Shanghai Diesel Engine SC9DF User manual

Operation and Maintenance Manual

SC9DF Series Diesel Engine

Shanghai Diesel Engine Co., Ltd.

March, 2010

Precautions

1. The Operator of diesel engine is obliged to read the operation and maintenance instruction

carefully, and strictly follow the technical operation and maintenance procedure specified by

the instruction.

2. As ECU, common-rail pipe, fuel pump and injector are precise parts, any user is not allowed

to regulate and remove these parts without permission. Otherwise, the relevant commitment

services arising therefrom will be the sole responsibility of the user.

3. The diesel engine is forbidden to run without air filter, in order to avoid damage to the engine

due to unfiltered air entering the cylinder.

4. When cleaning diesel engine, it is not allowed to inject water directly at the sensor and

harness connectors with high pressure water gun,in order to prevent the sensor and ECU

burning out due to internal circuit breaks.

5. Overhaul of all the components and parts of the electrical control system shall be conducted

by professionals.

6. Notes for quality information feedback of diesel engine

In case the diesel engine is running abnormally or in disorder, users should report to the call

center of our company in terms of repairs and services by contact way provided in Warranty

cards, and provide the information about the model, order number, operating conditions,

cumulative running time of the diesel engine, when and where the failure occurs , so that we

can provide you with better services.

7. Notices for repair and replacement of the diesel engine parts:

Users shall follow the Repair & Maintenance Manual of SC9DF Series Diesel Engine in the

process of repair; Please purchase the parts subject to the specifications of parts catalogue of

the diesel engine, and only adopt the products approved by our original equipment

manufacturer in order to ensure performance, reliability and service life of the diesel engine.

Foreword

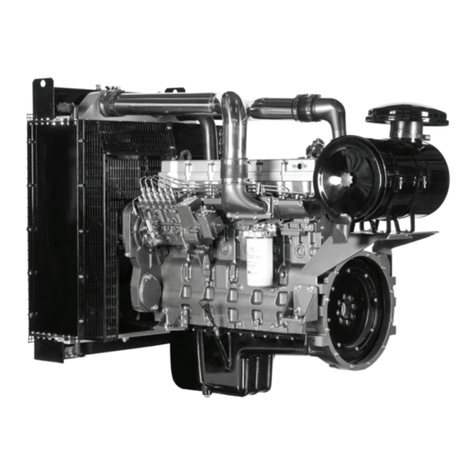

The SC9DF series diesel engine, an electronic-controlled four-valve diesel engine of high power, is

newly developed by Shanghai Diesel Engine Co., Ltd. and well-known foreign engine consulting

company on the basis of the D9 series diesel engine with advanced design concepts and technology. It is

compliant with the China Ⅲand Ⅳemission regulations. Featuring large power, good economy, good

reliability as well as convenient operation and maintenance, the engine is an ideal power for various

on-road and off-road vehicles.

The instruction mainly introduces the technical specification, operation, maintenance and common

troubleshooting, in hopes of offering related guidance to users.

Users also have to read the Repair & Maintenance Manual of SC9DF Series Diesel Engine for removal,

installation and repair of the diesel engine, and purchase relevant parts in terms of Parts Catalogue of

SC9DF Series Diesel Engine.

Users shall use appropriate fuel, lube oil and coolant as required in this instruction.

Users shall operate and maintain the diesel engine according to the requirement of the instruction, and

keep periodic maintenance records.

The instruction shall be always with the diesel engine and be passed to the new user when the engine is

transferred.

Comments on errors, omissions and improvements of the instruction will be appreciated.

Please send your letters to the R&D center of the company, ZIP: 200432.

Operation and Maintenance Instruction of SC9DF Series Diesel Engine

Contents

1 General

Model identification of SC9DF series diesel engine

Acronym and abbreviation definitions

Nameplate of the diesel engine

Outline drawing of SC9DFQ3 diesel engine

2 Main technical and performance specification of the diesel engine

Main technical specification of SC9DFQ3 diesel engine

Main performance parameter of SC9DFQ3 diesel engine

Main technical parameter of SC9DFQ3 diesel engine

Main bolt tightening specification of SC9DFQ3 diesel engine

Other technical requirements

3 Running and operation of the diesel engine

Startup of the diesel engine

Running the diesel engine

Running and operation of the diesel engine brake

Shutting down the diesel engine

Working scope of the diesel engine

4 Maintenance of the diesel engine

4.1 Maintenance sheet

4.2 Maintenance record sheet

4.3 Routine inspection and maintenance

4.4 Maintenance per 10,000 km, 250 h or 3 months

4.5 Maintenance per 20,000 km, 500 h or 6 months

4.6 Maintenance per 40,000 km, 1,000 h or 12 months

4.7 Maintenance per 80,000km, 2,000 h or 2 years

5 Failure Diagnosis & Treatment

Annex 1 Maintenance record sheet

Chapter 1 General

1.1 Model Identification of Diesel Engine

The diesel engine model denotes the following meanings:

SC 9 D F □ □ □

Example: SC9DF375Q represents 114 series 9-liter electronic-controlled four-valve vehicle diesel

engine of 375 HP compliant with China III made by Shanghai Diesel Engine Co., Ltd.

1.2 Acronym and abbreviation definitions

CRS Electronic-controlled High Pressure Common-rail System

ECU Electronic Control Unit

PCV Fuel Pressure Control Valve

TWV Two-way solenoid valve

Hg Mercury Column

kg Kilogram

kPa Kilopascal

kW Kilowatt

L Liter

MPa Megapascal

N Newton

N.m Newton. meter

Ppm Parts per million (number)

r/min Revolutions per minute

Emission standard

Application

Four-valve

114 series

Diesel engine emission (L)

Shangcai Power

Diesel engine power (horsepower)

1.3 Nameplate of the diesel engine

The nameplate of the diesel engine lists the special information of the diesel engine, which serves as the

main basis for the user to purchase the maintenance parts and for our company to conduct after-sale

technical service.

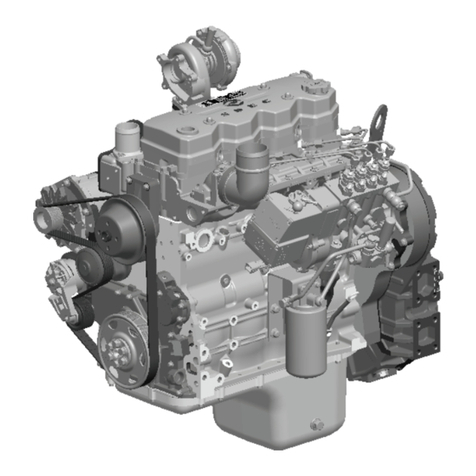

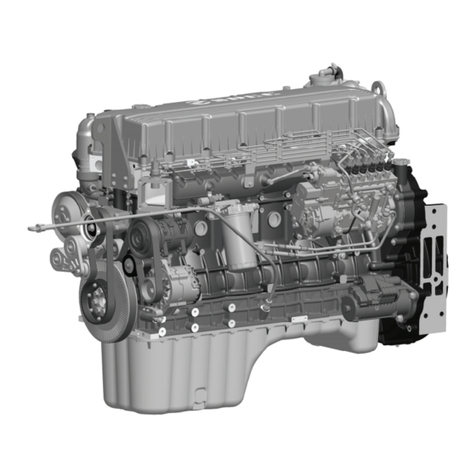

1.4 Outline drawing of SC9DF375Q3 diesel engine

Intake Side view

Ai i

Fuel inlet joint Fuel return

Compressor

Water drain

Exhaust outlet

Compressor air

outlet

Compressor air

inlet releasing

joint

Compressor

air inlet

j

oint

Z1/8 (for Oil

pressure

Fuel filter

Oil dipstick

M22×1.5

(

for electric heatin

g

)

Exhaust side view

Top view

En

g

ine water outlet

Warm water outlet

Flywheel

housing

Starting

motor

Water

drain

Oil drain

plug

Oil filte

r

Oil temp. sensor joint M15

Engine

w

ate

r inl

et

Output pulley

A

ir Bleedin

g

j

oint

Water filter control

i

h

Compressor air outlet

Compressor ai

r

inl

et

Turbine

outlet

Oil filler

Engine air

inlet

Chapter II Main Technical & Performance Specifications for Diesel Engine

2.1 Main technical specifications

1 Type Four stroke, water-cooled, in-line, charged and

inter-cooled intake air

2 Number of cylinders 6

3 Number of valves per cylinder 4

4 Bore × stroke, mm 114×144

5 Displacement, L 8.82

6 Fuel injection equipment High-pressure common rail

7 Compression ratio 17.3

8 Ignition order (from free end) 1-5-3-6-2-4

9 Crankshaft rotation direction (facing

flywheel end) Counterclockwise

10 Starting method Electric startup

11 Lubrication method Composite lubrication

12 Cooling method Forced circulation

13 Longitudinal

inclination allowed, °Forward/backward 25

14 Transverse

inclination, °

Exhaust side/intake

side 30

2.2 Main performance parameters

Unit SC9DF375Q3 SC9DF340Q3 SC9DF320Q3 SC9DF290Q3

Rated power kW 276 251 236 215

Rated speed r/min 2200

Max. torque Nm 1500 1430 1350 1200

Max. torque speed r/min 1300-1500

Idle speed r/min 700

High idle speed r/min 2500

Min. specific fuel

consumption g/kW·h ≤195

-15

Cold startup

- without aid

- with aid

℃

-35

Emission level China Ⅲ

Noise at 1m dB ≤96

Service life (B10) Km 8×106

2.3 Main technical parameters

Engine model

Technical parameters

SC9DFQ3

Valve clearance (cold state)

Intake valve, mm

Exhaust valve, mm

0.30

0.50

Valve timing (°) crankshaft angle

(Valve clearance: when intake is 0.30 mm

and exhaust is 0.55 mm)

Intake valve opening: 22.5°CA BTDC

Intake valve closing: 42.5°CA ABDC

Exhaust valve opening:69.5°CA BBDC

Exhaust valve closing: 34.5°CA ATDC

Lubrication system

Oil pressure, kPa

At idle (Min. allowance)

At rated speed (Min. allowance)

100

350

Pressure regulating valve opening pressure,

kPa 505

Filter bypass valve opening pressure, kPa 392

Highest oil temperature in oil sump, °C 95 - 122

Oil sump capacity, L (oil dipstick

“high”-“low”) 26.5-22.5

Total system capacity, L About 30

Cooling system

Thermostat

Opening temperature, °C

Full-open temperature, °C

Lift, mm

76-82

90

≥11

Top chamber temperature in water tank

Max, °C

Min, °C

95

70

Pressure of pressure cap (to adapt to the

top chamber temperature of 95°C in water

tank), kPa

50

Coolant pressure, kPa (at 2,200 r/min) 120

Coolant volume, L 12

Intake/Exhaust System

Max air intake resistance allowance (under

rated working condition), kPa (with dry air

filter)

6.2

Max pressure drop allowance from

compressor outlet to intake manifold, kPa 13.6

Max resistance allowance at the outlet of

turbocharger , kPa 10.0

Max exhaust temperature allowance, °C

750

(at the inlet of the turbocharger)

Fuel system

Max absorption vacuum of fuel transfer

pump, kPa 30

Max fuel return resistance, kPa 69

Fuel inlet flow temperature, ℃35-45

Electrical system

Min. battery capacity recommended

24V system: *

Cold start current at -18°C , A

(Reserve capacity current, A)**

900

(320)

Cold start current at 0°C, A

(Reserve capacity current , A)**

640

(240)

Starter motor

Voltage, V 24

Power, kW 7.5

* Two sets of 12V batteries are installed in series, and each cold start current is calibrated with at -18°C.

** In the case of given battery dimension, the electrode plate can determine the reserve capacity current,

which in turn determines the duration of continuous startup.

2.4 Other technical requirements

2.4.1 Fuel

Warning: the gasoline or alcohol is not allowed to be used with diesel, as their mixture may

cause detonation.

△Caution: as the parts of the fuel system are precise in size, and the fit tolerances small, it is

important to keep the diesel clean and get rid of impurities and moisture in the diesel in

order to prevent serious damage to the fuel injection pump and nozzle. Therefore, full

precipitation treatment of the diesel is necessary before using.

The quality of the diesel used by this series of diesel engines shall not be below the specification of the

national standard of light diesel fuel (GB252).

Main specifications of light diesel fuel (GB252)

Cetane number

Distillate

temperature ℃

Item

Number

≥

50%≤

90%≤

95%≤

Kinematic viscosity (20℃)

mm2/s

Sulphur content%(m/m) ≤

Moisture %(v/ v) ≤

Acidity mg KOH/ 100mL ≤

Ash %(m/m) ≤

Mechanical impurities %

Condensation point ℃≤

Cold filter plugging point, ℃≤

Flash point (close) ≥

10# 10 12

0# 0 4

-10#

3.0-8.0

-10 -5

65

-20# 2.5-8.0 -20 -14 60

Grade A

-35#

45 300 355 365

1.8-7.0

0.5 Trace 7 0.01 Non

-35 -29 45

-50# -50 -44

It is necessary to choose the diesel grade according to the working environment of diesel engine. Light

diesel fuel with high condensation point shall be used in hot regions, while that with low condensation

point in cold regions. Condensation point of diesel should be at least 10℃below the lowest ambient

temperature in the regions where the diesel engine is used, so as to ensure necessary liquidity.

In order to provide sufficient lubrication for the fuel system, the fuel viscosity should be maintained at

1.3mm2/s or above during the diesel engine is working.

2.4.2 Lube oil

As per the specification, SC9DF series diesel engine shall apply the special oil for D6114 diesel engine

provided by Shanghai Diesel Engine Company or the oil above CF level.

The oil shall be properly used according to different ambient temperatures. The range of ambient

temperatures, to which the diesel engine oil of different viscosity grades is applicable, is shown in the

following figure:

△Caution: The diesel engine oil with appropriate viscosity shall be used according to the local

environmental temperature.

△Caution: In order to ensure oil service characteristics, it is recommended to use special oil for

D6114 series diesel engine produced by Shanghai Diesel Engine Company for SC9DF series

diesel engine.

For most areas, 15W/40 CF-4 oil is recommended. For those areas where the ambient temperature is

below -15℃, 10W/30 CF-4 is recommended in order to ensure easy start-up and sufficient oil provision.

In the cold areas where the diesel engine keeps working below -23℃, and no warm-keeping measures

can be taken when it stops, 5W/50SJ/CF CF-4 oil with good low-temperature characteristics shall be

used.

△Caution: The oil with low viscosity is helpful to start up the diesel engine. Due to abrasion,

continuous use can affect the service life of diesel engine, so try not to use or limit the use of

such oil.

Oil deterioration and replacement interval

The oil should be replaced when the diesel engine has been running for 350h or the vehicle has been

driving for 22,000 km generally, while for the diesel engines working in the environments with urban

public transportation, heavy dust, highland, extremely cold weather, it should be replaced when the

diesel engine has been running for 250 h or the vehicle has been driving for 10,000 km.

△Caution: Please don't extend the oil replacement interval, or it can affect service life of diesel

engine due to corrosion, carbon deposition and abrasion.

A

ll seasons

Winter

environment

The North

Pole

environment

2.4.3 Coolant

The coolant for SC9DF series diesel engine shall be the composite liquor mixed by certain ratio of

antifreeze and DCA4 chemical additive.

As the antifreeze can prevent the coolant from freezing and increase the boiling point of coolant, we

require the antifreeze be used under any weather conditions.

Warning: Water and antifreeze both have no protection for the cooling system. It is not

allowed to separately use them as the coolant without adding DCA4 chemical additive,

otherwise, it can result in corrosion, cavitation erosion, scale depositing in the cooling

system, block of the engine vents, causing local overheat, thus to cause serious accident

such as piston scuffing, cylinder head cracking, seizure of injector, burnout of valve, etc.

Antifreeze

As specific heat and thermal conductivity coefficient of water and ethylene glycol is greater, it is

recommended to use their mixture as antifreeze in diesel engine. The contents of silicate (sodium

silicate anhydrous), oxide and acetic acid in antifreeze shall not be higher than 1,000 PPM, 5 PPM and

100 PPM respectively.

Adjust the ratio of water and ethylene glycol in order to get the antifreezes with different ice point, i.e.

freezing points. Under most climates, relation of volume ratio and freezing point of ethylene glycol and

water as follows:

Ratio of

ethyleneglycol

and water

10:90 20:80 30:70 40:60 50:50 55:45 60:40 65:35

Freezing point,

°C

-3.8 -7.5 -14.1 -22 -32 -42 -55 -64

The recommended ratio of water and ethylene glycol is 50:50, whereas, the freezing point shall reach

the lowest level (e.g. the antifreeze realizes its utmost anti-freeze ability) when water/ ethylene glycol

ratio is 32:68. Under no circumstances shall the ratio go beyond this value, otherwise, the freezing point

can arise, and the density of ethylene glycol will be over high. This may cause solid matter subside. As a

result, the sediment on the part surface of the coolant system will block the heat sink and cause leakage

of pump seal ring. The over high ratio of ethylene glycol can also degrade the thermal conducting

performance. Therefore, appropriate density of ethylene glycol in antifreeze shall be 40-60%.

In general, the ice point of selected antifreeze shall be 10℃lower than the lowest temperature of the

area where the engine is used.

The ice point of antifreeze can be checked precisely with a refractometer, or be measured with a test

paper specially designed for antifreeze.

△Caution: It is required to discard or replace the antifreeze every 385,000 Km, 6,000 h or 2 years

(whichever comes first) in order to remove those harmful chemical sediments.

DCA4 chemical additive

As water and antifreeze both have no protection for the cooling system, it is not allowed to use either of

them as a coolant.

It is recommended to add DCA4 chemical additive with specified density to diesel engine coolant. DCA4

chemical additive can protect the cooling system from cavitation erosion, corrosion and scale depositing,

and restrain and eliminate air bubbles, etc. DCA4 chemical additive and concentration test package are

available from the after-service net of SDEC. Refer to the instructions provided with this test package

before application.

△Caution: never touch the test paper with hand; keep the DCA4 chemical additive away from

contact of eyes, skins or cloths; the test should be done in a bright place without contaminating

the test paper and containers used.

2.5 Main-bolt and -nut tightening torque and methods

Table 1 Torque specification for main fastening bolt

No. Name Thread spec. Final torque (Nm) Tightening method

1 Main bearing cap bolts M16-4h6h

125±5 N·m

Final angle

210°±5°

First: 50 N·m

Second: 120-130 N·m

Third: angle 210°±5°

2 Cylinder head bolts

M14-4h6h

115±5 N·m

Final angle

240°±5°

First: 50N·m

Second: 110~120 N·m

Third: angle 240°±5°

3 Connecting rod bolts

M12×1.25

-4g6g

60±5 N·m

Final angle

150°±3°

First: 60±5 N·m

Second: angle 150°±3°

4 Flywheel bolts

M12×1.25

-5h

70±5 N·m

Final angle

25°±3°

Tightened twice alternately

First: 70±5N·m

Second: 25°±3°

5 Vibration damper bolts M14×1.5

-5h6h

100±5 N·m

Final angle

30°±3°

First: 50±5 N·m

Second: 100±5 N·m

Third: angle 30°±3°

6 Fuel pump gear nut M14×1.5 64±5 N·m 64±5 N·m

7 Air compressor power

output drive gear nut M16 134±13 N·m

8 Fuel pump flange nuts and

bolts M8 32±3 N·m

9 Oil pump bolts M8 32±3 N·m

10 Injector bolts M8 31±2 N·m

11 Injector inlet pipe nuts M24 52.5±2.5 N·m

12 Engine support bolts M12 112±10 N·m

13 Rocker arm shaft bolts M10-6h 55±3 N·m

14 Air compressor power

output gear nuts M12 77±7 N·m

15 Flywheel bolts M12 112±10 N·m

16 Turbocharger bolts M10 45±4 N·m

17 for fastening the Alternator

pulley nut M16 80±8 N·m

18 Fuel filter 13/1″M16 Turn 3/4 circle

after contact

19 Inlet and outlet joint nuts of

fuel filter M14 24±3 N·m

20 High pressure fuel pipe joint

nuts M12 45±3 N·m

21 Fuel pump fuel return banjo

bolts M10 10±2 N·m

22 Fuel pump fuel inlet banjo

bolt M14 18±2 N·m

23 High pressure common rail

fuel return banjo bolt M10 16±2 N·m

24 Fuel filter sensor M11 20±3 N·m

25 Lifting plate bolts M12 77±6 N·m

26 Oil filter head M32 40±10 N·m

27 Oil drain plug M18 80±4 N·m

28 Heater plug in oil sump M22 80±4 N·m

29 Oil pressure regulating

valve M34 80±4 N·m

30 Oil suction pipe (flange) M10 45±4 N·m

31 Oil suction pipe (support) M6 9±1 N·m

32 Rocker arm adjusting

screws and nuts M10 45±4 N·m

33 Turbocharger oil inlet pipe M12 32±4 N·m

34 Fuel bump idle gear clamp

bolt M8 32±3 N·m

35 Mid cylinder head cover

bolts M8 24±3 N·m

36 Cylinder head cover bolts M8 24±3 N·m

37 Exhaust manifold bolts M10 50±4 N·m

Caution: the connecting bolt can be used once.

For bolts unlisted in Table 1, the torques in Table 2 can be applied. Tapered screw plug is tightened with

the torques in table 3, and pipe banjo bolts are tightened according to the torque in table 4.

Table 2 Approximate tightening torque for common screw plug and standard bolt

Performance

level 8.8 10.9

Torque TorqueDiameter of bolt

(mm) Cast iron Aluminum Cast iron Aluminum

6 9 7 14 11

8 25 18 32 25

10 40 30 60 45

12 70 55 105 80

14 115 90 160 125

16 180 140 240 190

18 230 180 320 250

Note: the torque values given in the above table only applies to the threads of bolts and nuts properly

lubricated.

Table 3 Recommended tightening torque for tapered screw plug

Specification of screw plug Torque N⋅m

Thread Effective thread (outer

diameter) Cast iron or steel Aluminum

1/16 8.1 15 5

1/8 10.4 20 15

1/4 13.7 25 20

3/8 17.3 35 25

1/2 21.6 55 35

3/4 26.7 75 45

1 33.5 95 60

11/442.2 115 75

11/248.3 135 85

Table 4 Recommended tightening torque for pipe banjo bolt

Specification M8×1 M10×1 M12×1.25 M14×1.5 M16×1.5 M18×1.5 M20×1.5 M22×1.5

Torque (N⋅m) 13 22 32 45 50 65 85 105

Note: The torque described above is applicable to steel, cast iron or aluminum substrate.

Chapter III Running & Operation of Diesel Engine

Oil, fuel and coolant with suitable specifications shall be chosen according to specific application

environment and conditions before running the diesel engine. The selected oil, fuel and coolant shall

comply with technical specifications as given in the Article 2.4.

Correct and reasonable application will provide a longer service life, better work performance and high

economical efficiency for your diesel engine.

3.1 Startup of the diesel engine

3.11 Normal startup

zCheck the throttle for operational flexibility

zDisengage all the drive system, and move the transmission gear (if equipped) to the neutral

position.

zWait until the preheating indictor lamp goes out.

zNo need to press the throttle when starting.

zCaution: The start time shall be less than 30 s to avoid damages of the starting motor. The interval

of two startups is 2 mines (only for the electrical starting motor).

zThe time of each startup is usually 2-3 s.

zCheck preheating device and electrically controlled fuel system if the engine is failed to start to run

after three consecutive startups.

zThe diesel engine will run at the idle speed of 700 RPS after being started. (Under low temperature

condition, the idle speed will go up automatically to speed up the engine warm-up. The diesel

engine speed will automatically come back to normal idle speed when the water temperature

reaches 60℃)

zThe oil pressure must be indicated on the pressure meter within 15 s after the engine has been

started, if not, immediately turn off the diesel engine in order to avoid being damaged. And check the

oil level of diesel engine.

zWhen the diesel engine is started from cold state, increase the speed slowly to ensure full

lubrication of all bearings; do not fully step down the throttle pedal at unloaded condition.

3.1.2 Low temperature startup

Some diesel engines of this series are equipped with an auxiliary intake pre-heater, which is used for

startup at a low temperature. It can heat up the intake air automatically when the temperature of the

coolant in the diesel engine is below -10℃.

zInsert the key and turn it from OFF position to ON position before starting to electrify the pre-heater,

and the indicator lamp lights up.

zTurn the electrical key from ON position to START position to start the diesel engine when the

indicator lamp blinks and goes off.

△Caution: SC9DF series electrically controlled diesel engine can usually be started quickly and

run smoothly even in a very low temperature environment. For those machines to be stopped

outside, the winter protections and specific warm-up time shall be provided. The lube oil, fuel

and coolant must be used properly according to different temperature ranges of local areas

where the vehicle will be working.

3.1.3 Startup after long time parking or oil replacement

zAfter the oil has been replaced, or the vehicle has been parked for more than 30 days, refill the

lubrication system, and then start the diesel engine.

zClose the throttle in case the diesel engine starts by ignition.

zRotate crankshaft by the starter motor until the oil pressure gauge reads the pressure.

zOpen the throttle.

zStart the diesel engine as per the start procedures specified in 3.1.1 (Normal start) or 3.1.2 (Low

temperature starting).

zDischarge the air in the fuel system according to descriptions in article 4.4.2.

z

3.2 Running the diesel engine

3.2.1 New diesel engine running-in

New diesel engines or those after overhaul can be put into full-load service only after a specific period of

running-in, otherwise, their running reliability and service life will be affected unfavorably.

Automobile diesel engine: For the first running-in of 160 km, the speed of diesel engine shall be

controlled within 1,500-1,800 r/min, running-in at high gear. And in this period, its continuous running at

idle speed shall not be longer than 5 min anytime.

Non-vehicle diesel engine: For the non-vehicle diesel engine, it shall be run according to the following

requirements in the first three hours after assembly:

1. Continuous running time of the diesel engine at idle speed shall not be more than 5 min anytime.

2. It's appropriate to run under rated speed and 75% of full load for the diesel engine.

3. Continuous full-load and full speed running shall not be longer than 5 min at any time.

△Caution: the oil or oil filter shall be replaced after new diesel engine is running for 80-100 h or

1,500-2,500 km accumulatively.

3.2.2 Normal operation

Continuous full-throttle running at the speed lower than maximum torque speed shall not longer than 1

min.

zCheck oil pressure and coolant temperature frequently during engine operation and see Chapter II

"Main Technical & Performance Specifications for Diesel Engine" for details. If the running-in

parameters is not met, stop the engine for check, or repair it if necessary.

△Caution: The diesel engine will be damaged in case of continuous operation when the coolant

temperature is lower than 60℃or higher than 100℃.

zIn the case of too high temperature of coolant, decrease the engine speed or change to the lower

gear or both until the temperature recovers to the range of normal working conditions, otherwise,

find the cause and trouble shoot the problems as specified in Chapter V "Troubleshooting

Guidelines".

zMost failures will develop with a sign, i.e. observe the performance change of the diesel engine,

sound of abnormity, or check if one of following signs occurs. If so, it's necessary to repair it.

-misfire -abnormal smoke color

-vibration -power loss

-abnormal noise -oil consumption increases

-sudden change of oil pressure or -fuel consumption increases

coolant temperature

Caution: the diesel engine will be damaged in case of running at overspeed (the speed

exceeds the maximum value under empty load).

In order to avoid overspeed, the gear box and brake shall be used to control the speeds of vehicle and

diesel engine when the vehicle is driving down the slope.

3.3 Operation and control of diesel engine brake

Some of SC9DF series diesel engines are equipped with in-cylinder braking system, which can be used

to reduce the loads on the vehicle braking system effectively, so that you can decrease and control the

vehicle speed without pressing down the accelerator pedal, especially when driving down the slope, and

avoid overheating of breaking drum to ensure driving and life safety, as well to reduce vehicle running &

maintenance costs.

Braking system can provide "High" or "Low" braking capacity, which can be controlled by selecting the

switch ("OFF", "LOW", "HIGH"). The system must meet the following three conditions during operation:

1)The switch is in ON position.

2)The clutch is in OFF position.

3)Fuel shut-off instruction exists.

That's to say, when driving, the brake switch is in ON position and the clutch is in OFF position; the

braking system will operate automatically as long as you release the accelerator pedal; when you step

down the accelerator pedal again, the braking system will stop working automatically; therefore, the

system can help you decrease the vehicle speed easily.

△Caution: The following principles shall be followed during activation of the brake:

1) Make sure the engine has been warmed up before activating the brake. Make sure to shift the

switch from LOW to HIGH.

2) Prohibit activating the brake during driving on wet road; otherwise, the vehicle will skid and

be out of control.

3) Suitable brake gears shall be chosen for different road conditions to ensure that enough

deceleration capability will be provided for the vehicle to run at a suitable speed: the braking

capability is better when the engine is operating at a high speed, shift to lower gears, but the

overspeed should be avoided. (it is recommended to choose the same gear when driving up

and down a slope)

4) Suitable brake gears shall be chosen according to quickly changed road condition: the brake

should be deactivated until the road condition has been improved in case of the vehicle

skids with the brake being activated; when reactivating the brake, the same sequence from

"Low" to "High" shall also be followed.

3.4 Stopping the diesel engine

zAfter the diesel engine starts has run with full loads, keep it running for 3-5 min at idle speed before

stopping it, so that the diesel engine can cool down gradually and evenly.

zTurn the diesel engine ignition key switch to "OFF".

zUnless it is necessary, no emergency stop should be done while running under high loads, or

serious failures will occur due to overheating.

3.5 Working range of the diesel engine

△Caution: The diesel engine can operate under the transitional working conditions at a speed

above the maximum torque speed, which is in line with recommended strategy for economical

running. If the vehicle is running with full throttle at a speed below the maximum torque speed

for a long time, this will shorten the engine service life, causing overhaul or cause serious

damage to the diesel engine, which is treated as an abuse behavior.

△Caution: The diesel engine will be operating at a speed below the maximum torque speed

during shifting gears. This is due to different transmission ratios among transmission gears.

However full-throttle running at a speed below the maximum torque speed shall not be longer

than 1 min.

△Caution: The diesel engine will be damaged seriously if the speed exceeds 2,500 RPM. When

sliding from the steep slope, control the vehicle and diesel engine speeds with combination of

transmission gear and diesel engine, or with the foot brake; the exhaust brake function shall be

applied if equipped.

Chapter IV Repair & Maintenance of Diesel Engine

4.1 Repair and Maintenance schedule

It is recommended to maintain the SC9DF series electronically controlled diesel engine according to the

"Repair and Maintenance Procedures" specified in this Section. The maintenance interval shall be

shortened appropriately in case of the diesel engine is always operating at the ambient temperature

lower than -18℃or higher than 38℃, or running in dust environment, or working in the case of frequently

stopping vehicle.

Maintenance Schedule for SC9DF Series Electronically Controlled Diesel Engine

Daily maintenance

Every 10,000

kilometers, 250

hours or 3 months

Every 20,000

kilometers, 500

hours or 6 months

Every 40,000

kilometers, 1,000

hours or 1 year

Every 80,000

kilometers, 2,000

hours or 3 years

Replacement

●Oil

●Oil filter cartridge

●Oil

●Oil filter cartridge

●Diesel filter

(include fine filter

and oil-water

separator)

●Oil

●Oil filter

cartridge

●Diesel filter

(include fine filter

and oil and water

separator)

●Oil

●Oil filter

cartridge

●Coolant

●Diesel filter

(include fine filter

and oil-water

separator)

Adjustment

●Valve clearance ●Valve clearance

check

●Check oil level

●Check coolant

level

●Check belt for

being damaged

●Check drive

system of the fan

●Check oil and

water separator

●Visually check for

leakage

●Fastening

condition of

attachments

●Check smoke

color of the engine

●Check indicator

light for failure

●Air filter

●Air intake system

●Air intake

intercooling system

●Wiring harness

●Sensor

●Air filter

●Air intake system

●Air intake

intercooling

system

●Coolant (DCA4,

anti-freeze fluid

concentration)

●Air bleed of fuel

system

●Wiring harness

●Sensor

●Air filter

●Air intake

system

●Air intake

intercooling

system

●Coolant (DCA4,

anti-freeze fluid

concentration)

●Air bleed of fuel

system

●Fan

transmission

bearing

●Belt tensioner

bearing

●Belt tension

●Wiring harness

●Sensor

●Air filter

●Air intake

intercooling

system

●Air compressor

●Coolant (DCA4,

anti-freeze fluid

concentration)

●Fan hub

●Fan

transmission

bearing

●Belt tension

pulley bearing

●Belt tension

●Wiring harness

●Sensor

●Supercharger

●Damper

The users should make periodical maintenance and keep the record in the format specified in Annex 1.

Note: It’s recommended to make periodical maintenance needed on those items in the authorized

maintenance station.

4.2 Daily check and maintenance content

This manual suits for next models

3

Other Shanghai Diesel Engine Engine manuals

Shanghai Diesel Engine

Shanghai Diesel Engine H Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine SC9D Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine H Series Manual

Shanghai Diesel Engine

Shanghai Diesel Engine 6114 Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine SC11CB User manual

Shanghai Diesel Engine

Shanghai Diesel Engine E Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine D Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine E Series User manual