Operation and Maintenance Manual E Series Natural Gas Engine

1

1 Introduction

1.1 To User and Operator

Thank you for purchasing a product of Shanghai Diesel Engine Co., Ltd!

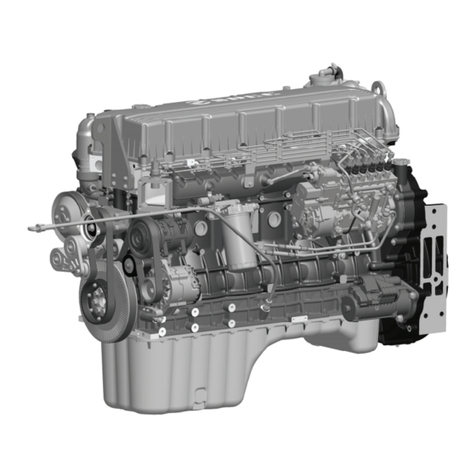

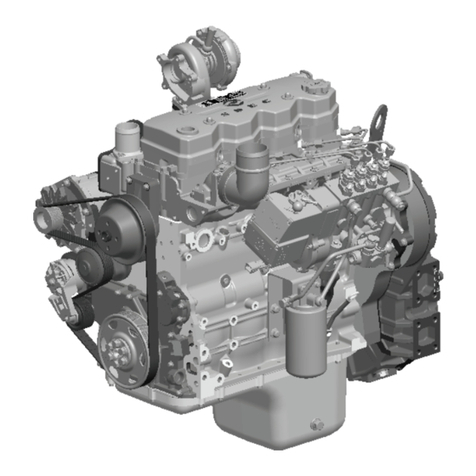

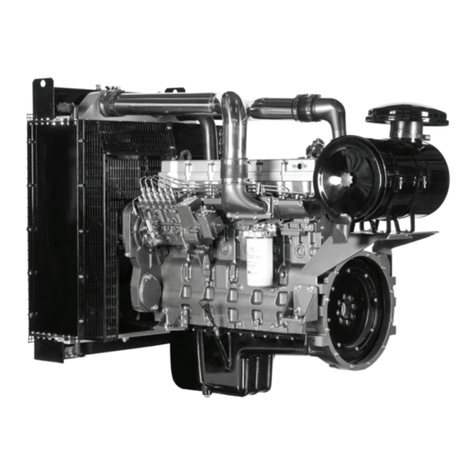

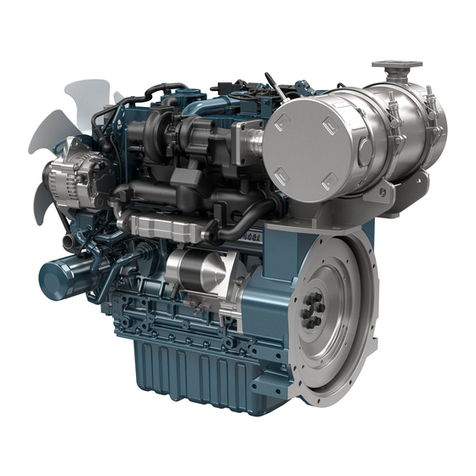

The E series natural gas engine, available in two displacements of 10L and 12L, is a large-power four-valve

electronic-controlled natural gas engine with four or six cylinders that is newly developed by SDEC. Featuring strong

power and low gas consumption and with the emissions conforming to relevant national regulations, the E series

natural gas engine is a perfect power for middle- and high-end vehicles and industrial equipment.

This manual mainly covers the technical specifications, operation and maintenance instruction, with an aim to

familiarize you with the engine, as well as the proper operation and maintenance thereof. Before using the engine,

read carefully the relevant contents and requirements in this manual. Due to the continuous improvement of

performance and structure of the engine, the technical specifications and illustrations of the engine in this manual

may be slightly different from those of the engine you have, please note that we will provide the supplement and

perfection in the later editions without notice. In case of any question during your engine operation and maintenance,

please

nev

er

hesitate

to

contact

SDEC’s

after-sale

service

center

[email protected] for

technical

advic

e

or

guidance.

SDEC has adopted the latest technology and high-quality parts for the engine. The genuine SDEC spare parts are

recommended to be used for repair and maintenance. Please contact SDEC’s after-sale service center

1.2 Notices for Engine Quality Feedback

To better our service, please provide following information when you make feedback about quality issues, whereby,

we can understand and analyze quality issues and the root causes thereof, and make the improvement in time:

1) When and where fault occurred;

2) Engine serial number, model, order number, delivery date and the detailed address of consignee;

3) Service conditions, cumulative operation time (in hours or kilometers), operating conditions (power, speed) and the

specification of the lubricating oil that has been used;

4) The characteristics of the driven equipment (model, power consumption and structural feature, etc.)

5) The description of faults;

6˅Parts or components claimed for compensation or repair should be mailed or sent in person to SDEC headquarter

with the damage process record or description for facilitating analysis. If there are several problems or a very serious

problem, please leave the site as it was and inform us promptly, and then SDEC will send staff for a joint analysis.

Quality issues should be settled based on the relevant provisions in the quality warranty manual.

1.3 Safety Instructions

ƔDo not wear a loose garment or any jewelry when working around the engine or its driven equipment. If necessary,

wear the safety goggles, work clothes, safety helmet or other protective items.

ƔAll the exposed rotating parts should be provided with guards in firm installation to prevent personal injury.

ƔThe workroom of the engine should be well ventilated with waste gas exhausted outside.

ƔDo not operate the gas engine in a place where there is or may be flammable gas, for the gas may enter the air

intake system of the engine and cause the engine to speed up or overspeed, which leads to fire, explosion or serious

engine damage.

ƔTake all tools, wires, other odds and ends away from the engine prior to starting.

ƔMake sure to shutdown the engine before any adjustment is performed to it and its driven equipment.

ƔSmoking is not allowed during filling gas, otherwise, gas steam can cause fire easily.

ƔSmoking is also not allowed when checking electrolyte level because electrolyte will release flammable gas.

ƔContact between electrolyte and skin or eyes must be prevented when replenishing electrolyte for the battery,

because it is an acid. In case of skin contact, please flush the contacted part with soap and clean water; in case of

eyes contact, flush your eyes for 15 minutes with clean water and seek for medical treatment immediately.

ƔAdded with an odorous chemist, natural gas can be smelled when it leaks. Be on alert when smelling natural gas.

When entering the engine cabinet or being close to the engine and smelling natural gas, shut down the engine and

check and remove gas leakage. And keep the area free from spark, arc switch or device, smoking, indicator lamp, fire

or other fire source and take a good ventilation measures. Do not start the equipment or the equipment nearby until

the leakage has been removed and the area has been well ventilated. Avoid placing the equipment fueled with natural