Transmax TR Series User manual

TR Series

Europe Technology & Design

Helical Geared Motor

6

SUMMARIZE

MODEL MARK

RELEVANT PARAMETER

TYPE SELECTION MANUAL

MEANS FOR TYPE SELECTION

SELECTION TABLES COMMENTS

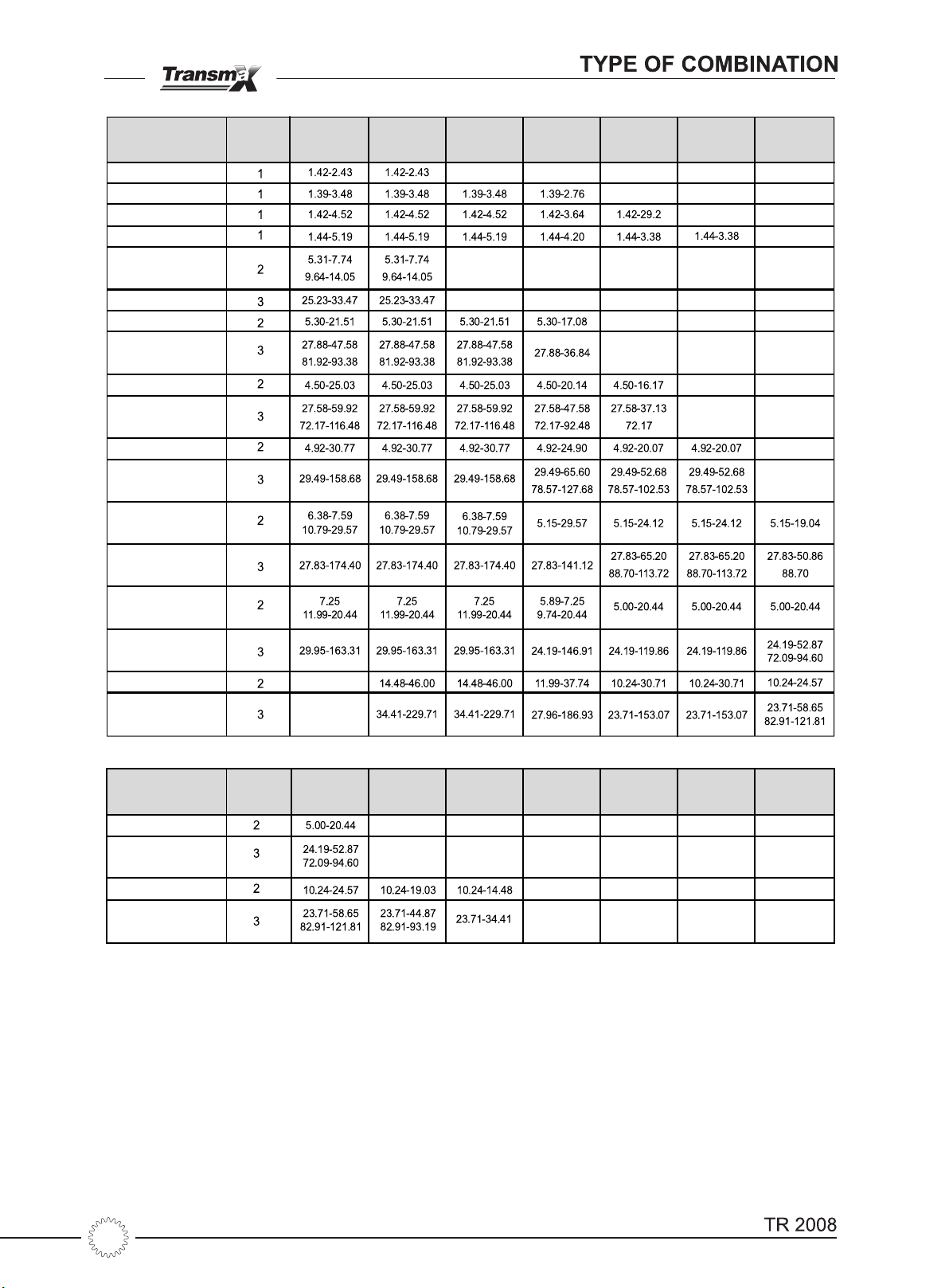

TYPE OF COMBINATION

PERFORMANCE PARAMETER

OUTLINE DIMENSION SHEET

LUBRICANTS

TYPES OF LUBRICANTS

LUBRICANT FILL QUANTITY

INSTALLATION

INSTALLATION POSITIONS DIAGRAM

INSTALLATION POSITIONS

INSTALLATION METHODS

MAINTENANCE

STORAGE

NOTICE FOR ORDER

MALFUNCTIONS

ADDENDUM

CHARGE CHARACTERISTIC CHART

7

Page

8

9 - 12

14

13

15- 16

34 - 105

106 - 185

186

186-187

188

189-193

194

195

196

197

198-199

200-201

CONTENTS

YAD

®

RATIO AND MAX TORQUE

17- 31

SELECTION TABLE

32 - 33

TR2007

7

TR2007 1

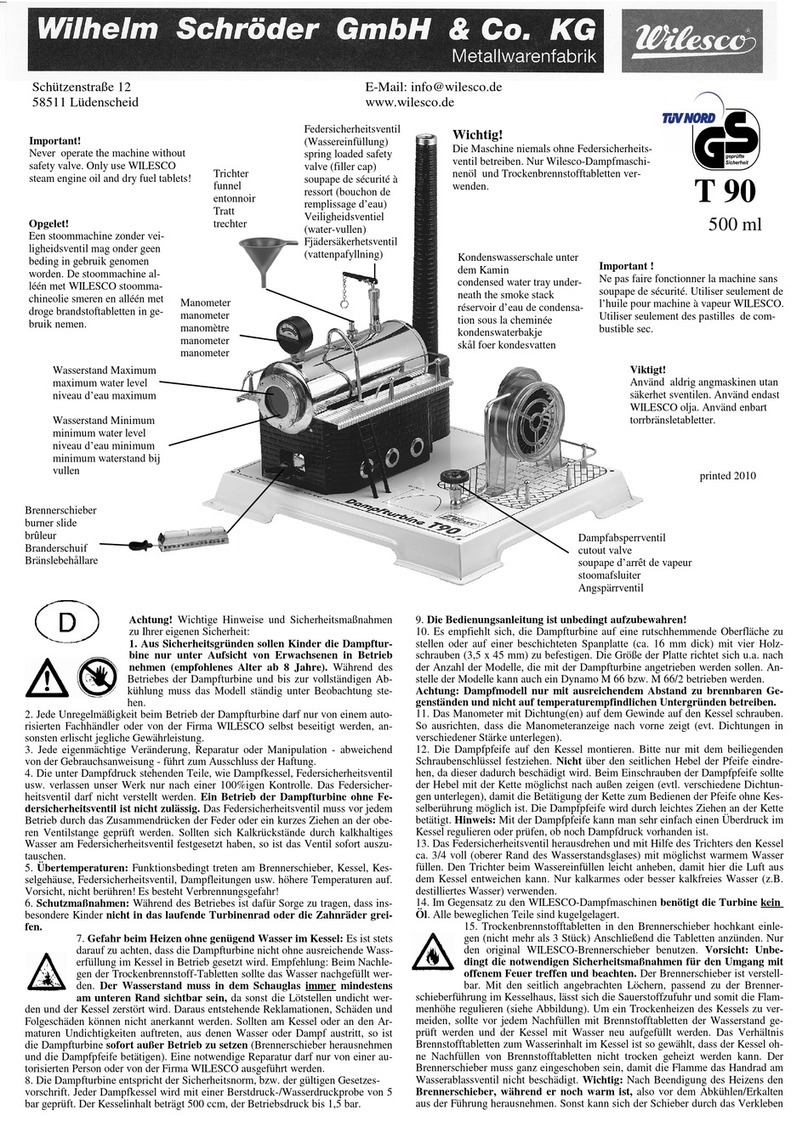

SUMMARIZE

TR Series helical gearmotor is a new generation mechanic-electrical integrated product, which

designed basing on the modular system. It can be connected respectively with motors such as normal

motor, brake motor, explosion-proof motor, frequency conversion motor, servo motor, IEC motor and so

on. It can be mounted discretionary six orientation in solid space. This kind of product is widely used in

drive fields such as textile, foodstuff, beverage, chemical industry, automatic arm ladder, automatic

storage equipment, metallurgy, tobacco, environment-protection, logistics and so on.

1. Transmission ratio with fine stage covers a wide range;

2. Compact structure takes up small room;

3. low vibration; low noise; low energy dissipation;

4. Refined design; reliable and wearable; wide usage;

5. Modular, multistructure, can be combined in many forms to meet needs of all kinds of transmission

conditions.

TR Series helical gearmotor

of 1-stage, 2-stage or 3-stage

helical gears

unit and motor. The

helical

gear

which use the material of high quality alloy steel with the surface hardened takes shape through

processing of high-precision equipment. Except the TR..28 housing with aluminum alloy, all are cast iron

housing. housing is exactly processed to ensure the shape and position precision. And it reaches advanta-

geous performance such as: strong bearing capacity, long service-life; small volume; big ratio; light weight,

high efficiency, low noise.

TR Series helical gearmotor

has more than ten models. Combined with TRF series, the multi-stage

gear reduction can be achieved. Power 0.12-160KW; Ratio 1.3-27001;Torque 69-18000Nm. It can

connect (foot, flange) discretionary and use multi-mounting positions according to customers’ require-

ments.

SUMMARIZE

PERFORMANCE CHARACTERISTICS

YUEMA ASIAN DRIVE

®

TR..27

Housing

8

TR2007 3

MODEL MARK

yuema asian drive

®

MODEL MARK

TR F 87 II - YDT 112 M 4 / BMG / HF / TF - 27.88 - M6 / 270

Example:TR47 - YDT71D4 - 121.87

TRXF67 - YDT90S4 / BMG - 1.86 - M1 / R

TRF57III - AM80 - 80.55

1 2 3 4 5 6 7 8 9 10 11 12 13 14

NO

COMMENTS

1TR: code for gear units series

2

I,II,III:B5 output flange specification, default Inot

1). No code means foot-mounted

2). F: B5 flange mounted

3). Z: B14 flange mounted

4). X: single-stage foot-mounted

5). XF: single-stage flange-mounted

to write out is ok

3Specification code of gear units 28, 38,… …

4

51). YDT: motor code

2). AM: IEC input couplings

6Specification code of motor (high in motor centre )

7Length code of stator core D, K, L, M, ML, N, S

82, 4, 6, 8rotomforebmuneloP

91). No code means no brake

2). BMG: brake

10

1). No code means no manual release device

2). HF: manual release device with self-locking function

3). HR:

manual release device with outself-locking function

11 1). No code means no motor heat-protection device

2). TF: motor heat- protection device

12 Transmission ratio of gear units

13 M1: Mounting position,default mounting position M1 not

14 Position diagram for motor terminal box default position

0 (R) not to write out is ok

1) No code means foot-mounted, no flange

2) F: foot-mounted,B5 output flange

3)

to write out is ok

9

YAD

®

TR2007

4

RELEVANT PARAMETER

3) i Transmission ratio i

4) Torque

1) Power

Usually transmission ratio is decimal fraction with 2 radix point tagged in selection tables.

RELEVANT PARAMETER

5) fsService factor fs

The effect of the driven machine on the gear unit is taken into account to a sufficient level of accuracy

using the service factor fs. The service factor is determined according to the daily operating time and

n1

n2

Gear units input speed

Gear units output speed

M2

M2n

P1

η

fs

Output torque

Selected output torque

Input power

Transmission efficiency

Service factor

P1

P2

P1n

fs

η

Input Power

Output Power

Selected Motor Power

Service Factor

Transmission Efficiency

i = n1

n2

M2=9550

•

P1

•

η

n2

The efficiency of TR Series gear units varies with the number or gear stages, between 94 % (3-stage),

96% (2-stage) and 98% (1-stage)

2) Rotation speed

which in selection table means the motor rotation speed 1400/min. If driven by the external gearing,

1400r/min or lower rotation speed is suggested so as to optimize the working conditions and prolong

the service life. Higher input rotation speed is permitted, but in this situation, the rated torque M2

will be reduced.

P1n

≥

P1

• fs[kW]

P1=P2

η

[kW]

M2n

≥

M2

• fs[Nm]

[Nm]

starting frequency Z. Three load classifications are considered depending on the mass acceleration factor.

10

TR2007

Load classifications see the addendum.

5

RELEVANT PARAMETER

YUEMA ASIAN DRIVE

®

Jc

fa

=Jm

To keep the service-life of gear units, the use factor fsselected from the catalogue must be equal or

slightly higher than the calculated use factor fs

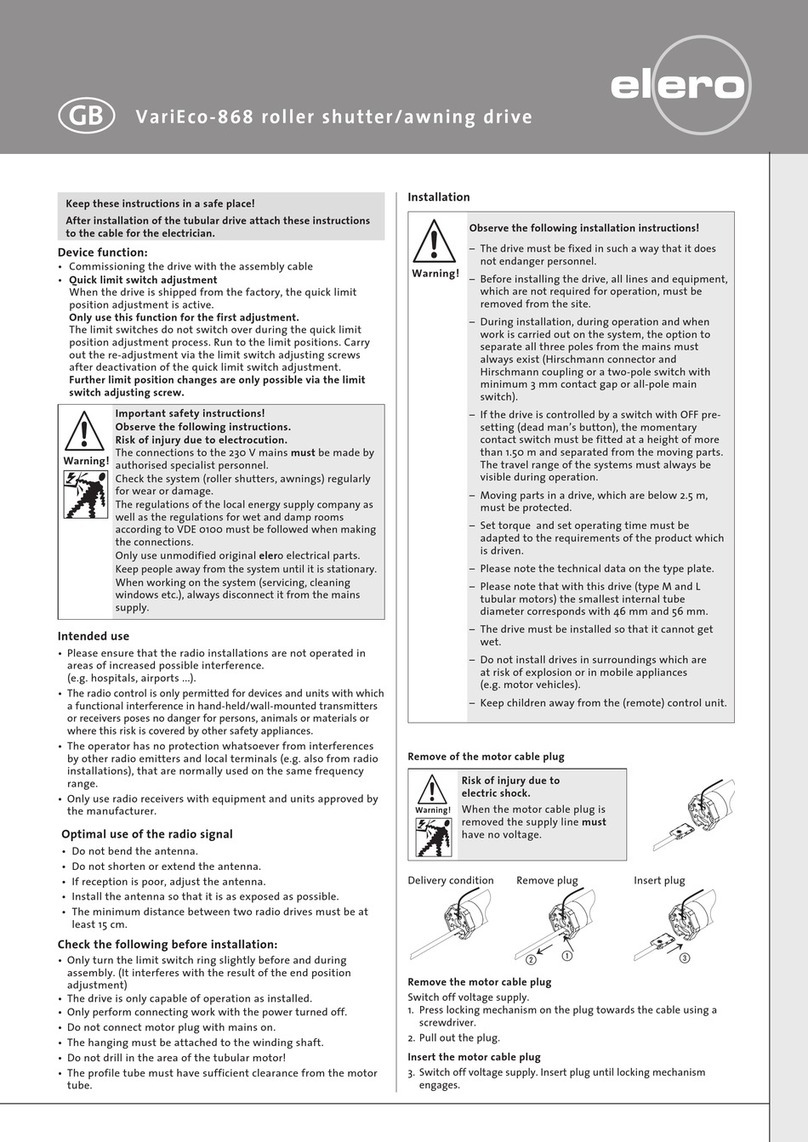

1000 1200 1400800600400200

16h 8h

24h

0.8

0.9

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.0

1.1

1.2

1.3

1.4

1.5

1.6

1.7

1.2

1.3

1.4

1.5

1.6

1.7

1.8

run time (h/day)

start up frequency Z(1/h) #

Service factor ( fs)

#Starting Frequency Z: The cycles include all starting and braking procedures as well as change

over from low to high speed.

Load classifications :

Uniform, permitted mass acceleration factor

≤ 0.2

Moderate shock load, permitted mass acceleration factor ≤3

Heavy shock load, permitted mass acceleration factor ≤10

The mass acceleration factor is calculated as follows:

fa Mass acceleration factor

Jc All external mass moments of inertia ( kgm 2 )

Jm Mass moment of inertia on the motor end ( kgm 2 )

If mass acceleration factors fa>10, please call our Technical Service.

C

B

A

A

B

C

You can read off the service factor applicable to your application in following Figure. The service factor

selected using this diagram must be less than or equal to the service factor as given in the performance

parameter table.

11

YAD

®

TR2007

6

RELEVANT PARAMETER

6)

Radial loads & axial loads Fr2

The overhung loads exerted on the motor or gear shaft is then calculated as follows:

Fr2

Md

d0

fz

Radial loads [N]

Orque [Nm]

Mean diameter of the mounted transmission element [mm]

Transmission element factor

When determining the resulting radial loads, the type of transmission elements, mounted on the shaft

end must be considered. Various transmission elements are corresponding with following

transmission element factors :fz

:

M

d

• 2000 • f

z

Fr2

=

[N]

d

0

The basis for determining the permitted radial loads is the computation of the rated service life LH10

of the bearings (according to ISO 281). For special operating conditions, the permitted radial loads can

be determined with regard to the modified service life Lna. The permitted radial loads Fr for the output

shaft of foot-mounted gear units with a solid shaft are listed in the selection tables.

Contact our company in case of other versions.

The permitted radial loads given in the selection tables must be calculated using the following

formula in the event of force application not in the center of the shaft end. The smaller of the two values

FxL (according to bearing service life) and FxW (according to shaft strength) is the permitted value for

the radial load at point x. Note that the calculations apply to M2 max.

Transmission element Transmission element factor FzComments

Gears 1.00 ≥ 17 teeth

1.15 < 17 teeth

Chain sprockets 1.00 ≥ 20 teeth

1.25 < 20 teeth

1.40 < 13 teeth

V Narrow V-belt pulleys 1.75 Influence of the tensile force

Flat belt pulleys 2.50 Influence of the tensile force

Toothed belt pulleys 2.50 Influence of the tensile force

12

TR2007 7

RELEVANT PARAMETER

YUEMA ASIAN DRIVE

®

= Permitted overhung load (x = L/2) for foot-mounted gear units according to the selection

tables in [N]

= Distance from the shaft shoulder to the force application point in [mm]

=

Gear unit constant for overhung load conversion [mm]

= Gear unit constant for overhung load conversion [mm]

Fr2

x

a, b, f

c

F

xL

= F

r2 •

a

b + x [N]

F

xW

= F

r2 •

c

f + x [N]

x

x

F

r 2

F

r 2

F

X

F

xL

d

d

L

L/2

Gear unit type a

[mm]

b

[ mm]

c

[Nmm]

f

[mm]

d

[mm]

L

[mm]

04022.43501x15.15.325.3457XRT

05527.93501x24.25.725.2567XRT

06030501x59.15.035.0677XRT

08049.84501x96.75.335.3787XRT

001059.35601x34.15.635.6897XRT

021063.26601x74.25.245.201071XRT

05528.11501x65.15.185.60127RT

05520501x42.13981137RT

060351501x44.270173147RT

075381501x77.35.2115.74157RT

07530501x15.25.3315.86167RT

08040501x79.37.3317.37177RT

001050501x74.87.6617.61287RT

021060601x91.15.5915.55297RT

041070601x60.25.5125.582071RT

0710903601x41.65.8525.343371RT

01201133601x56.8792204471RT

0120210701x62.1543054671RT

13

YAD

®

TR2007

8

MEANS FOR TYPE SELECTION

SELECTION EXAMPLE

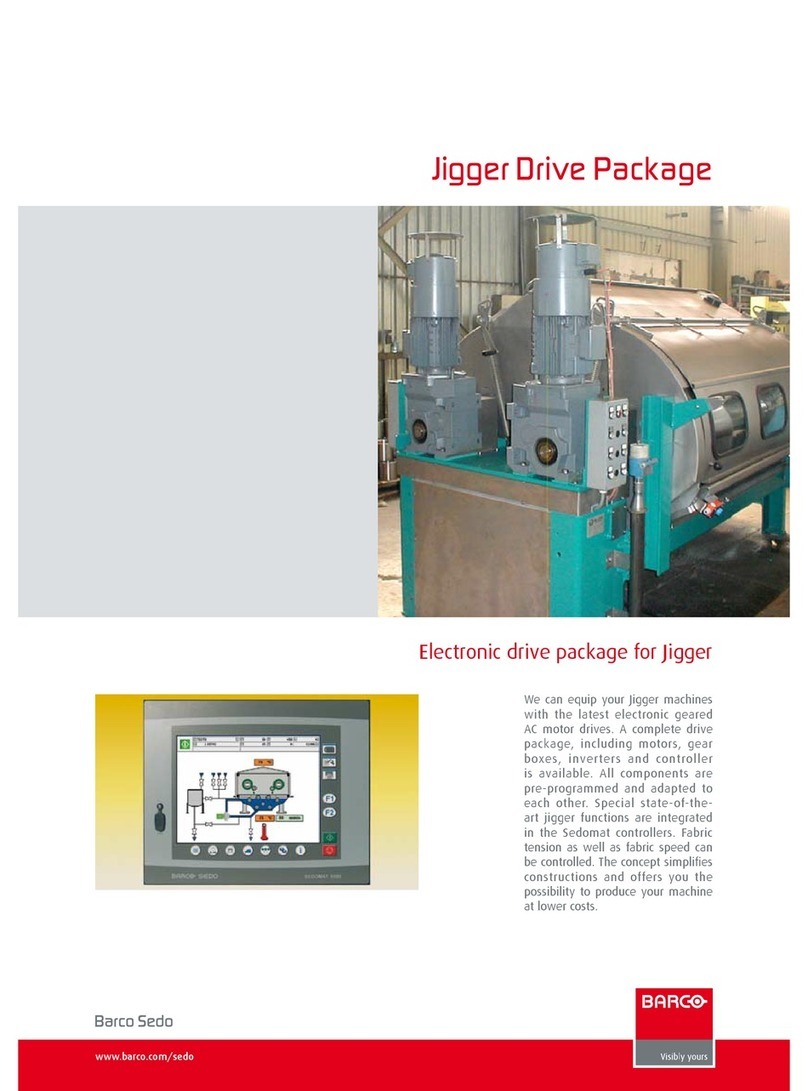

1) Gear motor

Example:

Required power 16kW on driven machine, work for 8h/day, moderate shock load, so f

s

=1.3,

M6 foot-mounted

, n2=61.9 r/min

Choose type:

TR107 - YDT180L4 - 22.62 - M6

2) Gear units

Example: Recluired torquc 480Nrn on driven machine, work 6h/day, uniform load, so fs=1.2,flange-

mounted, n2=2.5 r/min, choose TR../TRF..

Choose type:

TRF77 / TRF37 - YDT63M4 - 560

M2n

≥

M2

•fs= 480 x 1.2 = 576 [Nm]

P1n

≥

P1

•fs

=

•fs

=

x 1.3

= 21.67 [kW]

P2

η

16

0.96

i = = = 22.62

n1

n2

1400

61.9

i = = = 560

n1

n2

1400

2.5

P1n

≥

P1

• f

s

=

•

f

s

=

x 1.2

= 0.167 [kW]

M2

• n

1

9550

•

η

• i

480x1400

9550 x 0.94 x 0.96 x 560

14

TR2007 9

SELECTION TABLES COMMENTS

YUEMA ASIAN DRIVE

®

L

L1

B

B1

AC

AD

AD1

Total length of gearmotor

Total length of gearmotor including brake

Length of motor

Length of brake motor

Diameter of motor

Center of motor shaft to top part of terminal box

Center of brake motor shaft to top part of terminal box.

SELECTION TABLES COMMENTS

P1n

n2

M2n

M2 max

Fr2

i

fs

page

*

Rated power driving motor [kW]

Output speed [r/min]

Output torque [Nm]

Max. permissible output torque [Nm]

Permissible overhung load output side [N]

Gear unit ratio

Service factor

Gear unit type

Motor type

Dimension sheet page no

Finite gear unit reduction ratio

B1

B

L

L1

AC

AD

AD1

15

TRX/TRXF57

TRX/TRXF67

TRX/TRXF77

TRX/TRXF87

TRX/TRXF97

TRX/TRXF107

TR/TRF17

TR/TRF17

TR/TRF27

TR/TRF27

TR/TRF37

TR/TRF37

TR/TRF47

TR/TRF47

TR/TRF57

TR/TRF57

TR/TRF67

TR/TRF67

TR/TRF77

TR/TRF77

TR/TRF87

TR/TRF87

TR/TRF97

TR/TRF107

TR/TRF107

TR/TRF137

TR/TRF137

Gear Unit Size Stages

The Below is combination Table between gear box and electromotor in each list the ratio range

YDT63/

YDT71 YDT80 YDT90 YDT100 YDT112 YDT132S YDT132M

16

Gear Unit Size Stages

Gear Unit Size Stages

TRX/TRXF77

TRX/TRXF87

TRX/TRXF97

TRX/TRXF107

TR/TRF107

TR/TRF107

TR/TRF107

TR/TRF137

TR/TRF137

TR/TRF147

TR/TRF147

TR/TRF147

TR/TRF147

TR/TRF167

TR/TRF167

TR/TRF167

TR/TRF167

TR/TRF77

TR/TRF87

TR/TRF87

TR/TRF97

TR/TRF97

YDT132ML YDT160M YDT160L YDT180 YDT200 YDT225 YDT250M

YDT280 YDT315 YDT

315M_A/B

17

TRX/TRXF57-67..

TRX/TRXF77-87..

TRX/TRXF87

TRX/TRXF77

AD2

AD2

AD3

AD3

AD4

AD4

AD5

TRX/TRXF57 TRX/TRXF67

AD

AD2

AD3

AD2

AD3

AD

AD AD

18

TRX/TRXF97-107..

TR/TRF17..

TRX/TRXF97

AD

AD3

AD4

AD5

AD6

TRX/TRXF107

AD5

AD4

AD6

AD

3-stages 2-stages

TR/TRF17..

19

TR/TRF27-37..

TR/TRF27 TR/TRF37

AD

AD1

AD1

AD1

AD2

AD2

AD2

AD

3-stages 3-stages

2-stages 2-stages

20

2-stages

2-stages

AD AD

3-stages 3-stages

TR/TRF47-57..

TR/TRF47 TR/TRF57300Nm 450Nm

AD2AD2

AD2

AD3

AD2

AD3

21

2-stages

2-stages

AD AD

3-stages 3-stages

TR/TRF67-77..

TR/TRF67 TR/TRF77600Nm 820Nm

AD2AD2

AD3

AD4

AD3

AD2

22

2-stages

2-stages

AD AD

3-stages 3-stages

TR/TRF87-97..

TR/TRF87 TR/TRF971550Nm 3000Nm

AD2

AD3

AD3

AD3

AD4

AD4

AD6

AD5

AD5

AD4

Table of contents