IM-DR580H

–4 –

FORACOMPLETEDESCRIPTIONOFTHEOPERATIONOFTHISUNIT,PLEASEREFERTO

THE OPERATION MANUAL.

Specifications for this model are subject to change without prior

notice

SPECIFICATIONS

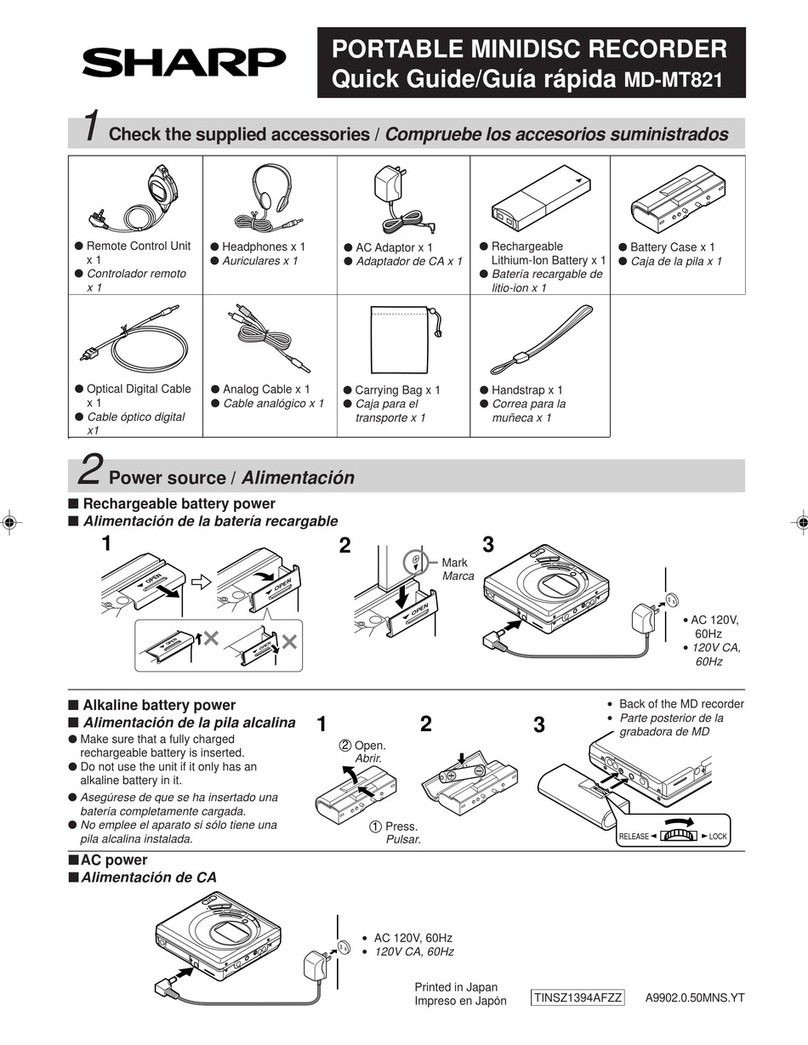

Power source: DC 1.2 V: Rechargeable Nickel-Metal Hydride Battery (AD-N55BT) x 1

DC 1.5 V: Commercially available, "AA" size (LR6), alkaline battery x 1

DC 3 V: AC adaptor (AC 110 - 240 V, 50/60 Hz), with the multi-link station

Power consumption: 60 mA (AC adaptor)

Output power: RMS: 16 mW (8 mW + 8 mW)

Charging time: Approx. 3.5 hours (90 %)

Approx. 5.5 hours (fully charged)(When using the AC adaptor included with the unit)

Dimensions: Width: 80.1 mm

Height: 16.6 mm

Depth: 72.6 mm

Weight: 120 g with rechargeable battery/95 g without rechargeable battery

USB socket: Multi-link station; exclusive USB socket

Input socket: Main unit; Microphone (powered by the main unit)

Multi-link station; Line/optical digital

Output socket: Main unit; Earphones (impedance: 32 ohms)/remote control

Multi-link station; audio output, speaker output

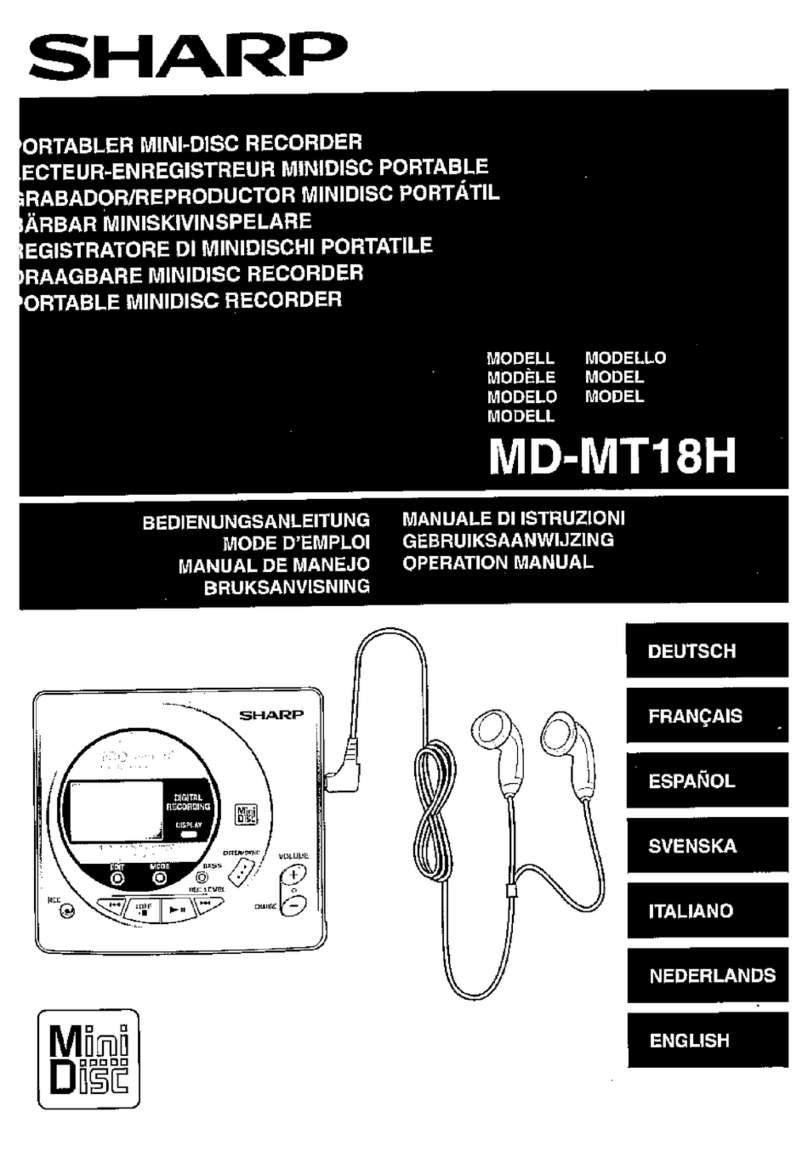

Type: Portable MiniDisc recorder

Signal readout: Non-contact, 3-beam semiconductor laser pickup

Audio channels: Stereo 2 channels/monaural 1 channel

Frequency response: 20 - 20,000 Hz (±3 dB)

Rotation speed: Approx. 400 - 1,800 rpm CLV (Playback), approx. 400 - 2,700 rpm CLV (Recording)

Error correction: ACIRC (Advanced Cross Interleave Reed-Solomon Code)

Coding: ATRAC/ATRAC3 (Adaptive TRansform Acoustic Coding), 24-bit computed type

Recording method: Magnetic modulation overwrite method

Sampling frequency: 44.1 kHz (32 kHz and 48 kHz signals are converted to 44.1 kHz, and then recorded.)

Wow and flutter: Unmeasurable (less than ±0.001 % W. peak)

Battery life:

Input sensitivity: Output level:

Stereo 2 times long 4 times long

When using the rechargeable

battery (fully charged) included

with the unit

Continuous

recording:

Approx. 8

hours

Continuous

play: Approx.

27 hours

Continuous

recording:

Approx. 12

hours

Continuous

play: Approx.

36 hours

Continuous

recording:

Approx. 15

hours

Continuous

play: Approx.

42 hours

When using a commercially

available, high capacity, "AA"

size (LR6), alkaline battery

Continuous

recording:

Approx. 8

hours

Continuous

play: Approx.

48 hours

Continuous

recording:

Approx. 15

hours

Continuous

play: Approx.

67 hours

Continuous

recording:

Approx. 20.5

hours

Continuous

play: Approx.

75 hours

When using one, commercially

available, high capacity, "AA"

size (LR6), alkaline battery with

the rechargeable battery (fully

charged)

Continuous

recording:

Approx. 20

hours

Continuous

play: Approx.

80 hours

Continuous

recording:

Approx. 30.5

hours

Continuous

play: Approx.

103 hours

Continuous

recording:

Approx. 40

hours

Continuous

play: Approx.

122 hours

The above values are the standard values when the unit is used at an ambient temperature of 25°C.

The continuous recording time is for microphone input when the volume level is set to "VOL 0" and the backlight is set to

"LIGHT OFF".

The continuous play time shows the value when the volume level is set to "VOL 15" and the backlight is set to "LIGHT OFF".

The operating time when using an alkaline battery may be different, depending on the type and manufacturer of the battery,

and on the operating temperature.

"Fully charged" means that the battery is charged for approx. 3.5 hours, and charged for another 2 hours after the battery

indicator disappears.

Reference input

level Input impedance

MIC H 0.25 mV 10 k ohms

MIC L 2.5 mV 10 k ohms

LINE 100 mV 20 k ohms

Specified out-

put Maximum out-

put level Load imped-

ance

Ear-

phones - 8 mW + 8 mW 32 ohms

Audio out-

put 125 mV (-12

dB) - 10 k ohms

Speaker

output 125 mV (-12

dB) *1 - 10 k ohms

*1 When the speaker output selector switch of the multi-link

station is set to MD.