8

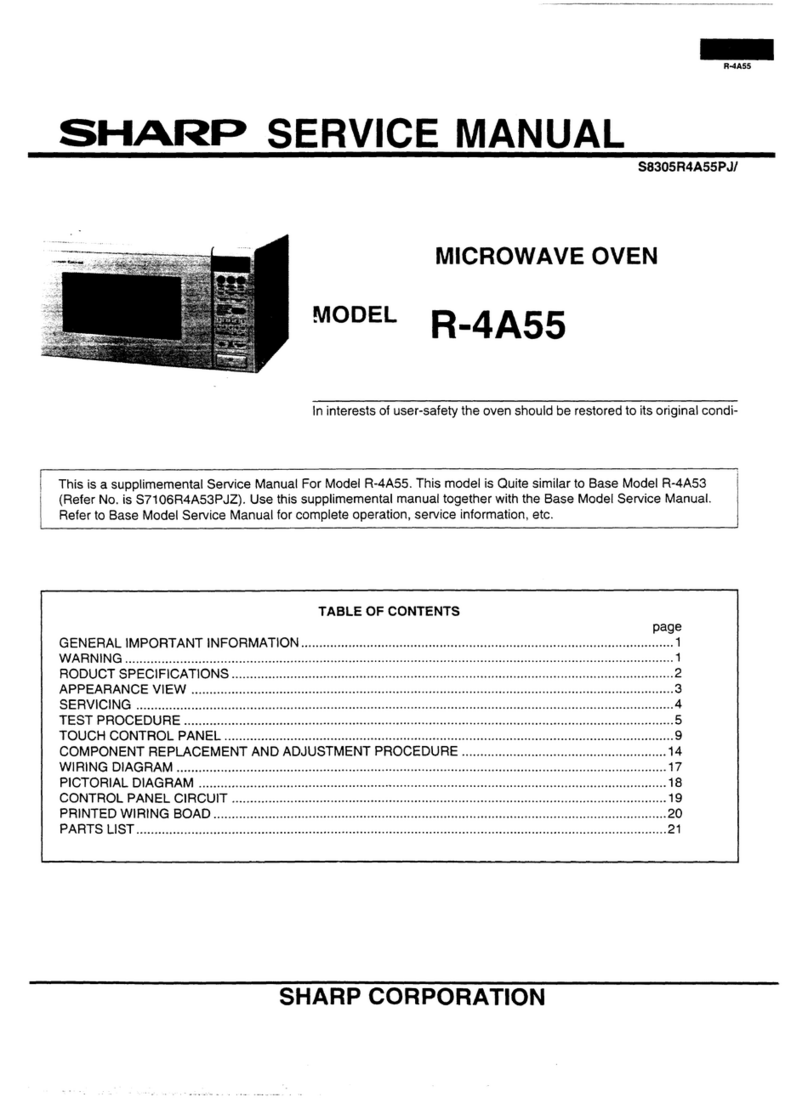

R-200BK

R-200BW

TURNTABLE MOTOR

The turntable motor rotates the turntable located on the

bottom of the oven cavity, so that the food on the turntable

iscookedevenly.Theturntable may turn in either direction.

COOLING FAN MOTOR

The cooling fan motor drives a blade which draws external

cool air. This cool air is directed through the air vanes

surrounding the magnetron and cools the magnetron. This

air is channelled through the oven cavity to remove steam

and vapours given off from the heating foods. It is then

exhausted through the exhausting air vents at the oven

cavity.

MAGNETRON THERMAL CUT-OUT

The thermal cut-out located on the top of the oven cavity is

designed to prevent damage to the magnetron if an over

heated condition develops in the tube due to cooling fan

failure, obstructed air guide, dirty or blocked air intake, etc.

Undernormaloperation,thethermalcut-outremainsclosed.

TROUBLESHOOTING GUIDE

Nevertouchanypartinthecircuitwithyourhandoranuninsulatedtoolwhilethepowersupplyisconnected.

Whentroubleshootingthe microwaveoven,itishelpfultofollowtheSequence ofOperationinperforming thechecks.Many

ofthepossiblecausesoftroublewillrequirethataspecifictestbeperformed.Thesetestsaregivenaprocedureletterwhich

will be found in the "Test Procedure "section.

IMPORTANT: If the oven becomes inoperative because of a blown C/T fuse, check the monitor switch, primary

interlock relay (RY1), door sensing switch and secondary interlock switch before replacing the C/T fuse.

If C/T fuse is replaced, the monitor switch must also be replaced. Use part FFS-BA020WRK0 as an

assembly.

IMPORTANT: Wherevertroubleshootingisperformed withthepowersupplycord disconnected.Itmayin,some cases,be

necessary to connect the power supply cord after the outer case has been removed, in this event,

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Disconnect the leads to the primary of the power transformer.

5. Ensurethatthe leadsremainisolatedfromothercomponentsandovenchassis byusinginsulationtape.

6. After that procedure, reconnect the power supply cord.

When the testing is completed,

1. Disconnect the power supply cord, and then remove outer case.

2. Open the door and block it open.

3. Discharge high voltage capacitor.

4. Reconnect the leads to the primary of the power transformer.

5. Reinstall the outer case (cabinet).

6. Reconnect the power supply cord after the outer case is installed.

7. Run the oven and check all function.

However,whenabnormallyhigh temperatures arereached

withinthemagnetron,thethermalcut-outwillopenat 257˚F

(125˚C), causing the oven to shut down.

C/T FUSE

1. TheC/T fuse blowswhenthecontacts(COM-NO) of the

primary interlock relay (RY2) and secondary interlock

switchremainclosedwith theovendooropenand when

the monitor switch closes.

2. If the wire harness or electrical components are short-

circuited,thisC/Tfuseblows topreventanelectricshock

or fire hazard.

3. The C/T fuse, located on the top of the oven cavity, is

designed to prevent damage to the oven by fire. If the

food load is overcooked, by either error in cook time or

defect in the timer, the C/T fuse will open.

Under normal operation, the C/T fuse remains closed.

However,whenabnormallyhigh temperatures arereached

within the oven cavity, the C/T fuse will open at 248˚F

(120˚C),causingtheoventoshut downorwhentheelectric

currents beyond 13A flow, the C/T fuse will open.