R-430BK

R-430BW

R-430BD

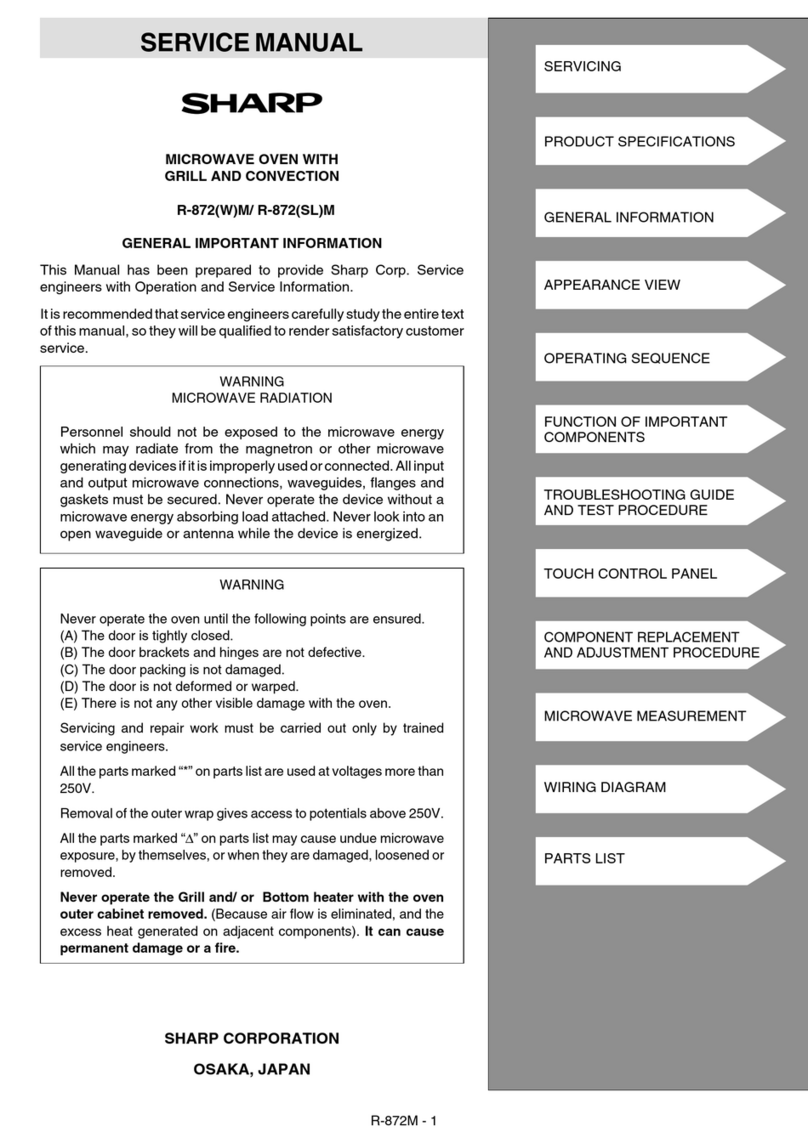

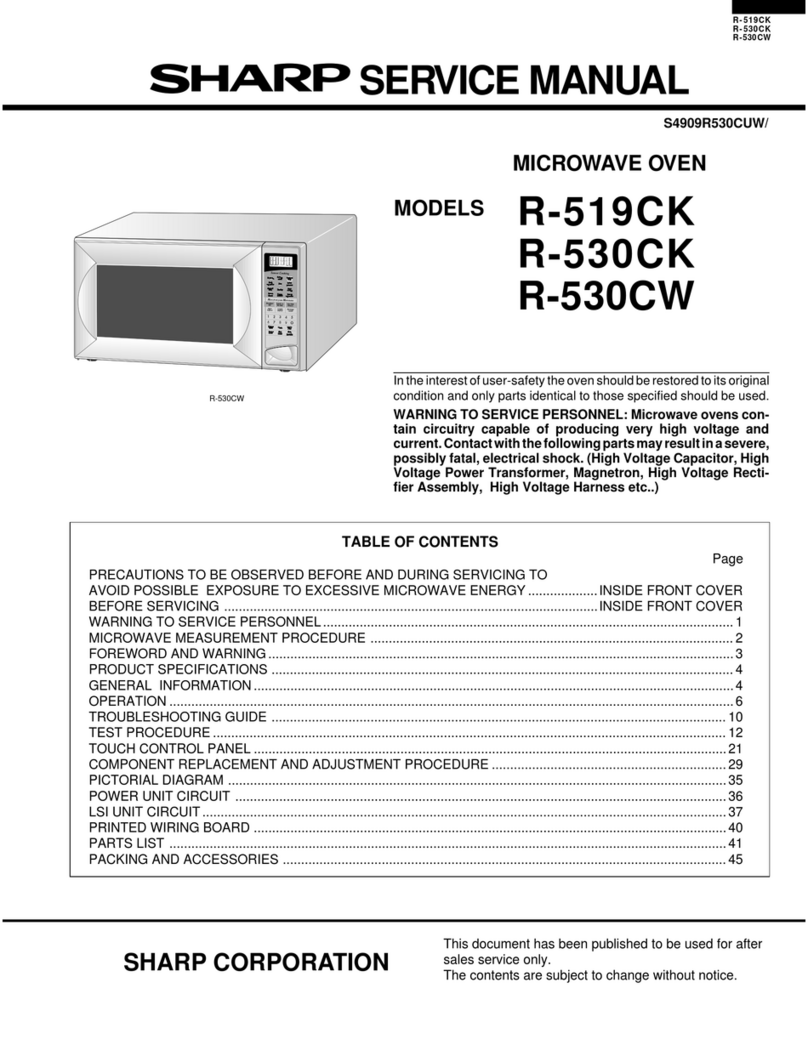

WARNING TO SERVICE PERSONNEL

Microwave ovens contain circuitry capable of

producing very high voltage and current. Con-

tact with following parts may result in a severe,

possibly fatal, electrical shock.

(EXAMPLE)

High Voltage Capacitor, High Voltage Power

Transformer, Magnetron, High Voltage Rectifier

Assembly, High Voltage Harness etc..

Read the Service Manual carefully and follow all

instructions.

Danger High Voltage

Before Servicing

1. Disconnect the power supply cord and then remove

outer case

2. Open the door and block it open.

3. Discharge the high voltage capacitor.

WARNING:RlSK OF ELECTRICAL SHOCK. DISCHARGE

THE HIGH VOLTAGE CAPACITOR BEFORE SERVICING.

The high-voltage capacitor remains charged about 60 se-

conds after the oven has been switched off. Wait for 60 se-

conds and then short-circuit the connection of the high volt-

age capacitor (that is the connecting lead of the high voltage

rectifier) against the chassis with the use of an insulated

screwdriver.

Whenever troubleshooting is performed, the power sup-

ply must be disconnected. In some cases it may be nec-

essary to connect the power supply after the outer case

has been removed, in this event:

1.

2.

3.

4.

5.

6.

Disconnect the power supply cord, and then remove

outer case cabinet.

Open the door and block it open.

Discharge the high voltage capacitor.

Disconnect the leads to the primary of the power

transformer.

Ensure that the leads remain isolated from other

components and oven chassis by using insulation

tape.

After the above procedure, reconnect the power sup-

ply cord.

When the testing is completed

1. Disconnect the power supply cord and then remove

outer case cabinet.

2. Open the door and block it open.

3. Discharge the high voltage capacitor.

4. Reconnect the leads to the primary of the power

transformer.

5. Re-install the outer case cabinet.

6. Reconnect the power supply cord after the outer

case cabinet is installed.

7. Start the oven and check all functions.

After repairing

1. Reconnect all leads removed from components dur-

ing testing.

2. Re-install the outer case (cabinet).

3. Reconnect the power supply cord after the outer

case is installed.

4. Reconnect the power supply cord after the outer

case is installed.

5. Run the oven and check all functions.

Microwave ovens should not be operated empty. To test

for the presence of microwave energy within a cavity,

place a cup of cold water on the oven turntable, close the

door and set the power to HIGH and set the microwave

timer for two (2) minutes When the two minutes has

elapsed (timer at zero), carefully check to see if the wa-

ter is hot. If the water remains cold, carry out Before

Servicing procedure and re-examine the connection to

the component being tested.

When all service work is completed and the oven is fully

assembled, the microwave power output should be

checked and the microwave leakage test should be car-

ried out.