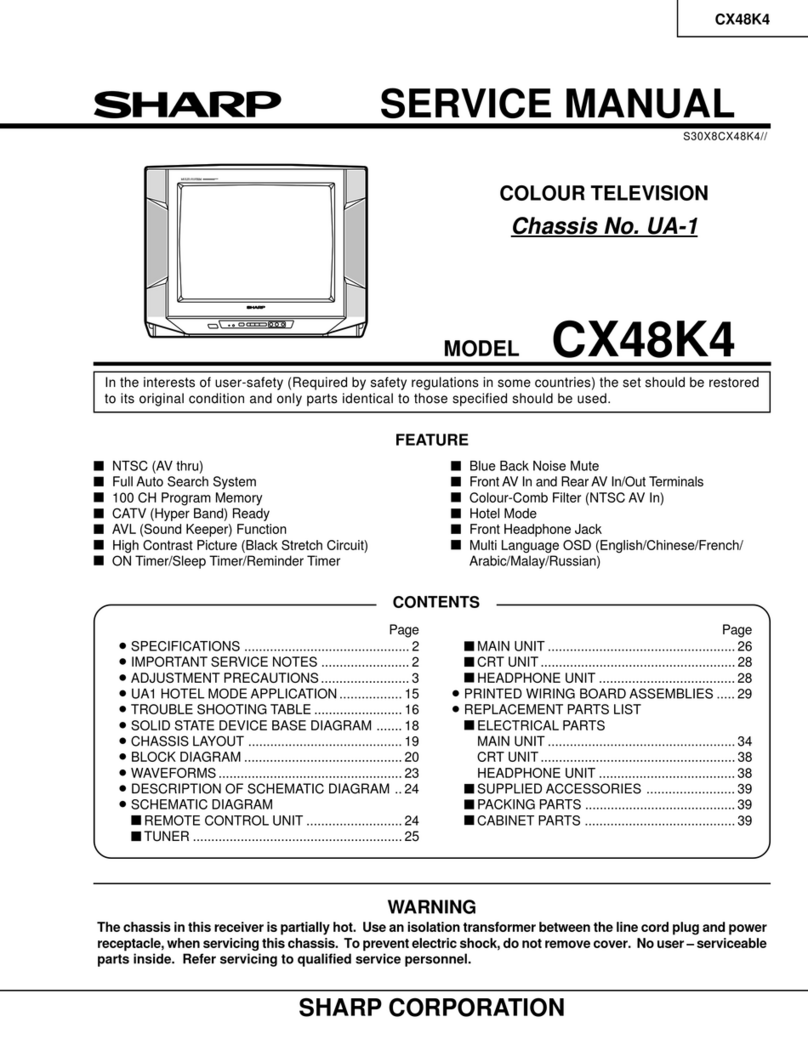

INSTALLATION AND SERVICE ADJUSTMENTS

INSTALLATION OF NEW COLOUR TELEVISION

RECEIVER

Adjust the receiver for a black and white picture. Check

the horizontal oscillator adjustment, focus, vertical size

and linearity. Observe the picture for good

black-and-

white reproduction over all areas of the screen. No ob-

jectionable

colour

shading should be evident. If shading

is evident, demagnetize the receiver. It is seldom necessary

to go through a complete “set-up” routine when installing

a new colour receiver. In the majority of cases a technician

needs only to

degauss

the face plate area of the picture

tube and touch up the static convergence.

Colour

television receivers leaving the factory are adjusted

by experts who specialize in the set-up of

colour

receivers.

Normally, readjustment of picture tube temperature or

even dynamic convergence should not be required upon

delivery. However, since a receiver or parts of it, may

become magnetized as it is transported from one location

to another, it is very important to demagnetize the picture

tube face plate area once the receiver is set in its final

operating position.

DEGAUSSING

This receiver is equipped with an automatic

degaussing

coil

which effectively demagnetizes the picture tube each time

the receiver is turned on. The

degaussing

coil will operate

at any time the set is turned on after having been off for at

least five minutes.

Since this

degaussing

effect is confined to the picture tube,

should any part of the chassis or cabinet become magnetized,

it will be necessary to

degauss

the affected area by means of

a manual

degaussing

coil. Move the coil slowly around the

parts to be demagnetized, then slowly withdraw for a

distance of six feet before disconnecting the coil from

the AC power supply.

Note:

Degaussing

(or

demagnetising)

is an important

function in the setting up and installation of

colour

T.V.

receivers.

The receiver should be positioned in its foal

location before

degaussing

because of possible loss of

purity due to the

re-location

of the receiver.

Because of possible loss of purity caused by the

re-location

of the receiver, the cabinet should be positioned in its

final location before

degaussing.

MODULE SERVICE PERCAUTIONS

1.

DO NOT remove or insert module units whilst the set is

switched on.

2.

Semiconductor heat sinks should be regarded as potential

shock hazards when the receiver is operation.

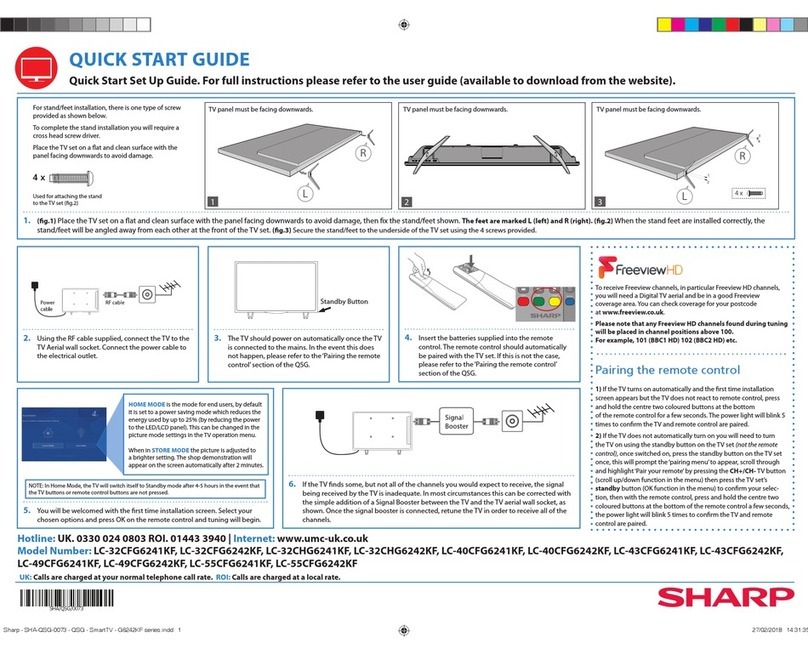

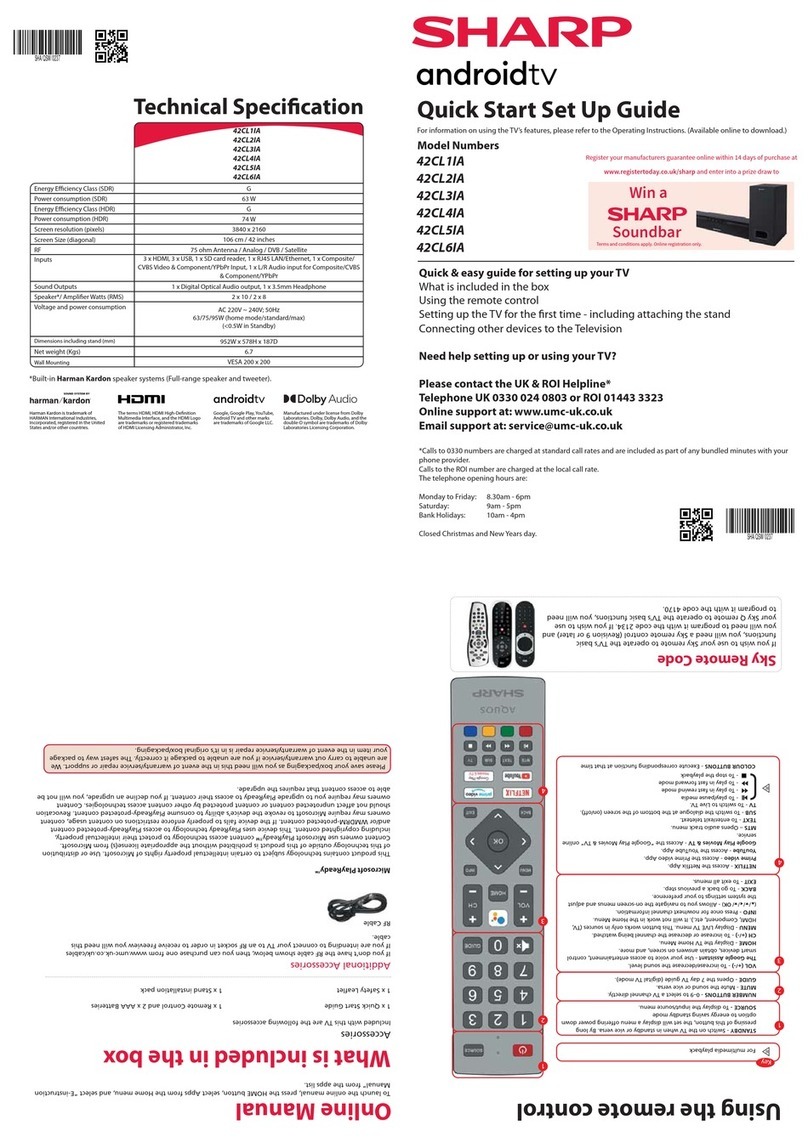

HOWTOADJUSTTHECHANNELSETTING(UHF/VHF)

(1)

Touch the Channel Selector Button corresponding to

the channel, that you wish to select.

(2)

Adjust the Band Selector switch to either of 3

positions

(VL,

VH

,

U)

as shown below, depending on

what channel you now wish to select.

BAND

VL

. . . . . . . . .

VHF 0

-

Sch.

BANDVH

. . . . . . . . .

VHF5A-llch.

BANDU

. . . . . . . . .

UHF21-69ch.

(3)

Note the number on the Channel Selector Button and

relate it to the Preset Tuning knob and Band Selector

switch with corresponding number.

(4)

Tune in the desired channel by turning the Preset

Tuning knob clockwise or counterclockwise until the

channel is properly tuned.

Note:

Whenever the ON-OFF switch is turned on, No. 1 program

will always be selected. However, when you want to change

this No. 1 program to another program by depressing the

channel selector button, it sometimes occurs that the

corresponding indicator lamp does not light up

-

this

means that your desired program has not been selected.

In this case, set the ON-OFF switch to “OFF” position and

reverse the polarity of power cord. Then, the unit will

function normally, assuring a proper program selection. The

aforesaid, however, may take place only when the antenna

terminal is grounded or a separate transformer is used as a

power supply source and, therefore, this is out of the

question as long as you operate the unit in a normal

receiv-

ing

condition.

Preset Channel Table

(at factory setting)

No. 1

A2

No.2

Al

No. 3 ASA

No.4

A6

No. 5

A2

No. 6

E23

No. 7 E34

No. 8 E68

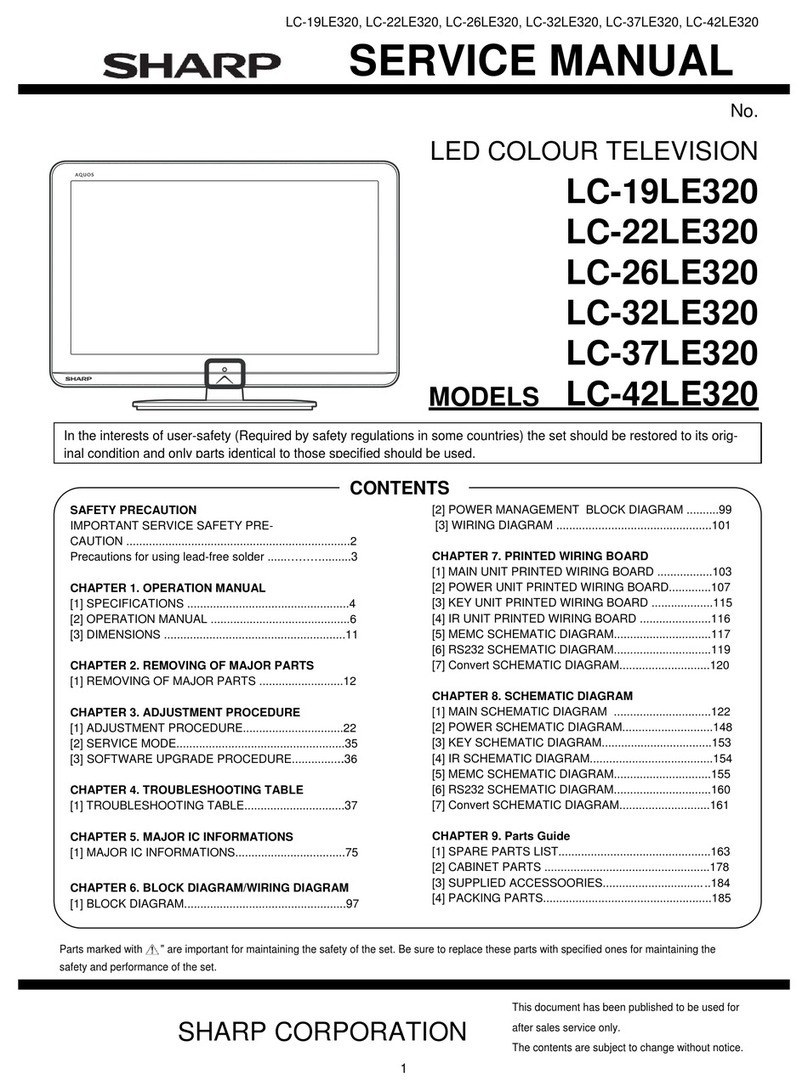

Figure

1.

Front Panel Controls

7