Contents

Operating Instructions – DOP11C Operator Panels 3

Contents

1 General information.................................................................................................................. 5

1.1 About this documentation ...............................................................................................5

1.2 Other applicable documentation .....................................................................................5

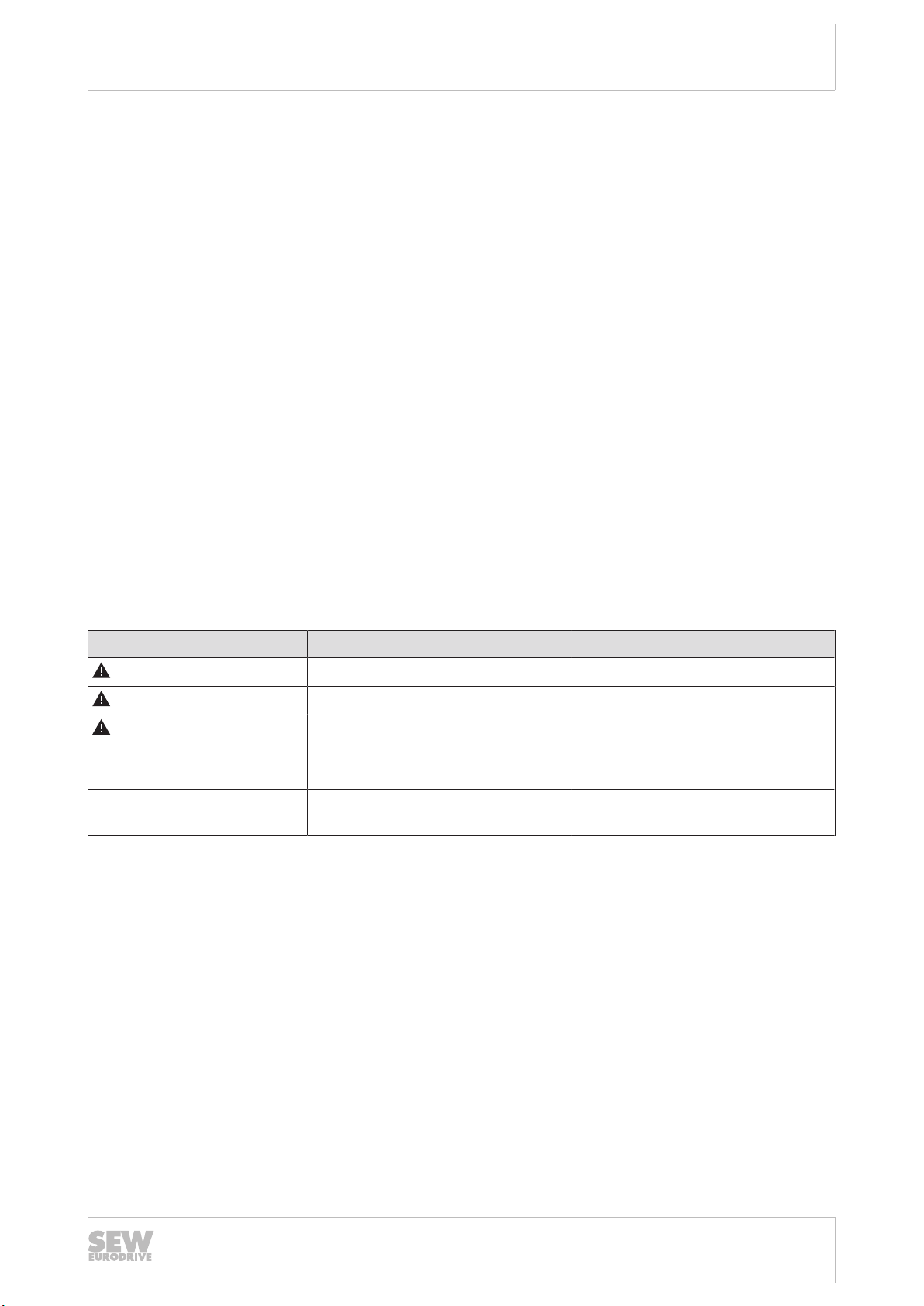

1.3 Structure of the safety notes ...........................................................................................5

1.4 Decimal separator in numerical values ...........................................................................6

1.5 Rights to claim under limited warranty ............................................................................6

1.6 Product names and trademarks......................................................................................7

1.7 Copyright notice ..............................................................................................................7

2 Safety notes .............................................................................................................................. 8

2.1 Preliminary information ...................................................................................................8

2.2 Duties of the user............................................................................................................8

2.3 Target group ...................................................................................................................8

2.4 Designated use ...............................................................................................................9

2.5 Functional safety technology ..........................................................................................9

2.6 Network security and access protection .......................................................................10

2.7 Transportation/storage..................................................................................................10

2.8 Setup/installation...........................................................................................................10

2.9 Installation.....................................................................................................................10

2.10 Electrical connection.....................................................................................................11

2.11 Protective separation ....................................................................................................11

2.12 Startup and operation ...................................................................................................11

2.13 Service/maintenance ....................................................................................................11

3 Device structure ..................................................................................................................... 12

3.1 Type designation and nameplates ................................................................................12

3.2 Scope of delivery ..........................................................................................................13

3.3 Connections of the operator panel................................................................................14

4 Installation............................................................................................................................... 17

4.1 Installation notes for the basic unit................................................................................17

4.2 UL-compliant installation...............................................................................................18

4.3 Space required for installation ......................................................................................20

4.4 Thickness of mounting plate .........................................................................................20

4.5 Unpacking the operator panel.......................................................................................21

4.6 Mounting the operator panel .........................................................................................21

4.7 Connecting the operator panel......................................................................................23

4.8 Connecting the operator panel to the inverter and engineering PC..............................25

4.9 Connecting a voltage supply.........................................................................................30

5 Startup ..................................................................................................................................... 31

5.1 Starting the operator panel ...........................................................................................31

6 Operation................................................................................................................................. 32

6.1 Opening the service menu ............................................................................................32

7 Service..................................................................................................................................... 33

7.1 Waste disposal..............................................................................................................33

23089717/EN – 03/2020