SharperTek Industrial Grade Ultrasonic Sewing Machine User manual

www.sharpertek.com Sales: 877.234.6938

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

Production Grade Ultrasonic Lace/Sewing MachineProduction Grade Ultrasonic Lace/Sewing Machine

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

Overview

The SharperTek ultrasonic sewing machine joins plastic and rubber film products. Its operation is

simple, resembling a normal sewing machine's operation.

Highly productive and versatile, the machine can join and slit in one process. The bonded joint produced

is attractive, strong and durable.

The machine joins materials using ultrasonic technology. A rotating work head die, located in the upper

armature of the machine, is lowered to the table's work surface and pinches rubber or plastic films

between itself and an ultrasonic mould located in the table top. The ultrasonic mould transmits ultrasonic

energy, and the rotating work head die feeds the pinched films through the joining process creating a

permanent, bonded joint.

Power up and configure the machine using each of two switch panel interfaces: one located on the table

top, the other located below in the machines frame. The table top switch panel interface configures the

machines feed operation. The frame mounted switch panel interface configures the machines

ultrasonics.

You can adjust the rotating work head die set height by rotating the large nut located on top of the

machines armature.

You can tune the ultrasonic frequency by rotating a recessed rheostat located on the frame mounted

switch panel interface.

You can alter the machines joining pattern by replacing the rotating work head die located in the

armature of the machine.

A

B

C

D

EF

GH

I

A - Table Top Switch Panel Interface

B - Frame Mounted Switch Panel Interface

C - Main Feed Pedal

D - Rotating Work Head Lower Pedal

E - Rotating Work Head Die

F - Ultrasonic Mould

G - Rotating Work Head Set Height Adjust

H - Rotating Work Head Manual Feed

I - Ultrasonic Booster and Power Source

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

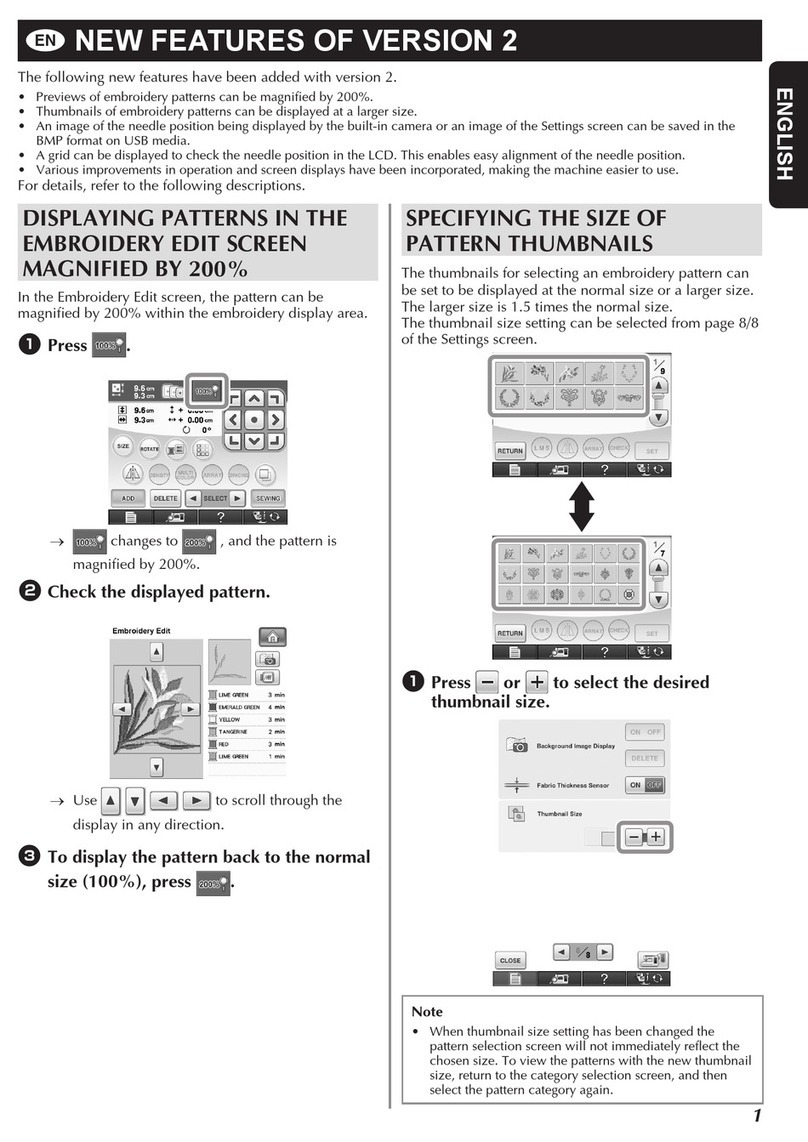

Using The Switch Panel Interfaces

Table Top Switch Panel Interface

Power Supply On/Off. This enables the upper armature feed mechanism, turns on the cooling fan and

readies the machine for operation.

Feeding On/Off. This enables the rotating work head die's rotation. It will not rotate in any mode until this

switch is in the On position.

Mould Rotation On/Off. This enables the ultrasonic mould's rotation. The ultrasonic mould will rotate

continuously if this switch is in the on position and feed is activated.

Auto/Hand Up/Down. This selects how the rotating work head die is rotated. In the up, or Auto position, it

is rotated continuously whenever the ultrasonic generator is engaged. In the down, or Hand position, it is

rotated only when the operator engages the process by depressing the large foot pedal on the base of the

machine. NOTE: in the middle detent position, no feed is enabled.

Speed Adjustment Rotate. This adjusts the rotating work head die rotational feed speed. Clockwise

rotation increases feed speed, counterclockwise rotation decreases feed speed.

Switch Panel Interfaces

Table Top Switch Panel

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

Using The Switch Panel Interfaces

Frame mounted switch panel interface

Power SW Up/Down. This enables the ultrasonics. Toggle the switch up for on, toggle the switch down

for off.

Continuous Work/Test Ultrasonics Down/Middle/Continuous Work. This switch determines how the

ultrasonics works with the armature feed. Select up for continuous operation. Select the middle position

for foot pedal operation. Select the momentary down position to enable the ultrasonics for testing.

NOTE: When you select Auto on the table top switch interface Auto/Hand switch, you must select

Continuous Work. When you select Hand on the table top switch interface Auto/Hand you must select the

middle positon of this switch.

Overload Illuminated/Not. When the ultrasonics is overloaded the Overload light is illuminated.

Power Ind. Illuminated/Not. When the power switch is Up, the Power Ind. Light is illuminated.

Amp Meter. This meter indicates the loading factor of the ultrasonics.

Switch Panel Interfaces

Frame Mounted Switch Panel

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

Typical Power Up And Usage Sequence

Turn on Armature Control

Turn on Ultrasonic Control

Select Continuous or Hand Feed

Note: Foot Pedal Enabled only with Hand Feed Selected

Set Feed Rate

Turn on Feeding

Turn on Mould Rotation if Required

Lower Rear Material Guide By Operating Lever At Rear Of Armature

Insert Material Between Work head Die And Mould

Depress Left Pedal (small) To Lower Work Head Die

Depress Right Pedal (large) To Enable Feed

Note: Feeding Switch Must Be On for Either Continuous or Pedal Feed

Adjustments

Frequency Adjustment

Tune the ultrasonic frequency by operating the front mounted tuning dial located on the ultrasonic

control panel.

Material Thickness Adjustment

Located atop the work armature is a large locking nut adjustment. To set the tools work height, loosen

the locking jamb nut, and turn the large nut by hand. Counterclockwise turns lower the rotating work

head die, clockwise turns raise it.

NOTE: The working head should NEVER come in contact with the rotating mould surface of the

ultrasonic horn. Use care to ensure that there is no contact between the two metal surfaces.

Adjust the rotating work head die such that the material is pressed together between the rolling working

head and the rotating mould. The pressure of the head working against the fabric friction feeds the

material through the ultrasonic process.

A

B

C

Rotate the adjustment knob A so that the

rotating work head die B pinches the

materials and feeds them through across

the rotating mould surface C.

Do not allow the adjustment of A to

cause the surface of the work head die B

to come in contact with the rotating

mould surface C. Damage may occur.

Power Up And Adjustments

www.sharpertek.com Sales: 877.234.6938

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

A - Electrode Switch K - Motor Switch

B - Electric Supply Switch L - Foot Control Switch

C - Electric Supply Indicator M - Energy Exchanger B

D - Ultrasonic Generator N - Entrance Control Point

E - Motor Speed Regulator O - Red

F - Potentiometer For Adjusting Speed P - White

G - Ground Q - Black

H - Cooling Fan R - Spin Position Restriction Switch

I - Control Wall S - Motor M1

J- Off Delay Timer T - Motor M2

Wiring Diagram

ST

B

C

H

L

G

R

A

D

IJ

E

F

K

N

M

Main Wiring Diagram

OPQ

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

Pattern Wheel Pressing Wheel

Filter Connection

Pneumatic Diagram

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

Screw

Pattern Roll

Slide Plate

Mould Head

Work

Surface

Note: Loosen screw, adjust the die to

be parallel to the mould head work

surface.

Die And Mould Assembly

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

SY-2015 Main Circuit Board

Ride The WavesRide The Waves

Industrial Grade Ultrasonic Sewing MachineIndustrial Grade Ultrasonic Sewing Machine

www.sharpertek.com Sales: 877.234.6938

SY-2015 Protection Board

This manual suits for next models

1