2

Note on electrostatic shielding

1. Electrostatically shielded MOS workstations

Components sensitive to electrostatic discharge

must be handled at workstation with electrostatic

shielding. An electrostatically shielded MOS work-

station is fitted with discharge resistor which earth

all conductive materials, including the technician

working there. Dielectrics are discharged by air

ionisation. The use of soldering irons and meas-

uring equipment at shielded workstation is only

possible in conjunction with isolating transformer

in each of the devices used. Measuring equip-

ment chassis are also earthed with discharge re-

sistors.

2. Shielded packaging using conductive

materials

To protect against electrostatic charges, electri-

cally conductive plastics are used for packaging

and transport purposes. Conductive plastics are

available in the form of transparent protective

bags, foam plastic, film sheeting or containers.

Sensitive components requiring the use of pro-

tective packaging must only be packed and un-

packed at shielded workstations.

Safety warnings/regulations

1. The repair, modification and testing of mains-op-

erated electronic devices and their accessories

must only be performed by qualified persons.

2. It is necessary to follow the regulations and safety

warnings to VDE 0701, part 200, as well as the

regulations and safety warnings applicable in the

country concerned.

3. VDE 0701, Part 2, contains regulations on the re-

pair, modification and testing of mains-operated

electronic devices and their accessories.

4. Before delivery, the device and the connecting

leads (including any protective earth conductor

fitted) must undergo visual inspection, and the

insulation resistance and the equivalent leak-

age current must be measured according to VDE

0701, part 200. The low-resistance continuity of

the protective earth conductor must be verified by

measurement to VDE regulation 0701, part 1.

5. The regulations of the country concerned must

also be observed.

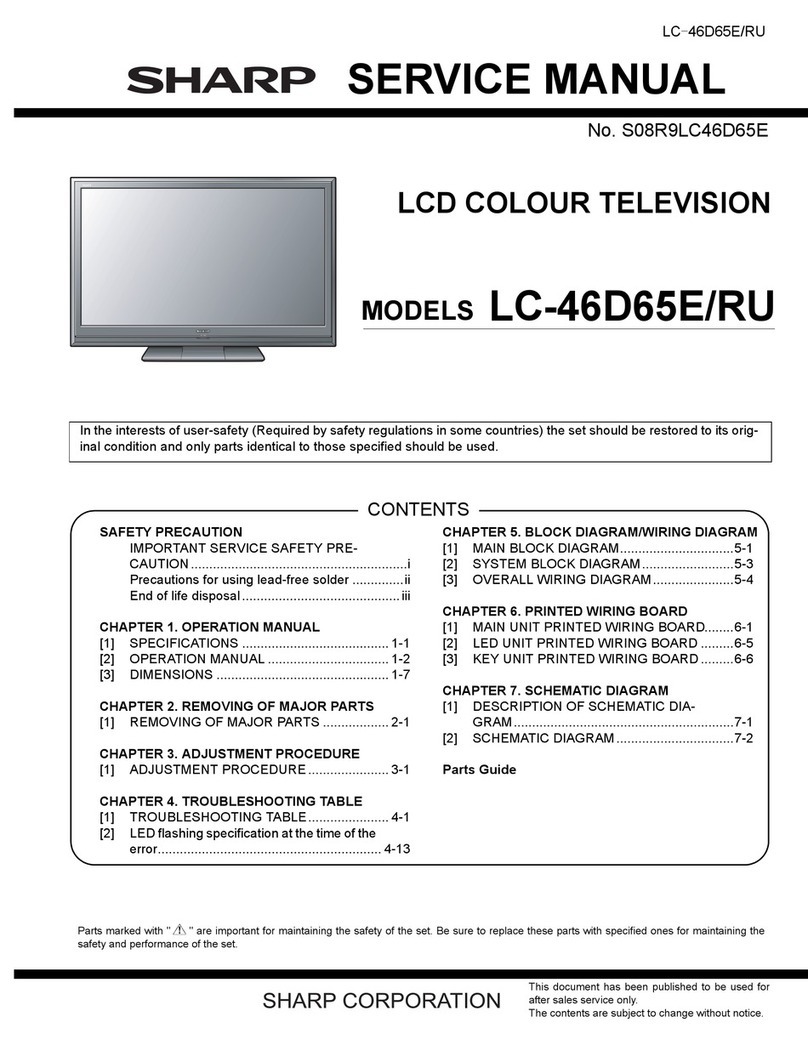

6. Only genuine parts must be used for replacing

components marked with the symbol .