Seventh Circle Audio OneShot PC01 User manual

1

Congratulations on your purchase of a new OneShot chassis! The PC01 OneShot combines a

rugged enclosure, power supply, and discrete instrument DI in a compact 1/4U package. A

few minutes of assembly are all that is required to ensure years of reliable service.

Who Should Build This Kit?

The PC01 is not difficult to assemble, but it is not intended for absolute beginners. If you’ve

never built an electronic project before, this is probably not the one to start with. To guarantee

success, make sure you have:

•The ability to make basic voltage and resistance measurements using a digital

multimeter (DMM).

•At least a rudimentary understanding of voltage, current, and resistance.

•Some experience soldering on printed circuit boards.

•The patience to follow instructions precisely and work carefully.

Essential Tools

Fine tipped 20-30 watt soldering iron w/ cleaning sponge (Hakko 936 or similar)

Eutectic (63/37) rosin core or “no clean” solder (.025” diameter is usually best)

Small needle nose pliers

Small diagonal cutters

Wire stripper

Phillips screwdriver (#1)

3/32” Hex Driver

Highly Recommended Tools

½” Socket

Work Area

Find a clean, stable, well-lit work surface. An anti-static mat is highly recommended for this

project. Good lighting will make assembly much easier.

Soldering Technique

Make sure your iron's tip is tinned properly and keep it clean! The trick to making perfect

solder joints is to heat the joint quickly and thoroughly before applying the solder, and a

properly tinned and clean tip is essential for this. Apply just enough solder to thoroughly

encapsulate the joint, but don’t use too much. The finished joint should be smooth and

shiny, not rough or gritty looking.

2

Instruction Conventions

Text in orange indicates a step where extra care needs to be taken. Doing it wrong isn’t a

disaster, but it’ll need to be corrected.

Text in red indicates a step that must be done correctly. Doing it wrong will guarantee

improper operation, and probably damage components and/or the circuit board.

Prepare the Module

The OneShot power supply board includes three relays that enable several optional features.

To take advantage of these features, most current preamp modules will require some

modifications. If you are not comfortable referring to the schematics, removing parts, wiring

jumpers, and possibly cutting PCB traces, do not attempt these modifications yourself.

You can always use the DI by using an external XLR jumper between the DI output and

preamp input if you do not want to make modifications to your module.

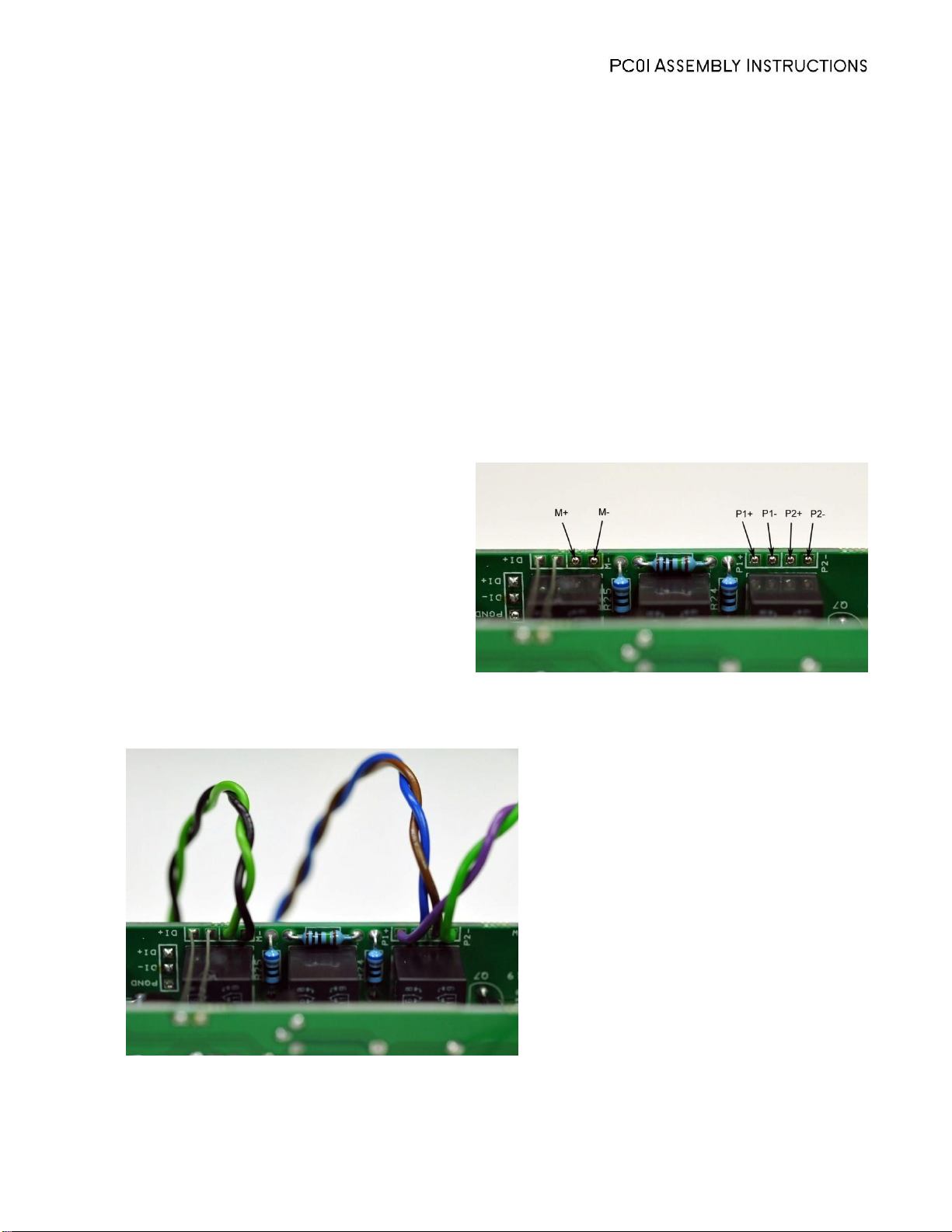

1. DI Switching. To enable this feature,

the signal flow from the module’s input

connector must be interrupted and

rerouted to the M+ and M- pads on the

OneShot power board. For most

modules, the easiest way to get the

signal from the module to the OneShot is

to remove the blue EMI filters. Solder

jumpers between the vacant filter pads

and the M+ and M- pads as shown.

Make sure you’re using the pair of pads that connect back to the female XLR. Be sure to

observe proper polarity. Consult the schematic and use your meter. To get the signal

back to the module, solder jumpers

between the P1+ and P2-pads and the

vacant filter pads as shown. The J99

and N72 have headers that can be used

to terminate the jumpers. For a more

permanent installation, solder directly to

the transformer pins as shown on the

next page.

2. Pad. The input pad attenuates

the microphone signal by 20dB.

Activating the pad increases the load on

the microphone, which can cause

changes in tone. The modifications for

DI switching also enable the pad.

3

3. Input Z. To enable input impedance

switching, solder jumpers from the P1-and

P2+ pads on the OneShot to the

appropriate transformer terminals on your

module. Keep in mind that only modules

with split-primary input transformers,

namely the N72 and J99, will work with the

“Input Z” switch. Both of these modules

have headers that can be used to

terminate the jumpers.

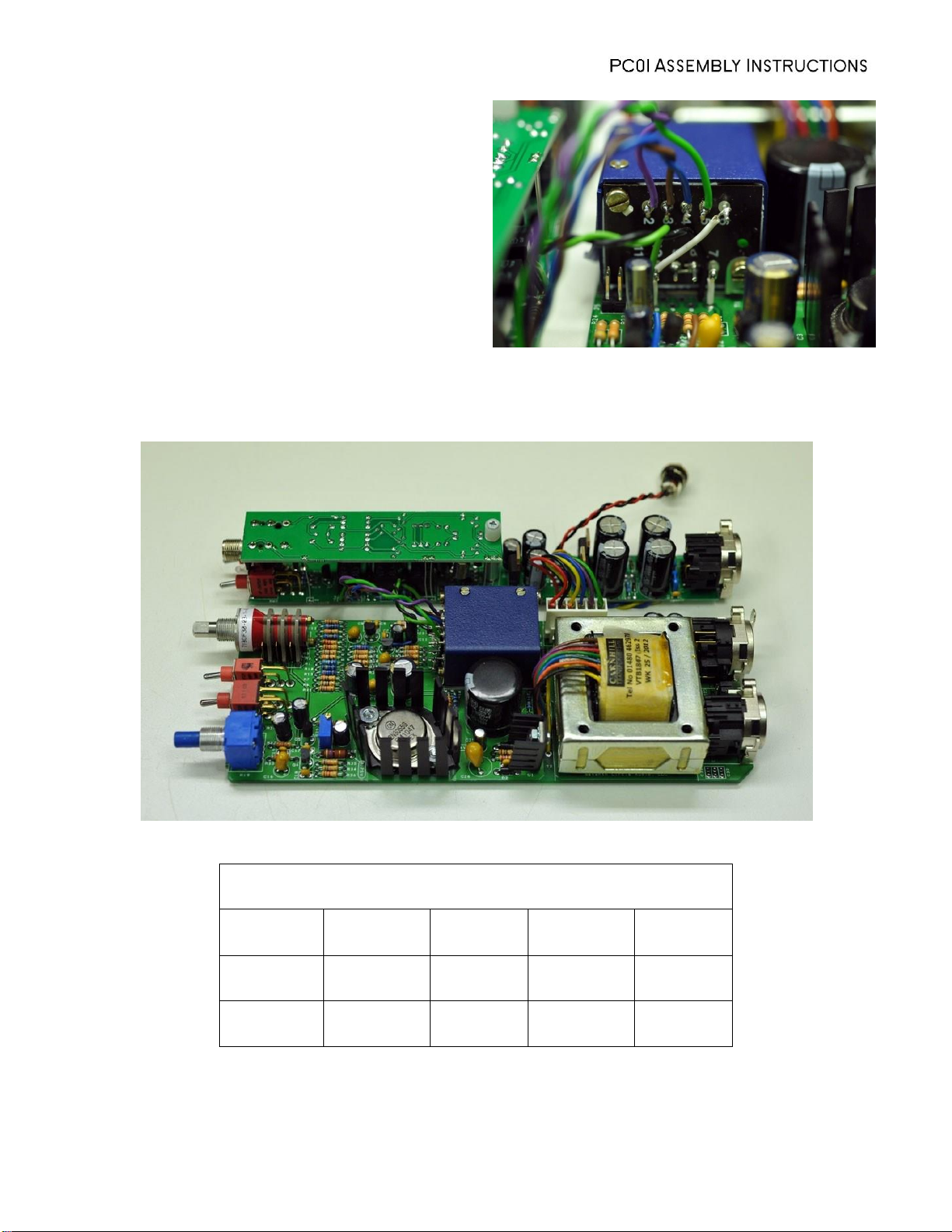

4. Modified N72 and OneShot boards ready for installation in the chassis.

Input Transformer Terminal Numbering –See Schematics

P1+

P1-

P2+

P2-

J99

1

2

4

3

N72

2

4

3

5

4

Assembly

5. Before you begin, carefully unpack the kit and examine the parts. Check the contents of

each small bag against the BOM to make sure all the parts have been included. If you

think something’s missing, please e-mail the details to [email protected] and

we’ll ship replacement parts ASAP.

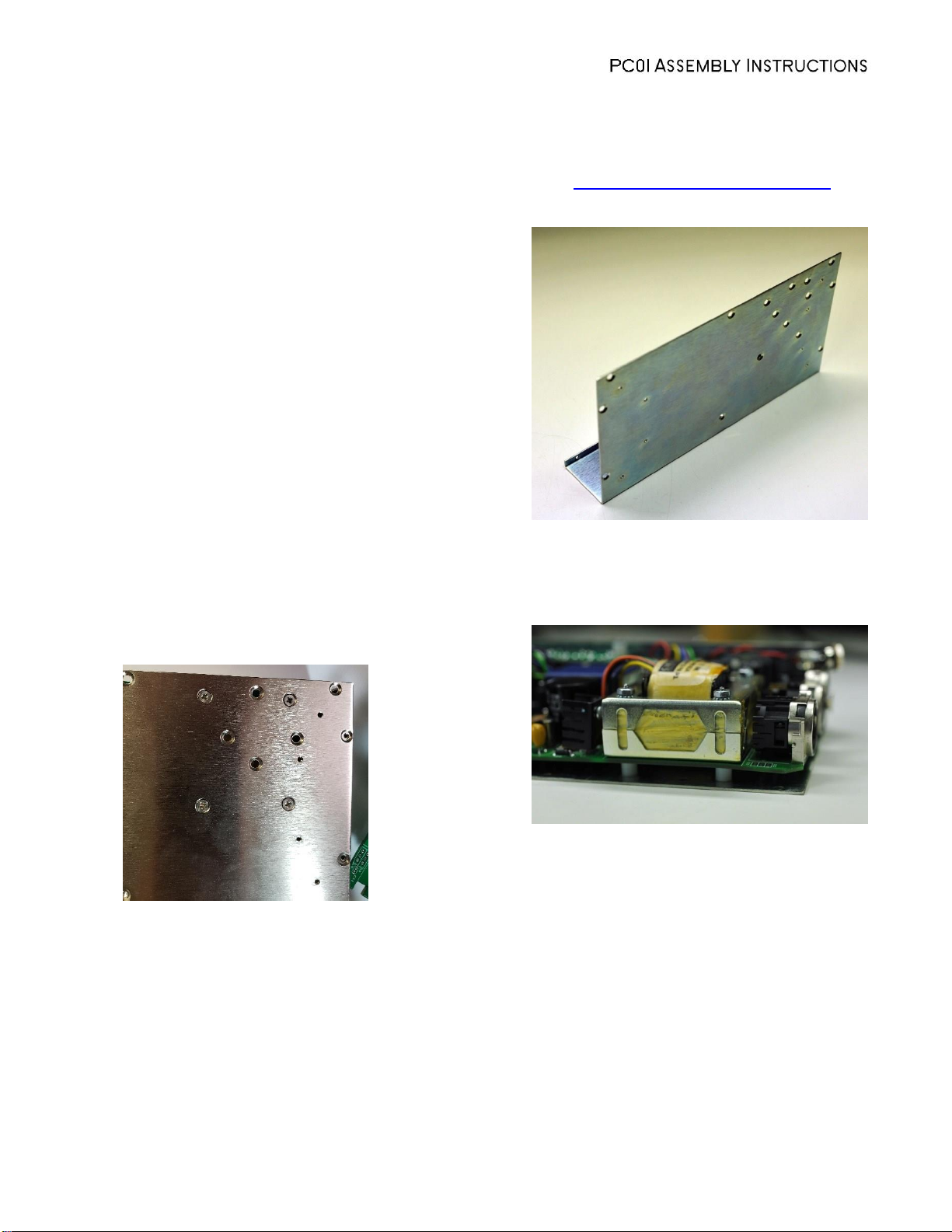

6. Arrange the chassis bottom on the bench as

shown. The bottom and top are identical,

except the bottom has more holes.

7. If your module has an output transformer, select the appropriate mounting screws and run

them through the holes that align with the circuit board. Use 4x 1½” screws for an N72.

Use 2x 1¼” for an A12B or J99B.

If you have an older module, you may have to drill your own holes.

8. Slide ¼” nylon spacers over the screws and run them through the module PCB and output

transformer. Don’t forget any spacers needed between the PCB and transformer. This

may require a bit of patience, but you only have to do it once.

9. Run #4 keps nuts onto the screws coming through the top of the transformer as shown.

Leave the nuts a bit loose at this point.

5

10. Maneuver the rear panel over the XLR connectors and into position as shown. Use 2x

M2.5 x 6mm screws to secure the panel

to the XLR connectors. You may need

to remove the back panel from the PCB

connectors! Use 2x #4 x 1/8” flat head

screws to attach the rear panel to the

bottom half of the chassis.

11. Attach the front sub-panel in a similar fashion to the

back. Take care not to push the LED into the chassis. Use

2x #4 x 1/8” flat head screws to attach the front panel to the

bottom half of the chassis.

12. Snug the screws left loose in the steps above. Don’t

over-tighten! A drop of blue Loctite on the transformer nut

threads is a good idea.

13. Use the remaining 1/8” screws to assemble the

chassis.

6

14. Carefully work the aluminum front panel over

all of the shafts and bushings and secure with 4x

#4-40 black cap screws as shown. Take care to

align the LED so it protrudes through the hole in the

panel

15. Install the serrated washers and panel

nuts. Carefully snug the nuts using a

½” socket and finger torque only.

Leave the ratchet wrench in the

toolbox. Cover the end of the socket

with a few small bits of tape to avoid

scratching the panel.

16. Install and align the knobs.

17. Using the #4-40 x 3/16” screws, attach the feet.

7

18. Congratulations! You’ve got an assembled OneShot preamp!

Table of contents

Popular Chassis manuals by other brands

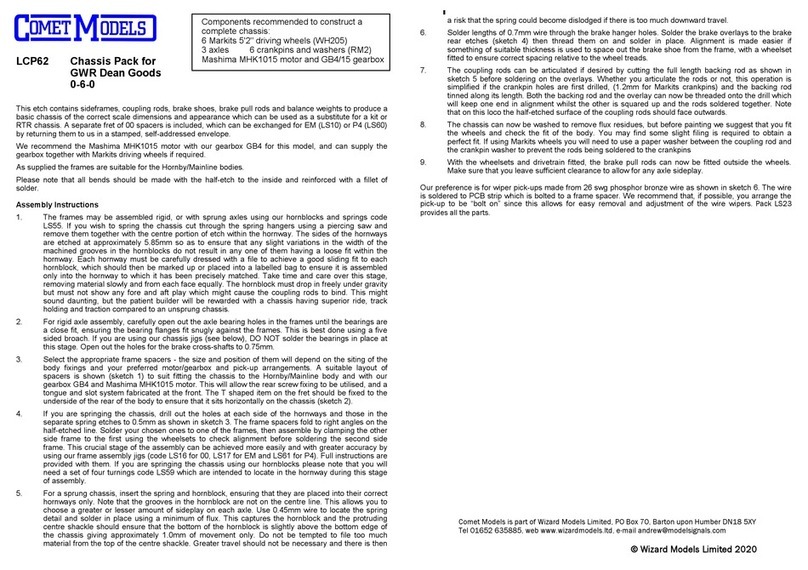

Comet Models

Comet Models LCP62 Assembly instructions

Bay Networks

Bay Networks Centillion 100 100 Chassis installation guide

HPE

HPE Apollo 2000 Gen10 user guide

Fractal

Fractal Meshify 2 Nano user guide

Razer

Razer Tomahawk Mini-ITX Getting started

HELVAR

HELVAR Digidim 458M Series Installation and user guide