYSTEM CONFIGURATION..........................................................................................................................................17

System Voltage .....................................................................................................................................................18

System I/O Configuration.....................................................................................................................................19

System / Motor Set-up ..........................................................................................................................................22

Contactor chopping..............................................................................................................................................24

Accelerator Full /Zero Setting .............................................................................................................................25

PERFORMANCE ..........................................................................................................................................................26

Acceleration Delay...............................................................................................................................................26

Drive Deceleration Delay ....................................................................................................................................26

Direction Change Deceleration Delay.................................................................................................................26

Neutral Deceleration Delay .................................................................................................................................26

Control Mode .......................................................................................................................................................27

Regen Braking......................................................................................................................................................28

Braking Levels......................................................................................................................................................28

Footbraking..........................................................................................................................................................28

Creep Speed .........................................................................................................................................................32

Maximum Speed ...................................................................................................................................................33

Accelerator Characteristics .................................................................................................................................34

FEATURES..................................................................................................................................................................36

STANDARD CONTROLLER FEATURES.........................................................................................................................36

Power Steer..........................................................................................................................................................37

High Speed Switch and Anti-Tie Down................................................................................................................38

Seat Switch ...........................................................................................................................................................41

Handbrake Switch ................................................................................................................................................42

Cutback speeds.....................................................................................................................................................43

Traction Drive Hours Meter ................................................................................................................................44

Reverse Speed ......................................................................................................................................................45

Pump Soft Start ....................................................................................................................................................46

Alarm Buzzer........................................................................................................................................................47

Line Contactor Drop out......................................................................................................................................48

SAFETY FEATURES ....................................................................................................................................................49

Start Up Sequence................................................................................................................................................49

FS1 Recycle..........................................................................................................................................................50

SRO (Static return to off) .....................................................................................................................................51

Belly Switch..........................................................................................................................................................52

Contents

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 4 13/08/03

Anti-Rollback .......................................................................................................................................................53

Anti-Rolloff...........................................................................................................................................................54

Fail-safe ...............................................................................................................................................................55

CONTROLLER PROTECTION FEATURES.........................................................................................................56

TEMPERATURE MONITORING.....................................................................................................................................56

SAFE OPERATING AREA (SOA) .................................................................................................................................59

UNDER-VOLTAGE AND OVER-VOLTAGE PROTECTION ................................................................................................60

PCPAK .........................................................................................................................................................................62

PCPAK FUNCTIONALITY ...........................................................................................................................................62

PROGRAM MODE .......................................................................................................................................................62

COMMISSIONING CHECKLIST ............................................................................................................................64

PERSONALITY RECORD..............................................................................................................................................65

FAULT FINDING .......................................................................................................................................................67

FAULT CLEARANCE ...................................................................................................................................................68

FAULT REPORTING FORM ..........................................................................................................................................69

SOFTWARE VERSION AND SERIAL NUMBER INDICATION ...........................................................................................70

SPECIFICATIONS .....................................................................................................................................................71

POWER CONFIGURATIONS .........................................................................................................................................71

EMC STANDARDS......................................................................................................................................................71

SOCKET B PROTECTION .............................................................................................................................................71

CONTACTOR DRIVE RATINGS .....................................................................................................................................71

ANALOGUE INPUT IMPEDANCE ..................................................................................................................................71

DIGITAL INPUT IMPEDANCE.......................................................................................................................................71

EMC GUIDELINES....................................................................................................................................................72

ORDERING INFORMATION...................................................................................................................................73

Introduction

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 5 13/08/03

Introduction

The MillipaK 4QPM (Four Quadrant Permanent Magnet) range of controllers provides a new

range of power frames for 24V-48V, 330A in small, highly efficient packages. This is achieved

using a Sevcon patented power switching scheme and radical new construction techniques, which

enable large powers to be incorporated into very small packages.

The MillipaK provides a completely sealed (IP66) unit containing both power and logic circuitry,

as well as all suppression components and an optional integrated pump soft start/stop chopper.

MillipaK supports Sevcon’s existing MOS90 calibrator for adjustment of vehicle performance

characteristics. MillipaK is ideally suited to applications requiring a single traction controller, for

example walkies, golf cars and basic ride-on trucks.

Controllers are FLASH microprocessor based enabling field re-programming for new features and

have numerous user set-up options. The MillipaK uses high frequency (silent) MOSFET power

switching technology, to control a 4Q power frame bridge. Armature current is monitored. Motor

feedback should not be necessary. Controllers have been designed to satisfy the requirements of

the relevant UL and EC standards.

Safety

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 6 13/08/03

Safety

The MillipaK controller contains a triple fail-safe system to give a high level of safety. If the

diagnostic LED is not illuminated or flashes, the safety circuit may have tripped and the truck

may not drive.

The controller must be used with a line contactor as indicated in the wiring diagrams.

As blow-out magnets are fitted to contactors (except 24V) ensure that no magnetic particles can

accumulate in the contact gaps and cause malfunction. Ensure that contactors are wired with the

correct polarity to their power terminals as indicated by the + sign on the top molding.

The MillipaK controller may be used with suitable onboard chargers, as supplied by Sevcon.

There are several software features which are intended to prevent inadvertent or unexpected

vehicle movement – SRO, Accelerator power up fault and sequence checking. Some of these

features cannot be disabled and the appropriate signals must be supplied to the controller before

drive will be allowed.

Installation Mounting

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 7 13/08/03

Installation

The small footprint of the MillipaK controller gives maximum flexibility to the user for mounting

options. The following section gives details of certain criteria that should be considered when

situating the controller on a vehicle.

Mounting

The MillipaK HP unit provides 4 x M6 clearance holes for mounting. The controller should be

mounted onto a metal base plate, as large as possible to provide heat-sinking. The surface finish

should be flat, clean and burr free and thermal compound should be applied to the controller base

before fitting.

Figure 1: MillipaK HP Dimensions

Maximum terminal torque: M8 terminals – 10NM

M6 terminals – 7NM

Installation Wiring/Power

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 8 13/08/03

MillipaK 4QPM Power Wiring

Figure 2: MillipaK 4QPM Power Wiring

NOTE: The Pump MOSFET’s are optional (soft start versions only).

Installation Wiring/Light

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 9 13/08/03

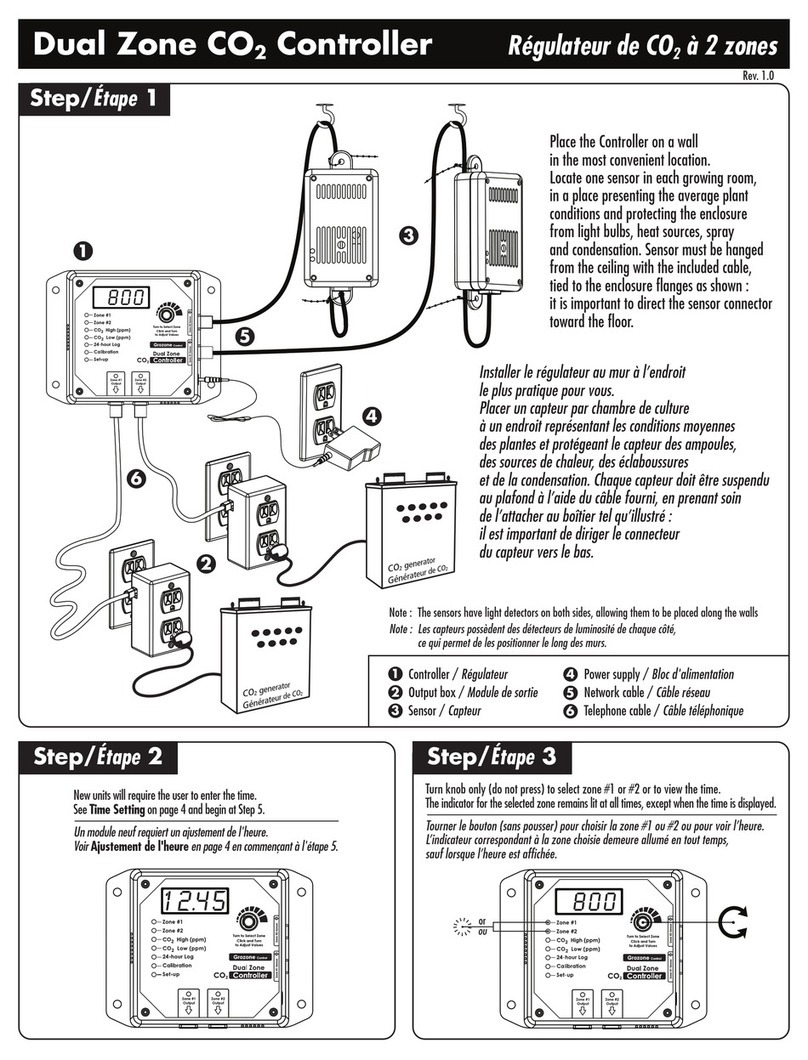

MillipaK Light Wiring example

1

2

3

4

5

6

0V

+ 10.5V

Clock

Dat a

Connector A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

Connector B

Fus e

Bat te r y +ve

Ke y- s w itch

e.g.

Accel

Module

Forw ar d (Dig 1)

Revers e (Dig 2)

FS1/ Be lly (Dig 3)

Seat / Tiller (Dig 4)

Digital Input 5

Bat te r y -ve

Digital Input 6

Analogue Input 1

Analogue Input 2**

12V Output

CALIBRATOR

Sevcontrol

SEL

Analog

Calibrator Detect

Line Contactor*

Auxiliary Contactor*

Extra Suppression 1***

Extra Suppression 2***

Horn Suppression***

Bat te r y +ve

Battery -ve

Extra Suppression 1 or 2

or Horn Suppression

External Contactor /

Ho r n

NOTES:

*Contactor Coil Suppression fitted internally.

**Analogue Input 2 can also be configured as a digital input.

***Extra Suppression and Horn Suppression inputs to be used as show n below :

Figure 3: MillipaK Light Wiring

Installation Wiring/Light

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 10 13/08/03

NOTES:

The line and auxiliary contactors are wired to B+, on the switched side of the key-switch.

Pin 12 is available for 100mA supply, typically used for (but not limited to) accelerator modules.

Pins 13,14 & 15 are general-purpose suppression connections and may be used to suppress spikes

generated by contactors opening / closing. The internal configuration is shown below:

Pin 16 is used to select FLASH memory program update mode and should normally be left

unconnected.

Calibrator Calibrator/General

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 11 13/08/03

Calibrator

The Calibrator is a hand-held adjustment unit which can be used to configure and test the system.

The MillipaK is designed to work with the Calibrator currently in use with SEVCON's MOS90

system. See diagram below. The menu structure is shown in the Calibrator Map located near the

end of this manual.

CALIBRATOR

Sevcontrol

+

-

SELECT

i.8.8.8

Figure 4: MillipaK Calibrator

Calibrator Calibrator/Traction Drive Hours Counter

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 12 13/08/03

Traction Drive Hours Counter

When the Calibrator is first plugged into the unit after power up, the Calibrator shows the

Traction Drive Hours Counter. Refer to the Traction Drive Hours Counter section for more

information on this function.

With no buttons pressed, the number displayed shows the number of minutes (accurate to 0.5

minutes). Pressing the '-' button displays the number of hours under 1000 and pressing the '-'

button displays the number of 1000 x hours.

For example, if the hours counter was 12, 345 hours, 13 minutes and 40 seconds, with no buttons

pressed, the display would show 13.5. Minutes are only shown to the nearest 0.5 minutes. If the '-'

button was pressed, the display would show 345 (number of hours under 1000) and if the '+'

button was pressed, the display would show 12 (number of 1000 x hours).

This is the only time that the hours counter can be viewed. Once the Select button has been

pressed to enter the normal calibrator menu structure, it is not possible to return to this point. To

view the hours counter again, you must recycle the Keyswitch.

This is also the point at which you can enter a password to enable different levels of access to

personalities. Refer to the section below on Calibrator Security Levels for more details.

Calibrator Calibrator/Security Levels

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 13 13/08/03

Calibrator Security Levels

Which personalities and status items which can be viewed on the Calibrator is restricted using

passwords. There are three levels of Calibrator access. These are shown in Table 1.

Access Level Text Password Description

Service Ser -

Default. This level is selected when no password or an

invalid password is entered. Only items shown in the

Calibrator Map with a thick solid border are displayed.

Engineering Eng 1645 All items, except those in the Setup menu, can be

displayed.

All Adjust All Contact

SEVCON All items are be displayed, regardless of configuration.

Table 1: Calibrator Security Levels

Note, for Service and Engineering security levels only items appropriate to the current system

configuration are displayed. For example, if none of the switch inputs are configured as a Cutback

1 Speed Switch, then the Cutback 1 Speed personality will not be displayed.

The All Adjust security level allows access to all personalities, including those not required by the

current configuration. The items in the Setup menu can only be accessed at this security level.

The password can only be entered just after power up when the Traction Drive Hours Counter is

displayed. The '+' and '-' buttons are used to enter the password. The first digit is entered by

pressing the '+' button the appropriate number of times (i.e. once to enter 1). The second digit is

entered by pressing the '-' button the appropriate number of times (i.e. 6 times to enter 6). The

third digit is entered using the '+' button again and the final digit is entered using the '-' button

again. Note that when the '+' or '-' buttons are pressed, the display still changes to show hours or

1000 x hours.

When the password has been completely entered press either the '+' button or the SELECT button

to initiate verification. If the password has been entered correctly, the text shown in Table 1

appropriate to the required level will be displayed for 1s indicating the password was accepted. If

the password was incorrect or no password was entered, the system always defaults to Service

mode.

After the Security Level has been displayed, the system enters the normal menu structure shown

in the Calibrator Map. To change the password level, you need to recycle the Keyswitch.

Calibrator Calibrator/Navigation

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 14 13/08/03

Navigation

The Calibrator uses all three buttons for navigating through the menu structure.

Use the SELECT button to move through the menu structure. When the SELECT button is

pressed the next menu item is displayed. The default direction is from left to right, top to bottom.

If the '+' and '-' buttons are held down together, the ID of the currently displayed menu item is

shown. For example, if the Armature Current Limit personality was selected, then the ID would

be 0.01 (menu 0, item 1). This allows the operator to locate where they are in the map.

If the '+' and '-' buttons are held down together for more than 3 seconds, the direction through the

menu structure is reversed. Now when the SELECT button is pressed the direction is from right to

left, bottom to top. In this mode, the LED on the Calibrator will flash. If the '+' and '-' buttons are

held down together for more than 3 seconds again, the direction reverts back to the first direction

and the Calibrator LED stops flashing.

The SELECT button is used to navigate through most of the menu structure, however, the Test

menu (menu 19) is slightly different. Pressing the SELECT button will take you to the first item

in the Test menu, (item 19.01 - Accelerator Demand). To navigate the Test menu, you need to use

the '+' and '-' buttons. The '+' button moves up the Test menu and the '-' button moves back down.

Pressing the SELECT button at any time exits the Test menu and moves to the first item in the

menu structure (menu item 0.01 - Armature Current Limit).

The items which are displayed depends on the current system configuration and the Security

Level.

Calibrator Calibrator/Adjustments

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 15 13/08/03

Adjustments

Menus 0 to 12 are primarily used for configuring the system. All the personalities that the system

uses to configure each function are in one of these menus. A brief description of the purpose of

each menu is listed below. For more complete descriptions of each personality refer to the

appropriate section in this manual.

Menu Name Purpose

0 Current Limits Used to setup maximum currents for motor.

1 Braking Levels Used to setup braking strength and performance.

2 Accelerator

Used to setup acceleration and deceleration performance and to

configure the accelerator input voltage range.

3 Creep Speed Used to setup creep speed.

4 Bypass Not Used

5 Maximum Speed Used to setup maximum speeds.

6 Cutback 1 Speed Used to setup the speed for Cutback Speed 1.

7 Cutback 2 Speed Used to setup the speed for Cutback Speed 2.

8 Motor Setup Used to setup motor protection levels.

9 Power Steer Timer Used to setup the Power Steer timer.

10 Seat Delay Used to setup the Seat Switch debounce delay.

11 Additional

Personalities

Used to setup additional personalities. These are personalities

which do not belong in any of the menus shown above, or they

are deemed to be unsuitable for modification by service

engineers or end users.

12 System Setup

Used to configure the system at a high level. Items to configure

the system I/O and performance are located in here. It is

recommended that items in this menu are configured first before

any of the other personalities. Unlike the personalities in the

other menus, changes to items in this menu do not take affect

until the Keyswitch is recycled.

Table 2: Adjustment Menus

Calibrator Calibrator/Status and Test Information

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 16 13/08/03

Status and Test Information

Menus 13 to 19 are primarily used for providing information about the system. Every parameter

which the system measures in located in one of these menus. A brief description of the purpose of

each menu is listed below.

Menu Name Purpose

13 System Status

If there is a fault active in the system, this menu provides

information about what the fault is. Refer to the Diagnostics

section for more information.

14 - Reserved for future use.

15 System Voltages

Used to display Battery and Capacitor Voltage measurements.

The Battery Voltage measurement shows the voltage measured

at the Keyswitch pin (pin 1 on connector B). The Capacitor

Voltage measurement shows the voltage measured at the B+

terminal.

16 Motor Voltages Used to show the voltage measured at the Point A terminals.

17 Motor Currents Used to show the Armature Current Measurement.

18 Heatsink

Temperature

Used to access the Heatsink Temperature measurement. Refer to

the Temperature Monitoring section.

19 Test Menu

Used to access items which allow for testing of all the Analogue

and Digital inputs available on connector B. Also displays unit

information such as the Software Version, Controller Serial

Number and the Personality Checksum. Refer to the appropriate

sections for more information on each of these items.

Table 3: Status and Test Information Menus

Configuration System

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 17 13/08/03

Configuration

Configuration of the MillipaK controller is split into two categories – system and performance,

which will be discussed in turn.

System Configuration

The MillipaK system configuration items relate to how the MillipaK will interface with connected

hardware such as the system battery, vehicle control switches, accelerator and the traction motor.

Configuration System/Voltage

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 18 13/08/03

System Voltage

The system voltage usually refers to the main system supply battery voltage. The controller uses

this information to ensure low and high voltage settings are within an appropriate range.

Power UpSystem Voltage

Calibrator Menu Reference: 12.19

Minimum Maximum Step Size Default

24v 48v 2v 24v

Configuration System/IO Configuration

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 19 13/08/03

System I/O Configuration

The digital inputs, analogue inputs and contactor drive outputs available on socket B can be

configured in a number of ways to suit various applications. Table 4 shows a range of pre-

determined settings which are available to the user and should cover the majority of applications,

see below:

Digital I/O

Value

Description

1 Walkie vehicle with Speed Cutback 1 switch, Pump Trigger switch

and Electromagnetic Brake. Pump Trigger activates Pump Soft Start

function.

2 Walkie vehicle with High Mast switch, Pump Trigger switch and

Pump Contactor.

3 Walkie vehicle with High Mast switch, Pump Trigger switch and

Electromagnetic Brake. Pump Trigger activates Pump Soft Start

function.

4 Walkie vehicle with Speed Cutback 1 switch, Pump Trigger switch

and Pump Contactor.

5 Walkie vehicle with Quick Pick switch, High Speed switch,

Electromagnetic Brake and Hours Counter Drive.

6 Walkie vehicle with Pump Trigger switch, Brake Override switch,

and Electromagnetic Brake.

7 Ride On vehicle with Speed Cutback 1 and 2 switches and external

LED drive.

8 Ride On vehicle with Speed Cutback 1 switch, Handbrake switch

and external LED drive.

9 Ride On vehicle with Handbrake switch, Power Steer Trigger switch

and Power Steer Contactor.

10 Ride On vehicle with Speed Cutback 1 switch, Power Steer Trigger

switch and Power Steer Contactor.

11 Ride On vehicle with Handbrake switch, Pump Trigger switch and

Pump Contactor.

12 Ride On vehicle with Handbrake switch, Pump Trigger switch and

Pump Contactor.

13 Ride On vehicle with Power Steer Trigger switch, Pump Trigger

switch and Power Steer Contactor. Pump Trigger activates Pump

Soft Start function.

14 Ride On vehicle with Traction Motor Overtemperature switch,

Handbrake switch and external LED drive.

15 Ride On vehicle with Power Steer Trigger switch, Footbrake switch

and Power Steer Contactor.

16 Ride On vehicle with Speed Cutback 1 and 2 switches and Alarm

Buzzer drive.

Table 4: Description of each Digital I/O configuration.

Configuration System/IO Configuration

______________________________________________________________________________

MillipaK 4QPM Controller Manual Page 20 13/08/03

WARNING: Incorrect configuration could cause a vehicle to move unexpectedly,

for example if FS1 was inadvertently configured as a belly switch.

If your application doesn’t fit any of the above, please contact Sevcon with details of your

requirements.

Each of the above configurations allocates the controller i/o as shown below:

Value of Digital I/O Configuration ItemDigital

Function 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16

Forward B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2 B2

Reverse B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3 B3

Belly B4 B4 B4 B4 B4 B4

Tiller B5 B5 B5 B5 B5 B5

FS1 B4 B4 B4 B4 B4 B4 B4 B4 B4 B4

Seat B5 B5 B5 B5 B5 B5 B5 B5 B5 B5

Speed Cutback 1 B6 B6 B6 B6 B6 B6 B6

SpeedCutback2 B7 B7

Handbrake B7 B7 B7 B7

P.SteerTrigger B6B7 B6 B7

Pump Trigger B7 B7 B7 B7 B7 B6 B7 B7

HighMast B6B6

MotorOverTemp B6

HighSpeed B6

QuickPick B7

BrkOverrideSw B6

FootbrakeSw B6

Line Contactor B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8 B8

P.SteerContactor B9B9 B9 B9

Pump Contactor B9 B9 B9 B9

ElectroBrake B9 B9 B9

ExternalLED B9B9 B9

HoursCounter B9

Buzzer B9

Table 5: Digital Functions

Notes:

1. Bx refers to Socket B pin numbers.

2. All vehicles have Forward and Reverse Switches and a Line Contactor.

3. All Walkie vehicles have Belly and Tiller Switches.

4. All Ride On vehicles have FS1 and Seat Switches.

5. Pump Trigger will trigger Pump Soft Start function as well as the Pump Contactor. This is

why some configurations have a Pump Trigger but no corresponding Pump Contactor.

Table of contents

Other Sevcon Controllers manuals