R-244M - 5

OPERATING SEQUENCE

1. Whentheovendoorisopened,theovenlampcomeson

at this time.

MICROWAVE COOKING CONDITION

2. When the cooking time is up, a single tone is heard and

the relays RY1 + RY2 go back to their home position.

The circuits to the oven lamp, power transformer, fan

motor and turntable motor are cut off.

CONNECTED COMPONENTS RELAY

Oven lamp, Fan motor, Turntable motor RY1

Power transformer RY2

CONDITION

DURING DOOR OPEN

SWITCH CONTACT COOKING (NO COOKING)

Monitor switch COM-NC Open Closed

Monitored latch switch COM-NO Closed Open

Stop switch COM-NO Closed Open

3. When the door is opened during a cook cycle, the

switches come to the following condition.

The circuits to the power transformer, fan motor and

turntablemotorarecutoffwhenthe monitored latch switch

and stop switch are made open.

Theovenlampremains on even if the ovendoor is opened

after the cooking cycle has been interrupted, because the

relayRY1staysclosed.Showninthedisplayistheremaining

time.

HIGH, MEDIUM HIGH, MEDIUM, MEDIUM

LOW, LOW COOKING

When the microwave oven is preset for variable cooking

power,thelinevoltageissuppliedtothe powertransformer

intermittently within a 32-second time base through the

relaycontactwhichiscoupledwiththecurrent-limitingrelay

(RY2). The following levels of microwave power are given.

SETTING

MEDIUM HIGH

MEDIUM LOW

Approx. 10% = 80 Watts

32 sec. ON

6 sec. ON

12 sec. ON

18 sec. ON

24 sec. ON

26 sec. OFF

20 sec. OFF

14 sec. OFF

8 sec. OFF

LOW

MEDIUM

HIGH

Approx. 70% = 560Watts

Approx. 50% = 400 Watts

Approx. 30% = 240 Watts

NOTE: TheON/OFFtimeratiodoesnotexactlycorrespond

to the percentage of microwave power, because

approx. 3 seconds are needed for heating up the

magnetron filament.

Approx. 100% = 800 Watts

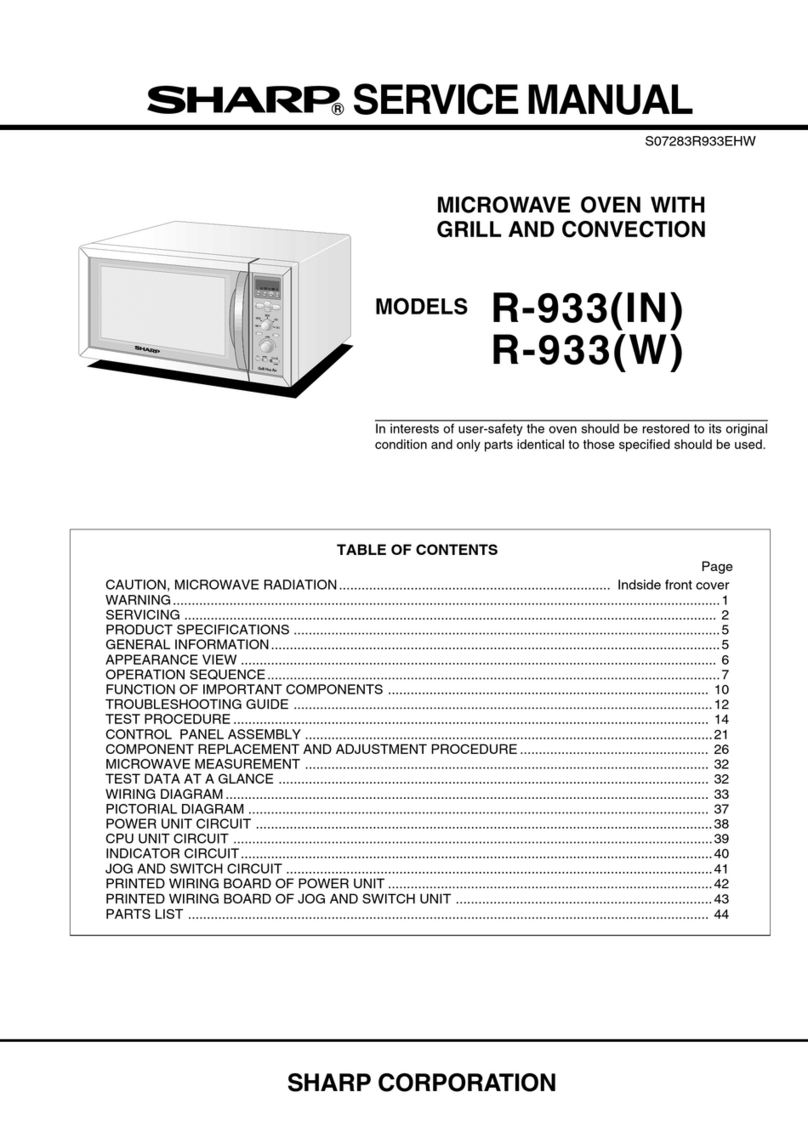

OFF CONDITION DOOR OPEN MECHANISM

The door can be opened by pulling the door.

Figure D-1. Door Open Mechanism

MONITORED LATCH SWITCH AND STOP

SWITCH

1. Whentheovendoor isclosed,thecontacts(COM-NO)

must be closed.

MONITOR SWITCH

1. Whenthe oven doorisclosed,thecontacts(COM-NC)

must be opened.

2. When the oven door is opened, the contacts (COM-

NC) must be closed.

3. If the oven door is opened and he contacts (COM-NO)

of the monitored latch switch fail to open, the fuse F1

blows immediately after closing the contacts (COM-

NC) of the monitor switch.

CAUTION: BEFORE REPLACING A BLOWN FUSE F1

TEST MONITORED LATCH SWITCH (SW1)

AND MONITOR SWITCH FOR PROPER

OPERATION. (REFERTOCHAPTER“TEST

PROCEDURE”).

FUSE

1. ThefuseF1blowswhenthecontacts(COM-NO)ofthe

monitored latch switch remain closed with the oven

door open and when the contacts (COM-NC) of the

monitor switch are closed.

2. If the wire harness or electrical components are short-

circuited,thefuseF1blowstopreventanelectricshock

or fire hazard.

HVT THERMOSTAT 150˚C

Thethermostatprotectsthehighvoltagetransformeragainst

overheating.Ifthetemperaturegoesuphigherthan150˚C

because the fan motor is interrupted or the ventilation

openings are blocked, the thermostat will cycle, line volt-

age to the high voltage transformer will also cycle. (If

operated, check the magnetron for damage.)

Latch hook

SW3: Stop switch

Door

SW2: Monitor switch

SW1: Monitored latch switch

Latch heads