R-677 - 10

TOP GRILL MODE

In this mode, the food is cooked by the grill heating

element (top grill). Select the TOP GRILL mode with the

COOKING MODE selector. Enter the cooking time by

rotating the TIME/WEIGHT dial. When the START button

is pressed, the following operations occur:

Figure O-3(a) on page 33

1. The relay RY1 + RY3 + RY5 are energized.

2. Thenumbersofthedigitalreadoutstartthecountdown

to zero.

3. Then the grill heating element (top), turntable motor,

oven lamp and fan motor are energized.

4. Now, the food is grilled by the grill heating element.

5. Uponcompletion of the selected cooking time, audible

signal sounds and the contacts of relays RY1 + RY3

are opened, then the grill heating element (top), turn-

table motor and oven lamp are de-energized.

6. TherelayRY5staysclosedforfive(5)minutes,andthe

fan motor operates.

BOTTOM GRILL MODE

In this mode, the food is cooked by the bottom heating

element.SelecttheBOTTOMGRILLmodewiththeCOOK-

INGMODEselector.Enterthecookingtimebyrotatingthe

TIME/WEIGHT dial. When the START button is pressed,

the following operations occur:

Figure O-3(b) on page 33

1. The relay RY1 + RY4 + RY5 are energized.

2. Thenumbersofthedigitalreadoutstartthecountdown

to zero.

3. Then the bottom heating element, turntable motor,

oven lamp and fan motor are energized.

4. Now,the food is grilled by thebottomheatingelement.

5. Uponcompletion of the selected cooking time, audible

signal sounds and the contacts of relays RY1 + RY4

areopened,then the bottom heatingelements,turnta-

ble motor and oven lamp are de-energized.

6. TherelayRY5staysclosedforfive(5)minutes,andthe

fan motor operates.

TOP AND BOTTOM GRILL MODE

In this mode, the food is cooked by both the grill heating

element(topgrill)and bottom heating element.Selectthe

TOP AND BOTTOM GRILL mode with the COOKING

MODE selector. Enter the cooking time by rotating the

TIME/WEIGHT dial. When the START button is pressed,

the following operations occur:

Figure O-3(c) on page 34

1. The relay RY1 + RY3 + RY4 + RY5 are energized.

2. Thenumbersofthedigitalreadoutstartthecountdown

to zero.

3. Then the grill heating element (top), bottom heating

element,turntablemotor,ovenlampandfanmotorare

energized.

4. Now, the food is grilled by the grill heating element

(top) and the bottom heating element.

5. Uponcompletion of the selected cooking time, audible

signal sounds and the contacts of relays RY1 + RY3 +

RY4 are opened, then the grill heating element (top),

bottom heating element, turntable motor and oven

lamp are de-energized.

6. TherelayRY5staysclosedforfive(5)minutes,andthe

fan motor operates.

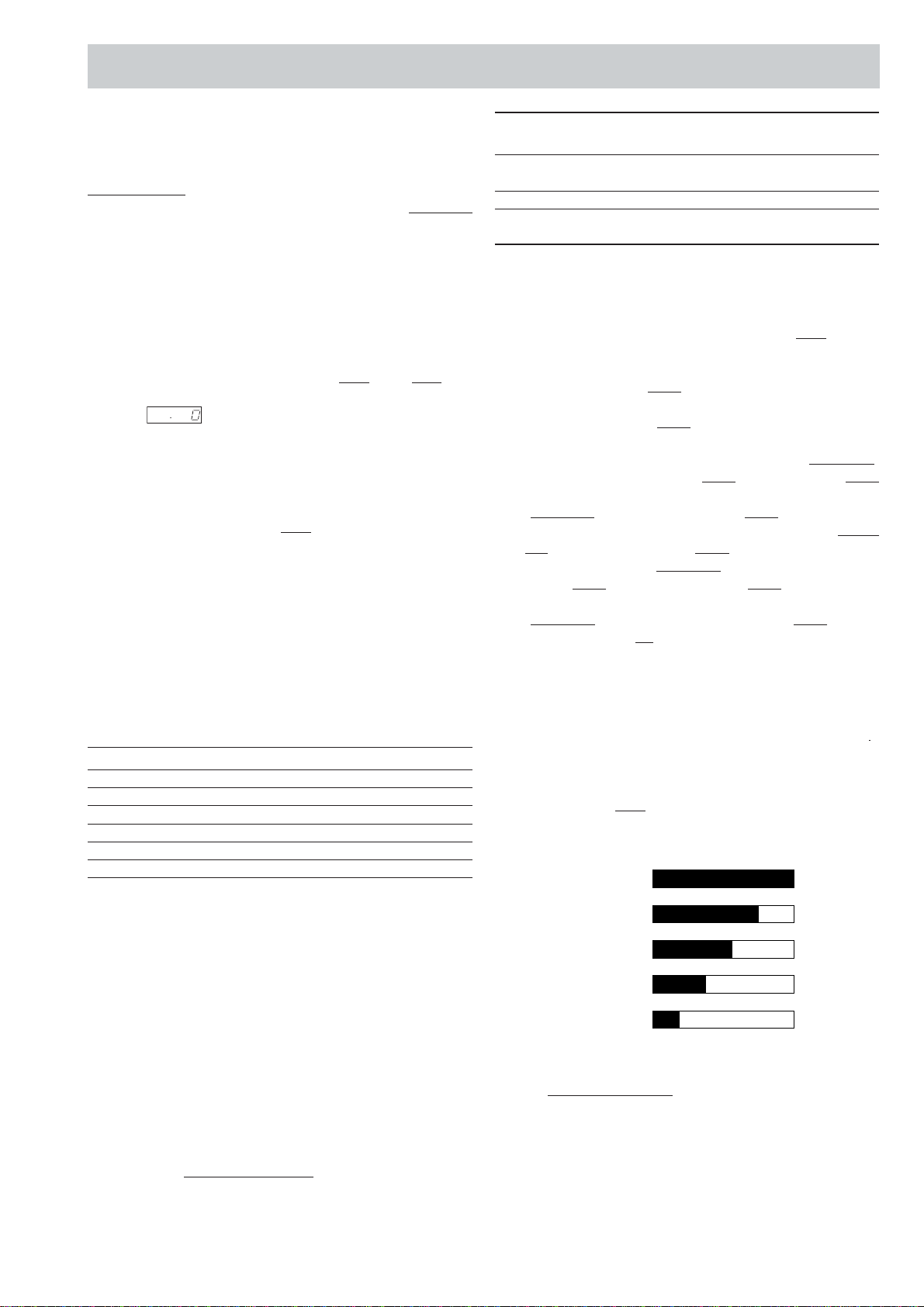

DUAL COOKING CONDITION

The oven has two dual cooking mode. One is MICRO-

WAVE AND TOP GRILL mode and other one is MICRO-

WAVE AND BOTTOM GRILL mode. In both modes, the

relayRY2operatesintermittentlywithina48secondstime

base as shown below.

Power level ON time OFF time

100% 48 sec. 0 sec.

70% 36 sec. 12 sec.

50% 26 sec. 22 sec.

30% 16 sec. 32 sec.

10% 8 sec. 40 sec.

MICROWAVE AND TOP GRILL MODE (DUAL 1)

Inthismode,thefoodiscookedbymicrowaveandthegrill

heatingelement(top).SelecttheMICROWAVEANDTOP

GRILLmodewiththeCOOKINGMODEselectorandthen

select the power level with the WATT button. Enter the

cookingtimebyrotatingtheTIME/WEIGHTdial.Whenthe

START button is pressed, the following operations occur

(Fig. O-4(a)):

1. The relay RY1 + RY2 + RY3 + RY5 are energized.

2. Thenumbersofthedigitalreadoutstartthecountdown

to zero.

3. The grill heating element (top), high voltage trans-

former, turntable motor, oven lamp and fan motor are

energized.

4. Now, the food is cooked by the microwave and grill

heating element (top).

5. Uponcompletion of the selected cooking time, audible

signal sounds and the contacts of relays RY1 + RY2 +

RY3 are opened, then the grill heating element (top),

high voltage transformer, turntable motor and oven

lamp are de-energized.

6. TherelayRY5staysclosedforfive(5)minutes,andthe

fan motor operates.

MICROWAVE AND BOTTOM GRILL MODE (DUAL 2)

In this mode, the food is cooked by microwave and the

bottom heating element. Select the MICROWAVE AND

TOPGRILLmodewiththeCOOKINGMODE selectorand

thenselectthepowerlevelwiththeWATTbuttonEnterthe

cookingtimebyrotatingtheTIME/WEIGHTdial.Whenthe

START button is pressed, the following operations occur

(Fig . O-4(b)):

1. The relay RY1 + RY2 + RY4 + RY5 are energized.

2. Thenumbersofthedigitalreadoutstartthecountdown

to zero.

3. Thebottomheatingelement,highvoltagetransformer,

turntable motor, oven lamp and fan motor are ener-

gized.

4. Now,the food iscooked bythe microwave andbottom

heating element.

5. Uponcompletion of the selected cooking time, audible

signal sounds and the contacts of relays RY1 + RY2 +

RY4 are opened, then the bottom heating elements,

high voltage transformer, turntable motor and oven

lamp are de-energized.

6. TherelayRY5staysclosedforfive(5)minutes,andthe

fan motor operates.

OPERATION SEQUENCE CONT...