Shell Solar SP150-L User manual

Shell Solar

Installation Guide

for Shell Solar Photovoltaic Modules

www.shell.com/solar/

First Edition 2003

Purpose of this guide

This guide contains information regarding

the installation and safe handling of

Shell Solar photovoltaic modules (hereafter

referred to as “modules“).

Please follow these instructions carefully

and observe all of the safety precautions.

Although this guide describes several typi-

cal systems using photovoltaic solar power

modules, it does not describe how to install

or operate such systems. Please consult your

solar power dealer for additional information

on the following subjects:

} dimensioning and constructing solar pho-

tovoltaic systems

} wiring materials

} connectors

} stands and supports

Before installing a solar photovoltaic system,

you should familiarize yourself with the

mechanical and electrical requirements for

such systems. For this reason, we recommend

that you read this guide completely before

starting the installation.

In the guide, the term ‘module’ should gener-

ally be understood to refer to individual

modules and/or groups of modules accord-

ing to the context.

Caution

If these products are used in the

USA, please observe the instruc-

tions marked ‘[USA]’.

General information

Installing solar photovoltaic systems may

require specialised skills and knowledge.

It should only be performed by qualified

electricians.

Caution

If the total DC voltage available

from several modules connected

in series (the sum of the open-cir-

cuit voltages of the individual modules) can

exceed 120 V, installation and commission-

ing of the system must be performed by a

licensed electrician or specialized company.

The installer assumes the risk of all injury that

might occur during installation, including,

without limitation, the risk of electric shock.

Shell Solar electric modules do not require

the use of special cable assemblies. All mod-

ules come with a permanently attached junc-

tion box that will accept a variety of wiring

applications or with a special cable assembly

for ease of installation. It is recommended

to utilize a qualified installer or reseller for

service.

WARNING

All instructions should be read

and understood before attempt-

ing to install, wire, operate, and

maintain the module. Contact with electrically

active parts of the module such as terminals

can result in burns, sparks, and lethal shock

whether the module is connected or discon-

nected.

Proper use

Photovoltaic solar modules produce direct-

current electrical energy from light. They are

designed for outdoor use, and depending on

their construction can be mounted on support

frames, stands, flat surfaces, vehicles or boats.

} Do not disassemble the module, and do

not remove any attached nameplates or

components.

} Do not apply paint or adhesive to the rear

surface.

} Do not use mirrors or lenses to artificially

concentrate sunlight on the module.

Table of Contents

Purpose of this guide 2

} General information 2

} Proper use 2

} Safety precautions for installing

a solar photovoltaic system 3

Product Identification 4

Mechanical Installation 4

} Selecting the location 4

} Selecting the proper support frame 4

} Ground/Roof/Pole mount 5

} Roof Mounting 5

} Mounting hole locations

} Installing frameless modules 5

} Unpacking and handling the module 6

Electrical Installation 7

} Off-grid electrical system with battery

storage using a charge regulator 7

} Off-grid electrical system with battery

storage using a self-regulating module 7

} Grid-connected electrical system 7

} Comparison of series and parallel wiring 8

} Use suitable solar-power wiring 8

} Use suitable connectors 8

} Installing solar-power wiring 8

} Electrical connections to the module 9

} Grounding 9

} Junction box arrangements 9

} Installing a ProCharger™ CR

cable junction box 10

} Connecting modules with

ProCharger™-S junction boxes 11

} Connecting modules with Spelsberg

junction boxes 11

} Connecting modules with permanently

attached cables but no plug connectors

(ProCharger™ junction box cover) 12

} Blocking diodes 12

} Bypass diodes 12

Commissioning and Maintenance 12

} Testing, commissioning and

troubleshooting 12

} Maintenance 12

} Testing and replacing bypass diodes 12

Disclaimer of Liability 13

SHELL SOLAR LIMITED WARRANTY

FOR PV-MODULES (“Limited Warranty”) –

(Excluding U.S.) 14

SHELL SOLAR LIMITED WARRANTY

FOR PV-MODULES (“Limited Warranty”) –

(U.S.) 15

2

3

When installing the system, observe all local,

regional and national statutory regulations,

such as obtaining a building permit. Also

observe local and national regulations with

regard to use on vehicles or boats.

Safety precautions for installing

a solar photovoltaic system

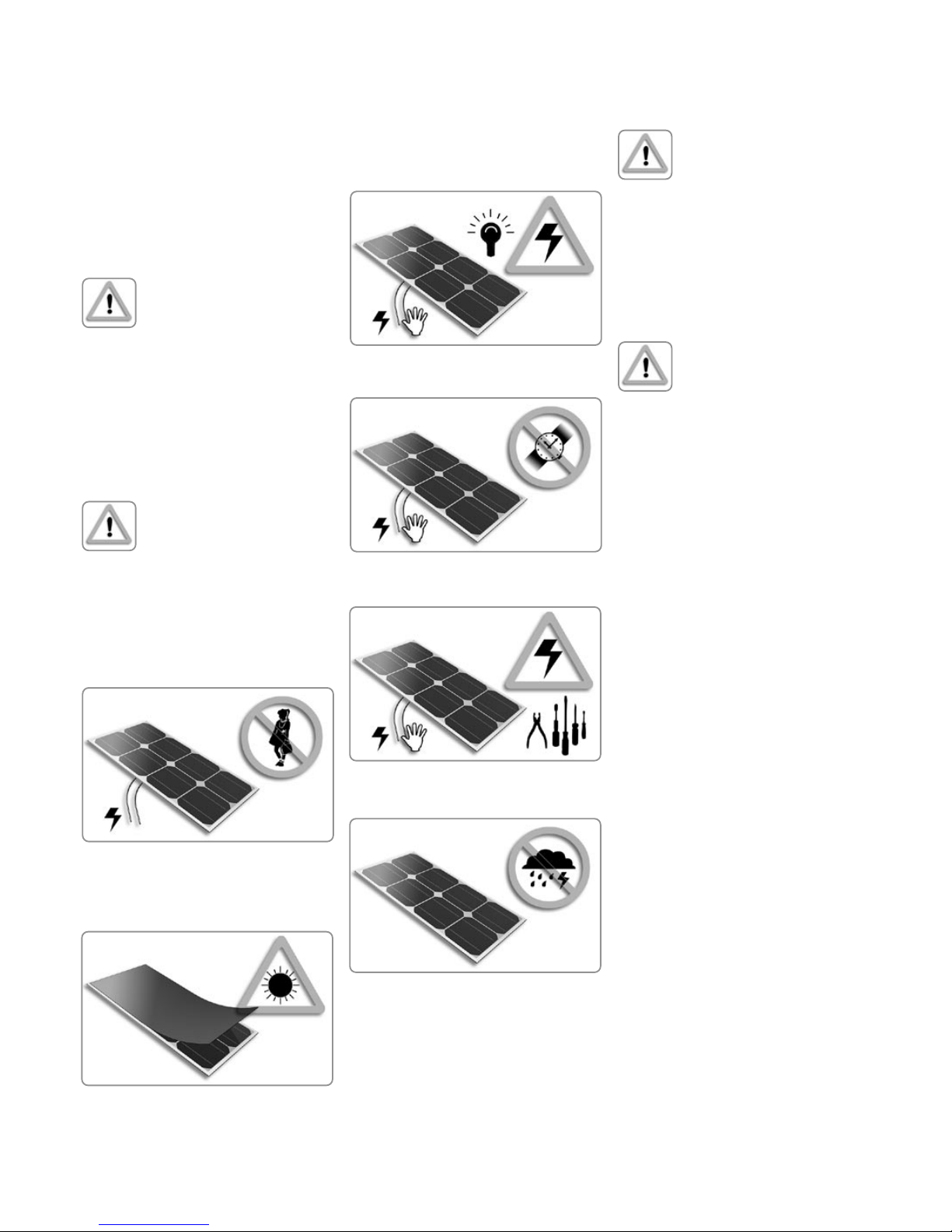

Caution

Solar modules produce electri-

cal energy when light shines on

their front surfaces, regardless of

whether they are connected. A system with

several modules can generate potentially

lethal voltages and currents.

If modules are connected in series, the total

voltage is equal to the sum of the individual

voltages. If they are connected in parallel,

the total current is equal to the sum of the

individual currents. Contact with a DC voltage

of 30 V or more is potentially hazardous.

Personal safety precautions:

} Respect the directives and regu-

lations of local authorities and/

or industrial accident prevention

organisations with regard to:

< working safely on roofs and

buildings

< electrical installations

} Keep children well away from the system

while installing mechanical and electrical

components.

} Completely cover the module with an

opaque material during mechanical and

electrical installation to stop electricity be-

ing generated.

} Do not touch electrical terminals or ends

of wires while the module is exposed to

light or while installing the module.

} Do not wear metallic jewellery while perfor-

ming mechanical or electrical installation.

} Use only insulated tools that are approved

for working on electrical installations.

} Work only under dry conditions, and use

only dry tools.

} Observe the safety regulations for all

other components used in the system,

including wiring and cables, connectors,

charging regulators, inverters, storage

batteries and rechargeable batteries, etc.

Operational safety and

reliability precautions:

} Use only equipment, connectors, wiring

and support frames suitable for use in a

solar electric system.

} Always use the same type of module

within a particular system.

} Keep this guide in a safe place for future

reference (care and maintenance) and in

case of sale or disposal of the module.

Instructions to ensure conformity

with the Underwriters Laboratory

Listings [USA]:

} For module wiring that is directly exposed

to weather, use only ‘UF’ type wiring with

solid or stranded copper conductors and

insulation resistant to sunlight (UV) and

weather.

} Observe the requirements listed in the

Technical Specifications for the type of

module used.

} The module frame must be earthed. If an

earth wire with a cross-section greater

than No. 10 AWG is used, a connector

that can be fastened to the module frame

using the supplied fastening screw must be

fitted to the module.

} Under normal conditions, a photovoltaic

module may experience conditions that

produce more current and/or voltage than

reported at standard test conditions. Ac-

cordingly, the values of short-circuit current

(Isc) and open-circuit voltage (Voc) marked

on UL listed modules should be multiplied

by a factor of 1.25 when determining

component voltage ratings, conductor

capacities, fuse sizes, and size of controls

connected to the module output. Refer

to Section 690-8 of the National Electric

Code for an additional multiplying factor

of 1.25 which may be applicable.

2

3

4

Ground mount Roof mount Pole mount

P

301134 A 2080200001

Serial No.

Serien Nr.

Class II Equipment

Power OutputRated Power Output

Schutzklasse II

Leistung

Nennleistung

Alle technischen Daten unter Standard-Testbedingungen

All technical data at standard test conditions: AM 1.5; G = 1000 W/m²; T cell = 25°C

Kurzschluss-Stro m Nennstrom

Short Circuit Current

Open Circuit Voltage

Leerlaufspannung

Rated Current

Rated Voltage

Nennspannung

MPP 150

Solar Modul Shell SP150-L

W

V

V 715

max

PMPP A

I 4,8

sc A

I 4,4

MPP

V

V 43,4

oc V

V 34,0

MPP

+

-5%

Shell Solar B.V.

P.O. Box 38000

1030 BN Amsterdam

The Netherlands Made in Germany

Berührung eine Gefahr dar! Berühren Sie keine Anschlußklemmen, wenn das Modul Sonnenlicht

Modulen erhöht die Spannung bzw. Stromstärke. Spannungen von dreißig Volt und darüber stellen bei

erzeugt bei Einstrahlung von Sonnenlicht elektrische Energie. Jede Reihen- oder Parallelschaltung von

anleitung aufgeführten Hinweise zu Sicherheitsvorkehrungen gelesen und befolgt werden. Dieses Modul

Vor Installation, Einsatz oder Wartung dieses Produktes müssen alle in der Montage- und Gebrauchs-

Warnung! Elektrische Gefahr!

Wenn zusammen mit den Modulen Batterien verwendet werden, ist den Sicherheitshinweisen des

ausgesetzt ist. Achten Sie darauf, dass in der Nähe von entzündbaren Gasen keine Funken entstehen.

Warning! Electrical Hazard!

des Produktes hat durch qualifiziertes Personal zu erfolgen.

Booten und Campingwagen ist der entsprechende Hersteller zu Rate zu ziehen. Installation und Wartung

Inspektion erteilen die örtlichen Behörden. Für die sachgemäße Installation auf Spezialfahrzeugen wie

elektrischen Bestimmungen installiert werden. Nähere Auskünfte über Genehmigung, Installation und

konzentrieren! Module und Traggestelle müssen gemäß den lokalen Vorschriften oder den nationalen

nicht abschatten! Sonnenstrahlen nicht mit Spiegeln, Linsen oder ähnlichen Hilfsmitteln auf das Modul

wassertauglich! Vermeiden Sie Beschädigungen des Modules durch spitze, scharfe Gegenstände. Zellen

Batterieherstellers Folge zu leisten. Module nicht in Flüssigkeiten eintauchen! Das Modul ist nicht see-

voltages/amperages are additive. Thirty volts or greater is considered a shock hazard.

electricity when exposed to sunlight. When modules are connected in series/parallel,

follow all safety precautions detailed in the instruction manual. This module produces

Before attempting to install, use and maintain this product, read, understand and

Do not contact terminals when module is exposed to sunlight. Do not produce sparks near flammable

vapors. Follow safety precautions of the battery manufacturer if batteries are used with modules. Do not

immerse in liquids. Module is not sea-water-resistant! Do not wear jewelry. Do not shadow cells. Do not

expose module to concentrated sunlight with mirrors, lenses or similar means. Install module and ground

frames in accordance with local codes or the National Electrical Code. Consult local authorities for

permit, installation and inspection requirements. Consult manufacturer for proper installation on special

vehicles such as boats and camper. Product should be installed and maintained by qualified personnel.

Keep module away from children.

Each module has a label on its rear side

providing the following information:

} The Module Type name - consisting of an

“S“ and a second letter which determines

the cell technology, followed by a number

that is equivalent to the rated power of the

module.

} The Serial Number - used to identify the

specific product. Each individual module

has a unique serial number.

} Rated Power, Rated Current and Rated

Voltage. All are characteristic values im-

portant for the design of your PV-system.

} The Open Circuit Voltage exceeds the

rated Voltage. Take care that the Open

Circuit Voltage multiplied by the number

of modules in series is not higher than the

Maximum System Voltage.

} Maximum System Voltage. This voltage is

certified per UL1703 and/or TÜV Safety

Class II.

} Warning Notes.

Do not remove the label. If the label is

removed the product warranty will no longer

be honoured by Shell Solar.

Product Identification Mechanical Installation

Selecting the location

Select a suitable location for installing the

module. It should be positioned such that it

is not shaded by other objects between 9 am

and 3 pm on the shortest day of the year. The

modules must be facing south in the northern

latitudes and north in the southern latitudes.

For detailed information on the best tilt angle

for your installation, please consult your local

solar power dealer.

Caution

} The module should not be

shaded at any time of day.

} Do not use modules near equipment or

locations where flammable gases can be

generated or can collect.

Selecting the proper support frame

Always observe the instructions and

safety precautions included with the support

frame. If necessary, you can obtain more in-

formation from your dealer or sales partner.

Caution

} Do not drill holes in the frame

or glass of the module. Doing

so will void the warranty.

Modules must be securely attached to a

surface using support frames or installation

kits. The entire solar system must be able to

withstand the mechanical loads that are typi-

cal for the region where it is installed.

Make sure the support structure is strong

enough to withstand the anticipated wind

and snow loads according to local standards

and regulations.

Ensure that the modules are not subjected to

excessive forces due to thermal expansion of

the support structure.

The support structure should be made of

durable, corrosion-resistant and UV-resistant

material.

Support structures and installation kits for

many different uses are available from Shell

Solar and specialist companies. Ask your

dealer or sales partner for advice.

5

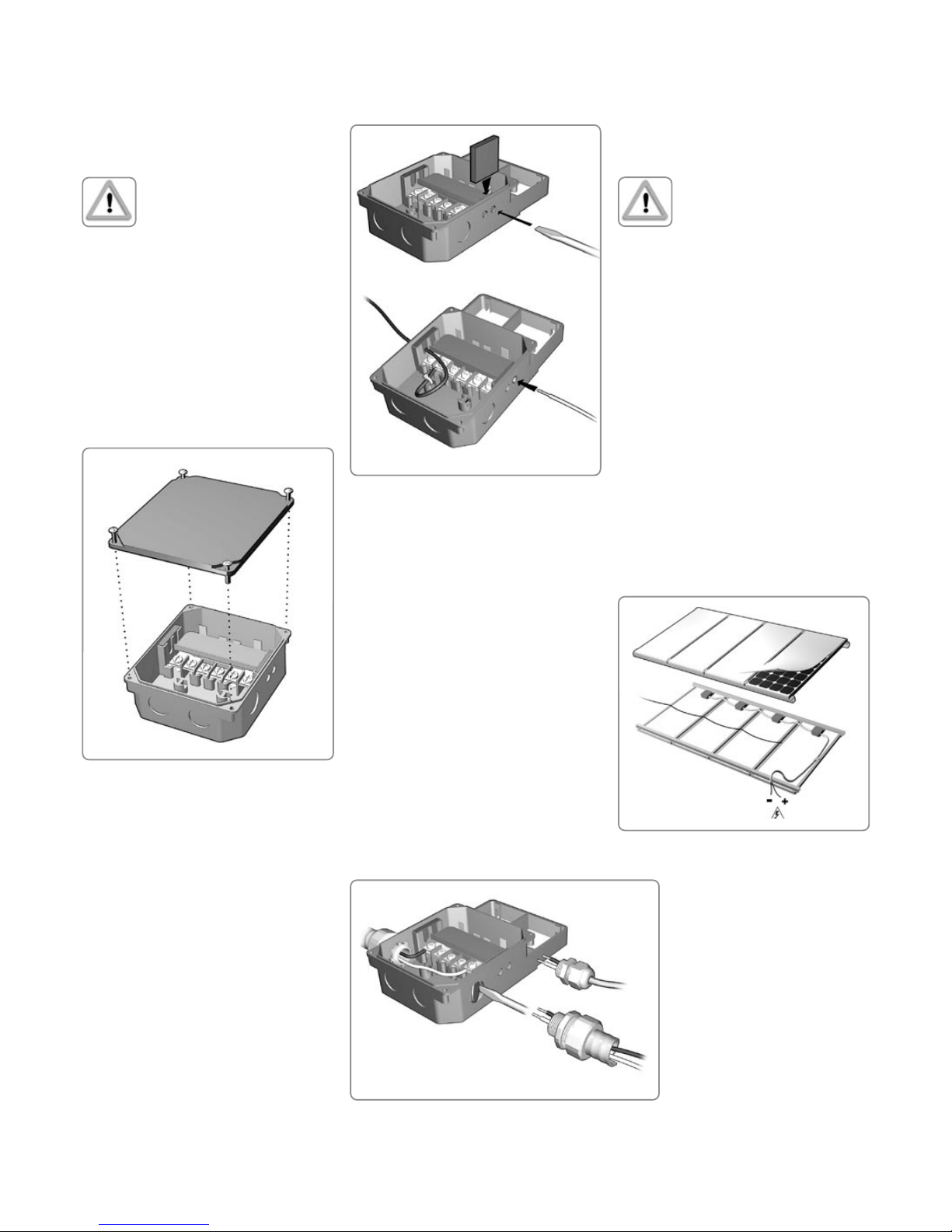

Mounting hole locations

quarter points

Ground mount:

Select the height of the mounting system to

prevent the edge of the lowest module being

covered by snow for a long period of time.

Also make sure the lowest module is placed

high enough so that it is not shaded by plants

or trees.

Roof mount:

When installing a module on a roof or

building, ensure that it is securely fastened

and cannot fall as a result of wind and snow

loads.

Observe prevailing safety regulations when

installing modules on roofs and buildings,

and use prescribed safety equipment (safety

nets, lifelines etc.).

Provide adequate ventilation on the rearside

of the modules. For proper operation and to

avoid damage from condensation, the mod-

ule requires an adequate flow of air across

the rear surface.

When installing the module, ensure that

there is sufficient distance between the rear

of the module and the mounting surface. The

minimum distance between the roof and the

modules should be 5 cm (2 Inches).

Pole mount:

When installing a module on top of a pole,

make sure the pole is strong enough to

withstand anticipated wind speeds and gusts

without substantial bending. The pole must

be installed with adequate foundations. Use

a mounting frame to fasten the module to the

top of the pole.

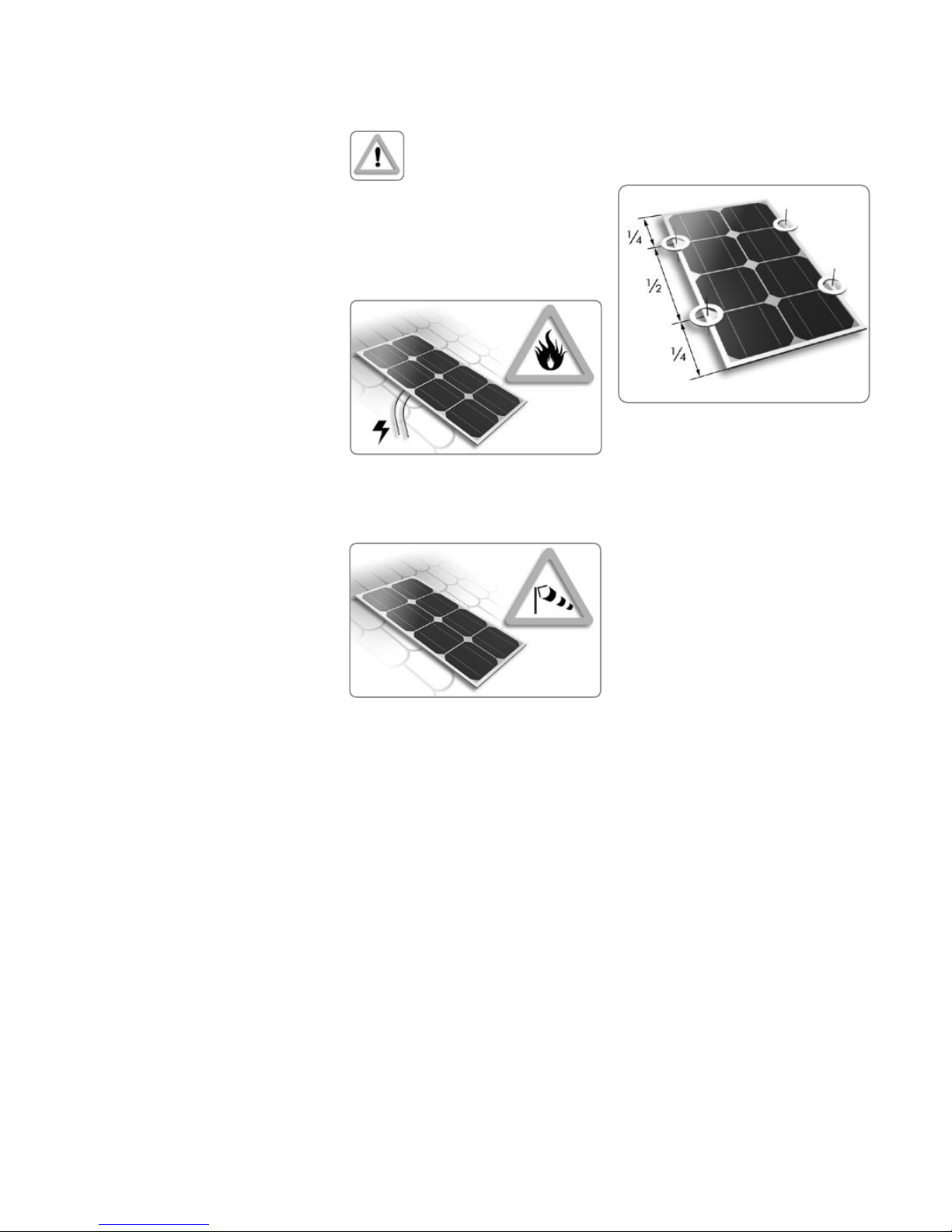

Roof Mounting

When installing modules on a roof, ensure

that the roof construction is suitable. In some

cases, a special support frame may be neces-

sary.

Caution

} The roof construction and

installation may affect fire

safety. Consequently, it may

be necessary to use components such as

earth ground fault circuit breakers, fuses

and circuit breakers. An improper instal-

lation can create an additional hazard.

Please consult knowledgeable experts

regarding the installation.

} When installing a module on a roof or

building, ensure that it is securely fastened

and cannot fall as the result of wind or

snow loads.

} Observe prevailing safety regulations

when installing modules on roofs and

buildings, and use prescribed safety

equipment (safety nets, lifelines etc.).

Mounting hole locations

For secure installation use only the recom-

mended mounting locations on the modules.

Wherever possible mount the module using

the predrilled holes in the frame. The most

secure mounting is achieved by mounting

the module using the four “quarter” points as

shown.

For modules with a slot in the frame on the

rearside, use the quarter points for the most

secure mounting.

Seek advise from your dealer if you intend

to mount the modules without using the pre-

defined mounting locations in the frame.

Shell Solar will not honour the product

warranty if additional holes are drilled in the

frame.

Installing frameless modules

Shell Solar supplies two types of frameless

modules - one type provided with factory as-

sembled (pre-mounted) clamps for mounting

and pre-certified to IEC61215, the other type

provided without factory assembled clamps

and certified as a UL recognised component

[USA].

Shell Solar will only warrant products if they

are installed in mounting systems which

are IEC or UL certified. IEC requires mount-

ing systems to be certified together with

the frameless modules being used. UL must

approve of the mounting method being used

with a frameless module before full UL ap-

proval can be obtained.

For any other mounting method contact your

Shell solar representative for more information.

General Requirements:

} Frameless modules are not suitable for

applications on vehicles, boats etc. for

mobile use.

} Frameless modules shall only be used in

regions with moderate snow loads and

wind speeds up to 130 km/h. - Frame-

less modules are vulnerable to breakage

during transportation and installation.

Handle them with care.

} No structures or objects that could touch

the module at its maximum permitted

flexure of 5 mm should be located in front

of or behind the module.

} The deviation of the four mounting

surfaces from a plane surface must not

exceed 1.2 degrees.

} The support surface at each mounting

position should have an area of at least

25 mm x 25 mm.

Frameless modules with pre-mounted clamps

A Shell Solar frameless module provided with

pre-mounted clamps is an IEC tested and

certified system and comes with the standard

Shell Solar product warranty.

} Attach clamps to a solid, clean and flat

surface

} Avoid putting the module under stress

when tightening the clamps. Do not create

any forces that could affect the module or

cause the clamps to pull away from the

module or slide towards the module.

} Use high quality M8 screws with strength

class 8.8 (in accordance with DIN

EN 24014) and washers compliant with

EN ISO 7093-8-200HV (minimum

diameter 24 mm, thickness 2 mm).

} We recommend using full-metal, self-lock-

ing nuts with spring-washers.

} Use a torque wrench and tighten the nuts

with a torque of 30 Nm.

} Two days after installing the modules test

all screws for proper tightness using a

torque wrench.

} Always arrange frameless modules in

landscape position with the mounting

clamps along the bottom and top edges. If

positioned in portrait position, the narrow

bottom edge must be secured against

slipping.

[USA] Frameless modules without

pre-mounted clamps

This product is a UL recognized component

and can only be used with a UL certified

mounting system. Follow strictly the instructions

in the installation guide of the mounting system.

Provide adequate rear ventilation

For proper operation and to avoid damage

from condensation, the module requires an

adequate flow of air across the rear surface.

When installing the module, ensure that

there is sufficient distance between the rear

of the module and the mounting surface. For

roof-mounted modules, the minimum distance

between the roof and the modules should be

5 cm (2 in).

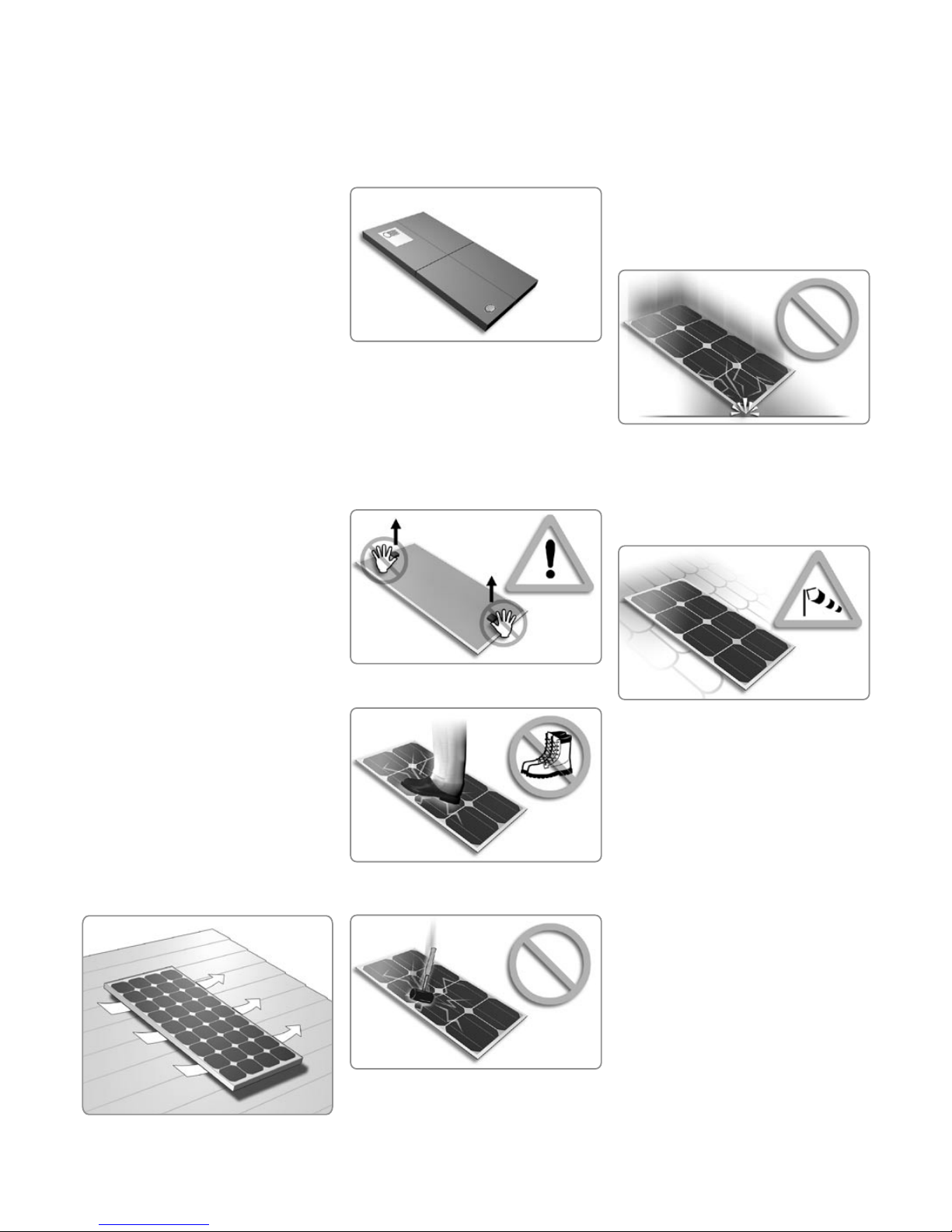

Unpacking and handling the module

} Leave the module in its package until you

are ready to install it.

} When installing or working with module

or wiring, cover module face completely

with opaque material (e.g. cardboard

packaging) to halt prodution of electricity.

These precautions are not necessary if the

module is fitted with a connecting cable

and a shock proof plug connector.

} Do not use the attached junction box to

hold or transport the module.

} Do not stand or step on module.

} Do not drop module or allow objects to

fall on module.

} To avoid glass breakage and damage to

the module, do not place any heavy ob-

jects on the module or on its rear surface.

Avoid setting the module down hard on

any surface, particularly when placing it

on a corner. Do not lay the module on an

uneven surface. If the glass of the module

is broken, it cannot be used.

} Do not carry out installation work for

modules on roofs or buildings when there

are strong winds. There is also a risk of

damage or injury from wind forces when

lifting or moving support frames with

several attached modules.

6

7

Off-grid electrical system with battery storage

using a charge regulator

Typical off-grid electrical system with battery

storage using a self-regulating module

Typical Photovoltaic system coupled to the public electricity grid

1 solar modules

2 inverter

3 utility meter (electricity generated)

4 utility grid

5 utility meter (electricity drawn)

6 appliances

1

2

34

5

6

6

There are many different applications for

photovoltaic solar energy systems. This guide

describes some of the most important typical

uses as representative examples.

Off-grid electrical system with battery stor-

age using a charge regulator

Solar power systems are frequently used to

supply electrical power to technical equip-

ment, remote cottages and hunting cabins,

camping vehicles and boats. In such systems,

the photovoltaic system charges a storage

battery via a charging regulator. The charg-

ing regulator controls the charging proc-

ess in order to protect the battery against

overcharging and ensure long battery life. If

necessary, an inverter can be used to provide

electrical power from the storage battery to

equipment operating at the normal mains

voltage.

Off-grid electrical system with battery stor-

age using a self-regulating module

When a self-regulating module is used, it is

not necessary to use a charging regulator.

The charging current provided by the self-

regulating module depends on the charge

state of the battery and decreases as the

battery voltage increases. This means that

during daylight hours, the charging current

automatically adjusts to suit the charge state

of the battery and the power consumption of

the connected loads.

} When using a self-regulating

module, make sure there is

sufficient battery capacity.

In the dark a small current could flow from

the battery and through the module. This

can reduce the state of charge of the battery

during the night. To eliminate this reverse

current, connect a “blocking diode” in series

between the solar module and the battery.

Use a diode that is specified for a current

that is at least 1.5 times more than the

maximum current generated by the module.

Mount the diode in such a way that allows

for proper cooling of this device. Please

check with your dealer for an appropriate

diode type.

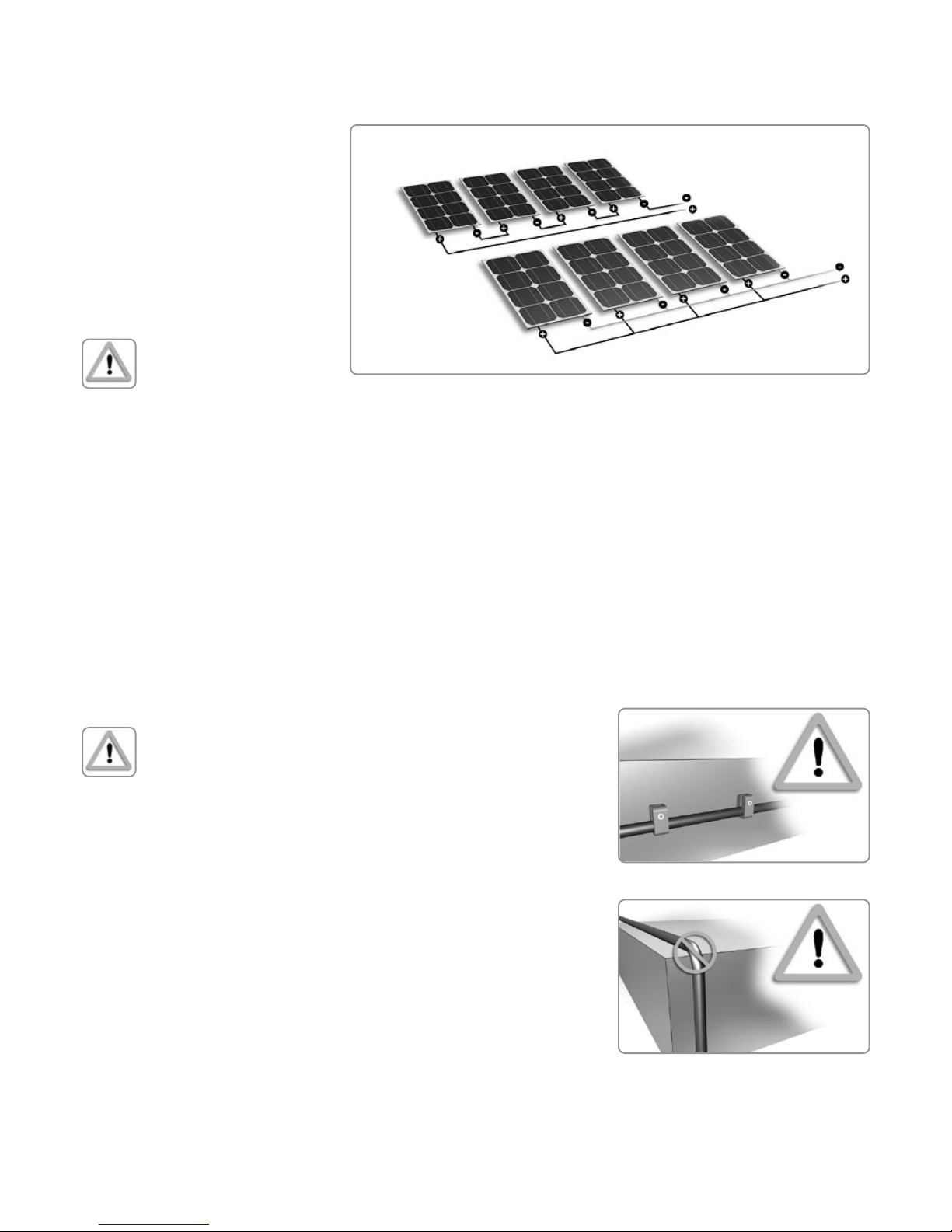

Grid-connected electrical system

For this purpose, the electrical energy

generated by the solar power system

is supplied to the public electricity grid.

The structure and dimensioning of the system

vary from system to system. Usually, several

modules are connected in series to form a

block, and several blocks are connected in

parallel to a network inverter that links the

photovoltaic solar power system to the public

electricity grid. The amount of power fed into

the public electricity grid can be measured

using a supplementary meter. See “Compari-

son of series and parallel wiring“, page 8.

The amount of compensation paid for the

power fed into the public electricity grid de-

pends on contractual agreements with elec-

tricity companies and statutory provisions.

A permit is always required for any system

coupled to the public electricity grid, and

such a system must be formally approved

and accepted by an authorised expert.

Electrical Installation

6

7

series wiring

parallel wiring

If you select or assemble your own wiring for

a photovoltaic solar power system, please

observe the following points:

} Use only wiring material that is specifi-

cally intended to be used in photovoltaic

solar power systems.

} At extreme low temperatures the cable

should be handled with more than usual

care.

} Select wiring material with insulation that

is UV-resistant and weatherproof. It should

have a rated voltage of at least 600 V.

} The cross-sectional area of the (stranded)

conductor depends on the maximum

short-circuit current and the overall length

of the wiring.

} If you use multi-conductor cable, the

insulation of the individual conductors

must be resistant to damage resulting from

movement

Typically, conductors with a cross-sectional

area of at least 2.5 mm2 are used, although

4 mm2 is recommended. Shell Solar recom-

mends using wiring specially designed for

solar power systems. Ask your dealer to

recommend manufacturers that can provide

cables with connectors made to meet your

requirements.

Use suitable connectors

If you select or assemble connectors for a pho-

tovoltaic solar power system, please observe

the following points:

} Use only connectors that are specifically

intended to be used in photovoltaic solar

power systems.

} Use the tools recommended or prescribed

by the connector manufacturer for assem-

bling connectors.

} Do not unplug a connector while the circuit

is under load. It is OK to unplug a connec-

tor while the circuit is ‘live’.

} Use protective caps to guard loose con-

nectors against the effects of weather.

Special connectors for solar power system

are commercially available - ask your dealer.

Installing solar-power wiring

Correctly installed wiring assures reliable

long-term operation of the photovoltaic solar

power system. Please observe the following:

} Keep cable length as short as possible to

reduce efficiency / voltage drop.

} If you connect several modules together,

secure the wiring to the support frame.

} Where possible, use suitable fasteners to

restrict the range of motion of loose sec-

tions of wiring.

} Avoid running wiring over sharp edges.

Comparison of series and parallel wiring

For applications with a high operating volt-

age, several photovoltaic modules can be

connected in series:

Vtotal = V1+V2+Vn

Itotal = I1 = I2 = In

A photovoltaic system with a high open-cir-

cuit voltage is suitable for use with a battery

storage system having an operating voltage

of 48 V or more.

} The maximum open-circuit

voltage of the system must not

be greater than the specified

maximum system voltage for

the module.

} There is an increased risk of short circuits

and arcing with high DC voltages. Use

adequately insulated wiring and connectors

that are approved for use at the maximum

open-circuit voltage.

For applications with a high current con-

sumption, several photovoltaic modules can

be connected in parallel:

Itotal = I1+I2+In

Vtotal = V1 = V2 = Vn

A parallel wiring is suitable for use in sys-

tems containing low-voltage loads with high

power consumption, or for optimising the

charging process with high-capacity battery

storage systems.

} The wiring and connec-

tors can become overheated

at high currents. Use wiring

with suitable cross-sectional

areas and connectors that are approved

for use at the maximum short-circuit cur-

rent. Observe the manufacturer’s instruc-

tions and local electrical code.

} It is recommended to use additional

junction boxes when connecting several

modules in parallel. Modules with conduit

ready (CR) ProCharger™ junction boxes

can be directly connected in parallel.

Use suitable solar-power wiring

Modules supplied with pre-assembled cables

can easily be connected to other modules

or matching electrical components, such as

charge regulators or inverters, using plug

connectors.

8

9

Correct connection of the grounding wire [USA]

} Observe the allowable minimum bending

radius for the type of wire used.

} Never open electrical connections or un-

plug connectors while the circuit is under

load.

} Cable conduits should be used in locations

where the wiring is accessible to children

or small animals.

Electrical connections to the module

} Fully cover the module with an

opaque material during

mechanical and electrical

installation.

} Protect the wiring against damage.

} Grounding must be performed in compli-

ance with all national standards and regu-

lations (see “Selecting the proper support

frame“, page 4).

} Connecting a module to a battery with

the leads reversed (reversed polarity) can

cause:

< damage to the bypass diode in the

module,

< a risk of explosion due to excessive gas

generation in the battery.

Grounding

Ground the modules and the support frame.

Modules with frames have a predrilled hole

in the lateral frame member for fitting a

No. 10 self-threading clamping screw and

washer. [USA]

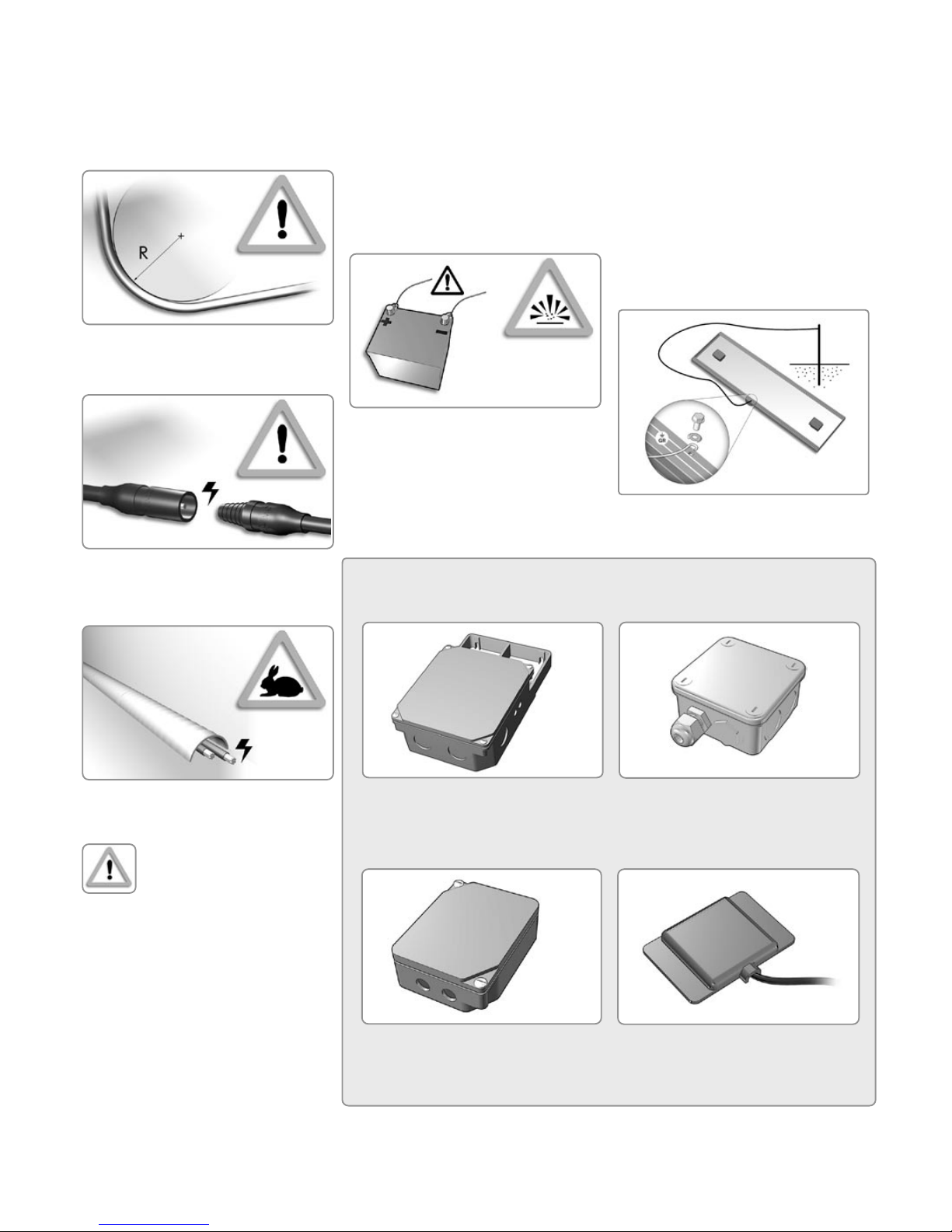

Junction box arrangements

ProCharger™ CR junction box,

see page 10.

Note, some CR boxes do not have the

“handle“ configuration as shown here.

ProCharger™ S junction box,

see page 11.

} If the ground wire is not fitted with a ring

lug, first insert the clamping screw with the

dished washer into the drilled hole.

} Strip 16 mm of insulation from the end

of the conductor, and pass the bare wire

between the head of the screw and the

washer.

} Finally, tighten the screw.

Spelsberg S junction box,

see page 11.

Note, some S junction boxes have 2 cable

glands.

ProCharger™ terminal cover,

see page 12.

8

9

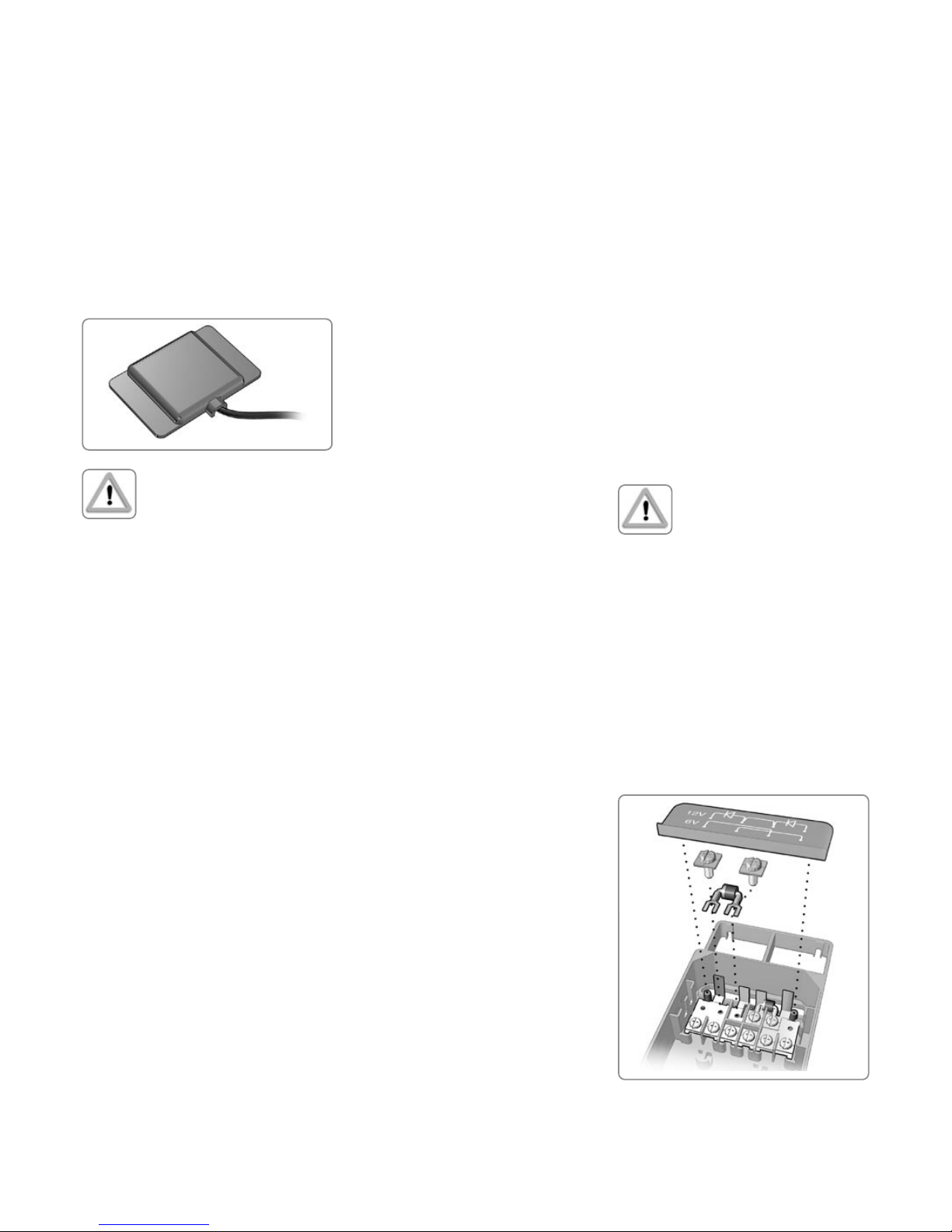

Wiring ProCharger™ CR cable junction box

Waterproof ” cable fitting or conduit fitting

Cover the module with an opaque

material during installation

Installing a ProCharger™ CR

junction box

Match the polarities of the

cables and terminals when

making the connections.

Opening the junction box

} The ProCharger™ - CR junction box has

four captive screws that secure the lid to

the base. To remove the lid, loosen the

screws with a small flat or Phillips screw-

driver.

} Once wiring is complete, install the

junction box lid and tighten screws to

0.5 - 0.7 Nm (4 - 6 in-lb.).

Caution, DO NOT OVERTIGHTEN

the lid screws.

} Do not use sealant to bond lid to its base.

Wiring

} Remove the knockout plug from the entry

by carefully punching it out with a screw-

driver.

} Slide the foam seal into the cavity behind

the cable entry and press it down using a

screwdriver.

} Strip 16 mm of insulation from the end

of the wire. Wire size must range from 8

AWG - 14 AWG (1.5-10 mm²)

} Pass only one wire through the wire entry

by pressing it through the foam seal.

} Route the wire around the strain relief,

and then pass the bare end between the

clamping plate and the washer of the

screw. Tighten the screw to a maximum

torque of 2.3 Nm.

Waterproof ” cable fitting or

conduit fitting

You will need a UL-approved ” cable fit-

ting. Refer to the manufacturer’s instructions.

} Remove the knockout plug by placing the

tip of a screwdriver at the edge of the

plug and striking the screwdriver with a

hammer.

} Attach the fitting to the junction box and

leave it loose.

} Pass the wire through the fitting and route

it to a terminal. Be careful to select the

proper polarity.

} Insert the wires between the clamp-

ing plates and the washer of the screw.

Tighten the screw to a maximum torque of

2.3 Nm.

} Tighten the fitting.

The same procedure should be used

for a conduit fitting.

Interconnecting several modules with

ProCharger™ cable junction boxes

Use conduit fittings in all places

where the wiring is accessible to

children or small animals.

Series circuit:

} Connect the negative terminal of each

module to the positive terminal of its adja-

cent module.

} Fasten loose lengths of wiring using UV-

and weather-resistant cable clamps.

} At the first and last modules in the series,

replace the regular cable fitting for the

wire leading away from the module with

a conduit fitting. To remove the fitting,

loosen its lock nut.

} If a regular cable fitting is present at the

first and last modules of the series, replace

it with a conduit fitting.

Parallel circuit see “Comparison of series and

parallel wiring“, page 8.

Use a conduit fitting that can be used to route

the cable leading from each module group

connected in parallel.

After making the electrical

connections …

} Replace the covers on the

junction boxes and carefully

tighten the four retaining screws

(0.5-0.7 Nm). Do not apply any

supplementary sealant to the

junction boxes.

10

11

Wiring ProCharger™-S-junction box

ProCharger™-S-junction box

with two terminals

ProCharger™-S-junction box

with a single terminal

Spelsberg-junction box with two terminals

Spelsberg-junction box with a single terminal

Connecting modules with

ProCharger™-S junction boxes

Always check the polarity of

the cables and the junction box

terminals.

Opening the junction box

} To open the junction box, use a Philips

screwdriver to loosen the retaining screws.

Versions

Junction box with a single terminal

(single pole).

Do not remove the plastic cover

from the unused terminal.

Wiring

} Strip 16 mm of insulation from the end of

the wire. Wire size must range from

12 AWG - 16 AWG (1.5-4 mm²)

} Pass only one wire through the wire entry

by pressing it through the foam seal.

} Pass the bare end between the clamping

plate and the washer of the screw. Tighten

the screw with a maximum torque of

2.3 Nm

} If strain relief is necessary, route the wire

along the bracket, pass a short cable tie

through the slot and secure the cable tie.

After making the electrical

connections……

} Replace the covers on the junction boxes

and carefully tighten the four retaining

screws (0.5-0.7 Nm). Do not apply any

supplementary sealant to the junction

boxes.

Junction box with two terminals (dual pole).

Connecting modules with Spelsberg

junction boxes

Opening the junction box

} To open the junction box, use a flat-blade

screwdriver to loosen the retaining screws.

Versions

Junction box with a single terminal (single

pole).

Junction box with two terminals

(both poles).

Wiring

} Strip 16 mm of insulation from the end of

the wire.

} Loosen the nut of the cable fitting.

} Pass the wire through the fitting and

route it to the terminal. Pay attention

to the polarity.

} Using a small flat-blade screwdriver, press

down on the terminal clamp. Feed the

end of the wire into the opening in the

terminal.

} Tighten the nut of the cable fitting.

After making the electrical connections…

} Replace the covers on the junction boxes

and carefully tighten the four retaining

screws (0.5-0.7 Nm). Do not apply any sup-

plementary sealant to the junction boxes.

10

11

12

Replacing a bypass-diode in

a ProCharger™-CR-junction box

Connecting modules with permanently at-

tached cables but no plug connectors

(ProCharger™ junction box cover)

Crimp-type connectors are recommended.

If spliced joins are used, they should be

soldered, and they must be protected against

corrosion and short circuits with insulating

tape.

For more detailed information, refer to:

} ‘Installing solar power wiring’ (page 8)

Modules with permanently

attached cables may only be con-

nected in parallel. Never connect

such modules in series.

Blocking diodes

Blocking diodes prevent current from flowing

from the battery to the module when no elec-

tricity is being generated. It is recommended

to use blocking diodes when a charging

regulator is not used. Your specialist dealer

can advise you with regard to suitable types,

such as Schottky diodes.

If it is necessary to connect modules in

parallel within a series circuit, the integrated

diodes will not be able to equally distribute

the current. In this case, a supplementary

blocking diode must be used as follows:

} Connect the modules in parallel, and

connect a large external diode across the

parallel group

} Fit a heat sink to the diode.

Bypass Diodes

In systems with more than two modules in se-

ries high currents can flow through cells in the

reverse direction in the case of partial shading

(where part of a module is shaded and the

rest is exposed to the sun). These currents can

cause the affected cells to get very hot and

could even damage the module. To protect

modules from such high reverse currents, by-

pass diodes are used. All Shell modules rated

greater than 40 Watt have bypass diodes

already integrated in the junction box.

In the unlikely event of diode failure, a re-

placement can easily be fitted.

Commissioning and Maintenance

In the case of modules with CR cable junction

boxes, do not disconnect the wires from the

terminals. If the voltage across the terminals

differs from the rated value by more than 5

percent, this indicates a bad electrical con-

nection.

Maintenance

Shell Solar recommends the following main-

tenance in order to ensure optimum perform-

ance of the module:

} Clean the glass surfaces of the module

as necessary. Always use water and a

soft sponge or cloth for cleaning. A mild,

non-abrasive cleaning agent can be used

to remove stubborn dirt.

} Check the electrical and mechanical con-

nections every six months to verify that

they are clean, secure and undamaged.

} If any problems arise, have them be inves-

tigated by an authorised specialist.

Observe the maintenance instruc-

tions for all components used

in the system, such as support

frames, charging regulators,

inverters, batteries etc.

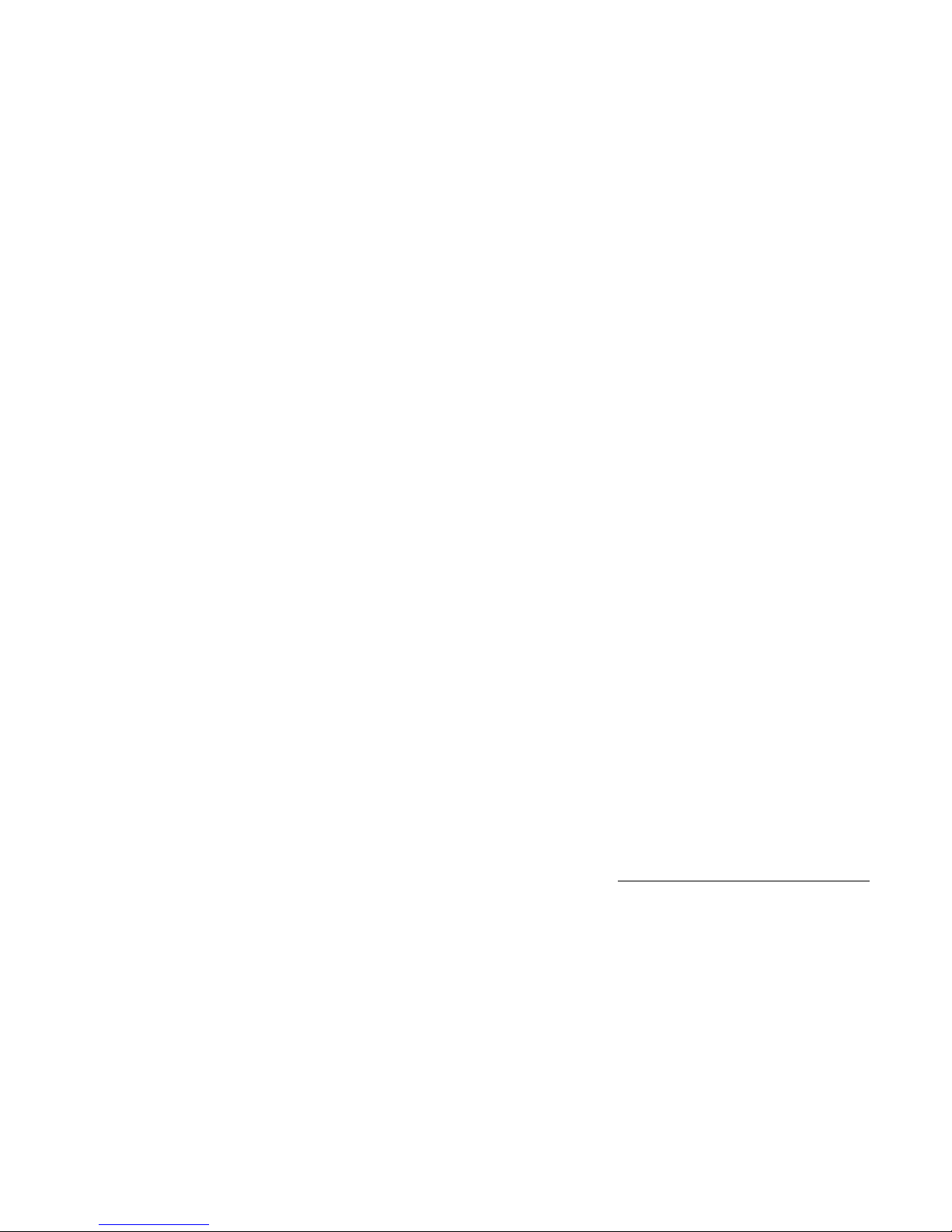

Testing and replacing bypass diodes

ProCharger™-CR junction box

The bypass diodes are located underneath a

protective cover. The connections for 6-V and

12-V operation are shown on this cover.

} Lift off the cover by gently pulling up a

corner of the cover with your finger.

} Remove the diodes by loosening the fas-

tening screws. Note the orientations of the

polarity markings on the diodes.

Protect yourself against electrical shocks

while commissioning and maintaining the

solar power system. Refer to the precautions

at the beginning of the ‘Electrical Installation’

section.

Testing, commissioning

and troubleshooting

Test all electrical and electronic components

of your system before commissioning it.

Follow the instructions in the guides supplied

with the components and equipment. Systems

having a DC voltage greater than 120 V and

systems coupled to the mains grid must be

tested and formally approved by authorised

technical specialists.

Testing modules connected in series before

they are connected to the system

} Check the open-circuit voltage of every

series circuit. The measured value should

correspond to the sum of the open-circuit

voltages of the individual modules. You

will find the rated voltage in the technical

specifications of the type of module used.

If the measured value is significantly lower

than the expected value, please proceed

as described under ‘Troubleshooting an

excessively low voltage’.

} Check the short-circuit current of every

series circuit with direct solar illumina-

tion. You will find the rated current in

the technical specifications of the type of

module used. The measured value can

vary significantly, depending on weather

conditions, the time of day and shading of

the module.

Troubleshooting an excessively

low voltage

Typical causes of this problem are improper

connections at the terminals and defective

bypass diodes.

} First, check all wiring connections.

} Check the open-circuit voltage of each

module:

} Fully cover the modules with an opaque

material.

} Disconnect the wiring at both terminals

of the modules.

} Remove the opaque material from the

module to be checked and measure the

open-circuit voltage at its terminals. If the

measured voltage is only half the rated

value, this indicates a defective bypass

diode. Refer to ‘Testing and replacing

bypass diodes’.

Modules with permanently attached cables

can only be checked at the open end of the

cable after it has been disconnected.

13

Replacing a soldered bypass-diode in a ProCharger™-CR-junction box

Replacing a bypass-diode in

a Spelsberg-junction box

} Check the conductivity of the diodes. They

should conduct electricity when the test

leads are connected in one direction and

show a high resistance in the other direc-

tion. If a diode conducts in both direc-

tions, it is defective.

} Replace a defective diode with a diode of

the same type, and ensure that its polarity

marking is oriented the same way as the

original diode.

} Finally, check the open-circuit voltage of

the module and replace both covers.

ProCharger™-S junction box

} Open the cover and remove the diodes by

cutting their leads with a wire cutter. Note

the orientations of the polarity markings

on the diodes.

} Check the conductivity of the diodes. They

should conduct electricity when the test

leads are connected in one direction and

show a high resistance in the other direc-

tion. If a diode conducts in both direc-

tions, it is defective.

} Replace a defective diode with a diode of

the same type, and ensure that its polarity

marking is oriented the same way as the

original diode. Solder the leads of the

diode to the contacts.

} Finally, check the open-circuit voltage of

the module and close the cover.

Spelsberg junction box

} Open the cover, and remove the diodes

by pressing on each terminal with a small

flat-blade screwdriver and extracting the

diode lead. Note the orientations of the

polarity markings on the diodes.

} Check the conductivity of the diodes. They

should conduct electricity when the test

leads are connected in one direction and

show a high resistance in the other direc-

tion. If a diode conducts in both direc-

tions, it is defective.

} Replace a defective diode with a diode of

the same type, and ensure that its polarity

marking is oriented the same way as the

original diode.

} Finally, check the open-circuit voltage of

the module and close the cover.

Disclaimer of Liability

Since the use of this manual and the condi-

tions or methods of installation, operation,

use and maintenance of the photovoltaic (PV)

product are beyond Shell Solar‘s control,

Shell Solar does not assume responsibility

and expressly disclaims liability for loss,

damage, or expense arising out of or in any

way connected with such installation, opera-

tion, use or maintenance.

No responsibility is assumed by Shell Solar

for any infringement of patents or other

rights of third parties, which may result from

use of the PV product. No license is granted

by implication or otherwise under any patent

or patent rights.

The information in this manual is based on

Shell Solar‘s knowledge and experience and

is believed to be reliable; but such informa-

tion including product specifications (without

limitations) and suggestions do not constitute

a warranty, expressed or implied. Shell Solar

reserves the right to make changes to this

manual, the PV product, the specifications,

or product information sheets without prior

notice.

1. Limited Product Warranty - Two Year Repair,

Replacement or Refund Remedy

Shell Solar B.V. having its registered office at Amsterdam,

the Netherlands (“Shell Solar”) warrants its Photovoltaic

modules (“PV-modules”), including field replaceable DC

connector cable assemblies, to be free from defects in

materials and workmanship under normal, application,

installation, use and service conditions. If the PV-modules

fail to conform to this warranty, then for a period ending

twenty-four (24) months from date of sale to the original

end-customer (“the Customer”), Shell Solar will, at its

option, either repair or replace the product, or refund the

purchase price as paid by the Customer (“Purchase Price”).

The repair, replacement or refund remedy shall be the sole

and exclusive remedy provided under the Limited Product

Warranty and shall not extend beyond the twenty-four (24)

month period set forth herein. This Limited Product Warranty

does not warrant a specific power output, which shall be

exclusively covered under clause 2 hereinafter (Limited Peak

Power Warranty).

2. ‘Limited Peak Power Warranty’ - Limited Remedy

A: 10 years

For the PV-modules (excluding the inverter/ converter)

ST5, ST10, ST20, ST36, ST40, S10, S25, and S36 Shell

Solar additionally warrants: If, within ten (10) years from

date of sale to the Customer any PV-module(s) exhibits a

power output less than 90% of the minimum Peak Power

at STC as specified at the date of delivery in Shell Solar’s

Product Information Sheet, provided that such loss in power

is determined by Shell Solar (at its sole and absolute

discretion) to be due to defects in material or workmanship,

Shell Solar will replace such loss in power by either

providing to the Customer additional PV-modules to make

up such loss in power, or by repairing or replacing the

defective PV-module(s), or by refunding the Purchase Price

taking into account a yearly depreciation of ten (10)% of the

Purchase Price, at the option of Shell Solar.

B: 20 years

For the PV-modules (excluding the inverter/ converter)

S60, S65, S70-C, S75-C, S105-C and S115-C Shell

Solar additionally warrants: If, within (a) the first ten (10)

years from date of sale to the Customer, any PV-module(s)

exhibits a power output less than 90% of the minimum Peak

Power at STC1 as specified at the date of delivery in Shell

Solar’s Product Information Sheet, or (b), within a period of

twenty (20) years from date of sale to the Customer any

PV-module(s) exhibits a power output less than 80% of the

minimum Peak Power at STC1, provided that such loss in

power is determined by Shell Solar (at its sole and absolute

discretion) to be due to defects in material or workmanship,

Shell Solar will replace such loss in power by either

providing to the Customer additional PV-modules to make

up such loss in power, or by repairing or replacing the

defective PV-module(s), or by refunding the Purchase Price

taking into account a yearly depreciation of five (5)% of the

Purchase Price, at the option of Shell Solar.

C: 25 years

For the PV-modules (excluding the inverter/ converter)

SM46, SM50, SM50-H, SM55, SM100-12, SM110-12,

SM100-24, SM100-24C, SM110-24, SM110-24C, SP65,

SP70, SP75, SP130, SP130-C, SP140, SP140-C, SP150,

SP150-C, SQ70, SQ75, SQ80, SQ140-C, SQ150-C and

SQ160-C Shell Solar additionally warrants: If, within (a) the

first ten (10) years from date of sale to the Customer, any

PV-module(s) exhibits a power output less than 90% of the

minimum Peak Power at STC1 as specified at the date of

delivery in Shell Solar’s Product Information Sheet, or (b),

within a period of twenty-five (25) years from date of sale to

the Customer any PV-module(s) exhibits a power output less

than 80% of the minimum Peak Power at STC1, provided

that such loss in power is determined by Shell Solar (at its

sole and absolute discretion) to be due to defects in material

or workmanship, Shell Solar will replace such loss in power

by either providing to the Customer additional PV-modules

to make up such loss in power, or by repairing or replacing

the defective PV-module(s), or by refunding the Purchase

Price taking into account a yearly depreciation of four (4)%

of the Purchase Price, at the option of Shell Solar.

The remedies set forth in this clause 2 shall be the sole and

exclusive remedies provided under the Limited Peak Power

Warranty.

3. Exclusions and limitations

A. Warranty claims must in any event be filed within the

applicable Warranty period.

B. The Limited Warranties do not apply to any PV-modules

which in Shell Solar’s absolute judgement have been

subjected to:

- misuse, abuse, neglect or accident;

- alteration, improper installation or application;

- non-observance of Shell Solar’s installation-, users- and

maintenance instructions;

- repair or modifications by someone other than an

approved service technician of Shell Solar;

- power failure surges, lighting, flood, fire, accidental

breakage or other events outside Shell Solar’s control.

C. The Limited Warranties do not cover any transportation

costs for return of the PV-modules, or for reshipment of

any repaired or replaced PV-modules, or cost associated

with installation, removal or reinstallation of the PV-

modules.

D. When used in non-land based applications the Limited

Peak Power Warranty, applying to any of the PV-modules

shall be limited to ten (10) years as per the provisions of

clause 2A hereof.

E. Warranty claims will not be honoured if the type or serial

number of the PV-modules have been altered, removed

or made illegible.

4. Limitation of Warranty Scope

THE LIMITED WARRANTIES SET FORTH HEREIN ARE

EXPRESSLY IN LIEU OF AND EXCLUDE ALL OTHER EXPRESS

OR IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED

TO WARRANTIES OF MERCHANTABILITY AND OF FITNESS

FOR PARTICULAR PURPOSE, USE, OR APPLICATION, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART

OF SHELL SOLAR, UNLESS SUCH OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES ARE EXPRESSLY AGREED

TO IN WRITING SIGNED AND APPROVED BY SHELL

SOLAR. SHELL SOLAR SHALL HAVE NO RESPONSIBILITY

OR LIABILITY WHATSOEVER FOR DAMAGE OR INJURY

TO PERSONS OR PROPERTY, OR FOR OTHER LOSS OR

INJURY RESULTING FROM ANY CAUSE WHATSOEVER

ARISING OUT OF OR RELATED TO THE PRODUCT,

INCLUDING, WITHOUT LIMITATION, ANY DEFECTS

IN THE MODULE, OR FROM USE OR INSTALLATION.

UNDER NO CIRCUMSTANCES SHALL SHELL SOLAR BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES, HOWSOEVER CAUSED. LOSS OF USE,

LOSS OF PROFITS, LOSS OF PRODUCTION, LOSS OF

REVENUES ARE THEREFORE SPECIFICALLY BUT WITHOUT

LIMITATION EXCLUDED.

SHELL SOLAR’S AGGREGATE LIABILITY, IF ANY, IN

DAMAGES OR OTHERWISE, SHALL NOT EXCEED THE

INVOICE VALUE AS PAID BY THE CUSTOMER, FOR THE

UNIT OF PRODUCT OR SERVICE FURNISHED OR TO BE

FURNISHED, AS THE CASE MAY BE, WHICH IS THE

SUBJECT OF CLAIM OR DISPUTE.

5. Obtaining Warranty Performance

If the Customer feels he/she has a justified claim covered

by this Limited Warranty, he/she must immediately notify the

(a) dealer, who sold the PV-modules, or (b) any authorised

Shell Solar distributor, of the claim in writing, or (c) send

such notification to Shell Solar (P.O. Box 38000, 1030

BN Amsterdam, the Netherlands) directly. Together with the

notification Customer should enclose evidence of the date

of sale on which the Solar Products have been purchased. If

applicable, Customer’s dealer or distributor will give advice

on handling the claim. If further assistance is required,

Customer is invited to write Shell Solar for instructions. The

return of any PV-modules will not be accepted unless prior

written authorisation has been given by Shell Solar.

6. Severability

If a part, provision or clause of this Limited Warranty, or

the application thereof to any person or circumstance, is

held invalid, void or unenforceable, such holding shall not

affect and shall leave all other parts, provisions, clauses or

applications of the Limited Warranty, and to this end such

other parts, provisions, clauses or applications of this Limited

Warranty shall be treated as severable.

7. Disputes

No action, regardless of form, arising out of or in any way

connected with this Limited Warranty, may be brought by

the Customer more than one (1) year after the cause of

action has accrued.

8. Various

The repair or replacement of the PV-modules or the supply

of additional PV-modules, does not cause the beginning

of new warranty terms, nor shall the original terms of this

Limited Warranty be extended. Any replaced PV-modules

shall become the property of Shell Solar. Shell Solar has

the right to deliver another type of PV-module (different in

size, colour, shape and/or power) in case Shell Solar

discontinued producing the PV-module in question at the

time of the claim.

In the event that any of the PV-modules purchased by

the Customer are not listed in this Limited Warranty, the

Customer should contact Shell Solar for further information

regarding the applicable warranties, if any.

9. Force Majeure

Shell Solar shall not be in any way be responsible or liable

to the Customer or any third-party arising out of any non-

performance or delay in performance of any terms and

conditions of sale, including this Limited Warranty, due

to acts of God, war, riots, strikes, unavailability of suitable

and sufficient labour, material, die, or capacity or technical

or yield failures and any unforeseen event beyond its

control, including, without limitations, any technological or

physical event or condition which is not reasonably known

or understood at the time of the sale of the PV-modules or

the claim.

1

“Peak Power” is the power in watt peak that a PV-module

generates in its maximum power point. “STC” are as

follows (a) light spectrum of AM 1.5, (b) an irradiation

of 1,000 W per m² and (c) a cell temperature of 25

degrees Centigrade. The measurements are carried out in

accordance with IEC60904 as tested at the junction box

terminals per the calibration and testing standards of Shell

Solar valid at the date of manufacture of the PV-modules.

Shell Solar’s calibration standards shall be in compliance

with the standards applied by international institutions

accredited for this purpose.

SHELL SOLAR LIMITED WARRANTY FOR PV-MODULES

(“Limited Warranty”) – (Excluding U.S.)

General Version excluding U.S. valid as from 1 August 2003

14

15

1. Limited Product Warranty – Two Year Repair,

Replacement or Refund Remedy

Shell Solar Industries LP with offices at 4650 Adohr

Lane, Camarillo, CA 93012 (“Shell Solar”) warrants

its Photovoltaic modules (“PV-modules”), including field

replaceable DC connector cable assemblies, to be free

from defects in materials and workmanship under normal,

application, installation, use and service conditions. If the

PV-modules fail to conform to this warranty, then for a period

ending twenty-four (24) months from date of sale to the

original end-customer (“the Customer”), Shell Solar will, at

its option, either repair or replace the product, or refund the

purchase price as paid by the Customer (“Purchase Price”).

The repair, replacement or refund remedy shall be the sole

and exclusive remedy provided under the Limited Product

Warranty and shall not extend beyond the twenty-four (24)

month period set forth herein. This Limited Product Warranty

does not warrant a specific power output, which shall be

exclusively covered under clause 2 hereinafter (Limited Peak

Power Warranty).

2. ‘Limited Peak Power Warranty’ – Limited Remedy

A: 10 years

For the PV-modules (excluding the inverter/converter) ST5,

ST10, ST20, ST36, and ST40 Shell Solar additionally

warrants:

If, within ten (10) years from date of sale to the Customer

any PV-module(s) exhibits a power output less than 90% of

the minimum Peak Power at STC1 as specified at the date of

delivery in Shell Solar’s Product Information Sheet, provided

that such loss in power is determined by Shell Solar (at its

sole and absolute discretion) to be due to defects in material

or workmanship, Shell Solar will replace such loss in power

by either providing to the Customer additional PV-modules

to make up such loss in power, or by repairing or replacing

the defective PV-module(s), or by refunding the Purchase

Price taking into account a yearly depreciation of ten (10)%

of the Purchase Price, at the option of Shell Solar

B: 25 years

For the PV-modules (excluding the inverter/ converter),

SM50-H, SM55, SM110-12P, SM110-24P, SP70, SQ75,

SP75, SQ80, SP140-P/PC, SP150-P/PC, SQ150-P/PC

and SQ160-P/PC Shell Solar additionally warrants:

If, within (a) the first ten (10) years from date of sale to the

Customer, any PV-module(s) exhibits a power output less

than 90% of the minimum Peak Power at STC1 as specified

at the date of delivery in Shell Solar’s Product Information

Sheet, or (b), within a period of twenty-five (25) years from

date of sale to the Customer any PV-module(s) exhibits a

power output less than 80% of the minimum Peak Power at

STC1, provided that such loss in power is determined by

Shell Solar (at its sole and absolute discretion) to be due to

defects in material or workmanship, Shell Solar will replace

such loss in power by either providing to the Customer

additional PV-modules to make up such loss in power, or

by repairing or replacing the defective PV-module(s), or by

refunding the Purchase Price taking into account a yearly

depreciation of four (4)% of the Purchase Price, at the option

of Shell Solar.

The remedies set forth in this clause 2 shall be the sole and

exclusive remedies provided under the Limited Peak Power

Warranty.

3. Exclusions and limitations

A. Warranty claims must in any event be filed within the

applicable Warranty period.

B. The Limited Warranties do not apply to any PV-modules

which in Shell Solar’s absolute judgement have been

subjected to:

- misuse, abuse, neglect or accident;

- alteration, improper installation or application;

- non-observance of Shell Solar’s installation-, users- and

maintenance instructions;

- repair or modifications by someone other than an

approved service technician of Shell Solar;

- power failure surges, lighting, flood, fire, accidental

breakage or other events outside Shell Solar’s control.

C. The Limited Warranties do not cover any transportation

costs for return of the PV-modules, or for reshipment of

any repaired or replaced PV-modules, or cost associated

with installation, removal or reinstallation of the PV-

modules.

D. When used in non-land based applications the Limited

Peak Power Warranty, applying to any of the PV-modules

shall be limited to ten (10) years as per the provisions of

clause 2A hereof.

E. Warranty claims will not be honored if the type or serial

number of the PV-modules have been altered, removed

or made illegible.

4. Limitation of Warranty Scope

THE LIMITED WARRANTIES SET FORTH HEREIN ARE

EXPRESSLY IN LIEU OF AND EXCLUDE ALL OTHER EXPRESS

OR IMPLIED WARRANTIES, INCLUDING BUT NOT LIMITED

TO WARRANTIES OF MERCHANTABILITY AND OF FITNESS

FOR PARTICULAR PURPOSE, USE, OR APPLICATION, AND

ALL OTHER OBLIGATIONS OR LIABILITIES ON THE PART

OF SHELL SOLAR, UNLESS SUCH OTHER WARRANTIES,

OBLIGATIONS OR LIABILITIES ARE EXPRESSLY AGREED

TO IN WRITING SIGNED AND APPROVED BY SHELL

SOLAR. SHELL SOLAR SHALL HAVE NO RESPONSIBILITY

OR LIABILITY WHATSOEVER FOR DAMAGE OR INJURY

TO PERSONS OR PROPERTY, OR FOR OTHER LOSS OR

INJURY RESULTING FROM ANY CAUSE WHATSOEVER

ARISING OUT OF OR RELATED TO THE PRODUCT,

INCLUDING, WITHOUT LIMITATION, ANY DEFECTS

IN THE MODULE, OR FROM USE OR INSTALLATION.

UNDER NO CIRCUMSTANCES SHALL SHELL SOLAR BE

LIABLE FOR INCIDENTAL, CONSEQUENTIAL OR SPECIAL

DAMAGES, HOWSOEVER CAUSED. LOSS OF USE,

LOSS OF PROFITS, LOSS OF PRODUCTION, LOSS OF

REVENUES ARE THEREFORE SPECIFICALLY BUT WITHOUT

LIMITATION EXCLUDED.

SHELL SOLAR’S AGGREGATE LIABILITY, IF ANY, IN

DAMAGES OR OTHERWISE, SHALL NOT EXCEED THE

INVOICE VALUE AS PAID BY THE CUSTOMER, FOR THE

UNIT OF PRODUCT OR SERVICE FURNISHED OR TO BE

FURNISHED, AS THE CASE MAY BE, WHICH IS THE

SUBJECT OF CLAIM OR DISPUTE.

SOME STATES DO NOT ALLOW LIMITATIONS ON IMPLIED

WARRANTIES OR THE EXCLUSION OF DAMAGES SO

THE ABOVE LIMITATIONS OR EXCLUSIONS MAY NOT

APPLY TO YOU.

5. Obtaining Warranty Performance

If the Customer feels he/she has a justified claim covered

by this Limited Warranty, he/she must immediately notify the

(a) dealer, who sold the PV-modules, or (b) any authorized

Shell Solar distributor, of the claim in writing, or (c) send

such notification to Shell Solar Industries LP (P.O Box

6032, Camarillo, CA 93011) directly. Together with the

notification Customer should enclose evidence of the date

of sale on which the Solar Products have been purchased. If

applicable, Customer’s dealer or distributor will give advice

on handling the claim. If further assistance is required,

Customer is invited to write Shell Solar for instructions. The

return of any PV-modules will not be accepted unless prior

written authorization has been given by Shell Solar.

6. Severability

If a part, provision or clause of this Limited Warranty, or

the application thereof to any person or circumstance, is

held invalid, void or unenforceable, such holding shall not

affect and shall leave all other parts, provisions, clauses or

applications of this Limited Warranty, and to this end such

other parts, provisions, clauses or applications of this Limited

Warranty shall be treated as severable.

7. Disputes

No action, regardless of form, arising out of or in any way

connected with this Limited Warranty, may be brought by

the Customer more than one (1) year after the cause of

action has accrued.

THIS LIMITED WARRANTY GIVES YOU SPECIFIC LEGAL

RIGHTS; YOU MAY ALSO HAVE OTHER RIGHTS THAT

VARY FROM STATE TO STATE.

8. Various

The repair or replacement of the PV-modules or the supply

of additional PV-modules, does not cause the beginning

of new warranty terms, nor shall the original terms of this

Limited Warranty be extended. Any replaced PV-modules

shall become the property of Shell Solar. Shell Solar has

the right to deliver another type of PV-module (different

in size, color, shape and/or power) in case Shell Solar

discontinued producing the PV-module in question at the

time of the claim.

9. Force Majeure

Shell Solar shall not be in any way be responsible or liable

to the Customer or any third-party arising out of any non-

performance or delay in performance of any terms and

conditions of sale, including this Limited Warranty, due

to acts of God, war, riots, strikes, unavailability of suitable

and sufficient labor, material, die, or capacity or technical

or yield failures and any unforeseen event beyond its

control, including, without limitations, any technological or

physical event or condition which is not reasonably known

or understood at the time of the sale of the PV-modules or

the claim.

1

“Peak Power” is the power in watt peak that a PV-module

generates in its maximum power point. “STC” are as

follows (a) light spectrum of AM 1.5, (b) an irradiation

of 1,000 W per m² and (c) a cell temperature of 25

degrees Centigrade. The measurements are carried out in

accordance with IEC60904 as tested at the junction box

terminals per the calibration and testing standards of Shell

Solar valid at the date of manufacture of the PV-modules.

Shell Solar’s calibration standards shall be in compliance

with the standards applied by international institutions

accredited for this purpose.

SHELL SOLAR LIMITED WARRANTY FOR PV-MODULES

(“Limited Warranty”) – (U.S.)

General U.S. Version valid as of 1 August 2003

14

15

Ordering Number ShSo/Int/MGA/0903

Environmentally friendly – paper bleached without

chlorine. Printed in Germany

Shell Solar B.V.

PO Box 38000

1030 BN

Amsterdam

The Netherlands

Fax: +31-20-630-2211

Shell Solar Industries

4650 Adohr Lane

Camarillo, CA 93011

United States

Fax: +1-805-388-6395

Shell Solar Pte. Ltd.

72 Bendemeer Road

Hiap Huat House #07-01

Singapore 339941

Fax: +65-6842-3887

Status 09/03 – Subject to modifications – © 2003 Shell Solar GmbH

Shell modules are recyclable.

Internet: www.shell.com/solar

Shell Solar GmbH

Domagkstrasse 11

80807 Munich

Germany

Fax: +49-89-636-59140

Table of contents

Popular Solar Panel manuals by other brands

STI

STI FKF 200 Series Assembly instructions

IBC SOLAR

IBC SOLAR TopFix 200 installation manual

CanadianSolar

CanadianSolar CS6R-MB-AG installation manual

Qcells

Qcells Q.PEAK DUO-G5 series Installation and operation manual

evergreensolar

evergreensolar Cedar Line Operation manual

Go Power

Go Power GP-PSK-90 user manual

Qcells

Qcells Q.PEAK DUO-G5.X Installation and operation manual

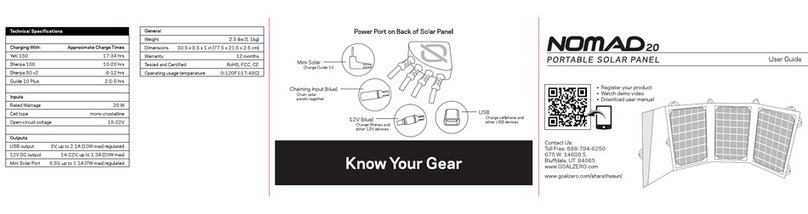

GOAL ZERO

GOAL ZERO Nomad 7 Plus user guide

evergreensolar

evergreensolar ES-A-190 Safety, installation, and operation manual

GOAL ZERO

GOAL ZERO Nomad 20 user manual

GOAL ZERO

GOAL ZERO Nomad 20 user guide

Sunsystem

Sunsystem VTC Series Installation and operation manual