- 9 - 122.6006.9

5 SERVICE

It is recommended that the Gas Dispensing System be inspected and serviced a minimum of once per year.

Morefrequent service periods may be required dueto: 1) the type, quality and quantityof the gas being handled,

2) the complexity of the gas supply system, 3) the quality and quantity of water or process liquid being used to

operatetheejector(s),and4) operation procedures.

MorefrequentserviceperiodsareespeciallyindicatedwhenventingoftheVRisoccurringduringtheoneyear

operationalperiod. Thisisusuallyindicative of foreign debris holdingtheinletvalveopenordestructionof the inlet

valve parts caused by the gas quality not up to industry purity standards.

Preventative maintenance kits for each of the assemblies are available from the factory. Each kit contains all the

parts and detailedinstructionsthatarerequired for complete maintenance. All o-rings andgasketsthat have been

disturbedduringthedisassemblymustbereplacedduring reassembly in order to insure safe, trouble free opera-

tion. Failure to replace these parts could result in a shortened operation period and bodily injury.

5.1 Nozzle Cleaning

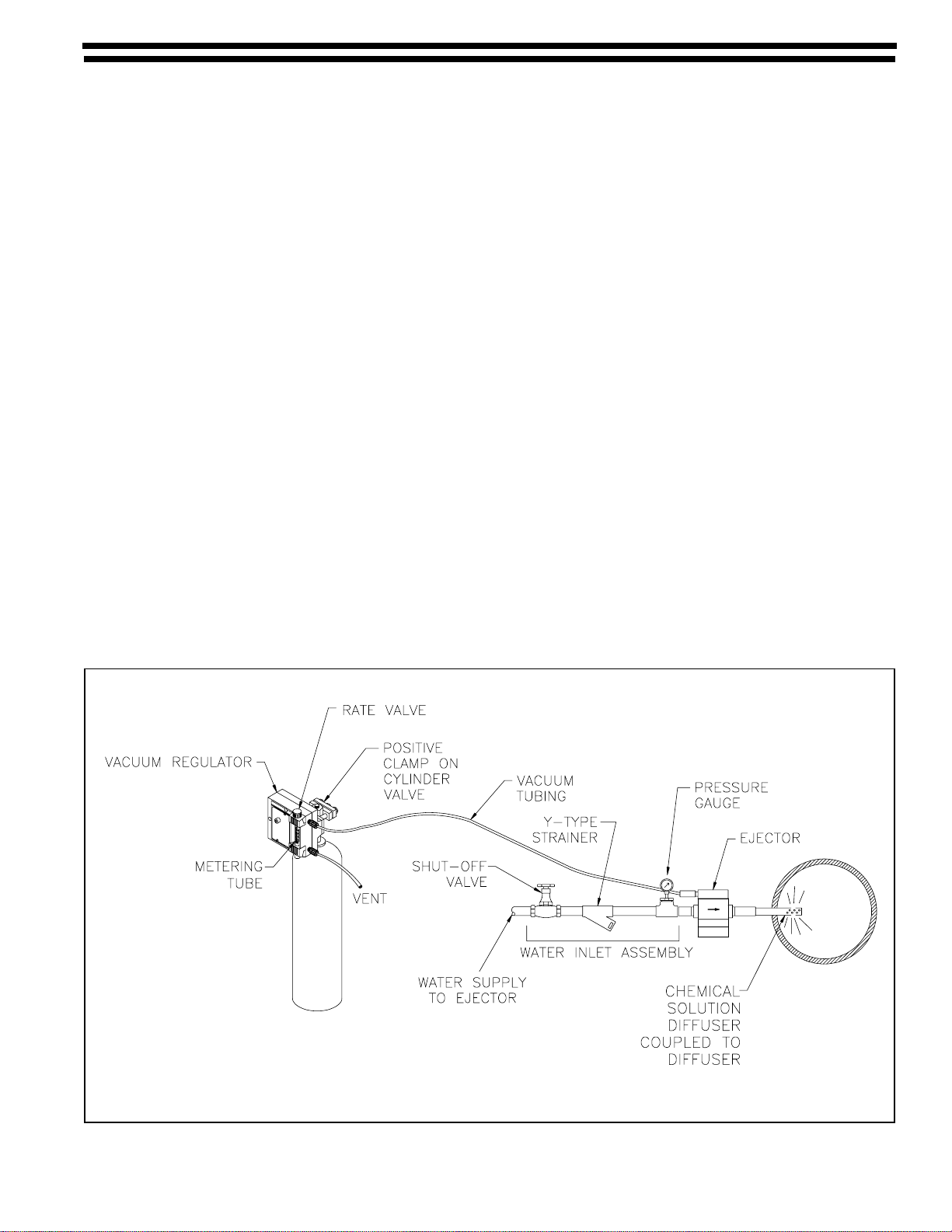

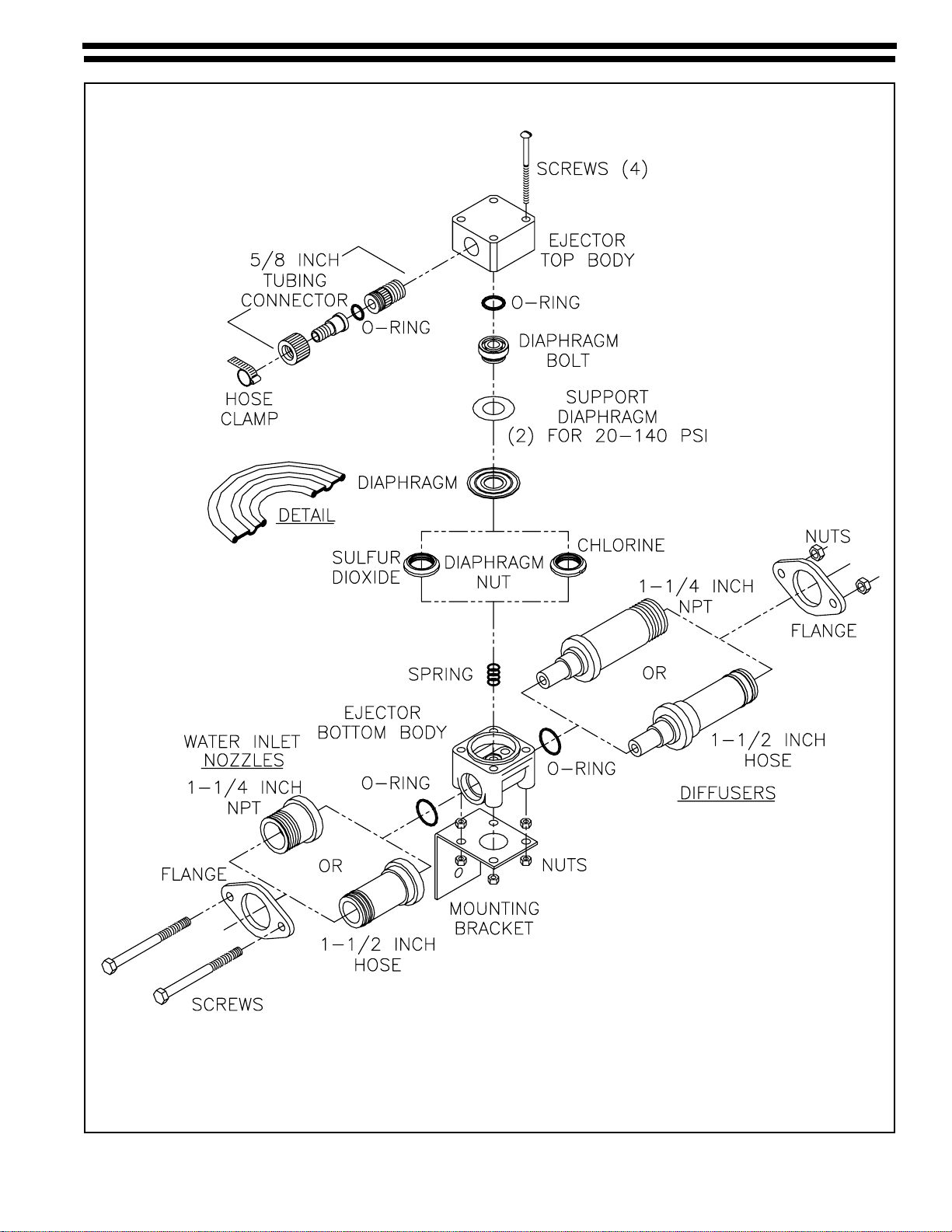

Refer to Figures 1, 2 or 3 and remove the nozzle as follows:

5.1.1 Ejector Disassembly

NOTE: Afterit has been confirmed that all residual gashasbeenevacuatedandwater pressure

hasbeenrelieved,proceedasfollows:

5.1.2 Removethe connecting hose to theejector assembly.

5.1.3 For 100 PPD (2 kg/h) ejectors, rotate the complete ejector body counterclockwise. This loosens

thethreadedportionof the nozzle from the diffuser, eliminatingtheneed for pliers on the hose

connection which may damage the plastic.

For 250 & 500 PPD (5 & 10 kg/h) ejectors, remove the two (2) screws and loosen the flange to

removethenozzle.

NOTE: Nozzlepluggingcanbecausedbyforeignmaterial(pipescale,stone,dirtaccumulation).

This can usually be blown out or pushed out with a wire.

Build-upofdeposits caused by iron, manganese or other material can usuallyberemove by

immersingthenozzleinmuriaticacidandrinsing.Somewatersmaycauseaninoperableejector

andrequirenozzlecleaningeverytwomonths.

5.1.4 To reinstall the nozzle, insert the nozzle through the ejector body and fasten to the dif-

fuser using new gaskets, or o-rings on each side of the ejector body.

NOTE: These parts are plastic and excessive tightening may cause breakage. For 100 PPD

(2 kg/h) ejectors, tighten only hand tight with the ejector body 90° to the left of its final position,

then turn the complete assembly 90°.

5.1.5 Reinstalltheejector supplyhose or pipeand vacuumtubing.

5.2 O-Ring Replacement

Ejectorscontain an o-ring that should be checked and theo-ring/diaphragm bolt assembly replaced as

necessary.

5.3 Diaphragm Replacement - Refer to Figures 2, 3 or 4

5.3.1 Removethefourbolts holding the ejector together to expose the internal parts.

5.3.2 The diaphragm bolt assembly is tightened at the factory, but can usually be separated by using

large,jaw pliers or a vice.Allassembliescontainasupport diaphragm. In high pressure applica-

tions, the assembly includes two thin plastic support diaphragms.

5.3.3 Replacethediaphragmandreassemblethediaphragmnutandbolt.Thesemustbeassembled

tightly using jaw pliers or a special tool to tighten. Install the diaphragm assembly in the recess

ofthetop hole,andboltthe twosectionstogether.(Notediaphragmorientation onFigure2,3 or4).

5.3.4 No adjustments are necessary, but ensure both ends of the spring are square.