R-6280

DESCRIPTION AND FUNCTION OF COMPONENTS

OVEN TEMP. FUSE

The temp. fuse located on the top wall of the oven

cavity is designed to prevent damage to the unit if the

foods in the oven catch fire due to overheating

produced by unproper setting of cooking time or failure

of the timer. Open temp. 145 “C(293 ‘F) not resetable.

MAGNETRON TEMP. FUSE

The temp. fuse located on the waveguide side wall is

designed to prevent damage to the magnetron if an

over heated condition develops in the tube due to

cooling fan failure, obstructed air ducts, dirty or

biocked air intake, etc.

Under normal operation, the temp. fuse remains closed.

However, when abnormally high temperatures are

reached within the magnetron the fuse will open at

145 “C(293 ‘F), causing the oven to shut down.

This is a fuse and it does not reset.

UPPER LATCH SWITCH

The switch is activated by the upper iatch head on the

door. When the door is opened, the switch interrupts

the circuit to all components (except oven lamp). A

cook cycle cannot take until the door is firmiy ciosed

and the start button depressed with the timer ser.

COOK (LOWER LATCH) SWlTCH

This switch functions both as a cook(iower iatch)

switch. Operation are as follows.

1. When the door is closed, the latch head moves

downward the cook switch lever which causes not

to close the cook(lower latch) switch contacts.

2. When the start button is pressed, it operates the

cook switch lever moving latch head downward

farther.

The cook switch lever now depresses the plunger

of the switch closing its COM- NO contacts (ON

condition).

3. When the open button is pressed, it pushes up the

cook switch lever raising the latch heads. As the

cook switch lever is raised, the switch plunger is

released, opening the COM-NO contacts of the

switch (OFF condition). The cook switch lever is

also returned to original position.

MONITOR SWITCH

The monitor switch is activated (the contacts opened)

by the latch head on the door while the door is closed,

The switch is intended to render the oven inoperative

by means of blowning the fuse when the contacts of

the cook switch, fail to open when the door is opened.

Functions:

1. When the door is opened, the monitor switch con-

tacts close (to the ON condition) due to their being

normally opened. At this time the cook(lower

latch) switch are in the OFF condition (contacts

open) due to their being normally open contacts

switches.

2.

3.

As the door goes to a closed position, the monitor

switch contacts are first opened and then the upper

latch switch contacts close. The cook (lower

latch)switch contacts close when the start button

is depressed (In case of opening the door, each of

these switches operate inversely.)

If the door is opened, and the cook(lower latch)

switch contacts fail to open the fuse blows simul-

taneously with closing of the monitor switch con-

tacts.

CAUTION:BEFORE REPLACING A BLOWN FUSE

M6.3A TEST THE COOK(LOWER LATCH)

SWITCH AND MONITOR SWITCH FOR

PROPER OPERATION.

(REFER TO CHAPTER “TEST PROCE-

DURE”).

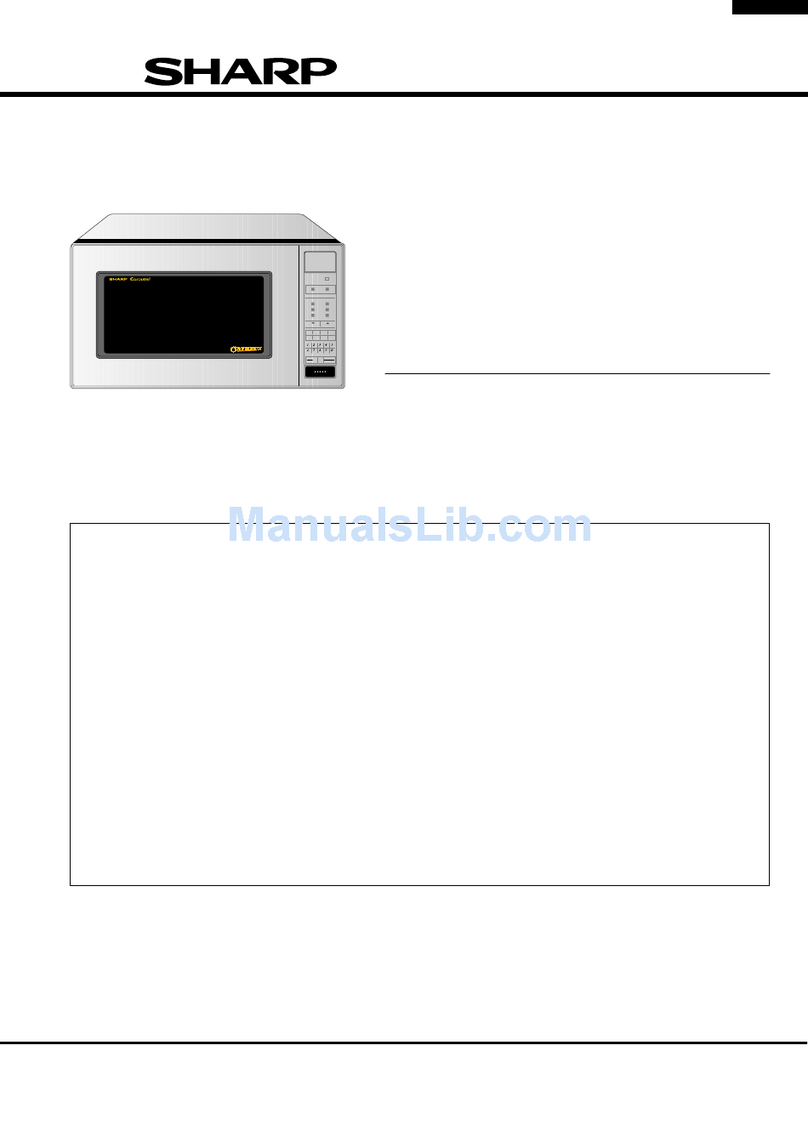

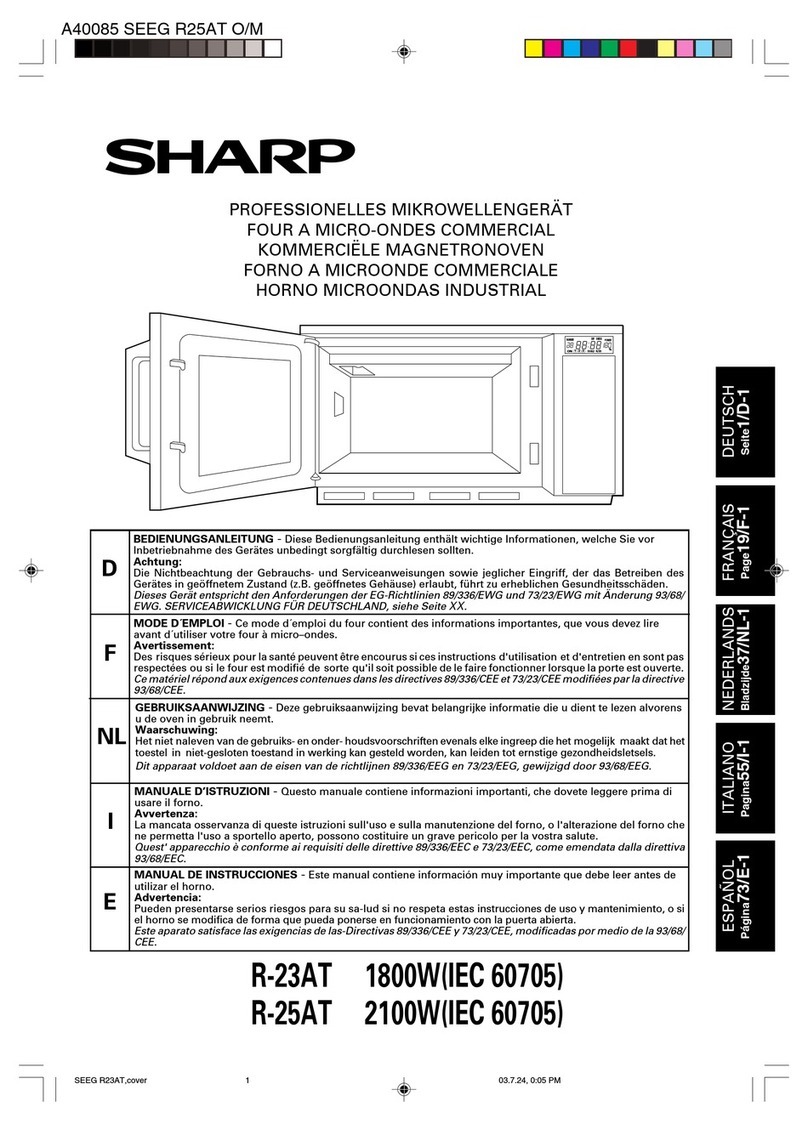

DOOR OPEN MECHANISM

The door is opened by pushrng the open button on the

control panel, refer to the Figure D-i.

When the open button Is pushed, the open lever

pushes up the switch lever. and then the switch lever

pushes up the latch head.

The latch head are moved upward and released from

the latch hook. Now the door will open.

\

UPPER

LATCH

SWITCH

MONITOR

SWITCH

COOK

(LATCH)

SWITCH

COOK

‘SWITCH

LEVER

J

/J al’x< ‘h-

O/

3 A.

START ‘L

BUTTON \OPEN

BUTTON

Fiaure D-l. Door ODen Mechanism

5