Shanghai Diesel Engine SC11CB User manual

Operation and Maintenance Manual

ForSC11CB Diesel Engine

121-SM-06+A

ShanghaiDieselEngineCompany, Ltd

January 2008

Foreword

SC11CB dieselengine,jointlydevelopedbySDECincooperationwithFEVofGermanyon

thebasis of 6C121 seriesdieselengines,isanewdieselengineoflowemissionandlowfuel

consumption.Withturbochargedorturbocharged/inter-cooled,theenginepowerrangesfrom162

kWto235 kW.ComplyingwithChinesenationalemissionstandardsofstage1andstage2,

SC11CB dieselengineisanidealpowerforapplicationsofvariousconstructionmachinery,

generatorset,marineandvehicle.

SC11CB dieselengineadoptsmetricthreadsystemtoall threadedpartsfortheconvenience

ofapplication.

Forbetterandsafeoperationoftheengine,readandstudytheinformationandinstructionsin

thisManualcarefullybeforestartingoperation.

Somespecificationsand illustrationsinthispublication mayslightlydifferfromthoseof

yourenginebecauseofcontinuousimprovementonperformanceandstructurethatmayhave

causedchangestoyourengine.Thechangeswill becoveredinnextedition.

Yourcommentsandsuggestionsonthemanualwill bemuchappreciated.Pleasecontactour

sales service center.

SafetyInformation

1. Providesecuredprotectiveguardsandcoversforall externalrotating partstopreventpersonal

injury.

2. Stoptheenginebeforeconductingadjustmentorrepairtoit and itsdrivedevices.

3. Donotwearlooseworkclotheswhenworkingaroundengineormachine.

4. Wearearsplugstopreventhurtofhearingwhiletheengineisrunning inanenclosedshop.

5. Wearprotectiveglasses,workclothes, safetyhatandotherprotectiveequipmentwhen

necessary.

6. Wearprotectiveglassesandworkclotheswhilecleaningwithpressureairorpressure

water. Themaximumairpressureandwaterpressureshouldnotexceed205 kPaand 275 kPa

respectively.

7. Donotsmokewhenrefillingfueltopreventburningoffuelfumes.

8. Donotsmokewhencheckingtheelectrolytelevelofabatterybecauseit mayemit flammable

fumes.

9. Avoidcontactingelectrolytewithyourskinandeyeswhilerefilling becauseit isacid.

10. Besurethereisproperventilationintheplace whereengineisunderoperation.

11. Donotattempttodorepairthatyoudon tunderstandtoavoidabadconsequence.

12. Removeall tools,wiresandotherarticlesfromtheenginebeforestarting.

13. Wipeoff any overflowingoflubeoil, fuel, coolantandotherliquidson theenginebefore

starting.

14. Adoptaproperandsafetymethodfordisposalofwasteoil.

15. Keepoilyragsawayfromtheengineandputtheminafireproofcontainer.

16. Donotkeepflammableliquidsneartheengine.

17. Disconnectandwrapbatterygroundingwirewithinsulatetapebeforerepairing the engine to

preventunexpectedenginestarting.

18. Disconnectthebatterytotheenginewhenit will notbeenusedforalongtimeorwhenit is

underrepairtoavoidunexpectedstarting.

19. Donotstarttheenginewhenthelinkageofagovernorisdisconnected.

20. Bepreparedforstoppingairsupplyatanytimeforanewlyrepairedengine, andstopair

supplyimmediatelyoncetheenginerunsawayafterstarting.

21. Becarefulwhenrefillingcoolantintoclosedcoolingsystemwhiletheengineisrunningto

avoidbeinghurtbycoolantsteam. Openthepressurecaponlywhenthecoolanttemperature

isbelow70 .

NecessaryInformationforEngineOperation

1. Checkanewlyinstalledengineforleaksbeforestarting.

2. Makegood “Starting Preparation”foreveryenginestarting.Remembernottoapplyanyload

whenstartingengine.

3. Breakintheenginefor60 hoursbeforetheoperationofanewengineoranoverhauledengine.

4. Runtheenginewithoutload for3~5minafterstartingand thenincreaseload gradually. Runthe

enginewithfull loadonly whentheenginecoolanttemperaturereachesover75 , oil temperature

over50 and oil pressureover0.4 MPa.

5. Disassembletheturbooilinletpipeofturbochargerandfilltheturbochargerwith50~60 ml

lubeoil fromoilinletportwhenoperatinganewengineoranenginewithreplacedturbocharger

topreventtheturbobearingfrombeingdamagedbecauseofnolubeoil.

6. Donotusemixtureoflubeoilswithdifferentspecificationswhenrefilling.

7. Donotstarttheenginewithoutairfilter.Airfiltercanpreventdustandparticlesintotheengine

thusavoidingearlyenginewear.

8. Observeengineoperation andvaluesindicatedby all gageindicatorswhentheengineruns.

Haveemergentenginestoppingmeasuresandtakethemwhenevernecessarytoavoidengine

seizingarisingfromengineoverheatduetolackofcoolantordecreasedoil pressure.

9. Checkfuellineforleaksregularlywhiletheenginerunsbecausethefuellineisontheexhaust

sideoftheengine. Removeanyproblemstimelytoavoidfire.

10. Donotruntheenginewhenadjustingtheenginebelttensionanddrivedevice.

11. Unloadengineslowlytopreventtheenginefromrunningawayduetomalfunctionofthe

governorresultingfromsuddendecreaseofload.

12. Replacethemalfunctionedthermostattimelyanddonotoperatetheenginewithoutthermostat.

13. Drainall coolantintheengineafterit isstopped,especiallywhentheengineisusedunder

freezingcoldweatherwithoutusinganti-freezeadditivetopreventtheblockandotherrelevant

partsfromfrozen fracture.

14. Checkall connectingboltsandnutsregularlyforloosening.

15. Donotremoveanyleadsealsontheengineandmakeadjustment atdiscretion.Sendthe

enginetoresponsibleshopsforadjustmentorrepairifnecessary.

16. Performdailyandthree-levelmaintenancesaspertherequirementsandinstructionsofthis

Manual.

TableofContents

Foreword

Safety Information

OperationInformation

1GeneralInformation ……………………………………………………………………1

EngineViewsandInformation ………………………………………………………… 4

EngineIdentification …………………………………………………………………… 4

1.2.1EngineNameplate ………………………………………………………………… 4

1.2.2 EngineModel ……………………………………………………………………………4

1.2.3PartNumber ………………………………………………………………………………5

1.3EngineSpecifications ………………………………………………………………………5

1.3.1BasicEngineParameters …………………………………………………………………5

1.3.2 MainEnginePerformanceData …………………………………………………………6

1.3.3 EnginePerformance Curves ………………………………………………………………8

1.4 ClearancesandWearLimitsofMainComponents ………………………………………10

1.5 TorquesforMainBolts …………………………………………………………………11

1.6 TorqueforGeneralFasteners ………………………………………………………………11

2. MainComponentsAssemblyData ………………………………………………………13

2.1 CylinderBlock …………………………………………………………………………13

2.2 CamshaftBearings …………………………………………………………………………14

2.3CylinderLiners …………………………………………………………………………14

2.4 ConnectingRods …………………………………………………………………………16

2.5 PistonsandPiston Rings ………………………………………………………………17

2.6TimingGears ………………………………………………………………………………18

2.7 Camshaft …………………………………………………………………………………18

2.8 ValveRockerArmsandTappets …………………………………………………………19

2.9Valves ……………………………………………………………………………………20

2.10CylinderHeadand ValveCover ………………………………………………………21

2.11 Crankshaft ………………………………………………………………………………22

2.12 FlywheelHousing ……………………………………………………………………23

2.13 Flywheel ………………………………………………………………………………26

2.14Alternator ………………………………………………………………………………28

2.15Starting Motor …………………………………………………………………………29

3. MainEngineSystem ……………………………………………………………………30

3.1 FuelSystem ………………………………………………………………………………30

3.2 Intakeand ExhaustSystem ……………………………………………………………31

3.3Lubrication System…………………………………………………………………………33

3.4Cooling System …………………………………………………………………………35

3.5 ElectricalSystem …………………………………………………………………………36

3.5.1 StartingMotor …………………………………………………………………………36

3.5.2 ChargeableAlternator …………………………………………………………………37

3.5.3Battery ………………………………………………………………………………37

3.5.4 Shut-off Solenoid ……………………………………………………………………37

3.5.5Wiring Arrangement ………………………………………………………………37

3.6 ColdStartAid ……………………………………………………………………38

4EngineOperation……………………………………………………………………… 39

4.1 Fuel …………………………………………………………………………………39

4.2Lubricating Oil ………………………………………………………………………39

4.3 Coolant ………………………………………………………………………40

4.4EngineStarting ………………………………………………………………………41

4.5 EngineOperationand Stopping ……………………………………………………42

5InspectionandAdjustment ……………………………………………………43

5.1ValveLash ………………………………………………………………………43

5.1.1 InspectionofValveLash ……………………………………………………43

5.1.2AdjustmentofValveLash ……………………………………………………44

5.1.3 Observation ofValveRotation ……………………………………………………45

5.2 InjectionTiming ………………………………………………………………………46

5.2.1 TDCon CompressionStrokeforNo1Piston …………………………………46

5.2.2 Inspection andAdjustmentofFuelInjectionTiming …………………………………46

5.3 InjectionNozzle ………………………………………………………………………48

5.3.1 NozzleOpening PressureTest ………………………………………………………48

5.3.2Disassemblyand Cleaning …………………………………………………49

5.3.3 TipLeakageTest ………………………………………………………………………49

5.3.4SprayQualityTest ………………………………………………………………………50

5.3.5 LeakTestofNozzleCouples ……………………………………………………50

5.4 LubricationSystem ………………………………………………………………………50

5.4.1OilConsumption high ……………………………………………………50

5.4.2 Oil PressureLow ………………………………………………………………………51

5.4.3Oil PressureHigh ………………………………………………………………………52

5.4.4 OilPumpBearing Worn ……………………………………………………52

5.5 Belt Tension ………………………………………………………………………52

6. Maintenance ……………………………………………………53

6.1 MaintenanceWhenNecessary …………………………………53

6.1.1 CleaningCoolingSystem ……………………………………………………53

6.1.2AirFilterService ……………………………………………………54

6.1.3 FuelFilterService ……………………………………………………57

6.2Maintenance Schedule ……………………………………………………59

6.3 DailyMaintenance(Every8Operating Hours) …………………………………60

6.4 Every50 Operating Hours ……………………………………………………61

6.5 Every250Operating Hours ……………………………………………………62

6.6 Every500Operating Hours ……………………………………………………65

6.7 Every1000Operating Hours……………………………………………………66

6.8 Every2000Operating Hours ……………………………………………………66

7Troubleshooting ………………………………………………………………………69

7.1 GeneralRequirementson Troubleshooting ………………………………………………69

7.2 CausesandCorrections …………………………………………………………………69

1

1. General

1.1 EngineViewsand Information

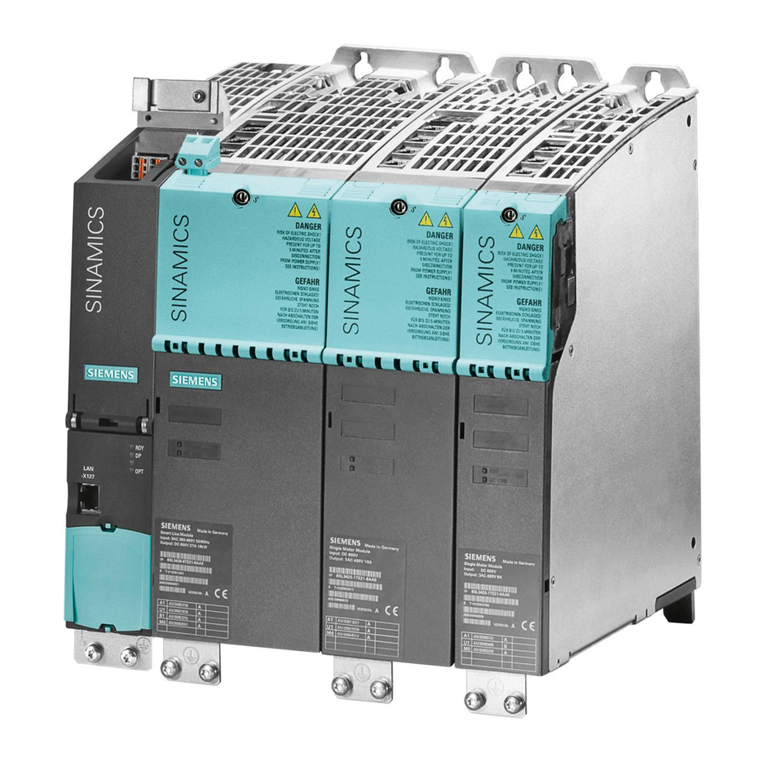

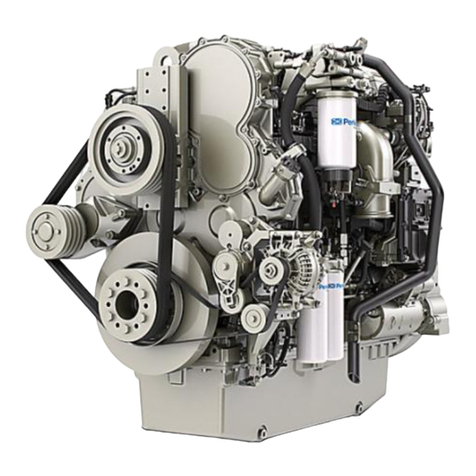

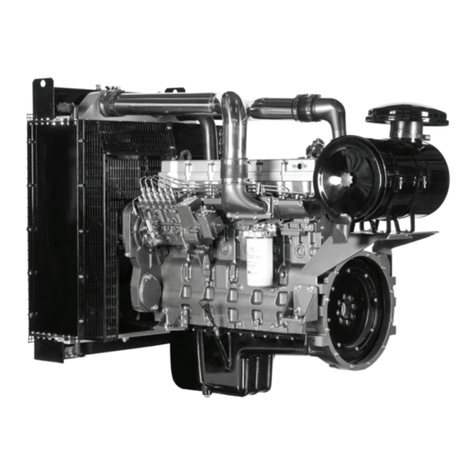

Fig1-1 SC11CBDieselEngineforConstructionMachinery(Turbocharged)

2

Fig1-2 SC11CBDieselEngineForVehicle(TurbochargedandInter-cooled)

3

Fig1-3 EngineViewandAuxiliaryArrangementofSC11CB DieselEngine

(1)Airfilter(2)Turbocharger(3)Turbineoutletpipe(4)Muffler

(5)Crankcasebreather(6)Fan(7)Liftingplate(8)Oil refillingport

(9)Fuelinjectionpump(10)Fuelfilter(11)Fuelprimingpump

(12)Crankcaseventpipe(13)Connectionforspeedsensor(14)Pulleybelt

(15)Flywheelhousing(16)Oil drainport(17)Oil dipstick(18)Oil filter

(19)Oil cooler(20)Torsionalvibrationdamper(21)Waterpump

4

1.2 EngineIdentification

1.2.1 EngineNameplate

SC11CB dieselenginehasapermanentnameplatethatcontainsimportantinformationsuchas

model,ordernumber,productionnumber,dateofdelivery,ratedpower,ratedspeed,etc.Record

thatinformationinthelogsofyourengineorequipmenttowhichtheengineisappliedand

providethemwhencontactingusforrepairorqualityfeedback.Theinformationishelpfulforus

toprovidegoodsolutionstoyourproblems.

Thenameplateisusuallylocatedontheleftsideofenginecylinderheadandneargear

housing.

Fig1-4 NameplateofSC11CB DieselEngineforConstructionMachinery

Keepthenameplatefree fromdamagebecausetheinformationonit isimportantforrepair

peopletogettherelevantspecificationsofengineand checkthepartnumbersofpartsthatneed

repairing.

1.2.2 EngineModelandOrderNumber

EnginemodelconsistsofArabicnumbersand Englishletterswithmeaningsasfollows:

SC11CB

EmissionLevel

Application

RatedPower(inPS)

StructureFeature(developedwithFEV)

C121 DieselEngineFamily

Displacement

ShangchaiPower(Brand ofSDEC s

Products)

Symbolofapplication

G-- ConstructionMachineryQ--VehicleD---Gen-set(forland)P-- Agriculturemachinery

5

CA--Marineengine(leftsideengine)C

F

-- Auxiliarymarinemachinery

EngineordernumberconsistsofArabicnumbersandEnglishletterswithmeaningsasfollows:

CB

Structurechange

Structurefeature(developedwithFEV)

C121 SeriesDieselEngineFamily

1.2.3 PartNumber

SC11CB dieselengines,jointlydevelopedwithFEVofGermanyonthebasisof6C121 series

dieselengines,isanewdieselengineoflowemission and lowfuelconsumption.Threaded

connectionofthisenginediscardsoriginalinchsystemandadoptsmetricsystem.Partnumberfor

theengineconsistsofthree kinds:1)partnumbersofsome6C121 dieselenginepartsand

components,2)partnumberofnewlydesignedpartsand components,3)partnumbersofmetric

threadedparts.

For6C121 engine,thepartnumberhastwokinds:oneconsistsof6wordscontainingArabic

numbersandEnglishletters, like6N9915, 7C3906;theotherconsistsof7 straightArabicnumbers

like1007861, 1218015.

Fornewlydesignedpartsand components,thepartnumberconsistsof6wordscontaining

ArabicnumbersandEnglishletterslike06CB003, 12AL006.

Formetricthreadedparts,thepartnumberadoptspartnumberofC6121 enginepartnumber

plusprefix “M”likeM6N9915, orpartnumberofnewlydesignedpartplusprefix “M”like

M06CB003.

Forthepurposeofidentifications,partnumberswill beusuallycast,forged,stamped,etched

orotherwisemarkedindeliblyonthepartsofSC11CBdieselengineornameplatesmarked

indeliblyonpurchasedassemblies.Look atthepartnumberofapartcarefullywhenrepairingand

replacing. Contactourservicedepartmentwhenyouhaveprobleminidentifyingapartnumber.

Therearesomesuffixes “M”, “X”, “U”etc.tothepartnumberonhardware,whicharecodes

indicatingpurchasingsourcesaroundtheworld.Suffix “M”meansthatthepartismadeinChina.

Partsofsamekindwiththesamepartnumberbutfromdifferentsourcesareexchangeable,like

6N9915Mand 6N9915 canbeexchanged;or1007861M,1007861 and 1007861Ucanbe

exchanged.However,metricthreadedpartswithprefix “M”cannotbeexchangedwiththeir

correspondingpartsininchsystem, likeM7E6167 and 7E6167 cannotbeexchanged.

1.3 EngineSpecifications

13.1 BasicParameters

SC11CB

Type In-line, 4-stroke, watercooled,directinjection

Bore×Stroke(mm×mm) 120.65×152.4

Numberofcylinders 6

Totaldisplacement(L) 10.45

Firingorder 1-5-3-6-2-4

Rotation

(viewedfromflywheelend) Counterclockwise

Aspiration Turbocharged Turbochargerandinter-cooled

6

Orderofcylindersandvalvesviewedfromgearendisasshowedbelow:

Fig1-5 SchemeofCylindersand Valves

1.3.2 SpecificationsofMainEngineModels

Model SC11CB

220G1

SC11CB

300G2

SC11CB

320G2

SC11CB

290Q2

Atratedcondition

Speed r/min 2200 2100 2200

Power kW 162 220 235 213

BSFC g/kW.h

225 230

SmokeFSN ≤2.0

Atpeaktoquecondition

Speed r/min 1400

Toque Nm 880 1300 1390 1200

BSFC g/kw.h 210 205

Smoke FSN ≤2.5

Atotherconditions

Outletwatertemp. ℃≤99

Inletairtemp.

(afterintercooler)

℃─50

Exhausttemperature

(beforeturbine).

℃£700

BSOC g/kW.h

0.5 0.3

Acceleration smoke FSN ≤3.0

High idle r/min 2390 2310 2530

Lowidle r/min 750 650

Injectiontiming

°CA

(BTDC)

12~19 79

EmissionStage1 Stage2

Noise dB(A)

≤118 ≤119

Altitudelevel m 2400

Firstoverhaulperiod h 8000

Netweight kg 960 980

Intakevalve

Exhaustvalve

Flywheel

7

Model SC11CB

300Q2

SC11CB

320Q2

SC11CB

330Q2

SC11CB

340Q2

Atratedcondition

Speed r/min 2200

Power kW 220 235 242 250

BSFC g/kW.h

230

SmokeFSN ≤2.0

Atpeaktorquecondition

Speed r/min 1400

Torque N.m 1300 1320 1370 1390

BSFC g/kw.h 205

SmokeFSN ≤2.5

Atotherconditions

Outletwatertemp. ℃≤99

Inletairtemp.

(afterintercooler)

℃50

Exhausttemp.

(beforeturbine)

℃≤700

BSOC g/kW.h

0.5 0.3

Acceleration smoke FSN ≤3.0

High idle r/min 2530

Lowidle r/min 650

InjectionTiming °CA

(BTDC)

7

Emission Stage2

Noise dB(A) ≤119

Altitude m 2400

Firstoverhaulperiod

h 8000

Netweight kg 980

8

1.3.3 EnginePerformanceCurves

Fig1-6 FullThrottleCurveofSC11CB220G1 DieselEngine

Speed[r/min]

600 800 1000 1200 1400 1600 1800 2000 2200 2400

BSFC [g/kW.h]

205

210

215

220

225

230

Power [kW]

40

60

80

100

120

140

160

180

Torque [N.m]

650

700

750

800

850

900

950

1000

9

Fig1-7 Full ThrottleCurveofSC11CB 290G2 DieselEngine

Speed [r/min]

600 800 1000 1200 1400 1600 1800 2000 2200 2400

Torque [N.m]

900

1000

1100

1200

1300

BSFC [g/kW.h]

190

200

210

220

230

240

Power[kW]

50

100

150

200

250

1300

1200

1100

1000

900

250

200

150

100

50

Torque{Nm}

Power{kW}

10

1.4 ClearancesandWearLimitsofMainParts

unit: mm

Sizeand tolerance

No.

Item Bore Shaft Clearance Wear

limit

1 Mainbearing journaland

bearing Φ88.88±0.02 0.076-0.165 0.25

2 Crankpinsandconnecting

rod bearing Φ76.18±0.02 0.076-0.168 0.25

3 Crankshafttrust 0.122-0.579 0.85

4 Camshaftbushingand

camshaftjournal Φ58.80±0.06 Φ58.699±0.013

0.101±0.073

0.23

5 Camshafttrust4.83±0.05 4.65±0.03 0.18±0.08 0.64

6 Rockarmshaft/

bushing Φ18.448±0.013

Φ18.402±0.013

0.046±0.026

0.20

7 TappetboreandtappetΦ33.388±0.050

Φ33.287±0.013

0.101±0.063

0.30

8 Piston pinandpinbore Φ43.175+0.032

+0.025 Φ43.175±0.005

0.000+0.037

+0.020 0.05

9 Connectingrodbushing

and pistonpin Φ43.210±0.008

Φ43.175±0.005

0.035±0.013

0.08

10

End playofinjection

pump gearidle 31.45±0.08 31.19±0.08 0.26±0.16 0.86

11

Injectionpumpgearidle

and bushing Φ35+0.014

-0.006 Φ34.955±0.013

0.045+0.027

+0.007 0.20

12

Valvestems Φ9.441±0.008 Φ9.408

13

Boreinvalveguideafter

installation Φ9.456 (Min.)

Φ9.581

14

Oil ring thickness andoil

ring groove 4+0.04

+0.02 4-0.01

-0.03 0+0.07

+0.03 0.15

15

Clearance betweenends

oftoppistonring

installedinastandard

linerwithboresizeof

120.65 mm

0.35~0.5 1.5

16

Clearance betweenends

ofintermediatepiston

ring installedina

standardlinerwithbore

sizeof120.65 mm

0.65~0.85 1.5

17

Clearance betweenends

ofoilcontrolring

installedinastandard

linerwithboresizeof

120.65 mm

0.4~0.6 1.5

18

Cylinderliner Φ120.65+0.025

0 Φ120.75

11

1.5 TorqueforMainBolts

No Description Torque

1

Mainbearing bolt

1)41±4N·m

2)Thenturnby90°±5°

2

ConnectingRodbolt

1)4164 N·m

2)Thenturn90°±5°

3 Camshafttiminggearbolt 55±7N·m

4 Crankshaftpulleybolt 1) 312±25 N·m

1)312±25 N·m

5 Cylinderheadbolt(large)

1)156N·m

2)250±17N·m

3)250±17N·m

6 Cylinderheadbolt(small)43±7N·m

7 Adjustingscrewforvalvelash 296±7N·m

8 Valvecoverbolt 11±3 N·m

9 Alternatorpulleynut 112±10 N·m

10 Flywheelbolt 200±25 N·m

11 Fuelinjectionpumpdrivegearbolt 270±25 N·m

12 Flywheelhousingbolt 100±15 N·m

13 Bolt holdingfrontcrankshaftsealbase

135±15 N·m

14 Nutsecuringhigh pressurefuelline 40.6±6.8 N·m

1.6 TorqueforGeneralFasteners

Torquesformetricfasteners

Metricthread

TorqueThreadsize

(Metricsystem) N·m

M6 12±3

M8 28±7

M10 55±10

M12 100±20

M14 160±30

M16 240±40

M20 460±60

M24 800±100

M30 1600±200

M36 2700±300

Torquesforstandardhoseclamps(wormtype)

Torqueforclampingnewhose

WidthofclampN·m

16 mm(0.625 inch) 7.5±0.5

13.5 mm(0.531 inch)

4.5±0.5

8mm (0.312 inch) 0.9±0.2

12

Torqueforreinstallationorretightening

Widthofclamp N·m

16 mm (0.625 inch) 4.5±0.5

13.5 mm(0.531 inch) 3.0±0.5

8mm (0.312 inch) 0.7±0.2

Note:

(1)All standardfasteners will betightenedaccordingtothetorqueslistedabove,unless

otherwisespecifiedinthisManual.

(2)FastenersofmetricandSAEinchsystemsarenotexchangeable.Besuretoinstall

correctones.Failuretodosowill damagethreadsandparts.Ametricbolt hassymbollike8.8,

10.9 etc.onitsheadindicatingbolt strengthgrade,whileaboltofinchsystemhassixshort

linesonitshead.Payattentiontothedifferencewhendisassemblingandassembling.Fasteners

ofsamestandardand samespecificationscanbeexchanged.

13

2Assembly Dimensionand SpecificationsofMainParts

2.1 CylinderBlock

1)Thickness ofspacerplate………………………………… 9.970±0.025mm

Thickness ofspacerplategasket …………………………0.208±0.025mm

Note:Forheightofalinerovertopofspacerplaterefertocylinderlinerprotrusion.

Fig2-1FrontEndViewofCylinderBlock

(2)Camshaftbearingbore(installed)………………………………………Ф58.80 0.06mm

Boreinblockforcamshaftbearing ……………………………………Ф65.100 0.025mm

(3)Boreinblockformainbearing (standardsize)……………………… Ф96.926 0.013mm

Boreinblockformainbearing0.51mm oversize………………………Ф97.436 0.013mm

(4)Dimensionfromcenterofmainbearing boretotopofcylinderblock……383.515 0.165mm

(5)Dimensionfromcenterofmainbearing boretobottomofcylinderblock…153.99 0.10mm

(6)Torqueforboltsholdingbearingcapformainbearing

a.Applyengineoil orthreadlubricanttothreadandwashersurfaces.

b. Tightenall boltsto41 4N·m

c. Makemarkson eachbolt andcap

d. Tightenall boltsfrommarkby90°5°

Note:Install bearingcapswiththepartnumbertowardthefrontoftheengine.Besurethat

themark(number) on thebearingcapnexttothebolt holeisinagreementwiththemarkinthe

cylinderblock.

(7)Clearance betweenmainbearingcapandcylinderblockfrom………………………

…………………………………………………… 0.033mmtightto0.043mmloose

Mainbearing capwidth …………………………165.095 0.020mm

Widthofcylinderblockformainbearing…………165.100 0.018mm

(8)Piston cooling jet

Fig2-2 PistonCoolingJet

Table of contents

Other Shanghai Diesel Engine Engine manuals

Shanghai Diesel Engine

Shanghai Diesel Engine 6114 Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine SC9DF User manual

Shanghai Diesel Engine

Shanghai Diesel Engine H Series Manual

Shanghai Diesel Engine

Shanghai Diesel Engine E Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine H Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine E Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine D Series User manual

Shanghai Diesel Engine

Shanghai Diesel Engine SC9D Series User manual