sewerin COMBIPHON User manual

Operating

Instructions

COMBIPHON®

EDENBROS, LLC

Measurable success by Sewerin equipment

Congratulations. You have chosen a quality instrument manufactured

by Hermann Sewerin GmbH.

Our equipment will provide you with the highest standards of perfor-

mance, safety and efciency. They correspond with the national and

international guide-lines.

Please read and understand the following operating instructions before

using the equipment; they will help you to use the instrument quickly and

competently. If you have any queries we are available to offer advice

and assistance at any time.

Yours

Hermann Sewerin GmbH

Robert-Bosch-Straße 3

33334 Gütersloh, Germany

Tel.: +49 5241 934-0

Fax: +49 5241 934-444

www.sewerin.com

info@sewerin.com

EDENBROS, LLC

PO BOX 247

ST. JAMES, MO 65559

Phone: +1

800-526-5246

Fax:

+1 800-807-9368

www.

edenbros.com

Operating Instructions

11.10.2010 – V 1.X – 103411 – en

COMBIPHON®

For your safety

This product may only be operated by appropriately-trained persons who

are familiar with the relevant operating manual.

It may only be used for its designated purpose, i.e. for industrial and com-

mercial use.

Repair work may only be carried out by specialists or by persons who have

undergone appropriate training.

Any alterations or modications to the product require the prior approval of

Hermann Sewerin GmbH. In the event of unauthorised alterations to the

product the manufacturer accepts no liability for damage.

Only Hermann Sewerin GmbH accessories may be used with the product.

Only spare parts approved by us may be used for repairs.

Hermann Sewerin GmbH accepts no liability for damage resulting from

non-compliance with the foregoing. The guarantee and liability provisions

in the Hermann Sewerin GmbH terms of sale and supply are not extended

by the foregoing.

We reserve the right to make changes in the context of continued techni-

cal development.

In addition to these instructions, please comply with generally applicable

safety and accident-prevention regulations!

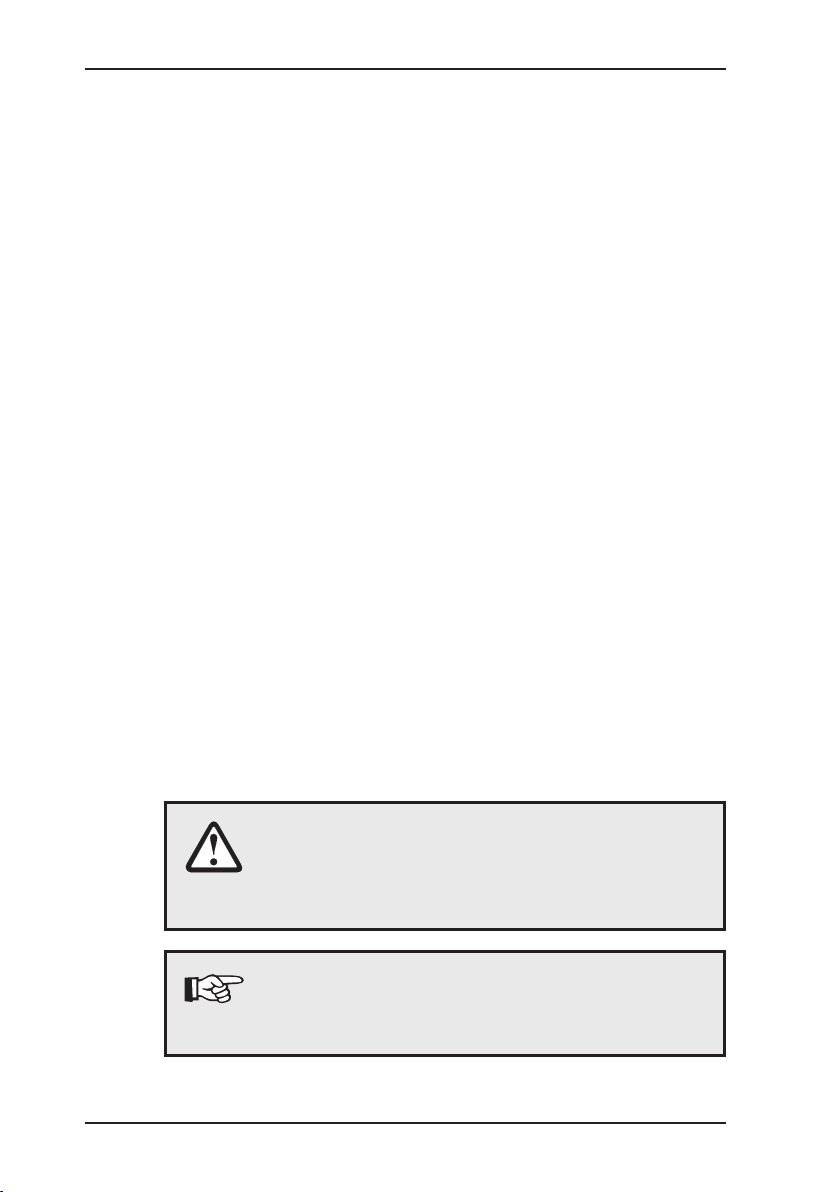

Symbols used:

CAUTION!

This symbol warns of dangers that may threaten

the safety of the user or maty damage or destroy

the product.

Note:

This symbol ags information and hints extending

beyond the actual operation of the product.

I

Contents Page

1 System overview .....................................................................1

2 Intended usage and principle of operation...........................3

3 COMBIPHON system ..............................................................5

3.1 Generator G5 ............................................................................6

3.2 Loading the Battery ...................................................................7

3.3 Generator G5 – Radio...............................................................7

3.4 AC/DC adapter L.......................................................................8

3.5 Car cable L................................................................................9

4 Knocker..................................................................................10

4.1 Knocker – Starting and operating ........................................... 11

4.2 Working with the Knocker........................................................ 11

4.3 Maintaining the Knocker..........................................................12

5 Stopper...................................................................................13

5.1 Stopper – Starting and operating ...........................................14

5.2 Working with the Stopper ........................................................15

5.3 Maintaining the Stopper ..........................................................16

5.4 Important notes on use and care ............................................18

6 Troubleshooting ....................................................................19

6.1 General ...................................................................................19

6.2 Knocker ...................................................................................19

6.3 Stopper....................................................................................20

7 Technical data........................................................................21

7.1 Generator G5 and G5 Radio ...................................................21

7.2 AC/DC adapter L.....................................................................21

7.3 Knocker ...................................................................................22

7.4 Stopper....................................................................................22

7.5 Radio remote control (Option).................................................22

II

Contents Page

8 Appendix................................................................................23

8.1 EC-Declaration of conformity ..................................................23

8.2 Advice on disposal ..................................................................23

8.3 Modication History - Software ...............................................24

9 Index.......................................................................................25

1

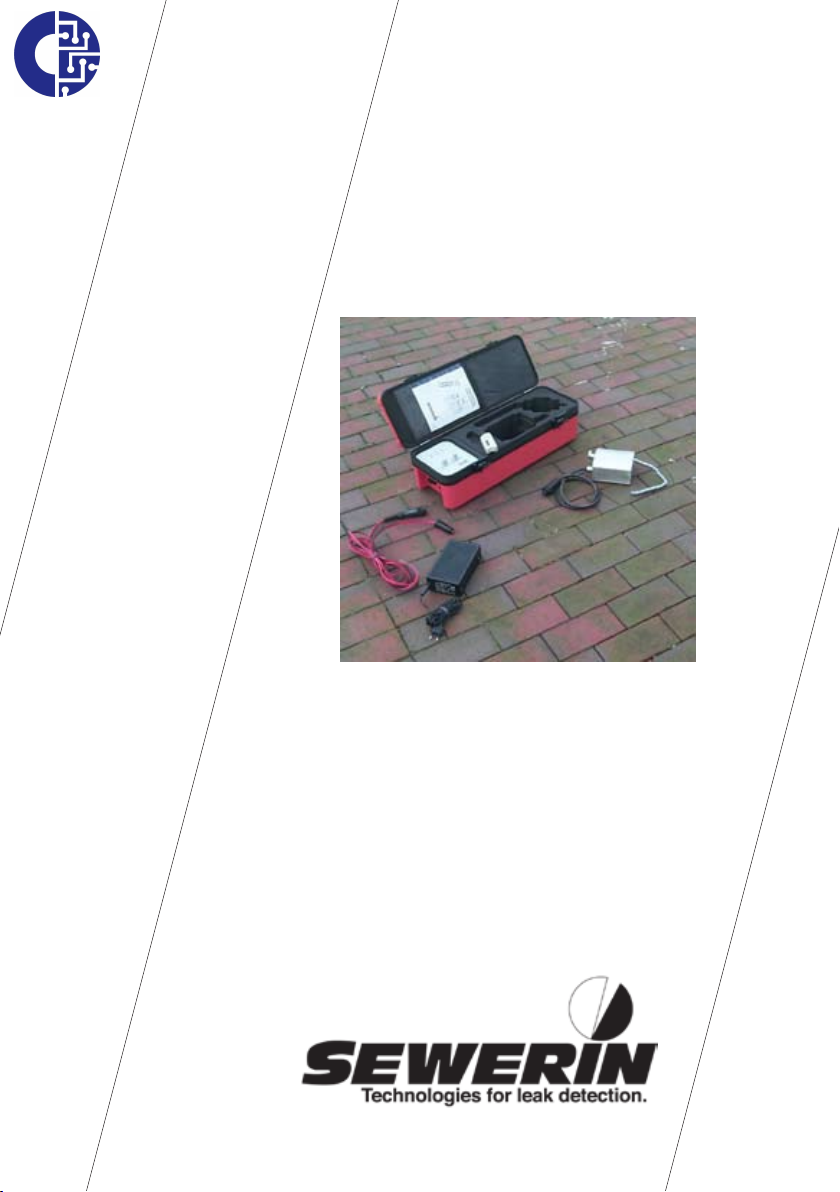

1 System overview

1 System overview

COMBIPHON system

1Foam insert for

accessories

1

4

2

3

6

78

5

2 AC/DC adapter L

3Car cable L

4 Knocker

5Remote control

6 Generator G5 with

control panel

7Connection for an

external power source

8Connection for

oscillator Picture 1: COMBIPHON system

9Stopper

10 Standpipe

Picture 2: Stopper and accessories

9

10

2

1 System overview

Generators G5 control panel

Knocker LED

COMBIPHON

G5

Stopper LED

Booster LED

ON/OFF switch /

Intensity adjuster*

Battery LED

Frequency LED

Frequency adjuster

(Knocker/Stopper)

Picture 3: Control panel

* Intensity adjuster for Knocker only. The intensity of the Stopper

is set via a valve.

3

2 Intended usage and principle of operation

2 Intended usage and principle of operation

Plastic pipes cannot be located using traditional electromagnetic

methods as they are not electrically conductive.

The acoustic method uses a different principle for locating pipes:

The pipes propagate mechanical oscillations better than the sur-

rounding earth. If the pipe is subject to the right oscillations, they

are transferred along the pipe and via the earth to the earth’s sur-

face. These oscillations can be detected according to the principle

of electro-acoustic leak detection by a ground microphone and

receiver equipped with headphones. The AQUAPHON System,

for example, is ideally suited for this task.

Picture 4: Acoustic leak detection

Similar to the acoustic detection of water leakages, the pipeline

is generally located where the highest intensity is detected. This

is how bre cement and metal pipes are principally detected.

The COMBIPHON system consists of the Generator G5 central

control unit, the AC/DC adapter L, a car cable L as well as vari-

ous oscillators (Knocker, Stopper).

The Knocker places the service pipes (water or gas) under oscil-

lation by knocking on the outside of the pipeline like an electric

hammer. Gas or air-lled pipes are sometimes difcult to detect

since the conductive water column is missing.

4

2 Intended usage and principle of operation

The Stopper creates a pressure wave by rapidly opening and clos-

ing the ow to the pipe. Main pipes (water) require more energy

to be placed under oscillation. The water column is set in motion

by extracting water from a hydrant. A special shut-off element

known as the Stopper slows down the motion of the water col-

umn at regular intervals. The resulting pressure waves propagate

along the pipeline and can be detected over long distances. The

intensity of the generated pressure wave can be adjusted via the

valve on the device.

5

3 COMBIPHON system

3 COMBIPHON system

The following describes the various system components as well

as their intended usage.

The described system elements are laid out in the carrying case

so that they can be easily removed for use and stowed away as

well as operated from the case itself.

* see note on page 23

Adhesive label showing software version (e.g., 1.1)*

Picture 5: Generator G5 and its components in the carrying

case

6

3 COMBIPHON system

3.1 Generator G5

The Generator G5 is located on the left of the carrying case. It is

an integral part of the carrying case and cannot be removed. The

control elements of the generator are used to set the frequency

(see Picture 3) and the intensity of the impulse used for detec-

tion. In addition, the control panel is tted with a number of LEDs,

which indicate the following statuses:

Knocker LED LED is lit when the Knocker is connected

to the system and switched on.

Stopper LED LED is lit when the Stopper is connected

to the system and switched on.

Booster LED without function

Battery LED This LED indicates the following ope-

rating states:

green (on): normal operation

red, ashing: under voltage

green, ashing: charging

green, double ashing: buffering

7

3 COMBIPHON system

3.2 Loading the Battery

Note:

To maintain the device in continuous operation, it

should always be connected to an external power

source (e.g., via the car cable L).

Detailed information

In buffer mode the battery is not charged, only monitored.

The battery is charged

once per week,z

when the battery voltage falls below 12 V or z

when the Generator G5, e.g., after use, remains connected to z

an external power source.

Charging is complete when the battery voltage has reached 14.5 V.

If the battery voltage falls below 10 V, the Generator G5 switches

to “standby mode” (all LEDs extinguish; the quiescent current

equals < 7 mA).

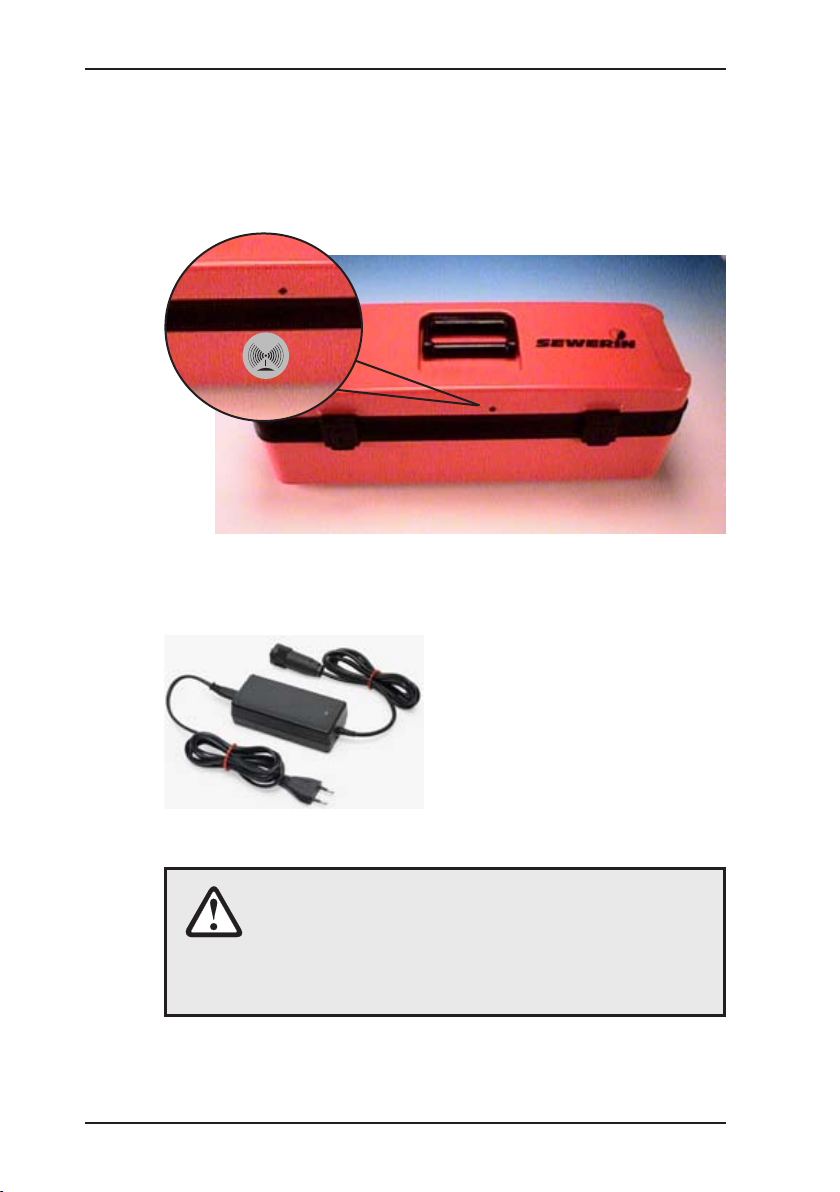

3.3 Generator G5 – Radio

The COMBIPHON Generator

G5 radio is to a great extent

identical to the standard version

described in Chapter 3.1.

The only difference is the sup-

plied remote control and the

corresponding receiver element

on the generator.

With the Stopper, only the

“Pause” key has a function.

Picture 6: Remote control

Increase intensity

Decrease intensity

Pause

SVS

8

3 COMBIPHON system

The remote control allows the intensity (Knocker) to be adjusted.

It is not possible to adjust the intensity beyond that dened by the

position of the adjuster on the generator. Therefore, to achieve

the maximum intensity at the Knocker via the remote control, the

intensity adjuster must also be rotated fully clockwise.

Picture 7: Generator G5 – Radio

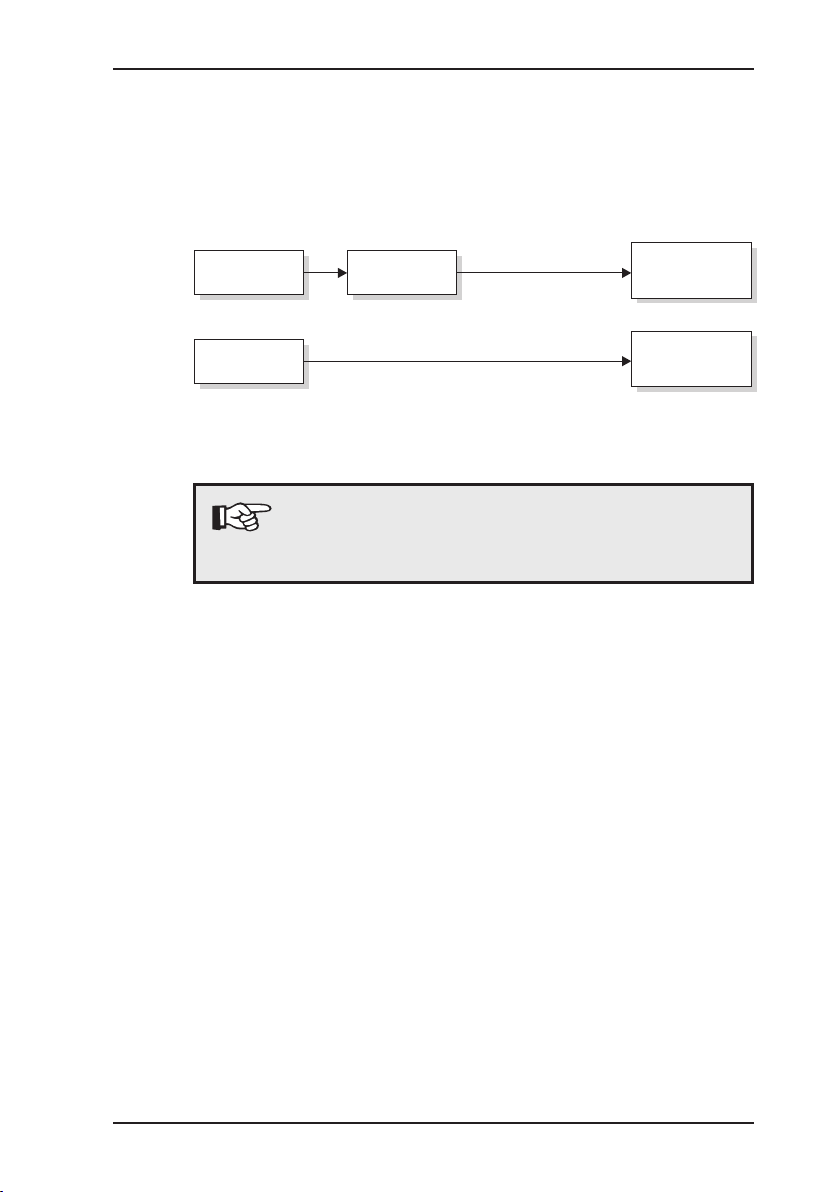

3.4 AC/DC adapter L

The AC/DC adapter L is used to

operate or charge the Generator

G5. Comply with the minimum

requirements listed in the techni-

cal data to ensure that the device

operates correctly.

Picture 8: AC/DC adapter L

CAUTION!

When operating the device outdoors, ensure

that the AC/DC adapter L is sufciently protected

against moisture. Otherwise, there is a risk of elec-

tric shock.

9

3 COMBIPHON system

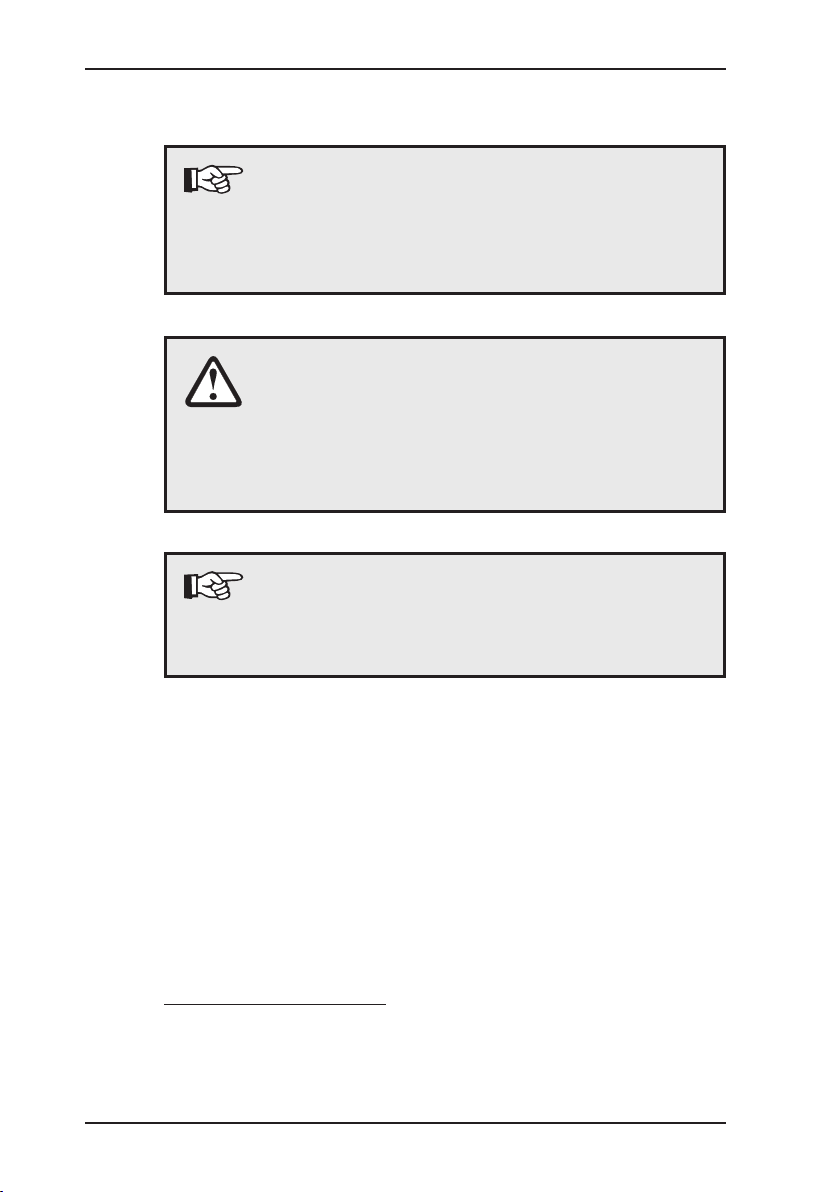

3.5 Car cable L

The car cable L is located in the carrying case in the compartment

to the right of the generator (see Picture 1), below the AC/DC

adapter L. It is used to supply the Generator G5 via the supplied

AC/DC adapter L or a car battery.

Picture 9: Connection to mains supply or car battery

Note:

Before connecting the cable to the AC/DC adapter L,

unscrew the red adapter cap on the cable connector.

230V~

Mains supply

~

12 V

Car battery

Car cable L

Car cable L

Generator

G5

Generator

G5

AC/DC

adapter L

10

4 Knocker

4 Knocker

The Knocker is located on the right-hand side of the carrying case.

This device is an oscillator which places service pipes under os-

cillation. For more detailed information about pipe and leakage

detection, refer to the operating instructions of the receiver (e.g.,

AQUAPHON).

The Knocker can be attached to pipes with a diameter up to

120 mm using the supplied chain attachment.

Picture 10: Knocker

11

4 Knocker

4.1 Knocker – Starting and operating

Carry out the following steps to put the Knocker into operation.

Using the chain attachment, attach the Knocker to the pipe1.

whose course is to be located.

Connect the Knocker to the Generator G5.2.

Switch on the Generator G5 using the ON/OFF switch (see 3.

Picture 3) on the generator’s control panel.

Take the device you want to use for electro-acoustic water leak 4.

detection (e.g., AQUAPHON), and put it into operation.

Use the adjuster on the Generator G5 to control the transmit-5.

ted knock impulse. We recommend to rotate both adjusters to

the central position, and then adjust the knock impulse to the

local conditions.

4.2 Working with the Knocker

The following provides a few instructions and tips that will make

your work with the Knocker easier.

Detection can be signicantly inuenced by the following fac-

tors:

Ground surfacez

Soil densityz

Background noisesz

When adjusting the intensity of the impulse, take the local condi-

tions into consideration.

After switch-on, rotate both adjusters to the central position.

Then adjust the impulse step-by-step until it suits the local con-

ditions.

For detection in the close vicinity of the Knocker, we recommend

that you do not select a too high frequency or intensity since, for

example, house walls transmit the oscillations, thus making pre-

cise detection difcult.

12

4 Knocker

4.3 Maintaining the Knocker

Note:

Repairs* to the device should be performed by

SEWERIN Service or by a competent person. Re-

habilitation* are to be carried out using only original

SEWERIN spare parts.

CAUTION!

The connectors of the oscillator and the AC/DC

adapter L are to be connected to the Generator

G5 in a dry and clean state. Disregarding this can

cause malfunctions and high wear and tear of the

contacts.

Note:

If the inside of the case becomes damp, store the

device with the case open. Rising damp can cause

damage.

* According to DIN 31051:

Servicing: Determining the actual state

Maintenance: Measures for ensuring the should-be state

Repairs: Measures for restoring the should-be state

Rehabilitation: Servicing, maintenance and if necessary repairs

13

5 Stopper

5 Stopper

The Stopper is a separate system component that is not stored

in the carrying case (see Picture 2).

The Stopper creates a pressure wave by rapidly opening and

closing the pipe. Main pipes (water) require more energy to be

placed under oscillation. The water column is placed in motion

by extracting water from a hydrant. A special shut-off element

known as the Stopper slows down the motion of the water col-

umn at regular intervals. The resulting pressure waves propagate

along the pipeline and can be detected over long distances. The

intensity of the generated pressure wave can be adjusted via the

valve on the device.

CAUTION!

If the set pressure waves are too large, damage to

the pipeline can occur.

Always begin operation with the lowest intensity.

Then increase the intensity as required step-by-step

keeping the local conditions in mind.

Picture 11: Stopper, stand pipe, ushing adapter

14

5 Stopper

5.1 Stopper – Starting and operating

Note:

Comply fully with the following instructions when

starting and operating the Stopper. Note that Her-

mann Sewerin GmbH cannot be held liable for dam-

age caused by non-compliance.

Connect the standpipe with the ushing adapter to the hydrant 1.

under professional guidance. Always ush out the hydrant

and the pipeline to prevent contamination and foreign particles

from collecting inside the device.

After ushing, close the shut-off valve, and remove the ush-2.

ing adapter.

Connect the Stopper to the standpipe3. under professional

guidance.

Connect the connection cable of the Stopper to the Generator4.

G5 (Oscillator connection, see Picture 1).

Rotate the intensity adjuster (see Picture 13) fully clockwise, 5.

i.e., to the lowest intensity.

CAUTION!

Always begin operation with the lowest intensity.

Then increase the intensity as required step-by-step

keeping the local conditions in mind (e.g., state of

the pipelines). The manometer on the standpipe indi-

cates the actual pressure for monitoring purposes.

6. Open the shut-off valve on the standpipe, thus opening access

to the Stopper.

7. Switch on the Generator G5 using the ON/OFF switch (see

Picture 2) on the generator’s control panel.

8. The device is now operating. Adjust the intensity carefully to

suit the local conditions.

9. Take the device you want to use for electro-acoustic water leak

detection (e.g., AQUAPHON), and put it into operation.

Other manuals for COMBIPHON

1

Table of contents

Popular Industrial Equipment manuals by other brands

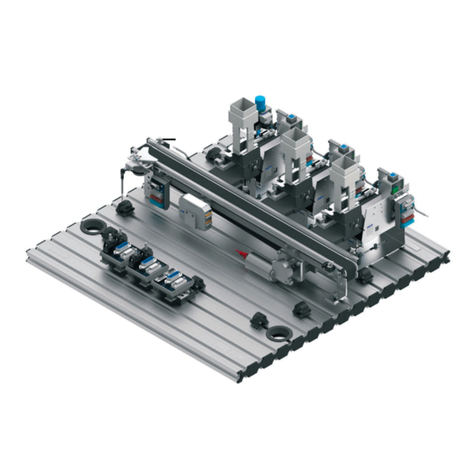

Festo

Festo Distributing Pro Station operating instructions

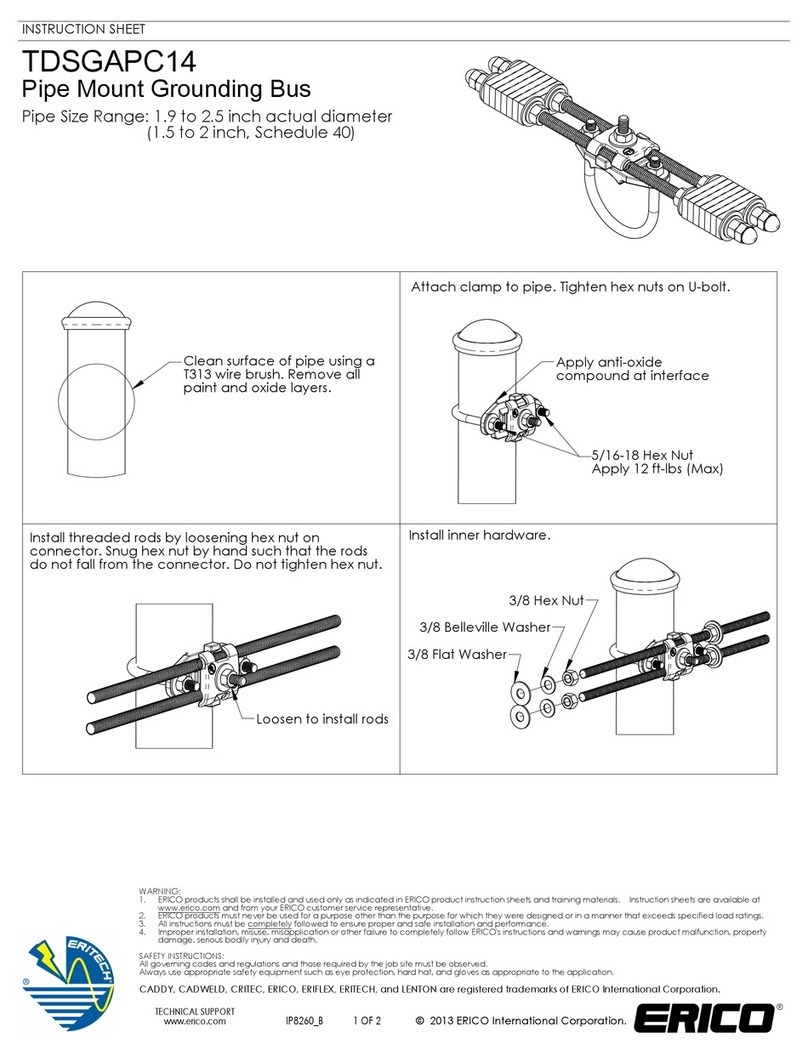

ERICO

ERICO TDSGAPC14 quick start guide

Master

Master MS Seeds Instructions for use and maintenance

Hanskamp

Hanskamp MultiFill 003-561-005 Installation and operating instructions

Enerpac

Enerpac Pull-pac BRP106C instruction sheet

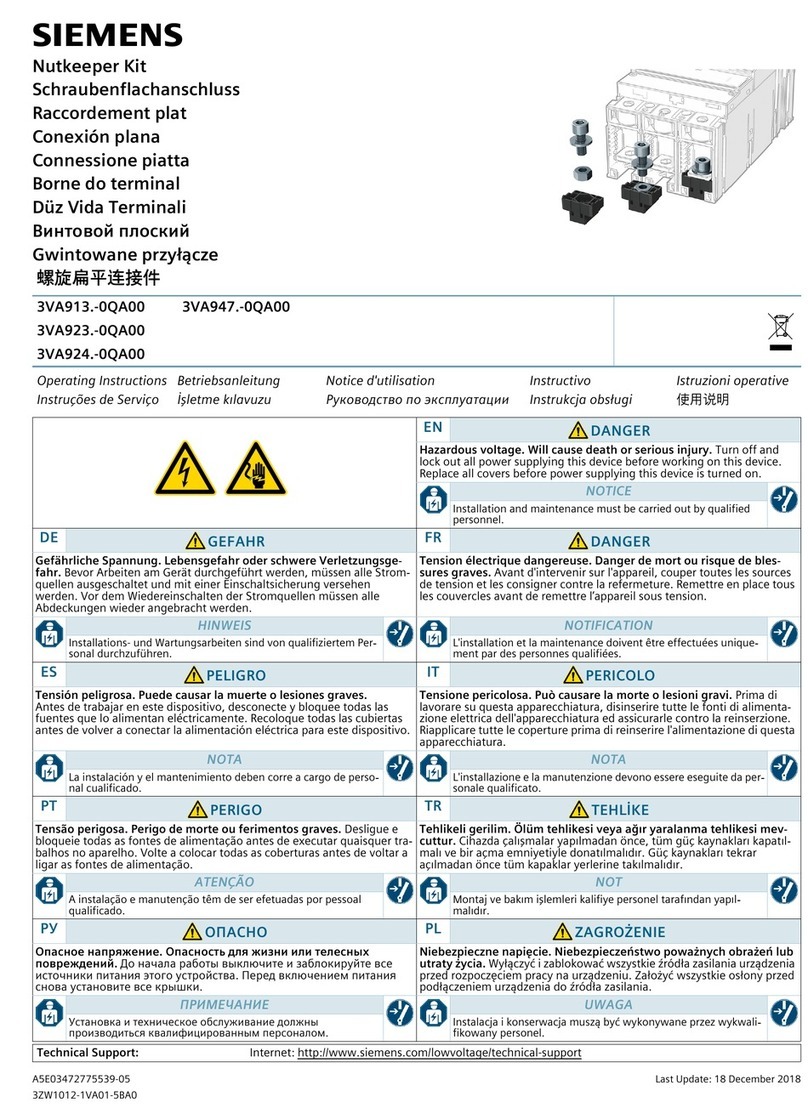

Siemens

Siemens 3VA913-0QA00 Series operating instructions