FOLLOW

INSTRUCTIONS

FOR

CHANGINGACCESSORIES

• Do not store in a closed area where fuel vapors can reach an open flame from hot

wa

ter

heaters, furnaces, etc. Store only in a locked,

we

ll ventilated area.

• Ensure safe and proper performance

of

your product. The use of any other acce.ssories or

attachments

may

cause a potential hazard or injury to the user, damage to the machine and void

this warranty.

• Clean the machine completely, especially, the fuel tank, its surroundings, and the air cleaner.

• When refueling, be sure to stop the engine and

co

nfirm that it is cooled

dow

n. Never refuel

wh

en the engine is running

or

hot. When gasoline spills, be sure to wi

pe

it up completely dispose

of those materials before starting the engi

ne

.

• Stay clear

of

other workers or

by

standers by

at

least 15 meters/50 feet.

• When ever approaching an operatorof the machin

e,

carefully call his attention and confirm that

the operator stops the engi

ne

. Be careful not to startle

or

distract the operator which can cause

an

unsafe situation.

• Never touch the nylon cutting head or blade when ever the engine is running. If it is necessary

to replace the

pr

otector

or

cutting attachment, be sure to st

op

tho engine and confirm that

the

cutting device has stopped running.

• The engine should be turned offwhen the machine is moved between work areas.

• Be careful not to hit the nylon cutting head against stones, or t

he

ground.

• Unreasonable rough operation will shorten the life

of

the machine as well as create an unsafe

environment for yourselfand those around you.

• Payattention and

be

aware

of

loosening and overheating

of

parts. Ifthere is any abnormality

of

the machine, stop operation immediately and check the machine carefu

lly.

If necessary, have the

machine serviced by an authorized dealer. Never continue to operate a machine which may

be

malfunctioning.

• In start-up or

dur

ing operation

of

the engine, never touch hot parts such as the muffler. the high

volt

ag

e wire

or

the spark·plug.

• After the engine has stopped, the muffl

er

is still hot. Never place the machine

in

any places

where there are flammable materials (drygrass, etc.), co

mb

ustible gasses

or

co

mb

ustible liquids

• Pay special attenti

on

to opera

ti

on

1n

I

lle

ra

in

oriusl aner

th

e rain

as

the

gr

ound may be slippery.

•

If

you slip

or

fall lo

th

o ground

or

tn

to n hal

o,

rolease

th

e throttle lever immediat

ely.

• Be car

ef

ul not to

dr

op lho mach1no

or

llll

1t

u9

t

11n

st obstacles.

• Before proceed

111g

to

ad

iust or repair lhe machine, be sure to st

op

the engine and detach the

spa

rk

plug.

• When the machine is placed in storage for a long time, drain fuel from the fuel tank and

carburetor, clean the parts, move the machine to a safe place and confirm that

th

e engine is

cooled down.

• Make periodic inspections to assure safe and efficient opera

ti

on. For a thorough inspec

ti

on of

yo

ur machin

e,

please contact a dealer.

• Keep the machine away from fire or sparks.

•

When

using the

ma

chine for a long period of time,

if

you experience discomfort, redness

1111d

swelling

of

the fingers followed by whitening and loss

of

feeling, consult your physician bof(ltu

further use.

• Always wear ear protection, loud noise

fo

r long periods can make hearing debase and loud tu

lost hearing.

• Total face and head protection must

be

worn to prevent possible injury.

• Wear no-slip heavy duty work gloves to improve your g

ri

p

on

the brush cutter·handlo CltlVllO

also reduce the t

ra

nsmission

of

m

ac

hine vibration to y

our

hands.

•WARNING

:

Th

e c

utt

er area is still dangerous while the

ma

chine is coasting t

oo

ot

op

.

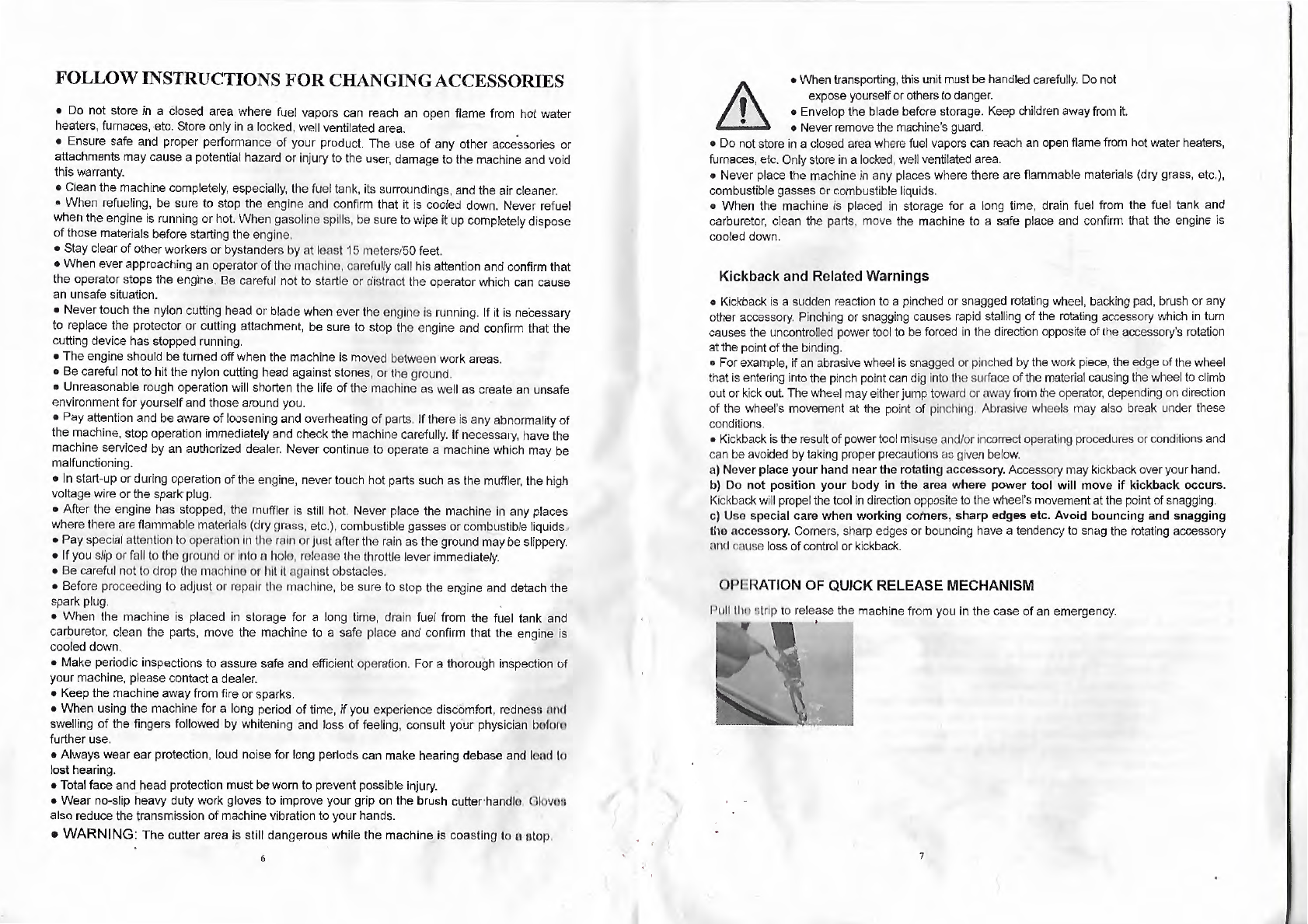

& •

When transporting, this unit must be handled carefully. Do not

expose you

rs

elf oro

th

ers to dan

ger.

• Envelop the blade before storage. Keep children away from it.

• Neverremove the machine's guard.

• Do not store in a closed area where fuel vapors can reach an open flame from hot water heaters,

furnaces, etc. Only store in a locked, well ventilated area.

• Never place the machine in any places where there are flammable mate

ri

als (dry grass, etc.),

combustible gasses

or

combustible liquids.

•

Wh

en the machine is placed in storage

for

a long time, drain fuel from the fuel tank and

carburetor, cle

an

the parts, move the machine to a safe place and confirm that the engine is

cooled down.

Kickback and Related Warnings

• Kickback is a sudden

re

action to a pinched or snagged rotating whee

l,

backing pad, brush orany

ot

her accessory. Pinching or snagg

in

g causes rapid sta

ll

ing

of

the rotat

in

g accessory which in turn

causes

th

e uncontro

lle

d power tool to be forced in the direction opposite

of

the accessory's rotation

at

the point

of

the bindin

g.

• Forexample, if an abrasive wheel is snagged or pinched by the work piece, the edge of the wheel

that is entering into the pinch point can d

ig

into the sur

fa

ce

of

the material causing the wheel to climb

out

or

kick

out.

The wheelmayeitherjump toward or nway from the operator,depending on direction

of

the wheel's movement at the point

of

pinching Abrasive wheels may also break under these

conditions.

• Kickback is the result

of

power tool misuse and/or incorre

ct

operating procedures or conditions and

can be avoided by

ta

king properprecautions as given below.

a) Ne

ve

r place

your

hand

near

th

e rota

tin

g

accesso

ry

. Accessory may kickback overyour ha

nd.

b)

Do

no

t

position

your

bo

dy

in

the

ar

ea

whe

re

power

t

oo

l

will

move

if k

ic

kb

ack

occurs.

Kickback will propel the tool in direction opposite tothe whee

l'

smovement

at

the point

of

snagging.

c) U

so

special care

wh

en

working

cotners

, sh

ar

p edges etc. Avoid

bouncing

and

snagging

tii

o access

ory

. Corners. sharp edges or bouncing have a tendency to snag the rotat

in

g accessory

nncl

e<

iuse loss of control orkickback.

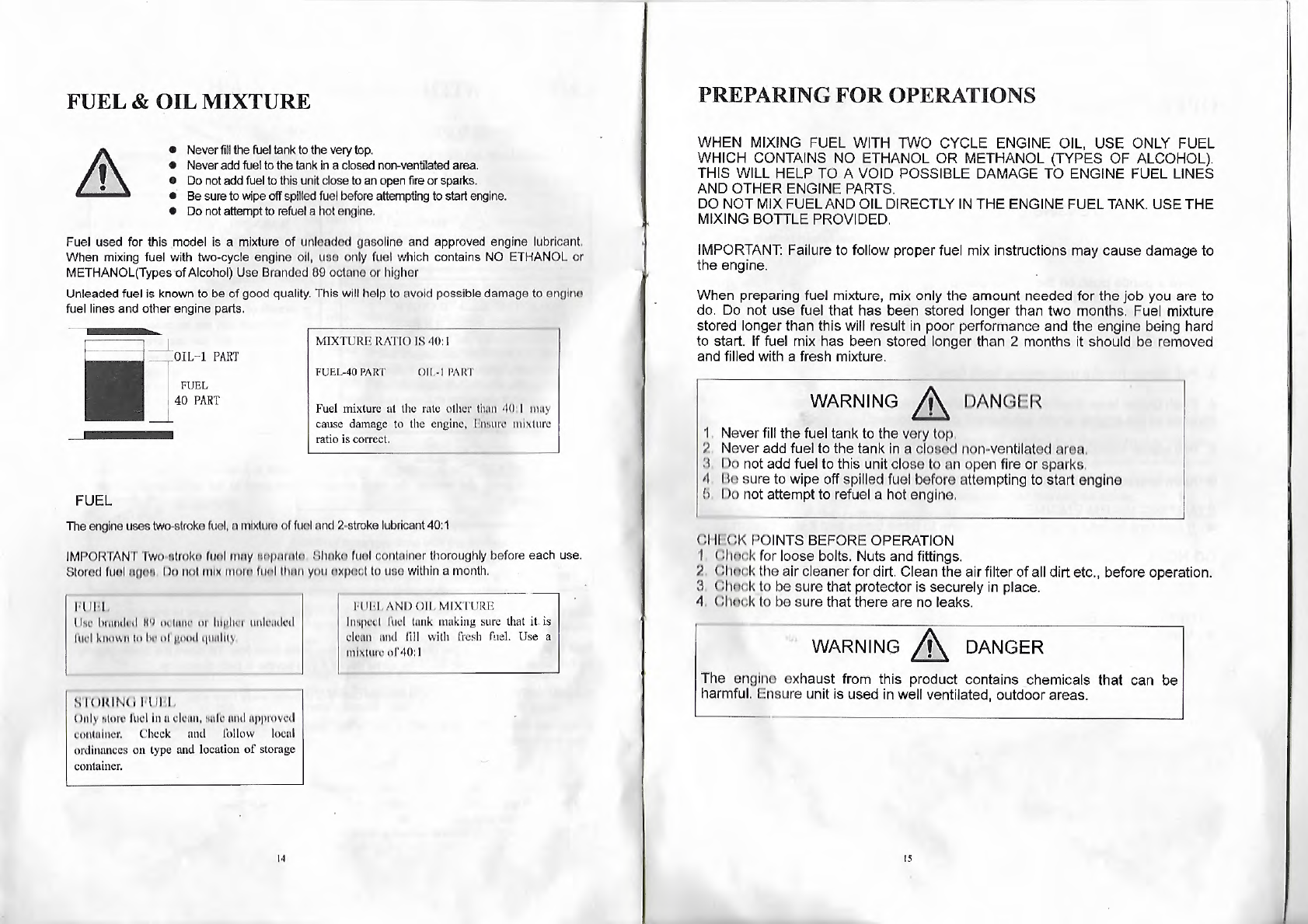

QPl:RATION

OF

QUICK RELEASE MECHANISM

IJ

11

ll

lli

ll

ntnp

10

release the machine from you in

th

e case of an emergency.

.