SHARPY 20R User manual

1Please read the manual carefully before use. 350W beam pattern

lamp three in one shaking head lamp

an instruction manual

(color display, touch operation)

catalogue

Chapter 1 precautions and installation.......................................... 1

1. Maintenance............................................. 1

2. Declaration......................................... 1

3. Precautions for products.......................................... 1

4. Product introduction........................................ 1

5. Signal line connection (DMX)................................................... 2

6. Installation of lamps........................................ 2

Chapter 2 panel operation........................................ 3

1. General......................................... 3

2. Operation......................................... 3

1. Use visual touch or encoder to operate lamps........................................ 3

2. Parameter value input......................................... 3

3. Set Boolean parameters........................................ 4

4. Sub page (parameter).................................................................... 4

3. Function operation and parameter setting........................................ 4

1. Set DMX address code.......................................... 4

2. Set the working mode of lamps.......................................... 5

3. Setting panel display settings.......................................... 6

4. Test lamps.......................................... 6

5. Setting the working parameters of lamps.......................................... 7

6. Check the current status of lamps.......................................... 7

Chapter 3 channel description........................................ 8

1. Channel table.......................................... 8

Chapter 4 common faults and precautions for use........................................ 11

1. Common fault handling........................................ 11

2. Precautions for use........................................ 11

Chapter 1 precautions and installation

1. Maintenance1. Maintenance

The lamp shall be kept dry to avoid working in humid environment.

Intermittent use will effectively prolong the service life of the lamp.

In order to obtain good ventilation effect and lighting effect, pay attention to

regularly cleaning the fan, fan net and lens.

Do not wipe the lamp shell with alcohol or other organic solvents to avoid damage.

2. Declaration2. Declaration

This product has good performance and complete packaging when leaving the

factory.All users shall strictly abide by the warnings and operating instructions

stated above. Any damage caused by misuse is not within the warranty of the company,

and the faults and problems caused by ignoring the operating manual are not within

the scope of the distributor's responsibility.

This manual is subject to technical changes without notice.

3. Product precautions3. Product precautions

In order to ensure the service life of the product, the product shall

not be placed in a wet or leaking place, nor shall it work in an

environment with a temperature of more than 60 ℃

Do not place the product in a place easy to loosen or shake.

In order to avoid the danger of electric shock, please ask a professional for

maintenance of this product.

When the bulb is used, the change of power supply voltage shall not exceed ±10%.

If the voltage is too high, the service life of the bulb will be shortened. If

the voltage is too low, the light color of the bulb will be affected.

After power failure, the lamp shall be fully cooled after 20 minutes before it

can be powered on again.

To ensure the normal use of this product, please read this instruction carefully.

4. Product introduction4. Product introduction

Light source power: 380W;

Rated power: 500W (high efficiency and reliable switching power supply);

Power supply: high efficiency and reliable switching power supply;

Color disk: one color disk, each color disk is composed of 14 color chips + white

light;

Pattern disc: 14 pattern effects, 9 rotating pattern effects;

Effect wheel: a rotatable 8 prism and a 6-sided array of mirrors;

Dimming: 0-100% electronic dimming;

Large adjustable range of beam angle;

Stroboscopic: support mechanical stroboscopic and adjustable speed stroboscopic

effects, and support stroboscopic macro functions;

Lens group optical system, electric focusing, beam angle 3.8 °- 45 °, linearly

adjustable;

Photoelectric reset system is adopted, which can automatically retrieve and reset

in case of accidental misoperation;

Horizontal 540 °, resolution 8bit / 16bit;

Vertical 270 °, resolution 8bit / 16bit;

Overheating protection;

Control mode: DMX512 / master-slave / automatic;

Protection grade: IP20;

5. Signal line connection (DMX)5. Signal line connection (DMX))

Use RS-485 cables that meet the specifications: shielded, 120ohm characteristic

impedance, 22-24 AWG, low capacitive reactance. Do not use microphone cables or

cables with different specified characteristics. The terminals must be connected

with 3 or 5-pin XLR male / female connectors. A 120ohm impedance matching resistance

(minimum 1 / 4 W) must be inserted between terminals 2 and 3 of the terminal plug.

Important: wires shall not contact each other or metal shell.

Figure 1 DMX signal line connection diagram

6. Lamp installation6. Lamp installation

Lamps can be placed horizontally, hung obliquely and upside down. Pay attention

to the installation method when hanging obliquely and upside down

As shown in Figure 2, before positioning the lamp, ensure the stability of the

installation site. During reverse hanging installation, ensure that the lamp does

not fall on the support frame. It is necessary to use safety rope to pass through

the support frame and lamp handle for auxiliary hanging to ensure safety and prevent

the lamp from falling and sliding.

During the installation and commissioning of lamps, pedestrians are not allowed

to pass below. Regularly check whether the safety rope is worn and whether the hook

screw is loose.

If the lamp falls due to unstable hanging and installation, our company will not

bear any responsibility.

chart2 Schematic diagram of upside down lamps

Chapter 2 panel operation

1. General1. General

The schematic diagram of the lamp panel is shown in Figure 3 (this diagram is a 4-key key).

The TFT display screen on the left supports touch operation, and the 4-key or 5-key keys or encoder

knob on the right can directly operate the lamp or set system parameters.

The display and operation are similar to "Android operating system". If the product you select

supports touch operation, you can click the corresponding item with your fingertips or blunt objects.

Note: do not use sharp or sharp objects to click on the display screen to prevent damage.

chart3 Display panel diagram

2. Operation2. Operation

1. Use visual touch or encoder to operate lamps1. Use visual touch or encoder to

operate lamps

The left area is TFT display area and touch area. Click the panel content with

your finger or blunt hardware to complete parameter setting or view status.

The right area is the "rotary encoder" as auxiliary input. If you do not use the

touch function of TFT, you can rotate the encoder to select the item to be set

or viewed, then press the encoder to confirm the selection, rotate the encoder

to set the parameter value again, and finally press the encoder protection

setting to complete the operation.

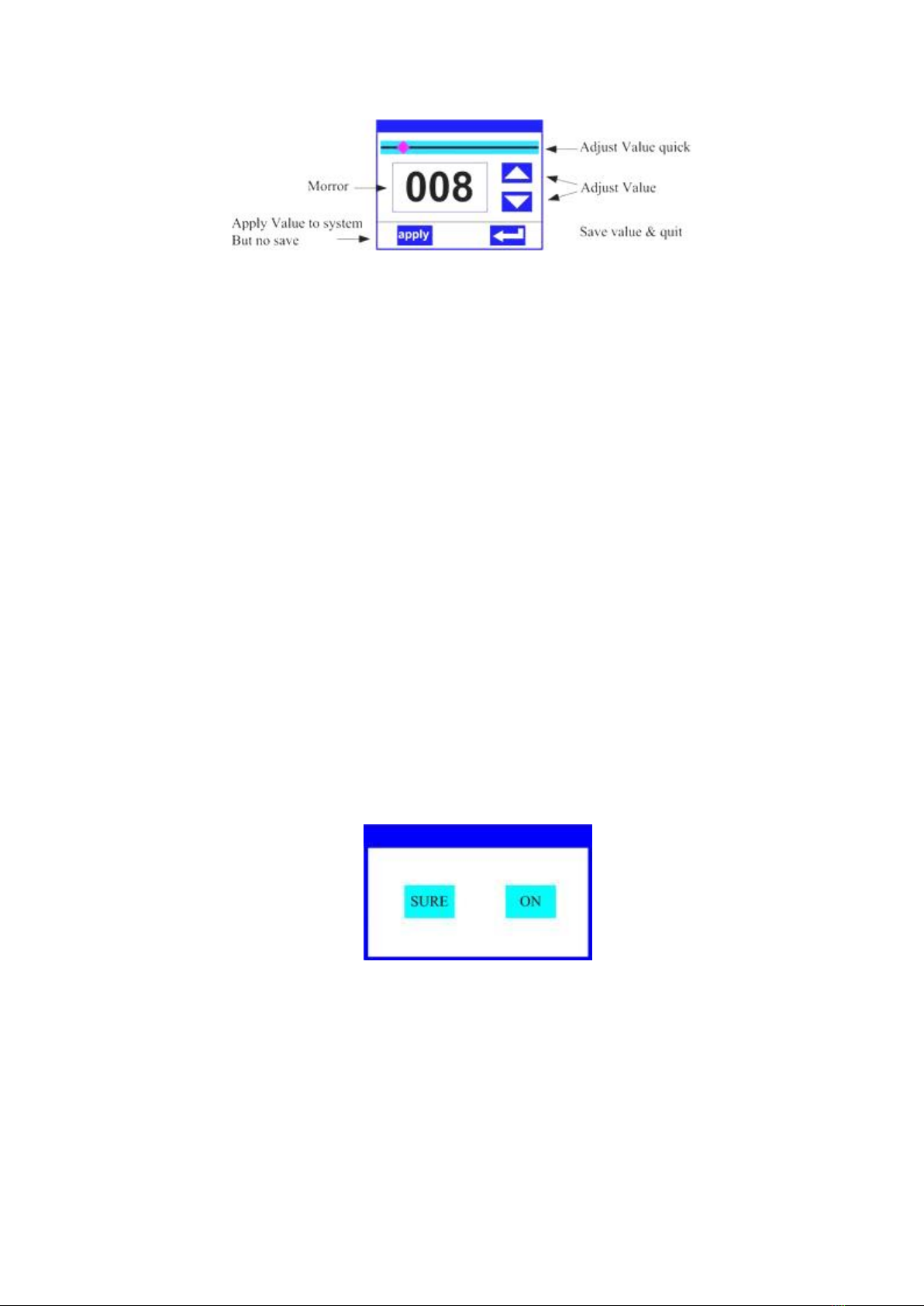

2. Parameter value input2. Parameter value input

When the selected parameter item needs to enter a value, the window as shown

in Figure 4 will open:

chart4 Value setting page

Set value:You can directly pull the slider to quickly set the required value,

or you can click the "up" or "down" button on the right to accurately set the

required value Or rotate the "rotary encoder" on the right to set it;

Application value:When the data is set through the "up" or "down" buttons, then

press the button in the lower left corner“apply”Application key, the value is

sent to the lamp immediately, but the value is not saved;

Save value:At any time, click the "OK" button in the lower right corner, that

is, save the current value to the internal memory, and apply the saved value

to the lamp next time.

3. Set Boolean parameters3. Set Boolean parameters

When the set parameter is Boolean (such as on or off)When pressing, you can directly

click the corresponding item to switch the parameter value, and the modified

parameters will be saved to the internal memory. Press the parameter option on

the right, and the corresponding option will become gray. When you release your

hand, the corresponding parameters will be changed and saved. If the pressed

parameter option is not the parameter you want to change, you can move your finger

to other parts of the screen, and the corresponding parameters will not be

changedChange.

Important Boolean parameters will be set through the confirmation window, as shown

in Figure 5 below:

chart5 OK input window

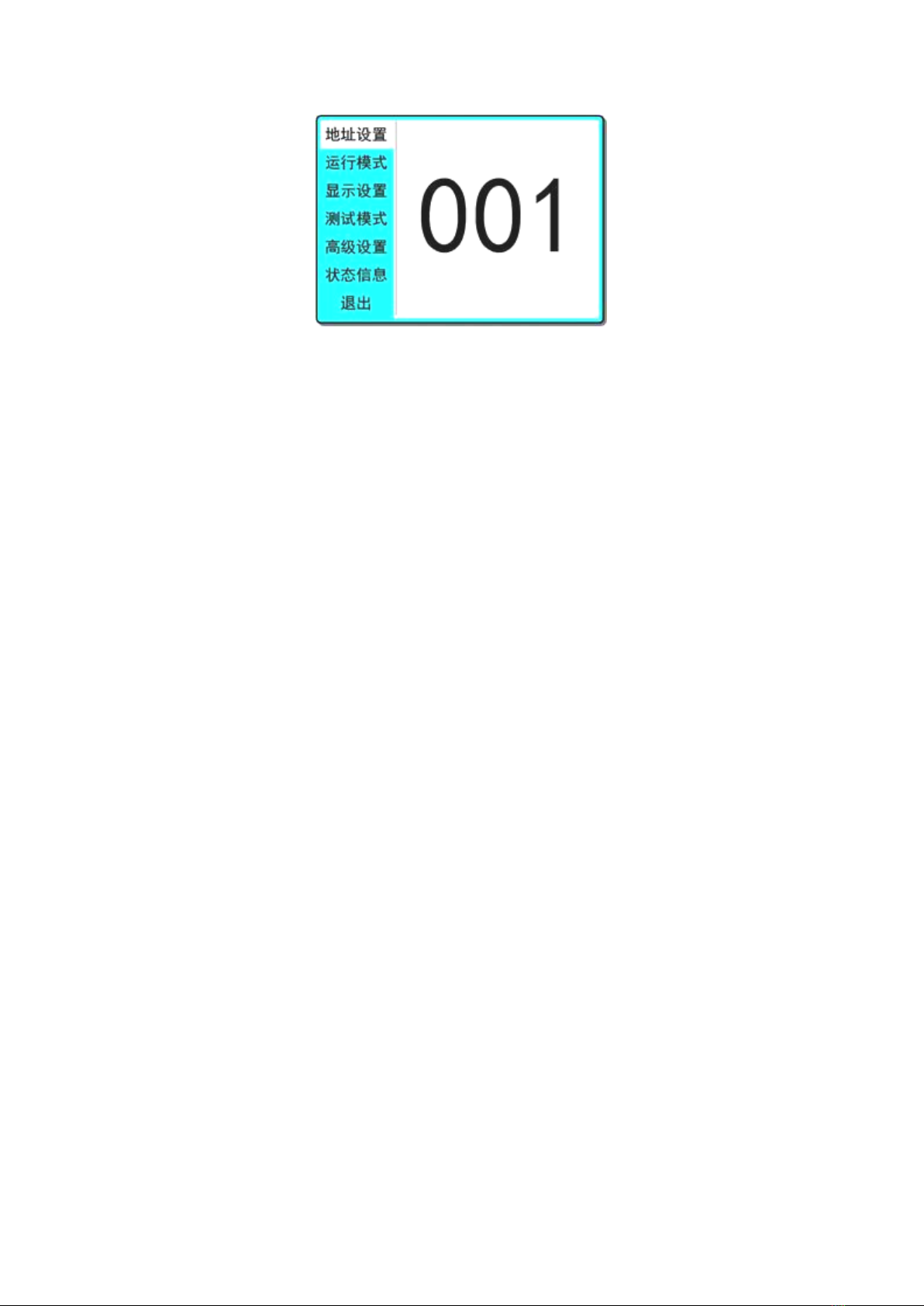

4. Sub page (parameter)4. Sub page (parameter)

Click the main menu to enter the sub menu page, as shown in Figure 6. There are

6 sub pages, including different types of parameters or states, as follows:

Address: set the DMX address of the lamp;

Workmode: set the working mode and master / slave mode of the lamp;

Display: set the parameters of the display interface, such as language,

screensaver mode, etc;

Test: it is mainly used to test lamps and simulate the values of corresponding

DMX channels. Refer to the channel menu for the corresponding functions of

channel values;

Advance: set the operating parameters of lamps;

Status: view the current status of lamps.

chart6 Page graph

3. Function operation and parameter setting3. Function operation and

parameter setting

Enter the setting interface, as shown in Figure 6:

In the main interface, you can touch six buttons to enter the corresponding

parameter setting interface.

In the parameter setting interface, you can press the blue option on the left to

quickly switch to other setting interfaces.

1. Set DMX1. Set DMXAddress code

Click and select "address (addr)" to enter the DMX address code setting page.

The address code value range is 1 ~ 512, and the address code cannot be greater than

(512 channel number), otherwise the lamp will not be controlled. The specific setting

operations are as follows:

Enter the DMX setting interface, as shown in Figure 7, click the white area on

the right to pop up the parameter setting window as shown in Figure 4. You can directly

pull the red square of the progress bar to quickly set the DMX address code value,

or press the "up" or "down" key to accurately set the desired DMX address code, and

then press the Enter key to save the data to complete the address code setting

operation.

chart7 Address code setting page

2. Set the lamp working mode2. Set the lamp working mode

The operation mode, control light gun and channel mode of the lamp can be set

through the page shown in Figure 8. The lamp supports three operation modes (DMX

mode, self-propelled mode and voice control mode). Please refer to the previous

section for detailed parameter value settings. The specific parameters are described

as follows:

DMX mode:In this mode, the lamp receives data from the console and operates

according to the data of the console (common mode);

Self propelled mode:In this mode, the lamp does not receive console data and runs

by itself with an internal fixed program;

Voice control mode:In this mode, the lamp does not receive console data. When

there is a strong sound in the environment, the lamp will run a scene, otherwise

it will maintain the last scene.

Master slave selection:"Master-slave selection" only takes effect when the lamp

works in "self-propelled mode" or "voice control mode". When this option is

turned off, the internal program data of lamp operation will not passDMXThe

data line is sent to other lamps. When it is turned on, the data will be sent

to other lamps in real time, and other lamps (slave) of the same type will run

synchronously with the lamp (host).

Lamp switch:Through this setting, the opening and closing of the lamp can be

controlled. Note that the lamp can not be opened and closed too frequently, which

will reduce the service life of the lamp. The time interval between turning on

and off the lamp has been limited to30Seconds, that is, after the light bulb

changes state30Within seconds, multiple on and off operations are ignored, and

only the last operation is retained.

Channel mode:The lamp supports two channel modes, "simplified" channel saves

several channels for setting motor speed, and each operation mode channel saves

energyDMXFor channel utilization, the "extended" channel is more than the

"thin" channel, as described above. Please refer toThe first3chapterChannel

table description for.

chart8 Operation mode setting page

3. Set panel display settings3. Set panel display settings

The lamp supports bilingual Chinese and English, inverted lamp display, etc.

enter the corresponding parameter setting as shown in Figure 9:

Language:Select Chinese or English to display, and the selection will take effect

immediately.

Screen saver:When the lamp is not set for a period of time(10Seconds), the screen

will enter the screensaver state. When this item is set to "mode"1”When, the

screen saver status is off screen (black screen); set to "mode"2”When, the screen

saver status is displayedDMXAddress code (DMXMode) or display icon

(self-propelled or voice control mode); when it is set to "off", it does not

enter the screen saver and displays the main interface.

Screen rotation:Select whether the screen is displayed in108Degree rotation

display. When the lamp is upside down, this option can be turned on to make the

display more intuitive and clear.

Touch screen switch:When "off" is selected, the touch screen function of the

display screen is turned off, and only the encoder knob can be used.

Touch screen correction:Click this item to enter the correction page to re correct

the touch accuracy of the touch screen. Under normal circumstances, please do

not enter this page.

chart9 Display settings page

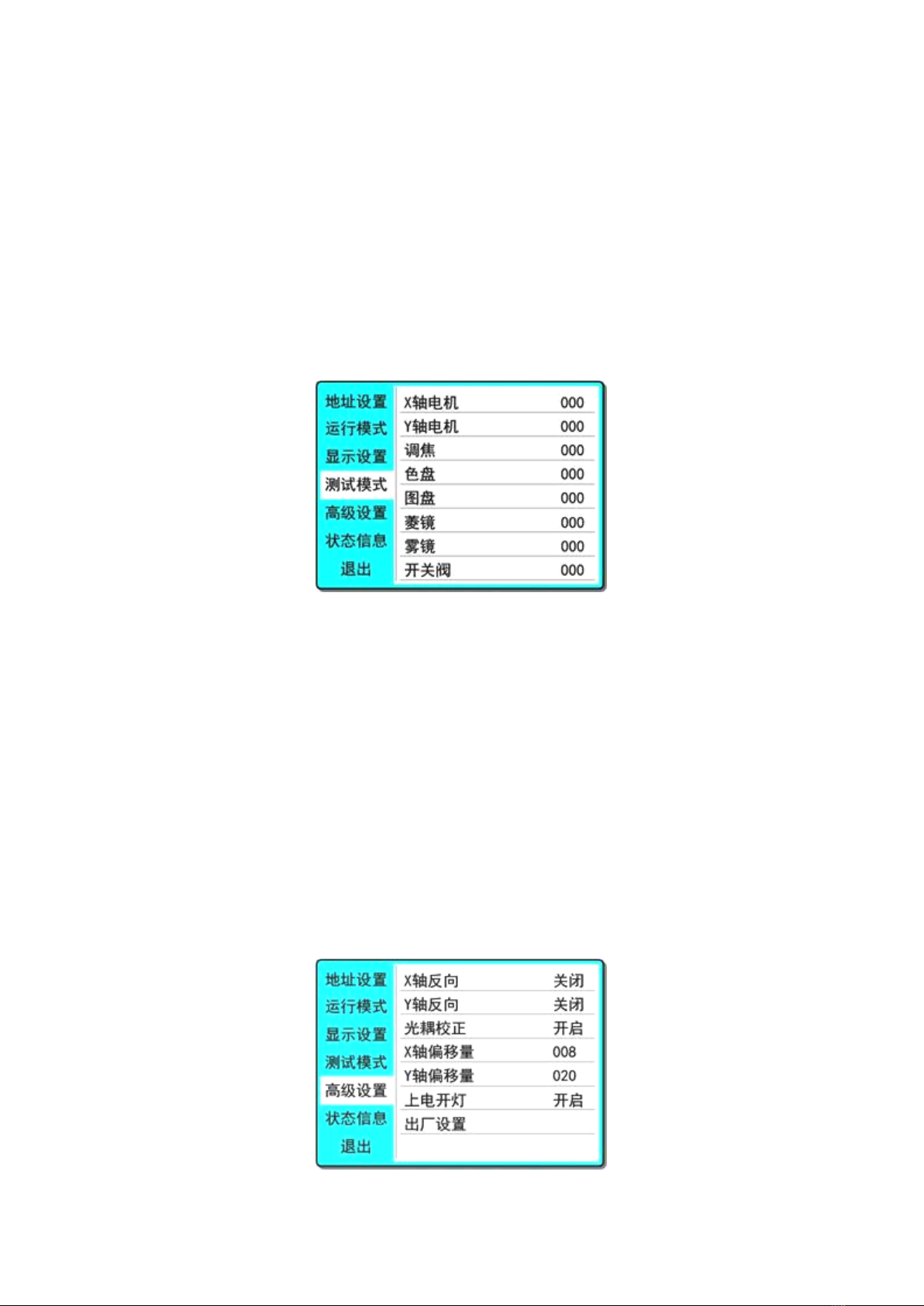

4. Test lamps4. Test lamps

Enter the page as shown in Figure 10, and the lamp enters the test mode. In this

mode, the lamp does not receive DMX console data. The parameters on the page

correspond to the value of DMX channel. The data of corresponding parameter items

can be changed to control the operation of the lamp:

X-axis motor (Pan): value (0 ~ 255);

Y-axis motor (tilt): value (0 ~ 255);

Focus motor: value (0 ~ 255);

Color: value (0 ~ 255);

Drawing disc (gobo): value (0 ~ 255);

Prism: value (0 ~ 255). When the prism is inserted, the prism rotation starts at

the same time;

Fog mirror (Frost): value (0 ~ 255);

On off valve (STROBE): value (0 ~ 255).

chart10 Test mode page

5. Set the working parameters of lamps5. Set the working parameters of lamps

Enter the page shown in Figure 11 to adjust the field parameters of lamps to

facilitate the field installation of lamps, etc

Pan invert of x-axis motor: the initial position and end position of x-axis motor are exchanged;

Tilt invert of y-axis motor: the initial position and end position of y-axis motor are exchanged;

Optocoupler correction: select whether to use the optocoupler to automatically

correct the position of X and Y. when "on", if the X or Y axis motor is out of

step, the lamp will automatically correct back to the position it should be in;

Pan offset: sets the offset angle of the initial position of the x-axis motor;

Tilt offset: sets the offset angle of the initial position of the y-axis motor;

Lamp up when: set the switching state of the bulb when powered on;

Factory setting: set all parameters to factory values.

chart11 Advanced settings page

6. Check the current status of lamps6. Check the current status of lamps

Enter the page shown in Figure 12:

In this interface, you can view the operation status of the current lamp and the

version information of the lamp;

DMX clear (dmxclr): clear the DMX data;

Motor reset (sysrst): system reset button;

chart12 Status information page

Chapter 3 channel description

1. Channel table1. Channel table

Watch1 Channel description (v1.10)

Channel 1

Channel 2

name

numerical

value

describe

CH1

CH1

X axis

0-255

0-540degree

CH2

X-axis trim

0-255

0-2degree

CH3

CH2

Y axis

0-255

0-270degree

CH4

Y-axis trim

0-255

0-1degree

CH5

CH3

XY speed

0-255

From fast to slow

CH6

CH4

function

30-50

3Full power after seconds

60-80

3Second half power

100-105

3Turn off the light gun

for more than seconds

200-205

3Turn on the light gun for

more than seconds

240-255

3Reset for more than

seconds

CH7

CH5

colour

0-129

Linear color matching

130-134

Color 1

135-138

Color 2

139-143

Color 3

144-147

Color 4

148-152

Color 5

153-157

Color 6

158-161

Color 7

162-166

Color 8

167-171

Color 9

172-176

Color 10

177-180

Color 11

181-185

Color 12

186-189

Color 13

190-220

From fast to slow forward

flow

221-224

stop it

225-255

Reverse flow from slow to

fast

CH8

Color tuning

0-255

Ch7 enabled when dimming

linearly

CH9

CH6

pattern

0-3

white light

4-9

Pattern 1

10-15

Pattern 2

16-21

Pattern 3

22-27

Pattern 4

28-33

Pattern 5

34-39

Pattern 6

40-45

Pattern 7

46-51

Pattern 8

52-57

Pattern 9

58-63

Pattern 10

64-69

Pattern 11

70-75

Pattern 12

76-81

Pattern 13

82-87

Pattern 14

88-95

Shake pattern 1 from slow

to fast

96-103

Shake pattern 2 from slow

to fast

104-111

Shake pattern 3 from slow

to fast

112-119

Shake pattern from slow

to fast 4

120-127

Shake pattern from slow

to fast 5

128-135

Shake pattern from slow

to fast 6

136-143

Shake pattern from slow

to fast 7

144-151

Shake pattern from slow

to fast 8

152-159

Shake pattern from slow

to fast 9

160-167

Shake pattern 10 from

slow to fast

168-175

Shake pattern 11 from

slow to fast

176-183

Shake pattern 12 from

slow to fast

184-199

Shake pattern 13 from

slow to fast

200-201

white light

202-227

From fast to slow forward

flow

228-229

stop it

230-255

Reverse flow from slow to

fast

CH10

CH7

Rotation

0-4

white light

pattern

5-8

Pattern 1

9-12

Pattern 2

13-16

Pattern 3

17-20

Pattern 4

21-24

Pattern 5

25-28

Pattern 6

29-32

Pattern 7

33-36

Pattern 8

37-40

Pattern 9

41-48

Shake pattern 1 from slow

to fast

49-56

Shake pattern 2 from slow

to fast

57-64

Shake pattern 3 from slow

to fast

65-72

Shake pattern from slow

to fast 4

73-80

Shake pattern from slow

to fast 5

81-88

Shake pattern from slow

to fast 6

89-96

Shake pattern from slow

to fast 7

97-104

Shake pattern from slow

to fast 8

105-112

Shake pattern from slow

to fast 9

113-119

white light

120-185

From fast to slow forward

flow

186-189

stop it

190-255

Reverse flow from slow to

fast

CH11

CH8

Gobo

Rotation

0-127

0-400degree

128-190

From fast to slow forward

flow

191-192

stop it

193-255

Reverse flow from slow to

fast

CH12

Rotation

fine

adjustment

0-255

CH13

CH19

Prism 1

0-63

Remove the prism

64-255

Insert prism 2

CH14

CH10

Prism 1

rotation

0-127

0-400degree

128-190

From fast to slow forward

flow

191-192

stop it

193-255

Reverse flow from slow to

fast

CH15

CH11

Prism 1

0-63

Remove the prism

64-255

Insert prism 2

CH16

CH12

Prism 2

rotation

0-127

0-400degree

128-190

From fast to slow forward

flow

191-192

stop it

193-255

Reverse flow from slow to

fast

CH17

CH13

atomization

0-127

nothing

128-255

atomization

CH18

CH14

enlarge

0-255

From small to large

CH19

Zoom in and

fine tune

CH20

CH15

focusing

0-255

From far to near

CH21

Focusing

fine

adjustment

CH22

empty

CH23

CH16

Stroboscopic

0-3

Guan Guang

4-103

From slow to fast pulse

stroboscopic

104-107

Open light

108-207

Gradually variable

frequency flashing from

slow to fast

208-212

Open light

213-251

Random stroboscopic from

slow to fast

252-255

Open light

CH24

CH17

Dimming

0-255

0-100% dimming

Chapter 4 common faults and precautions

1. Common fault handling1. Common fault handling

The lamp contains professional components such as microcomputer circuit

board and high-voltage power supply. For your safety and product life, non

professionals are not allowed to disassemble the lamp and related accessories

without authorization.

1. The bulb doesn't work

Possible causes: the bulb is not completely cooled, or the bulb has

reached its service life. The treatment is as follows:

If the bulb is not completely cooled due to abnormal operation, the lamp

body shall be cooled for more than 10 minutes to completely return to

the normal state, and then start the power supply again;

Check whether the bulb has reached its service life and replace it with

a new one;

Check whether there is leakage, falling off or poor contact between the

bulb and the lighter circuit;

Replace the lamp with a new one.

2. The beam looks dim

Possible causes: the bulb has been used for a long time or the optical

path is not clean. The treatment is as follows:

Check whether the bulb has reached its service life and replace it with

a new one;

Check whether the optical components or bulbs are clean and whether there

is dust accumulated on the bulbs and other optical components. The bulbs

and components in the lamps shall be cleaned and maintained regularly.

3. Pattern projection blur

Check whether the value of the electronic focus channel is appropriate for

the current projection distance.

4. Lamps operate intermittently

Possible causes: the internal circuit enters the protection state, and

the treatment is as follows:

Check whether the fan operates normally or becomes dirty, resulting in an

increase in the internal temperature of the lamp;

Check whether the internal temperature control switch is closed;

Check whether the bulb has reached its service life and replace it with

a new one.

5. The lamps will not be controlled by the console after normal reset

Possible causes: signal line failure or abnormal lamp parameter setting,

the treatment is as follows:

Check the start address code and the connection of DMX signal line (whether

the signal line cable is intact and whether the connector is loose);

Add signal amplifier and 120 ohm terminal resistance;

6. The lamp cannot be started

Possible causes: the power circuit is poor, and the treatment is as

follows:

Check whether the fuse on the power input socket is blown and replace the

fuse;

Poor line contact caused by vibration of lamps during long-distance

transportation

Check the input power supply, computer board and other plug-in devices.

2. Precautions for use2. Precautions for use

Check whether the local power supply meets the rated voltage requirements

of the product, and the leakage protector and overcurrent protector meet

the load requirements;

Do not use the power cord with damaged insulation, and do not lap the power

cord on other conductors;

The lamps are cooled by strong wind, which is easy to accumulate dust. They

must be cleaned once a month, especially the heat dissipation outlet,

otherwise they will be blocked by accumulated dust, resulting in poor

heat dissipation and abnormal lamps.

When installing lamps, the fixing screws must be fastened, equipped with

safety ropes, and checked regularly;

During the installation and positioning of lamps, the minimum distance

between any point on the surface of lamps and any inflammable and

explosive objects shall be 10m and 2.5m from the irradiated objects.

Please do not install lamps directly on the surface of combustible

substances;

It is recommended that the continuous working time of lamps should not

exceed 10 hours, and the interval between continuous starting lamps

should not be less than 10 minutes, otherwise it will not be triggered

normally due to bulb overheating protection;

The closing time of the on-off valve shall not exceed 5 minutes. If it is

necessary to close the light for a long time, the control console (lamp

control channel) shall be used to close the lamp;

In order to ensure that multiple lamps can better comply with the scene

effect, the lamps should not be in the current scene without completing

the current scene, that is, start the next scene action. It is best that

this state should not exceed 3 minutes to ensure that multiple lamps can

operate synchronously.

In the process of use, if the lamp is abnormal, stop using the lamp in time

to prevent inducing other faults;

Table of contents