Sharp SuperSteam Plus SSC3088AS User manual

Other Sharp Oven manuals

Sharp

Sharp K-50M22BL2-FR User manual

Sharp

Sharp SWA2450GS User manual

Sharp

Sharp SSC0586DS User manual

Sharp

Sharp STR3065HS User manual

Sharp

Sharp SMD2477AHC User manual

Sharp

Sharp KA-60D22IM1-EU User manual

Sharp

Sharp K-61V28IM1-EU User manual

Sharp

Sharp KA-62V19IM0-EU User manual

Sharp

Sharp K-61D27IM1-EU User manual

Sharp

Sharp SuperSteam+ SSC3088A User manual

Sharp

Sharp KA-73G68BNH-PL User manual

Sharp

Sharp EO-35K User manual

Sharp

Sharp AX-1700VN User manual

Sharp

Sharp K-70V19BM2-EN User manual

Sharp

Sharp SuperSteam AX-1200K User manual

Sharp

Sharp Warm & Toasty R-55TS User manual

Sharp

Sharp K-60D22BM1-UA User manual

Sharp

Sharp SUPERSTEAM AX-1500JS User manual

Sharp

Sharp AX-GX2T(R) User manual

Sharp

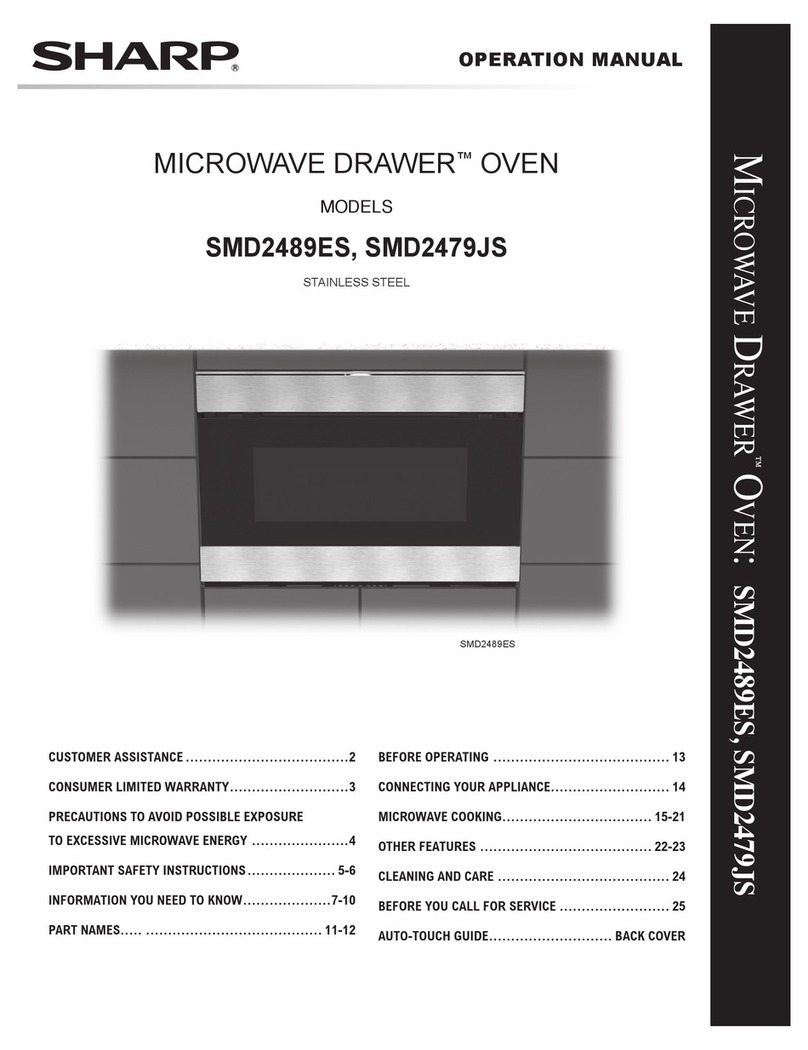

Sharp Microwave Drawer SMD2489ES User manual