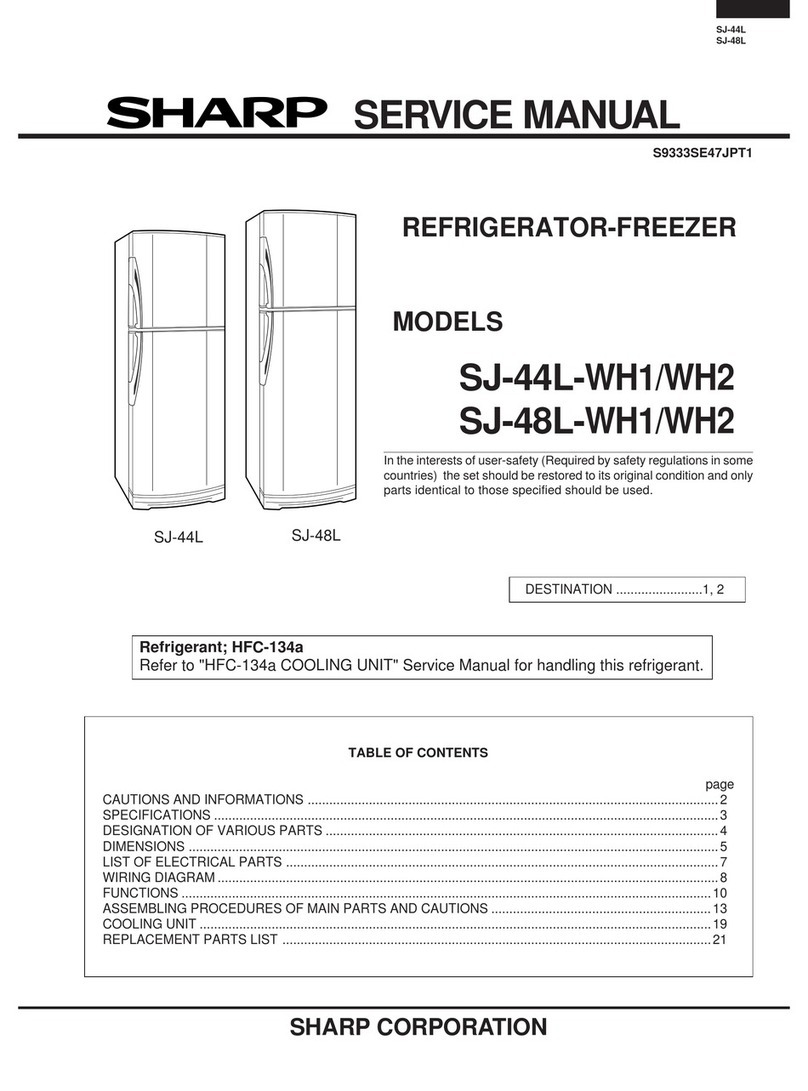

Refer to "HFC-134a COOLING UNIT" Service Manual for handling this refrigerant.

Refrigerant; HFC-134a

SJ-A28S-SL

SJ-B27S-SL

CHAPTER 1. SPECIFICATION

CHAPTER 2. DESIGNATION OF VARIOUS PARTS

[1] EXTERNAL DESCRIPTION........................... 2-1

[2] CONSTRUCTIONS........................................ 2-2

CHAPTER 3. DIMENTIONS

[1] OUTER DIMENTIONS AND

CLEARANCE ................................................. 3-1

[2] INNER DIMENTIONS .................................... 3-4

CHAPTER 4. LIST OF ELECTRICAL PARTS

CHAPTER 5. WIRING DIAGRAM

[1] WIRING DIAGRAM ........................................ 5-1

[2] ELECTRIC ACCESSORIES LAYOUT ........... 5-2

CHAPTER 6. FAILURE DIAGNOSIS

[1] OUTLINE OF CONTROL ............................... 6-1

[3] RE-SETTING OF MICROCOMPUTER AT

POWER FAILURE.......................................... 6-2

[4] DIAGNOSIS METHOD OF FAILURE ............6-2

[5] CONVERSION TABLE ..................................6-3

[6] CIRCUIT DIAGRAM OF MAIN PWB .............6-4

CHAPTER 7. FUNCTIONS

[1] ADJUSTABLE TEMPERATURE

CONTROL .....................................................7-1

CHAPTER 8. ASSEMBLI NG PROCEDURES OF

MAIN PARTS AND CAUTIONS

[1] F-LOUVER ASS'Y (SJ-A20S/B21S/A24S/

B25S/A28S/B27S)..........................................8-1

[3] R CONTROL COV. ASS'Y.............................8-7

[4] HOW TO REPLACE THE LAMP ...................8-9

[5] DEFROST HEATER ......................................8-10

CHAPTER 9. COOLING UNIT

[1] COOLING UNIT.............................................9-1

[2] LOCATION ....................................................9-2

Parts Guide

[2] F-LOUVER ASS'Y (SJ-A31S/A34S)...............8-4

[1] SJ-A20S/B21S/A24S/B25S/A28S/B27S........ 2-1

[2] SJ-A31S/A34S .......................................... 2-2

[3] PRECAUTION FOR USING LEAD-FREE

SOLDER........................................................5-3

[2] CHECK MODE OF DEFROST HEATER

(Forced Defrosting) ........................................ 6-1

SJ-F230G

SJ-F230G

SJ-F230G

Ag