2 FSK-RAP816-V2015.04

Contents

1. System Overview .................................................... 4

System Configuration .............................................................. 4

Control Panel ........................................................................... 5

Remote Keypads ...................................................................... 5

Graphic LCD Remote Keypad .................................................... 5

LED Remote Keypad .................................................................. 5

Wireless Devices ...................................................................... 5

Indoor PIR ................................................................................. 5

Door Contact ............................................................................ 5

Bidirectional Gate Module ........................................................ 5

Relay Module - 4 Channel ......................................................... 5

Remote Control 6 Button .......................................................... 5

Third Party PIR Interface ........................................................... 5

FSK Wireless External PIR ......................................................... 5

Repeater ................................................................................... 5

FSK USB Serial Adapter (FUSA) ................................................ 5

Upload/Download Software .................................................... 5

2. Installation .............................................................. 6

Installation Sequence .............................................................. 6

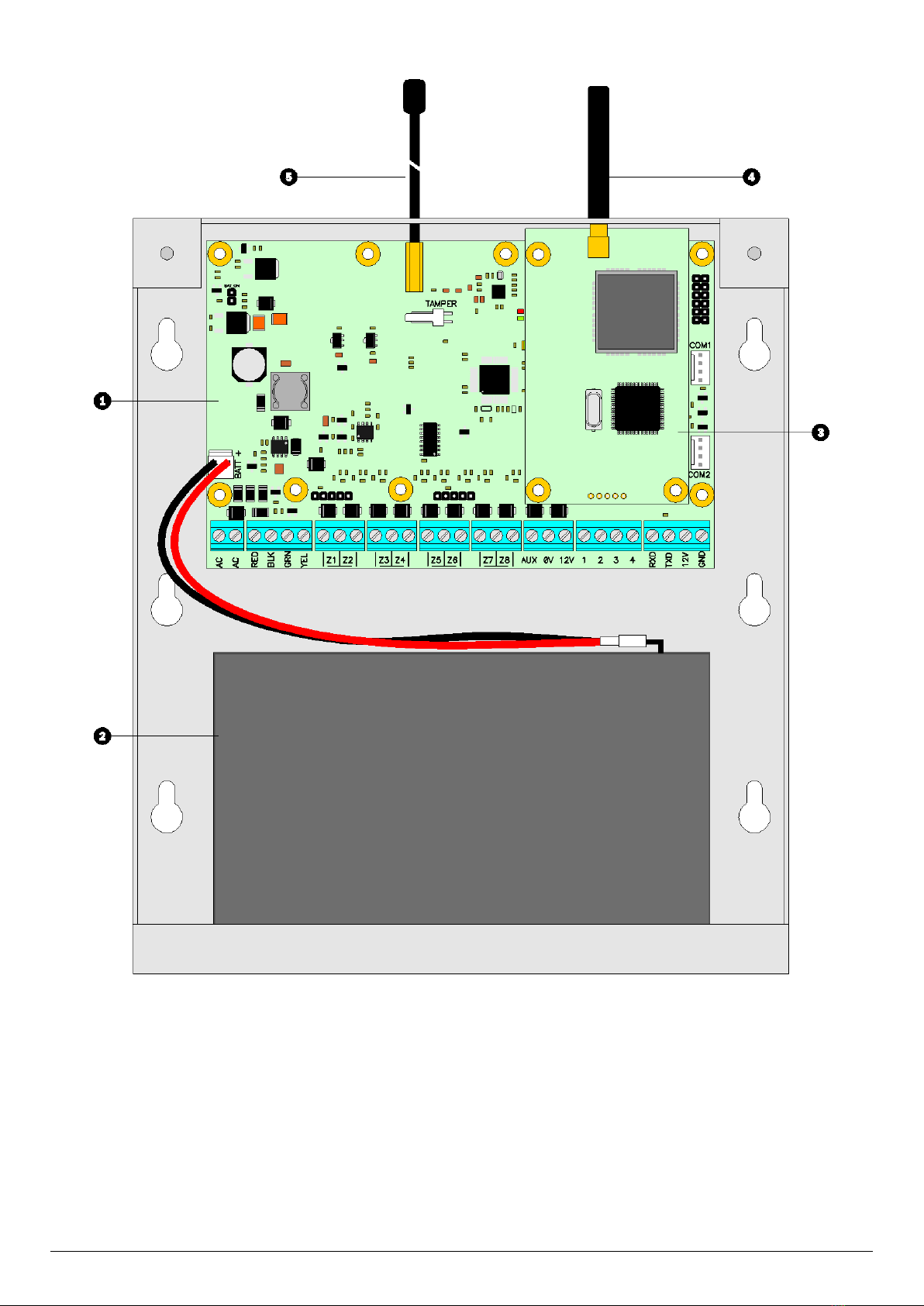

Control Panel ........................................................................... 6

Mounting .................................................................................. 6

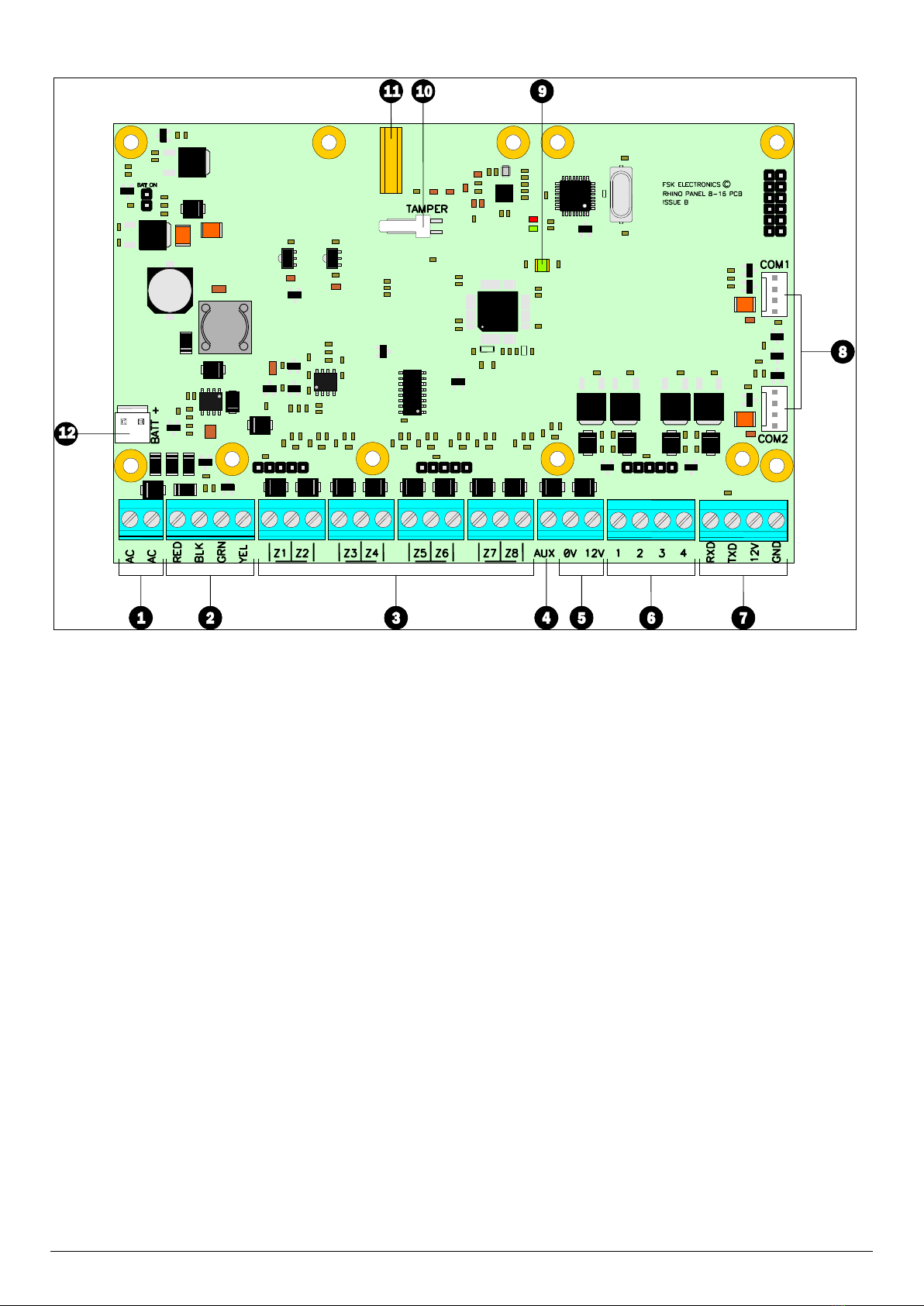

Wiring the Control Panel .......................................................... 6

Control Panel Layout ................................................................ 7

Connecting Devices to the Network ......................................... 9

Remote Keypads .................................................................... 10

PCB Layouts ............................................................................ 10

Wiring Detection Devices ...................................................... 10

Normally Closed ...................................................................... 10

Normally Open........................................................................ 10

Single EOL - N/C ...................................................................... 11

Double EOL ............................................................................. 11

Triple EOL................................................................................ 11

Loudspeaker Connections ..................................................... 12

External Sounder/Strobe Connections .................................. 12

0V ........................................................................................... 12

+12 .......................................................................................... 12

Bell (1)..................................................................................... 12

Strobe (2) ................................................................................ 12

Panel Outputs 1 - 4 ................................................................ 12

Configuring Wireless Devices ................................................ 13

On-board Wireless Interface ................................................... 13

RH-100 Wireless Door Contact ............................................... 13

RH-101 Wireless 3rd Party PIR Interface .................................. 13

RH-200 Wireless Indoor Passive ............................................. 14

RH-802 Bidirectional Gate module ......................................... 14

RH-806 Wireless Key Fob ........................................................ 15

Commissioning ...................................................................... 15

3. Programming the Control Panel ........................... 16

Introduction ........................................................................... 16

Easy Mode .............................................................................. 16

Expert Mode ........................................................................... 16

Exiting Engineer’s Program Mode ......................................... 16

Zone Configuration (Easy Mode) ............................................ 17

String Edit - Text Mode ............................................................ 17

Area Configuration (Easy Mode) ............................................ 17

Keypad Configuration (Easy Mode) ........................................ 18

Output Configuration (Easy Mode) ........................................ 18

User Configuration (Easy Mode) ............................................ 18

Expert Mode Menu Navigation .............................................. 19

1. Zone Programming ............................................................. 19

Zone Type ................................................................................ 19

Zone Wiring ............................................................................. 20

Zone Attributes ....................................................................... 20

Zone Areas .............................................................................. 21

Zone Bypass Options ............................................................... 21

Zone Chime ............................................................................. 21

Zone Soak Test ........................................................................ 21

Zone Text ................................................................................ 21

Zone Link ................................................................................. 22

2. Area Options....................................................................... 22

Area Timers ............................................................................. 22

Area Arming Modes ................................................................ 22

Area Configuration Options 1 .................................................. 22

Area Configuration Options 2 .................................................. 23

Area Configuration Options 3 .................................................. 23

Area Timer Control .................................................................. 23

3. System Configuration ......................................................... 24

System Timers ......................................................................... 24

System Counters ..................................................................... 25

Hardware - Volume Levels ...................................................... 25

Hardware - Output Monitoring ............................................... 25

Hardware - Monitoring ........................................................... 26

Speaker Sounds ....................................................................... 26

Configuration 1 ....................................................................... 26

Configuration 2 ....................................................................... 26

Control Timers ......................................................................... 27

Banner Text ............................................................................. 27

Remote Control Labels ............................................................ 27

Area Labels .............................................................................. 27

System Links ............................................................................ 27

Auto Arm and Auto Disarm ..................................................... 28

4. Keypad Configuration ......................................................... 28

Keypad Options 1 .................................................................... 28

Keypad Options 2 .................................................................... 28

Keypad Sounds ........................................................................ 28

Keypad Areas .......................................................................... 29

5. Expander Configuration ...................................................... 29

Expander Areas ....................................................................... 29

Expander Options .................................................................... 29

Expander Sounds ..................................................................... 29

Expander Outputs ................................................................... 30

Expander Output Attributes .................................................... 30

Expander Output Areas ........................................................... 30

Expander Output Link.............................................................. 30

Wireless Outputs ..................................................................... 30

Wireless Output Attributes ..................................................... 30

Wireless Output Areas ............................................................ 30

Wireless Output Link ............................................................... 30